Silicon carbide powder and preparation method thereof

A technology of silicon carbide powder and silicon carbide, which is applied in the field of refractory materials, can solve the problems of poor thermal shock stability and low strength of silicon carbide plates, and achieve high thermal shock stability, improved thermal stability, and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

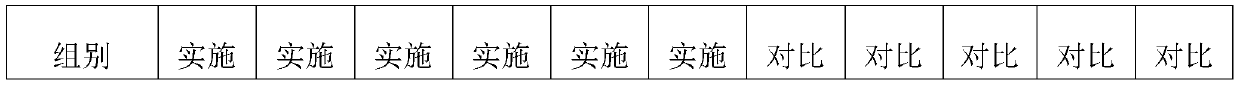

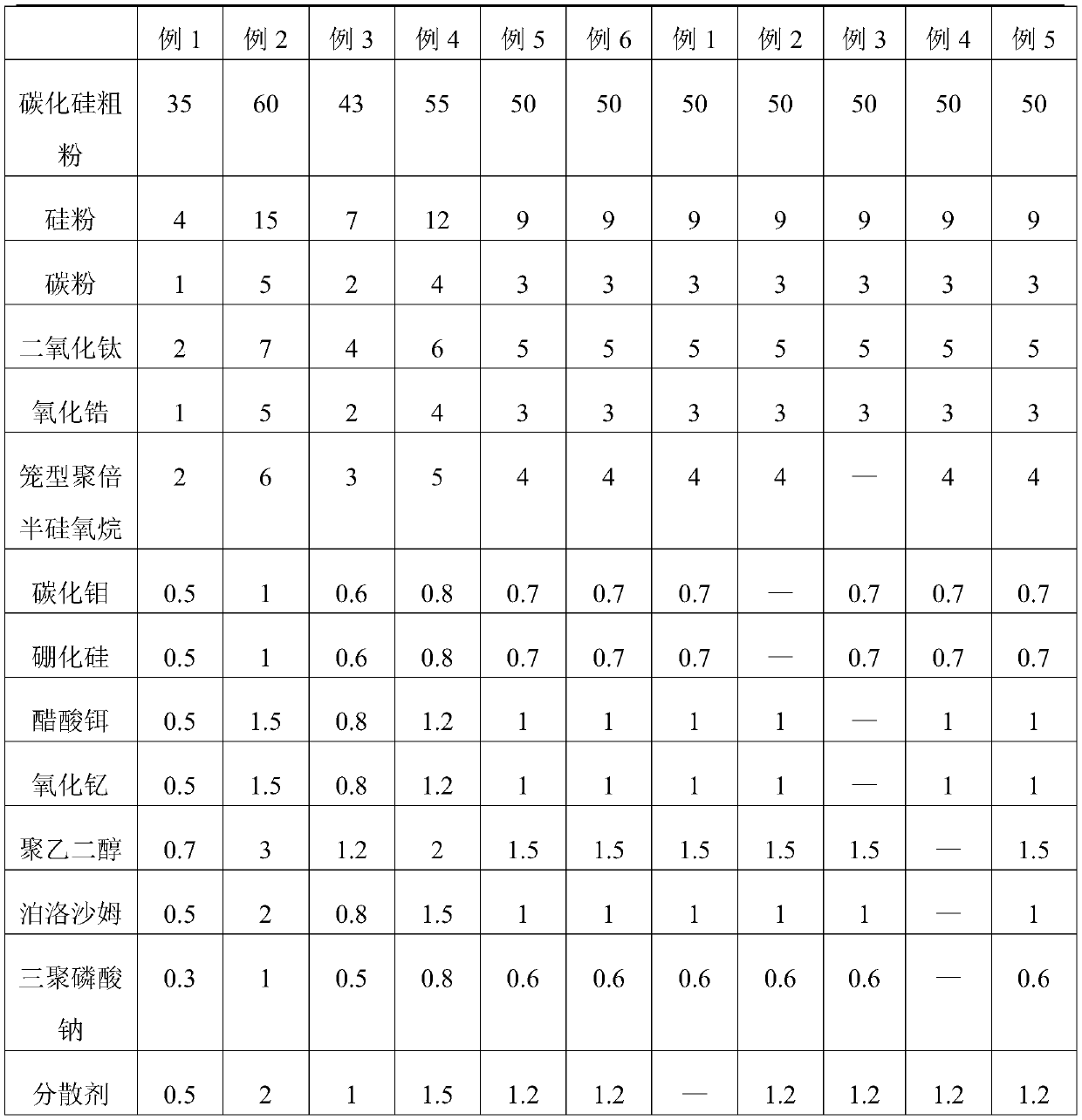

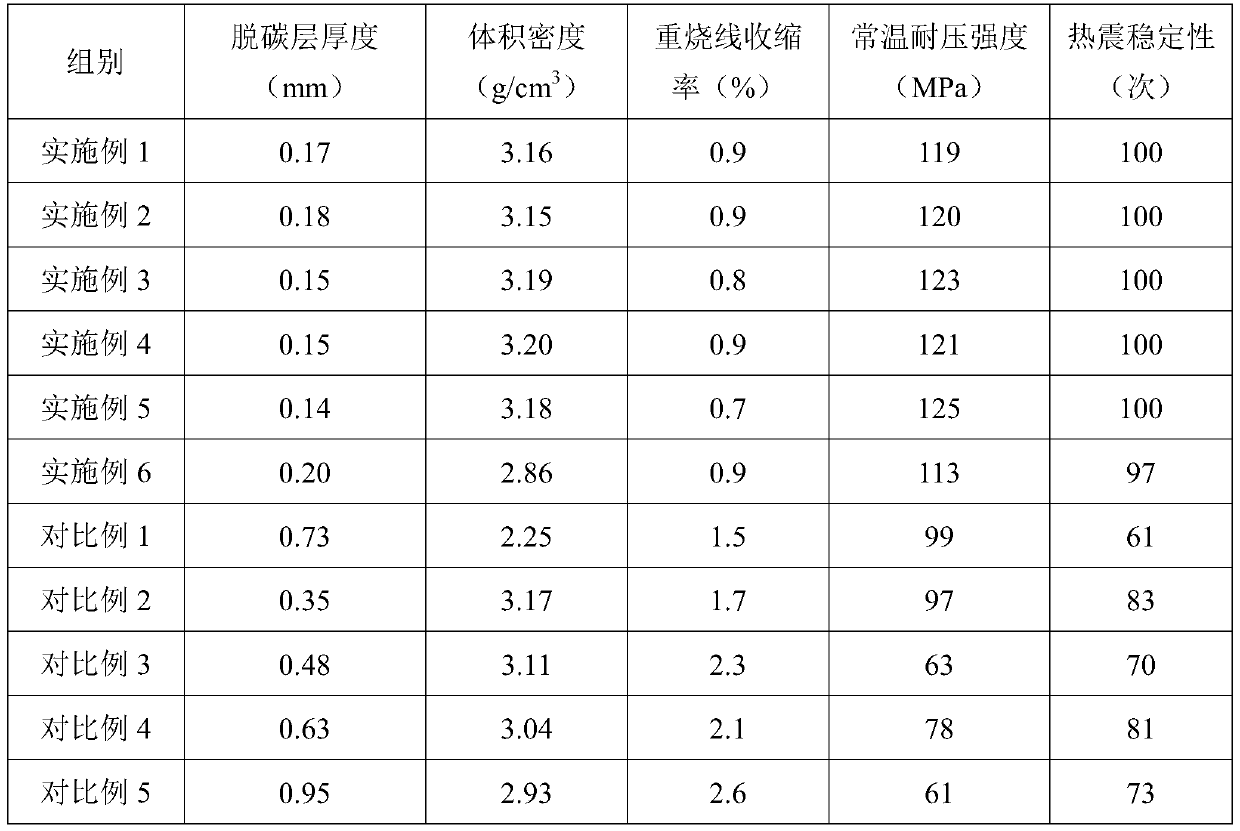

[0035] A silicon carbide powder, comprising the following components by weight:

[0036] 35 parts of silicon carbide coarse powder, 4 parts of silicon powder, 1 part of carbon powder, 2 parts of titanium dioxide, 1 part of zirconia, 2 parts of cage polysilsesquioxane, 0.5 part of molybdenum carbide, 0.5 part of silicon boride, erbium acetate 0.5 part, 0.5 part of yttrium oxide, 0.7 part of polyethylene glycol, 0.5 part of poloxamer, 0.3 part of sodium tripolyphosphate, 0.5 part of dispersant; wherein, the dispersant is lauryl glucoside and polyethyleneimine A mixture with a mass ratio of 2:1;

[0037] Among them, the particle size of silicon carbide coarse powder is 5-15 μm, and the oxygen content is 0.73wt%; the purity of silicon powder is ≥99.5%, and the particle size is 1-10 μm; the purity of carbon powder is ≥99.5%, and the particle size is 1-10 μm ; Cage polysilsesquioxane is aminopropyl isobutyl silsesquioxane;

[0038] Its preparation method comprises the following st...

Embodiment 2

[0046] A silicon carbide powder, comprising the following components by weight:

[0047] 60 parts of silicon carbide coarse powder, 15 parts of silicon powder, 5 parts of carbon powder, 7 parts of titanium dioxide, 5 parts of zirconia, 6 parts of cage polysilsesquioxane, 1 part of molybdenum carbide, 1 part of silicon boride, erbium acetate 1.5 parts, 1.5 parts of yttrium oxide, 3 parts of polyethylene glycol, 2 parts of poloxamer, 1 part of sodium tripolyphosphate, 2 parts of dispersant;

[0048] Among them, the dispersant is a mixture of dodecyl glucoside and polyethyleneimine with a mass ratio of 2:1; the particle size of the silicon carbide coarse powder is 5-15 μm, and the oxygen content is 0.73wt%; the purity of the silicon powder is ≥99.5 %, the particle size is 1-10 μm, the purity of the carbon powder is ≥99.5%, and the particle size is 1-10 μm;

[0049] Its preparation method is with embodiment 1.

Embodiment 3

[0051] A silicon carbide powder, comprising the following components by weight:

[0052] 43 parts of silicon carbide coarse powder, 7 parts of silicon powder, 2 parts of carbon powder, 4 parts of titanium dioxide, 2 parts of zirconia, 3 parts of cage polysilsesquioxane, 0.6 part of molybdenum carbide, 0.6 part of silicon boride, erbium acetate 0.8 part, 0.8 part of yttrium oxide, 1.2 part of polyethylene glycol, 0.8 part of poloxamer, 0.5 part of sodium tripolyphosphate, 1 part of dispersant;

[0053] Among them, the dispersant is a mixture of dodecyl glucoside and polyethyleneimine with a mass ratio of 2:1; the particle size of the silicon carbide coarse powder is 5-15 μm, and the oxygen content is 0.73wt%; the purity of the silicon powder is ≥99.5 %, the particle size is 1-10 μm, the purity of the carbon powder is ≥99.5%, and the particle size is 1-10 μm;

[0054] Its preparation method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com