Expanding clinker, expanding agent, concrete and preparation method of expanding clinker

A technology of expanded clinker and expansion agent, applied in the field of expanded clinker, can solve the problems of ring formation in the kiln and waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

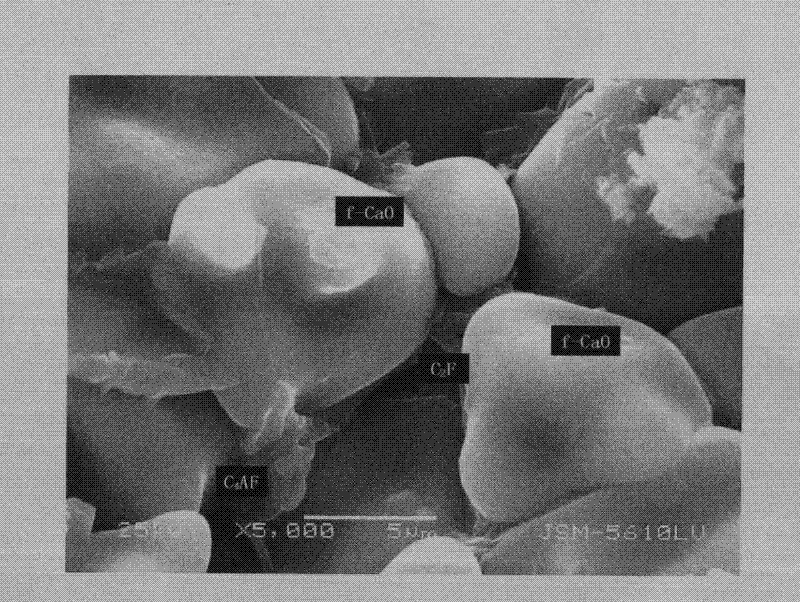

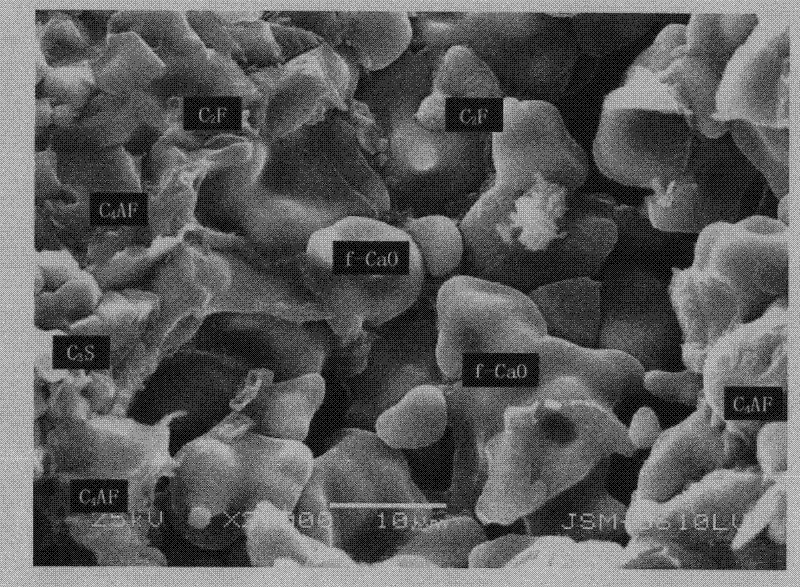

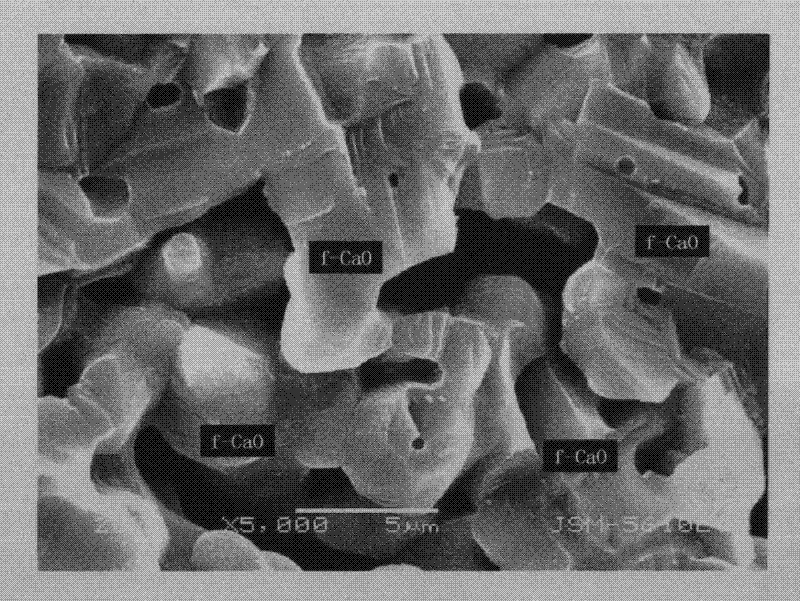

[0122] The preparation of embodiment 1-1 expansion clinker 1-3

[0123] By weight percentage 93%: 7%, 95%: 5%, 98%: 2%, limestone and iron powder are mixed, based on the total weight of limestone and iron powder, its chemical composition is shown in Table 1, and jointly ground to fine The sieve with a 0.08mm square hole is less than 18%, and the specific surface area is 180-300m 2 / kg, and then calcined at 1400°C in a preheating decomposition kiln to obtain expanded clinker 1-3, its chemical composition is shown in Table 2, and its calculated mineral composition is shown in Table 3. The data listed are based on the total amount of expanded clinker weight percent by weight.

[0124] Table 1

[0125] raw material

[0126] Table 2

[0127]

[0128] * : The silica content is affected by the raw coal.

[0129] table 3

[0130] Expanded clinker

[0131]

[0132] Expanding agent example

Embodiment 2-1

[0133] Example 2-1 Expansion agent 1

[0134] The expansion clinker 1 is directly used as the expansion agent 1.

Embodiment 2-2

[0135] Example 2-2 Expansion agent 2

[0136] The expanded clinker 1 was mixed with 5% anhydrite, 0.1% sodium gluconate and 0.1% lauric acid and ground to a specific surface area of 327m 2 / kg to obtain expansion agent 2, said percentage is based on the total weight of expansion clinker 1, anhydrite, sodium gluconate and lauric acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com