Cordierite-mullite kiln furniture material with high thermal shock resistance

A mullite kiln and cordierite technology, which is applied in the field of cordierite-mullite kiln furniture materials with high thermal shock resistance, can solve the problems of short life, cracking and damage of kiln furniture materials, and achieve high porosity and firing The effect of uniform temperature and small volume density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with embodiment the present invention is described in further detail.

[0041] Formula: cordierite clinker 20%, cordierite-mullite kiln furniture waste blank 20%, floating beads 10%, talc 10%, alumina 5%, clay 23%, clay clinker 10%, wood powder 2% , plus 0.3% yellow dextrin.

[0042] Mixing: According to the process mentioned above, add water at a ratio of 8% (solid content as the basis) to prepare a mixture, and seal and trap the material for 24 hours.

[0043] Forming: single-sided hydraulic forming, with 180KGF / CM 2 The pressure is used to form it, and the solid shed board green body of 398*398*14.9mm is obtained. The green body can be moved by hand and is very strong.

[0044] Drying: Dry according to the process mentioned above.

[0045] Firing: In a tunnel kiln, 6 blocks are stacked vertically, at 1370°C, and kept warm for 6 hours to fire to obtain shed slab kiln furniture of 400*400*15mm.

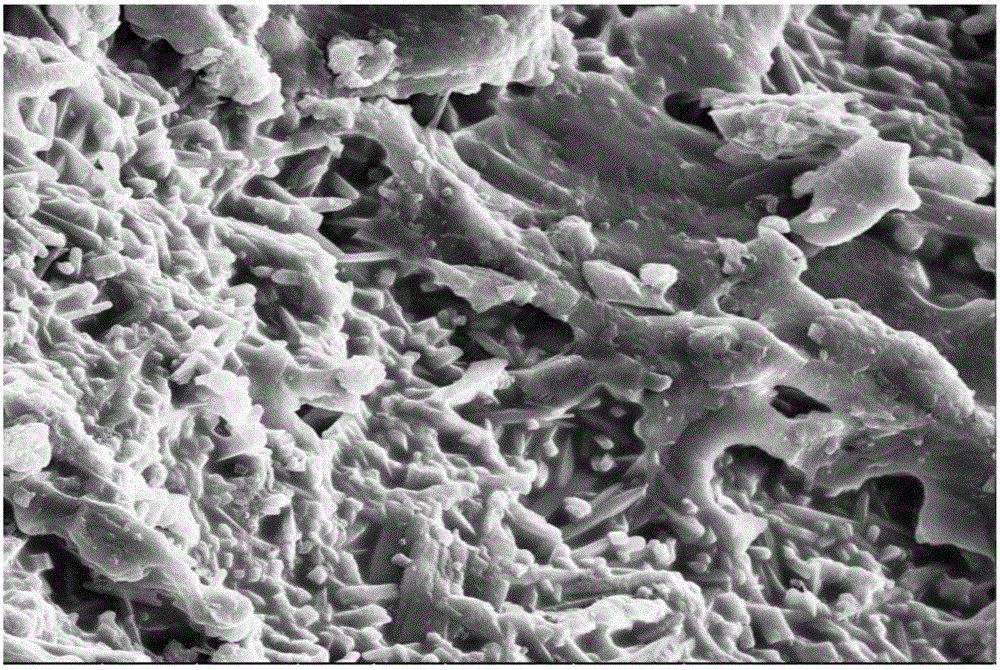

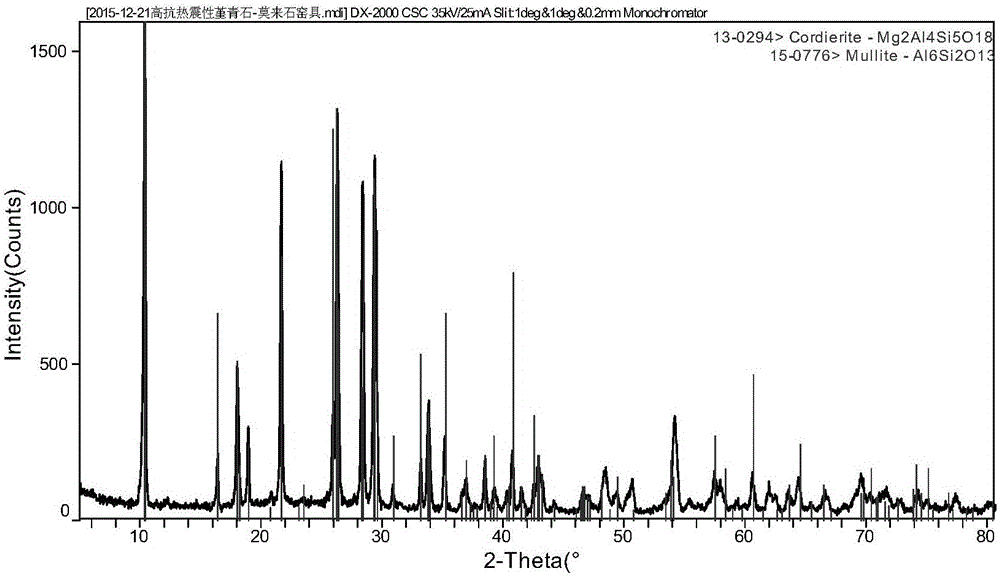

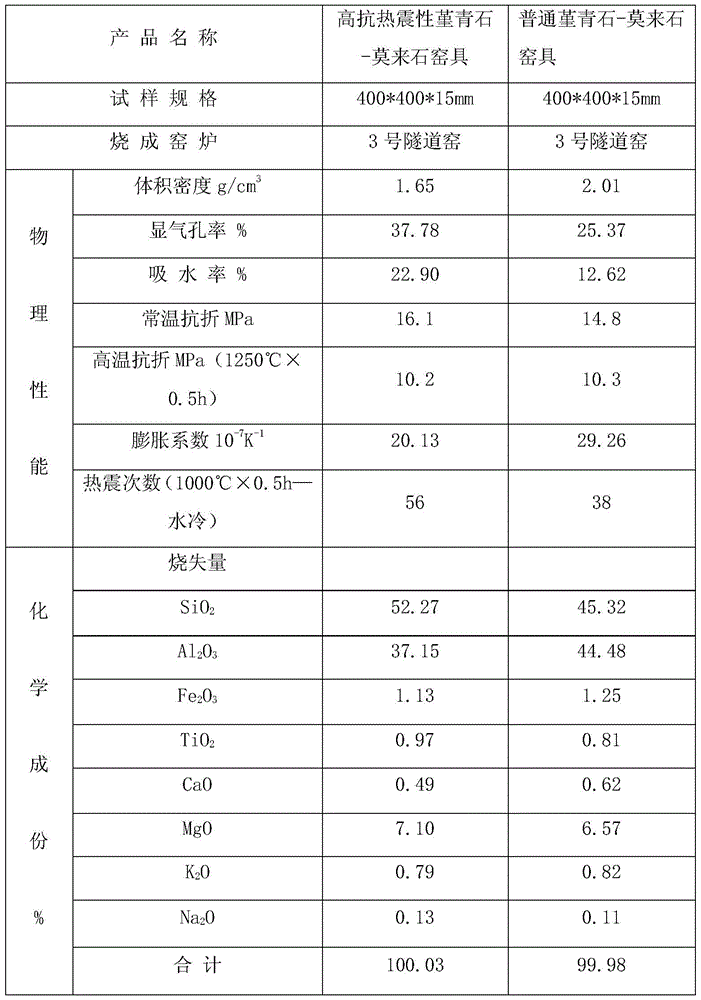

[0046] Internal structure analysis:

[0047] f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com