Preparation method of superhigh-temperature anti-oxidative ceramic heating unit

A ceramic heating element and anti-oxidation technology, applied in the field of heating element preparation, can solve the problems of an oxidizing environment that cannot be applied to ultra-high temperature, poor oxidation resistance of graphite heating element, etc., and achieve the effects of good mechanical properties and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

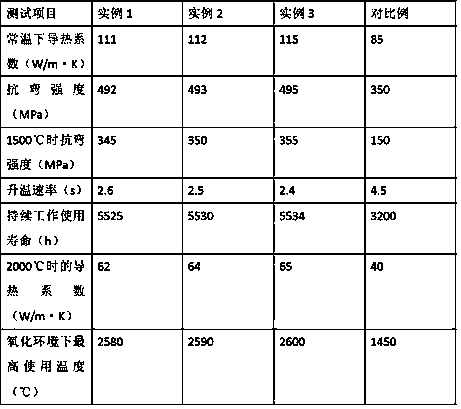

Examples

example 1

[0024] Add 40mL of butyl titanate into a beaker containing 180mL of a 25% ethylene glycol solution by mass fraction, heat up to 80°C, add 30g of citric acid into the beaker, start the stirrer, and stir and mix at a speed of 300r / min. Until the citric acid is completely dissolved, a light yellow transparent solution is obtained; 20g of neodymium oxide and 30g of lanthanum oxide are dissolved in 200mL of nitric acid solution with a mass fraction of 30%, to obtain a rare earth metal salt solution of nitrate. In parts by weight, 70 parts The above light yellow transparent solution, 20 parts of rare earth metal nitrate solution, 4 parts of calcium carbonate, 6 parts of lithium carbonate, and 40 parts of zirconia were mixed and placed in a water bath, heated to 80°C, kept for 2 hours, and continued to heat up to 130°C ℃, keep warm for 1 hour to get a thick resin; put the thick resin in a coking furnace, pass nitrogen gas, heat up to 230 ℃, keep warm and coke for 30 minutes, put it in...

example 2

[0026] Add 45mL of butyl titanate into a beaker containing 190mL of 25% ethylene glycol solution by mass fraction, heat up to 90°C, add 32g of citric acid into the beaker, start the stirrer, and stir and mix at a speed of 320r / min. Until the citric acid is completely dissolved, a light yellow transparent solution is obtained; 22g of neodymium oxide and 32g of lanthanum oxide are dissolved in 220mL of nitric acid solution with a mass fraction of 30%, to obtain a rare earth metal salt solution of nitrate. In parts by weight, 75 parts The above-mentioned light yellow transparent solution, 25 parts of rare earth metal nitrate solution, 4 parts of calcium carbonate, 6 parts of lithium carbonate, and 45 parts of zirconia were mixed and placed in a water bath, heated to 82 ° C, kept for 2.5 hours, and continued to heat up to 140°C, keep warm for 1.5h to get a thick resin; put the thick resin into a coking furnace, feed nitrogen, heat up to 240°C, keep warm and coke for 32min, put it i...

example 3

[0028] Add 50mL of butyl titanate into a beaker containing 200mL of ethylene glycol solution with a mass fraction of 25%, heat up to 100°C, add 35g of citric acid into the beaker, start the stirrer, and stir and mix at a speed of 350r / min. Until the citric acid is completely dissolved, a light yellow transparent solution is obtained; 25g of neodymium oxide and 35g of lanthanum oxide are dissolved in 250mL of nitric acid solution with a mass fraction of 30%, to obtain a rare earth metal salt solution of nitrate, and 80 parts by weight The above light yellow transparent solution, 30 parts of rare earth metal nitrate solution, 5 parts of calcium carbonate, 7 parts of lithium carbonate, and 50 parts of zirconia were mixed and placed in a water bath, heated to 85 ° C, kept for 3 hours, and continued to heat up to 150 °C ℃, keep it warm for 2 hours to get a thick resin; put the thick resin in a coking furnace, feed nitrogen, heat up to 250°C, keep it warm for 35 minutes, put it into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com