Heat resisting red porcelain chinaware

A technology of purple sand ceramics and utensils, which is applied to household utensils, other household utensils, clay products, etc., can solve the problems that purple sand is difficult to achieve, and achieve the effects of saving transportation costs, high efficiency, and improving heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: Make purple sand pottery soup pot liner, or rice pot liner, blank: meet the requirements of each raw material purple sand soil 5, aluminum clay 19, spodumene 30, clinker 5, talcum powder 5, kaolin 15, Bauxite 15, magnesia clay 6;

[0026] Glaze: this mud 30, that is, the mud made from the above-mentioned raw materials, clinker 19, loess 15, frit 12, iron red 7, water glass 2, lithium feldspar 15.

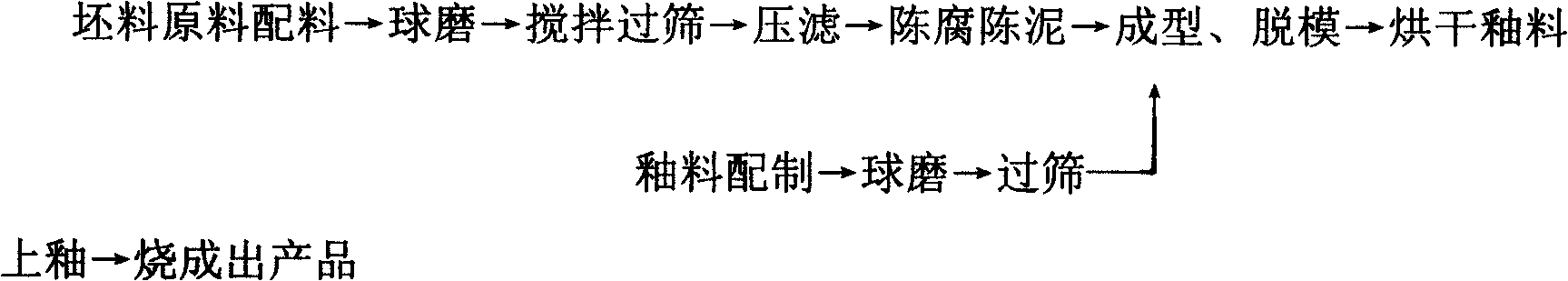

[0027] Production method: the billet is made into shape, and the raw materials of each component are selected and added to the ball mill according to the above ratio requirements to mix, wet ball milled for about 12 hours, put into the slurry tank and fully stirred, and passed through a 100-mesh sieve, and the spodumene is discharged Add it to the ball mill for the first 4 hours and pass through a 40-mesh sieve. Then press filter until the water content is about 20% to form a raw material mud, put the raw material mud into the warehouse and stale for 10 days, e...

Embodiment 2

[0030] Example 2 Making soup pot liner, raw materials: purple clay 6, aluminum clay 15, spodumene 30, clinker 5, calcined talcum powder 4, kaolin 15, bauxite 19, magnesia clay 5 iron red 1 ;

[0031] Glaze: 29 clay, 20 clinker, 15 loess, 13 frit, 6 iron red, 1.85 water glass, 15 lithium feldspar, 0.15 sodium tripolyphosphate.

[0032] Production method: the blank is wet ball milled through a 120-mesh sieve; the glaze is passed through a 380-mesh sieve, sodium tripolyphosphate is first added to the ball mill and water glass is added 5 hours before the end of the ball mill.

Embodiment 3

[0033] Example 3 Making an inner pot of an electric cooker, raw materials: purple clay 8, aluminum clay 10, calcined spodumene 32, clinker 5, bauxite 15, calcined talcum powder 2, ash 8, kaolin 10, magnesium quality sticky 10;

[0034] Glaze: 20 clay, 22 clinker, 18 loess, 8 frit, 9 iron red, 1.5 water glass, 20 lithium feldspar, 1.5 brilliant black, 0 sodium tripolyphosphate.

[0035] Production method: the blank is wet ball milled through a 90-mesh sieve; the glaze is passed through a 320-mesh sieve, and water glass is added 4 hours before the glaze ball mill is discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com