AZC (alumina-zirconia-chromium sesquioxide) lattice brick, manufacturing method of AZC lattice brick and heat accumulation chamber built of AZC lattice brick

A regenerator and checker brick technology, applied in the field of regenerators, can solve the problems of shortening the service life of a glass melting furnace, speeding up the damage rate of refractory materials, eroding refractory materials, etc., and achieving a simple and easy preparation method and low apparent porosity. , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Raw materials:

[0029] Alumina, 99.9% pure, 73%, particle size 6000 mesh; Zirconium dioxide, 99.9% pure, 10%, Chromium trioxide, 88% pure, 8%; Aluminum phosphate 10%; Carboxylic acid 3.5% Methylcellulose; 2% Rare Earth B nucleating agent.

[0030] Among the above raw materials, except for dichromium trioxide and aluminum phosphate, the rest can be purchased from outside.

[0031] (2) Preparation method:

[0032] 1. Prepare chromium trioxide: sinter the waste chromium trioxide at 1900°C for 4 hours, add 3% nano-sized alumina during the sintering process, and obtain chromium trioxide of 6000 mesh;

[0033] 2. Prepare aluminum phosphate: it is prepared from 1% phosphoric acid, 33% alumina and 66% water.

[0034] 3. After mixing all raw materials, carry out molding and pressing, drying, sintering and heat preservation in sequence to obtain AZC bricks. The sintering temperature is 1600°C, the sintering time is 55 hours, and the heat preservation time is 5 hours.

[...

Embodiment 2

[0042] (1) Raw materials:

[0043] Alumina, 99.9% pure, 70%, particle size 6000 mesh; Zirconia, 99.9% pure, 7%,; Chromium oxide, 80% pure, 6%; Aluminum phosphate 10%; Rare earth 0.3% B nucleating agent.

[0044] (2) Preparation method:

[0045] 1. Prepare chromium trioxide: sinter the waste chromium trioxide at a temperature of 1800°C for 3 hours;

[0046] 2. Prepare aluminum phosphate: it is prepared by mixing 1% phosphoric acid, 33% alumina and 66% water.

[0047] 3. After mixing all the raw materials, perform forming and pressing, drying, sintering and heat preservation in sequence to obtain AZC bricks. The sintering temperature is 1550°C, the sintering time is 48 hours, and the heat preservation time is 4 hours.

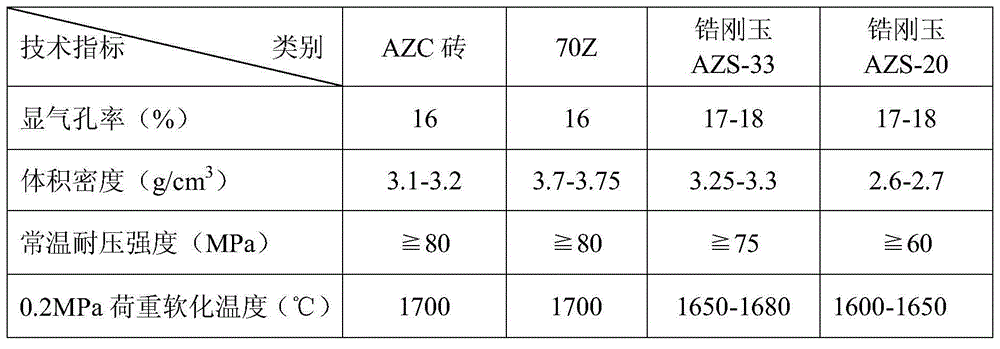

[0048] (3) Performance testing

[0049] According to the test, the apparent porosity of the brick is 16.5%, and the bulk density is 3.1g / cm 3 , The compressive strength at room temperature is 80MPa, and the softening temperature under 0.2MPa load is 1700℃.

Embodiment 3

[0051] (1) Raw materials:

[0052] 99.9% pure alumina, 75%, particle size 6000 mesh; 99.9% pure zirconia, 12%, 85% pure chromium oxide, 6%; aluminum phosphate, 12%; 2.5% carboxylate Methylcellulose.

[0053] Among the above-mentioned raw materials, except for dichromium trioxide, the rest can be purchased from outside.

[0054] (2) Preparation method:

[0055] 1. Prepare chromium trioxide: sinter the waste chromium trioxide at a temperature of 2000°C for 6 hours;

[0056] 2. After mixing all the raw materials, perform forming and pressing, drying, sintering and heat preservation in sequence to obtain AZC bricks. The sintering temperature is 1650°C, the sintering time is 60 hours, and the heat preservation time is 6 hours.

[0057] (3) Performance testing

[0058] According to the test, the apparent porosity of the brick is 16.2%, and the bulk density is 3.15g / cm 3 , The compressive strength at room temperature is 80MPa, and the softening temperature under 0.2MPa load is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com