Regenerative iron runner castable

A technology of iron trench castables and raw materials, which is applied in the field of metal smelting and recycled iron trench castables, can solve the problems of damage, waste of resources and environment, and achieve the goals of improving high temperature flexural strength, enhancing slag resistance, and reducing apparent porosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

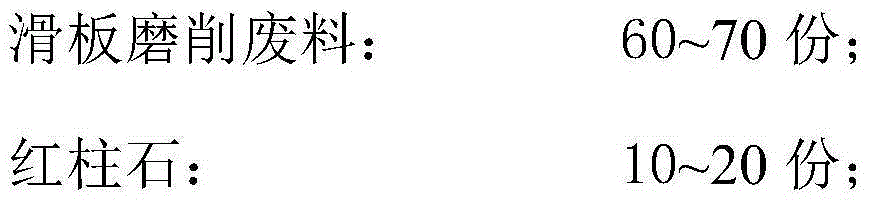

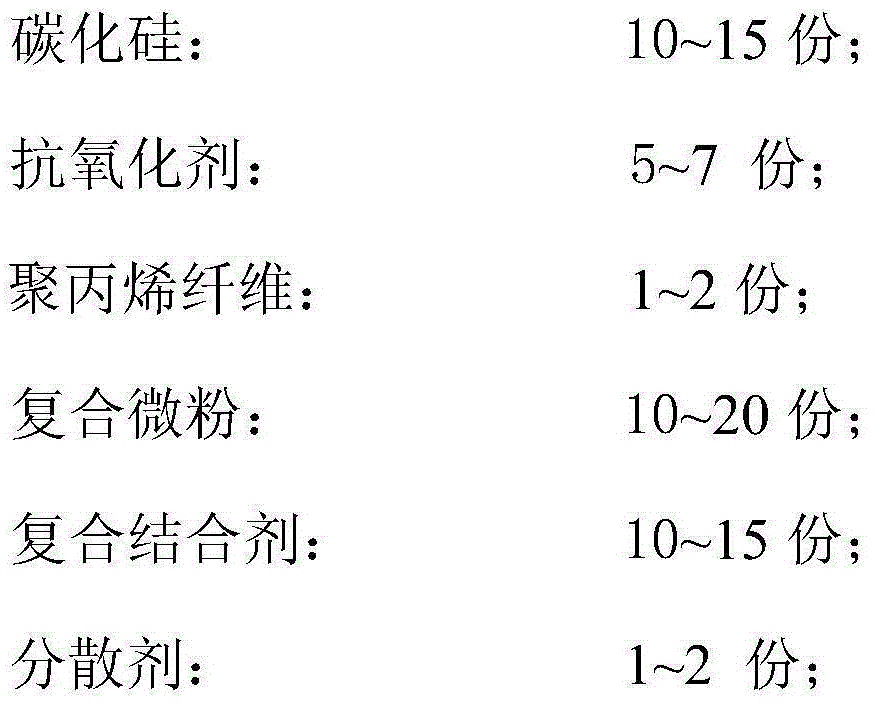

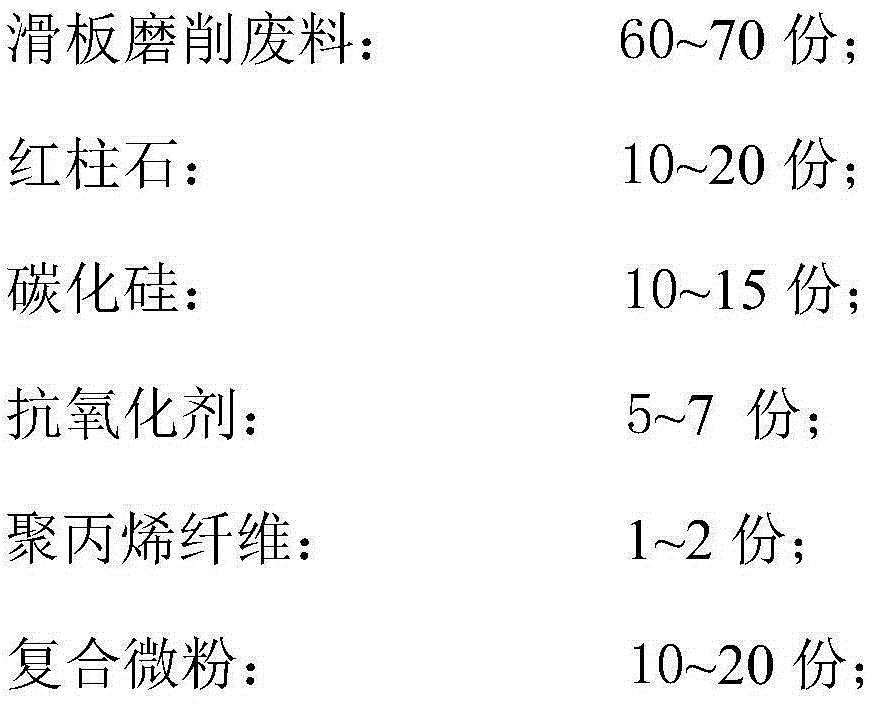

[0030] Example 1: Skateboard grinding waste: 60 parts; andalusite: 10 parts; silicon carbide: 11 parts; antioxidant: 5 parts; polypropylene fiber: 1 part; composite micropowder: 10 parts; composite binder: 12 parts; Dispersant: 1 part.

Embodiment 2

[0031] Example 2: Skateboard grinding waste: 65 parts; andalusite: 15 parts; silicon carbide: 12 parts; antioxidant: 6 parts; polypropylene fiber: 1 part; composite fine powder: 14 parts; composite binder: 11 parts; Dispersant: 1 part.

Embodiment 3

[0032] Example 3: Skateboard grinding waste: 70 parts; andalusite: 17 parts; silicon carbide: 12 parts; antioxidant: 5 parts; polypropylene fiber: 1 part; composite micropowder: 16 parts; composite binder: 14 parts; Dispersant: 2 parts.

[0033] The present invention utilizes cheap sliding plate grinding wastes whose main components are corundum, high alumina bauxite and carbon materials to manufacture low-cost iron ditch castables, and the iron ditch castables are added with slide grinding wastes to fill gaps and significantly reduce the The apparent porosity of the iron channel material increases the bulk density and flexural strength, and enhances the slag resistance. The composite silica sol-sodium polyacrylate in the iron channel castable is used as a binder to make the iron channel material form a large number of different shapes at high temperature. Reticular mullite crystals, reticular staggered in the structure, improve the high temperature flexural strength; on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com