Pouring glazed tile used for oversized coke oven of specific structure and preparation method thereof

A special structure, glazed tile technology, applied in the field of glazed tiles, can solve the problems of reducing the surface temperature of the furnace door, time-consuming and laborious masonry process, small size of furnace door bricks, etc., to improve the working environment, reduce labor intensity, and clean the furnace door. Convenience effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

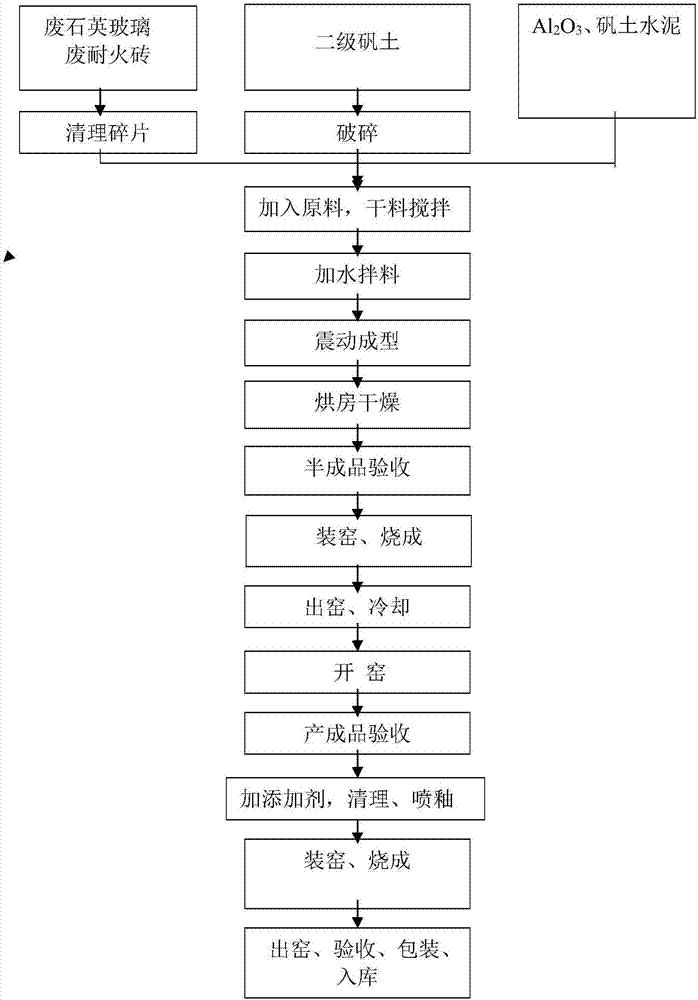

Image

Examples

Embodiment 1

[0032] A poured glazed brick for a coke oven with a super-large volume and specific structure, comprising the following components: secondary alumina, alumina cement, alumina, additives, water, waste quartz glass and waste refractory bricks, the waste quartz glass and waste refractory bricks The total weight of bricks is not more than 40% of the total weight of all components.

[0033] The components include: 40 parts of secondary bauxite, 10 parts of bauxite cement, 5 parts of alumina, 5 parts of additives, 10 parts of water, 5 parts of waste quartz glass and 35 parts of waste refractory bricks. .

[0034] The additives include spodumene, potassium feldspar, quartz, clay, alumina and water.

Embodiment 2

[0036] A poured glazed brick for a coke oven with a super-large volume and specific structure, comprising the following components: secondary alumina, alumina cement, alumina, additives, water, waste quartz glass and waste refractory bricks, the waste quartz glass and waste refractory bricks The total weight of bricks is not more than 40% of the total weight of all components.

[0037] The components include: 20 parts of secondary bauxite, 5 parts of bauxite cement, 1 part of alumina, 1 part of additive, 3 parts of water, 2 parts of waste quartz glass and 17 parts of waste refractory brick .

[0038] The additives include spodumene, potassium feldspar, quartz, clay, alumina and water.

Embodiment 3

[0040] A poured glazed brick for a coke oven with a super-large volume and specific structure, comprising the following components: secondary alumina, alumina cement, alumina, additives, water, waste quartz glass and waste refractory bricks, the waste quartz glass and waste refractory bricks The total weight of bricks is not more than 40% of the total weight of all components.

[0041] The components include: 30 parts of secondary bauxite, 7 parts of bauxite cement, 3 parts of alumina, 3 parts of additives, 6 parts of water, 3 parts of waste quartz glass and 26 parts of waste refractory bricks. .

[0042] The additives include spodumene, potassium feldspar, quartz, clay, alumina and water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com