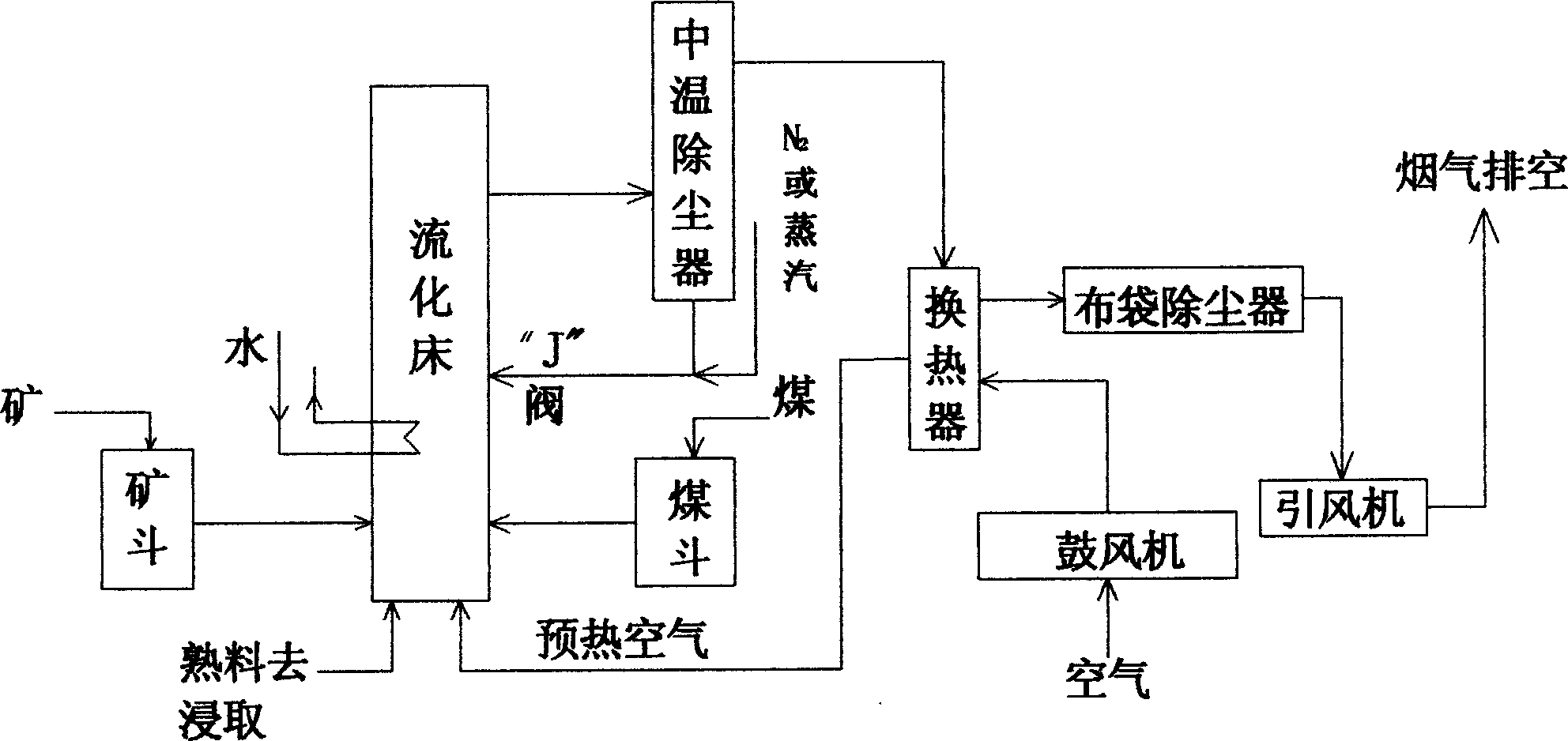

Circulating fluidized bed mineral reducing roasting device and reducing roasting method

A technology of circulating fluidized bed and roasting device, which is applied in the field of reduction roasting of inorganic minerals, can solve the problems of low product output and quality, large amount of fly ash, high energy consumption, etc., and achieves reliable operation of equipment and improved production. Indicators, the effect of improving the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

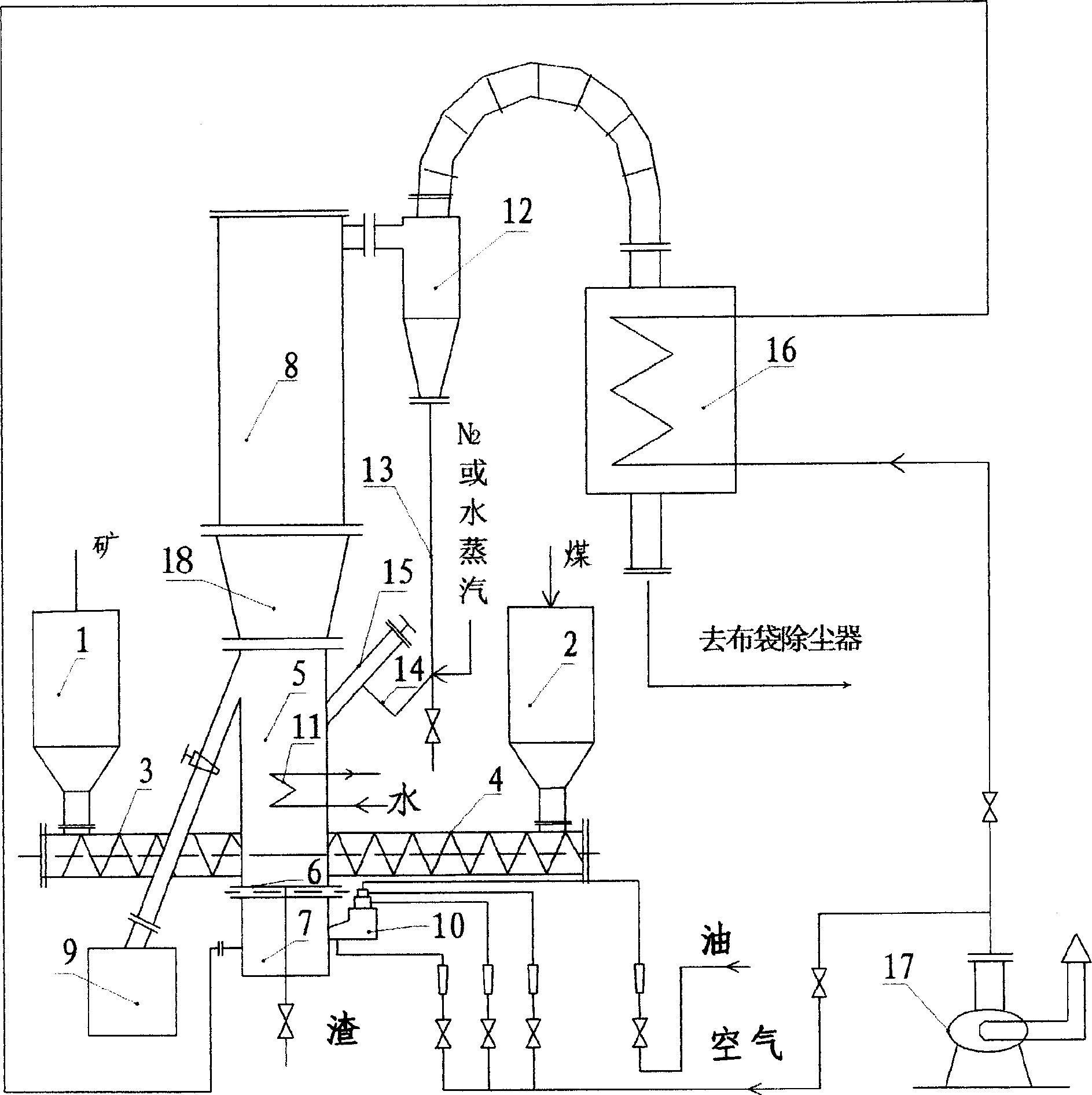

[0026] The embodiments of the present invention will be described below with reference to the drawings.

[0027] The pretreatment ore control particle size is ≤2mm, raise it to hopper 1, and use the speed-adjusting screw 3, and send it to the fluidization section 5 of the roasting furnace. The raw coal particle size is sieved to ≤10mm, and it is raised to the coal scuttle 2 and sent in with the speed-adjusting screw 4 The fluidization section 5 of the roasting furnace has a coal weight ratio of 1.5 to 1.65. The combustion air is provided by the blower 17, and the heat is recovered by the gas-gas heat exchanger 16 and then sent from the air box 7 at the bottom of the roasting furnace, and enters the roasting through the air distribution plate 6. In the furnace fluidization section 5, the coal is incompletely burned in this area, the temperature in the bed is controlled to be 900-935°C, and the apparent reaction time is 1.3-1.5 hours. The fly ash carried in the exhaust gas of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com