High-temperature-resistant low-creep sealing plate and preparation process thereof

A preparation process and sealing plate technology, which is applied in engine sealing, metal material coating technology, mechanical equipment, etc., can solve the problems of reduced sealing effect, large safety hazards, high maintenance and replacement costs, and achieve the effect of avoiding falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

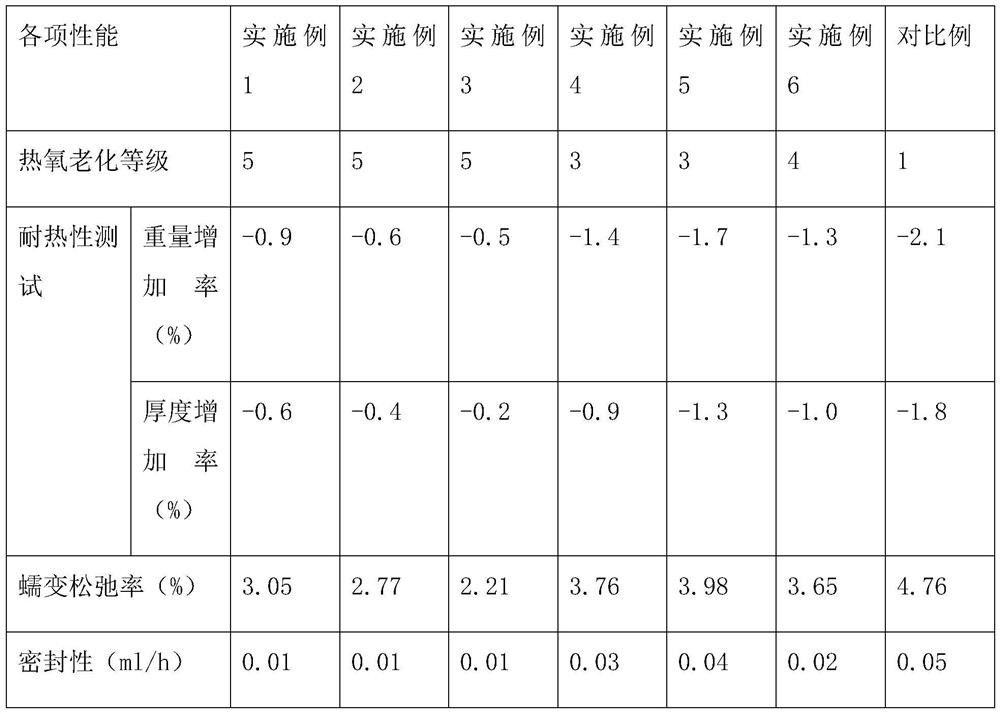

Examples

Embodiment 1

[0047] A high-temperature-resistant and low-creep sealing plate comprises a modified metal substrate and rubber layers coated on the upper and lower surfaces of the modified metal substrate, and the rubber layer is obtained by drying a rubber compound.

[0048] The modified metal base material includes the following raw material components: in parts by weight, 80 parts of metal base material, 30 parts of silane coupling agent, and 30 parts of 4,4'-diamino-2,2'-bipyridine.

[0049] The rubber compound includes the following raw material components: in parts by weight, 80 parts of polymerization liquid, 30 parts of filler, 100 parts of natural rubber, 120 parts of EPDM rubber, 120 parts of nitrile rubber, 20 parts of paraffin, and 40 parts of sulfur , accelerator 20 parts, stearic acid 40 parts, EDOT 70 parts.

[0050] The polymerization solution mainly includes: 80 parts of 2,7-dibromopyrene-4,5,9,10-tetraketone, 40 parts of bis(1,5-cyclooctadiene) nickel (0), 1,5-cyclooctadien...

Embodiment 2

[0061] A high-temperature-resistant and low-creep sealing plate comprises a modified metal substrate and rubber layers coated on the upper and lower surfaces of the modified metal substrate, and the rubber layer is obtained by drying a rubber compound.

[0062] The modified metal substrate includes the following raw material components: in parts by weight, 90 parts of metal substrate, 40 parts of silane coupling agent, and 40 parts of 4,4'-diamino-2,2,-bipyridine.

[0063] The rubber compound includes the following raw material components: in parts by weight, 90 parts of polymerization liquid, 35 parts of filler, 110 parts of natural rubber, 135 parts of EPDM rubber, 135 parts of nitrile rubber, 25 parts of paraffin, and 65 parts of sulfur , accelerator 25 parts, stearic acid 60 parts, EDOT 75 parts.

[0064] The polymerization liquid mainly includes: 90 parts of 2,7-dibromopyrene-4,5,9,10-tetraketone, 50 parts of bis(1,5-cyclooctadiene) nickel (0), 1,5-cyclooctadiene 60 part...

Embodiment 3

[0075] A high-temperature-resistant and low-creep sealing plate comprises a modified metal substrate and rubber layers coated on the upper and lower surfaces of the modified metal substrate, and the rubber layer is obtained by drying a rubber compound.

[0076] The modified metal substrate includes the following raw material components: in parts by weight, 100 parts of metal substrate, 50 parts of silane coupling agent, and 50 parts of 4,4'-diamino-2,2'-bipyridine.

[0077]The rubber compound includes the following raw material components: in parts by weight, 100 parts of polymerization liquid, 40 parts of filler, 120 parts of natural rubber, 150 parts of EPDM rubber, 150 parts of nitrile rubber, 30 parts of paraffin, and 80 parts of sulfur , accelerator 30 parts, stearic acid 80 parts, EDOT 80 parts.

[0078] The polymerization liquid mainly includes: 100 parts of 2,7-dibromopyrene-4,5,9,10-tetraketone, 60 parts of bis(1,5-cyclooctadiene) nickel (0), 1,5-cyclooctadiene 70 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com