Multiphase gradient furnace door brick of box-type resistance furnace and manufacturing method

A box-type resistance furnace, technology of manufacturing methods, applied in the direction of furnace, furnace components, furnace types, etc., can solve the problem of light clay bricks with poor mechanical strength, wear resistance and slag erosion resistance, unsuitable for load-bearing structures and direct contact with melting Solve the problems of slag molten metal and other problems, and achieve the effects of improving thermal shock resistance, improving compressive strength at room temperature, and reducing bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

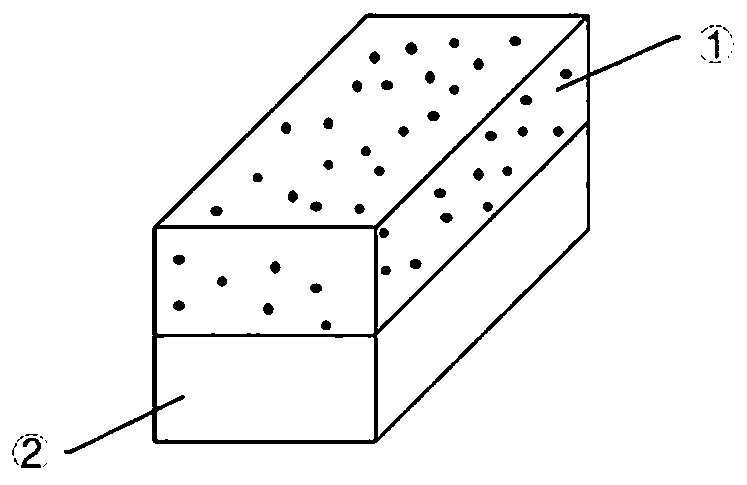

[0023] Premix 65kg of alumina hollow spheres, 34kg of alumina powder and 1kg of foaming agent in a mixer for 10 minutes to obtain premixed material 1; premix 45kg of light clinker, 45kg of plastic clay and 10kg of foaming agent in a mixer 10min to obtain premix material 2; mix premix material 1 with 5kg of water and continue to stir for 30min to obtain castable material 1; mix premix material 2 with 5kg of water and continue to stir for 30min to obtain castable material 2; The pouring method is to pour castable material 1 to 1 / 2 of the mold volume, then pour castable material 2 to fill the entire mold, and demould after curing for 24 hours to obtain a complex phase gradient furnace door brick body; the complex phase gradient furnace door brick body The body was dried at 110°C for 24 hours to obtain a dry multi-phase gradient furnace door brick body; the dried multi-phase gradient furnace door brick body was kept at 1000°C for 1 hour, and continued to heat up to 1350°C for anoth...

Embodiment 2

[0026] Premix 64.5kg of alumina hollow spheres, 34kg of alumina powder and 1.5kg of foaming agent in a mixer for 10 minutes to obtain premixed material 1; mix 48kg of light clinker, 37kg of plastic clay and 15kg of foaming agent in a mixer Premix for 10 minutes to get premixed material for two years; mix premixed material 1 with 5kg of water and continue stirring for 30 minutes to obtain castable material 1; mix premixed material 2 with 5kg of water and continue to stir for 30 minutes to obtain castable material 2 ;In the way of vibrating pouring, castable one is poured to 1 / 2 of the mold volume, and then castable two is poured to fill the entire mold, and after 24 hours of curing, the mold is demoulded to obtain a complex-phase gradient furnace door brick body; the complex-phase gradient The furnace door brick body was dried at 110°C for 24 hours to obtain a dry multiphase gradient furnace door brick body; the dried multiphase gradient furnace door brick body was kept at 1000°...

Embodiment 3

[0029] Premix 65kg of alumina hollow spheres, 33.5kg of alumina powder and 1.5kg of foaming agent in a mixer for 10 minutes to obtain premixed material 1; mix 55kg of light clinker, 30kg of plastic clay and 15kg of foaming agent in a mixer Premixed for 10 minutes to obtain premixed material 2; mixed premixed material 1 with 5 kg of water and continued to stir for 30 minutes to obtain castable material 1; mixed premixed material 2 with 5 kg of water and continued to stir for 30 minutes to obtain castable material 2; In the way of vibrating pouring, castable one is poured to 1 / 2 of the mold volume, and then castable two is poured to fill the entire mold, and after 24 hours of curing, the mold is demoulded to obtain a complex-phase gradient furnace door brick body; the complex-phase gradient furnace Dry the door brick body at 110°C for 24 hours to obtain a dry multi-phase gradient furnace door brick body; keep the dried multi-phase gradient furnace door brick body at 1000°C for 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Normal temperature compressive strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Normal temperature compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com