Manufacture process of immersive elongated-nozzle zirconia flow control

A manufacturing process and shroud technology, which is applied in the manufacturing process of submerged shroud zirconia flow control parts, can solve problems such as weak erosion resistance, poor thermal shock stability, and insufficient wear resistance, and achieve improved erosion resistance , enhance the stability, reduce the effect of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

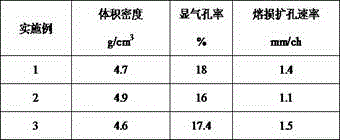

Examples

Embodiment 1

[0035] A manufacturing process of submerged shroud zirconia flow control parts, the process steps are:

[0036] 1) Mixing and grinding of raw materials: Mix and grind 85% zirconia, 12% basic magnesium carbonate and 3% strontium oxide for 14 hours to obtain fine powder; the ratio of fine powder to material is 2:1, fine powder Fineness requires 95wt% fine powder to pass through a 400 mesh screen;

[0037] 2) Raw material billet: add 2.5% chemical paste to the above fine powder, the chemical paste is prepared from carboxymethyl cellulose and water, wherein the mass ratio of carboxymethyl cellulose to water is 1 :10, and stir with a mixer, and press it into a raw material green body in a mould;

[0038] 3) Firing: Put the raw body into the kiln furnace, fire at 1350°C, keep the temperature for 9 hours, and the total firing time is 45 hours to obtain the sintered body;

[0039] 4) Particle preparation: sequentially crush the sintered green body with jaw crusher, roller compaction...

Embodiment 2

[0052] A process flow of a submerged long nozzle zirconia flow control member, the steps of the process flow are:

[0053] 1) Mixing and grinding of raw materials: 87% zirconium dioxide, 12% basic magnesium carbonate and 1% iridium oxide were mixed and ground for 16 hours to obtain a fine powder. The ball-to-material ratio of the fine powder was 2:1. Powder fineness 95% through 400 mesh;

[0054] 2) Raw material billet: add 3% chemical paste to the above fine powder, the chemical paste is prepared from carboxymethyl cellulose and water, wherein the mass ratio of carboxymethyl cellulose to water is 1 :10, and stir with a mixer, and press it into a raw material green body in a mould;

[0055] 3) Firing: Put the raw body into the kiln, fire at 1400°C, keep it warm for 10 hours, and the total firing time is 50 hours to obtain the sintered body;

[0056] 4) Particle preparation: successively crush the sintered green body with jaw crusher, roller compaction, and sieving machine to...

Embodiment 3

[0069] A process flow of a submerged long nozzle zirconia flow control member, the steps of the process flow are:

[0070] 1) Mixing and grinding of raw materials: 83% zirconium dioxide, 14% basic magnesium carbonate and 3% iridium oxide were mixed and ground for 15 hours to obtain a fine powder. The ball-to-material ratio of the fine powder was 2:1. Powder fineness 95% through 400 mesh;

[0071] 2) Raw material blanking: add 2.8% chemical paste to the above fine powder, the chemical paste is prepared from carboxymethyl cellulose and water, wherein the mass ratio of carboxymethyl cellulose to water is 1 :10, and stir with a mixer, and press it into a raw material green body in a mould;

[0072] 3) Firing: Put the raw body into the kiln furnace, fire at 1350°C, keep it warm for 12 hours, and the total firing time is 50 hours to obtain the sintered body;

[0073] 4) Particle preparation: successively crush the sintered green body with jaw crusher, roller compaction, and sievin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com