Preparation method and use method of modified magnesian unfired product binding agent

A binding agent and magnesia technology, applied in the field of refractory materials, can solve the problems of irritating odor and low oxidation resistance, and achieve the effects of being beneficial to carbonization cracking, improving slag resistance and thermal stability, and promoting sintering performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method of a modified magnesia unfired product binder:

[0041] Step 1, use anhydrous phenolic resin as the initial binder, and store in a dry, cool, dark, room temperature environment;

[0042] Step 2, get a certain amount of anhydrous phenolic resin, add ferrocene externally, the weight that ferrocene adds is 25% of anhydrous phenolic resin gross weight, ferrocene is dissolved in anhydrous phenolic resin, carry out sufficient Stir mechanically, the stirring time is 40min, and ensure that the surrounding temperature is 60-70°C during stirring, and the modified magnesia unfired product binder is obtained.

[0043] Get this modified magnesia unfired product binder whose weight is 3% of the aggregate of magnesia unfired product and the total weight of powder; carry out according to the use steps of the above-mentioned modified magnesia unfired product binder Hot mixing, molding under 300MPa pressure, heat treatment at 200℃ for 24h.

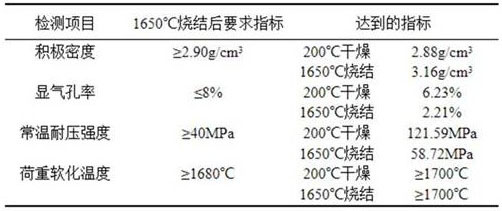

[0044] Experimental testi...

Embodiment 2

[0047] A preparation method of a modified magnesia unfired product binder:

[0048] Step 1, use anhydrous phenolic resin as the initial binder, and store in a dry, cool, dark, room temperature environment;

[0049] Step 2, get a certain amount of anhydrous phenolic resin, add ferrocene externally, the weight that ferrocene adds is 30% of anhydrous phenolic resin gross weight, ferrocene is dissolved in anhydrous phenolic resin, carry out sufficient Stir mechanically, the stirring time is 40min, and ensure that the surrounding temperature is 60-70°C during stirring, and the modified magnesia unfired product binder is obtained.

[0050] Get this modified magnesia unfired product binder whose weight is 5% of the aggregate of magnesia unfired products and the total weight of powder; carry out according to the use steps of the above-mentioned modified magnesia unfired product binder Hot mixing, molding under 300MPa pressure, heat treatment at 300℃ for 24h.

[0051] Experimental te...

Embodiment 3

[0053] A preparation method of a modified magnesia unfired product binder:

[0054] Step 1, use anhydrous phenolic resin as the initial binder, and store in a dry, cool, dark, room temperature environment;

[0055] Step 2, get a certain amount of anhydrous phenolic resin, add ferrocene externally, the weight that ferrocene adds is 28% of anhydrous phenolic resin gross weight, ferrocene is dissolved in anhydrous phenolic resin, carry out sufficient Stir mechanically, the stirring time is 40min, and ensure that the surrounding temperature is 60-70°C during stirring, and the modified magnesia unfired product binder is obtained.

[0056] Get this modified magnesia unfired product binder whose weight is 4% of the aggregate of magnesia unfired product and the total weight of powder; carry out according to the use steps of the above-mentioned modified magnesia unfired product binder Hot mixing, molding under 350MPa pressure, heat treatment at 1000℃ for 4h.

[0057] Tests show that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com