Resintered fused mullite brick and preparation method and application thereof

A technology of fused mullite and mullite bricks, applied in the field of refractory materials, can solve the problem of high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

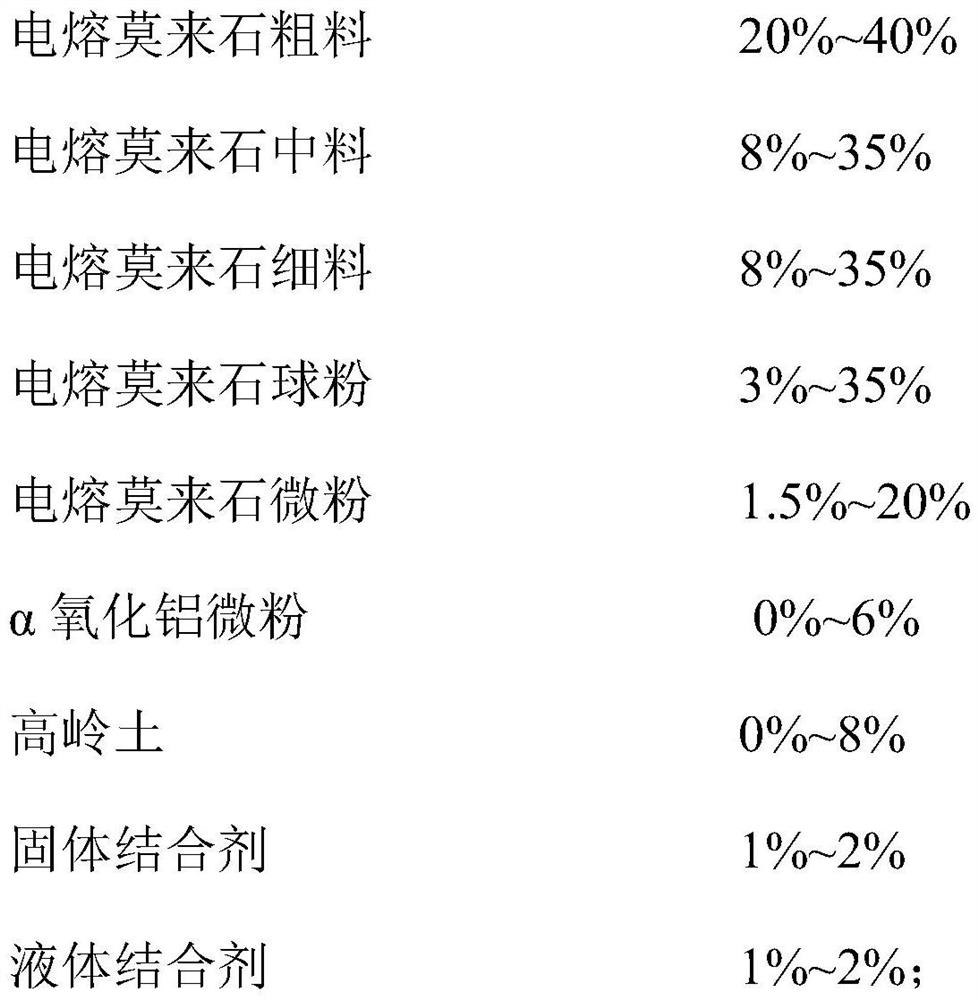

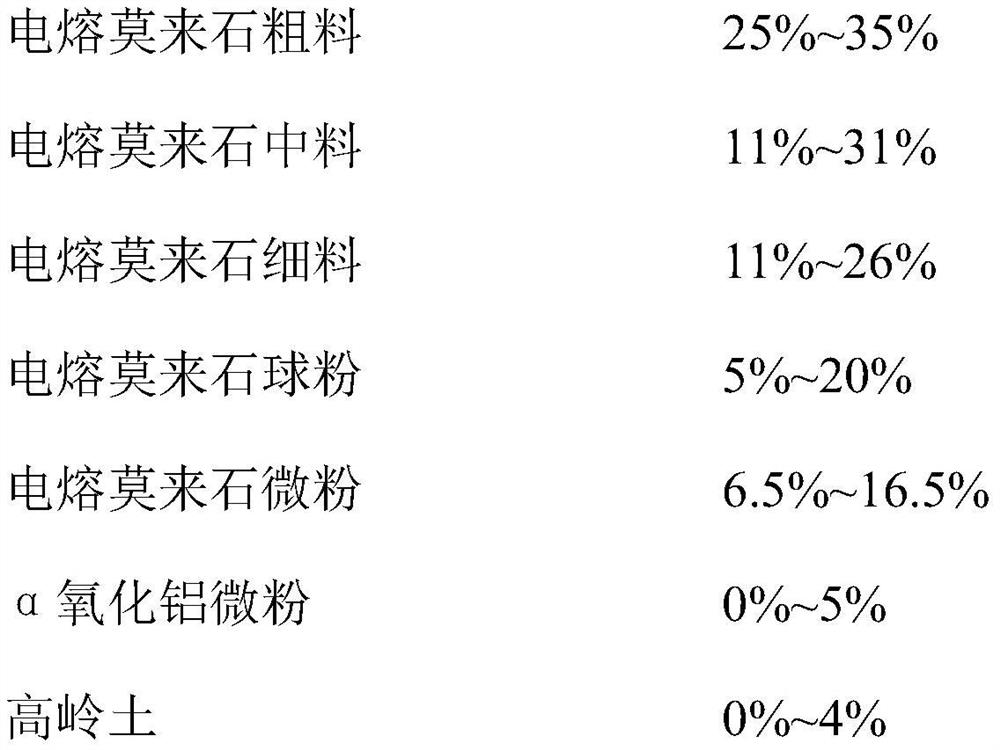

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing re-sintered fused mullite bricks, which includes the following steps S1-S4.

[0035] Step S1: mixing fused mullite ball powder, fused mullite fine powder, α-alumina fine powder, kaolin and peach gum powder in a cone mixer for 1.5h-2.5h to obtain mixed powder.

[0036] Specifically, the above-mentioned mixing time in the cone mixer can be, for example, 1.5h, 1.8h, 2h, 2.2h or 2.5h.

[0037]Step S2: Put the fused mullite coarse material, fused mullite coarse material and fused mullite coarse material into the inclined mixer in turn, then add peach glue, add the mixed powder after 1min to 2min, and mix for about 5min After ~8 minutes, seal the bag and trap the material to obtain the mixture.

[0038] Specifically, the above mixing time may be, for example, 5 min, 6 min, 7 min or 8 min.

[0039] In a specific embodiment, the moisture content of the molding material is 1.0% to 1.5%, and the time for sealing and tra...

Embodiment 1

[0047] This embodiment provides a re-sintered fused mullite brick, and its raw material powder ratio is shown in Table 1.

[0048] Mix fused mullite ball powder, fused mullite fine powder, α-alumina fine powder, kaolin and peach gum powder in a cone mixer for 2 hours to obtain mixed powder.

[0049] Put the fused mullite coarse material, fused mullite coarse material and fused mullite coarse material into the inclined mixer in turn, then add peach glue, add the mixed powder after 2 minutes, and seal the bag after mixing for about 5 minutes , The time for sealing the bag and trapping the material was 12h to obtain the mixture.

[0050] The mixture was molded in a friction press to obtain a molding material with a moisture content of 1.13%.

[0051] The molding material is placed in a tunnel kiln for sintering at a firing temperature of 1700°C and kept for 10 hours.

Embodiment 2

[0053] This embodiment provides a re-sintered fused mullite brick, and its raw material powder ratio is shown in Table 1.

[0054] Mix fused mullite ball powder, fused mullite fine powder, α-alumina fine powder, kaolin and peach gum powder in a cone mixer for 2 hours to obtain mixed powder.

[0055] Put the fused mullite coarse material, fused mullite coarse material and fused mullite coarse material into the inclined mixer in turn, then add peach glue, add the mixed powder after 2 minutes, and seal the bag after mixing for about 5 minutes , The time for sealing the bag and trapping the material was 12h to obtain the mixture.

[0056] The mixed material was molded in a friction press to obtain a molding material with a moisture content of 1.29%.

[0057] The molding material is placed in a tunnel kiln for sintering at a firing temperature of 1700°C and kept for 10 hours.

[0058] For the fused mullite bricks in Examples 3 to 21, the raw materials are fed according to Table 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com