Low-creep high-alumina brick and preparation method thereof

A creep high-alumina brick and high-alumina technology is applied in the field of low-creep high-alumina bricks and their preparation, which can solve problems such as performance improvement of high-alumina bricks, and achieve the effects of low cost, simple preparation method and convenient mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

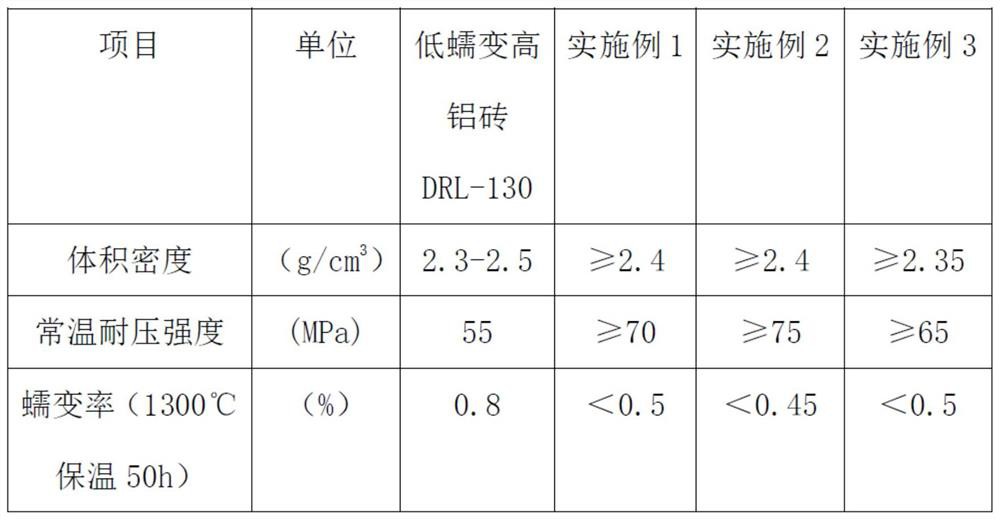

Embodiment 1

[0022] A low-creep high-alumina brick, comprising the following raw materials in proportions by weight: 52 parts of high-alumina material, 14 parts of high-alumina powder, 10 parts of alumina powder, 7 parts of sillimanite powder, 7 parts of andalusite powder, Guangxi 10 parts of white mud.

[0023] Mix high alumina material, high alumina powder, alumina powder, sillimanite powder and andalusite powder according to the ratio and stir evenly, then add an appropriate amount of water and stir for ten minutes, then add Guangxi white mud and mix for ten minutes; then add Guangxi white clay After the mud was mixed and stirred for ten minutes, the mixed mud was obtained. The finished product can be obtained by pressing the mixed mud into shape, drying and sintering. Preferably, after the mixed mud is pressed into shape, it is first dried at 130 degrees Celsius for eight hours, and then fired at a high temperature of 1430-1470 degrees Celsius for 12 hours to obtain a finished high-al...

Embodiment 2

[0026] A low-creep high-alumina brick, comprising the following raw materials in proportions by weight: 55 parts of high-alumina material, 14 parts of high-alumina powder, 10 parts of alumina powder, 7 parts of sillimanite powder, 7 parts of andalusite powder, Guangxi 7 parts of white mud.

[0027] Mix high alumina material, high alumina powder, alumina powder, sillimanite powder and andalusite powder according to the ratio and stir evenly, then add an appropriate amount of water and stir for ten minutes, then add Guangxi white mud and mix for ten minutes; then add Guangxi white clay After the mud was mixed and stirred for ten minutes, the mixed mud was obtained. The finished product can be obtained by pressing the mixed mud into shape, drying and sintering. Preferably, after the mixed mud is pressed into shape, it is first dried at 130 degrees Celsius for eight hours, and then fired at a high temperature of 1430-1470 degrees Celsius for 12 hours to obtain a finished high-alu...

Embodiment 3

[0030] A low-creep high-alumina brick comprises the following raw materials in proportion by weight: 52 parts of high-alumina material, 14 parts of high-alumina powder, 10 parts of alumina powder, 14 parts of andalusite powder, and 10 parts of Guangxi white clay.

[0031] Mix high-alumina material, high-alumina powder, alumina powder and andalusite powder according to the ratio and stir evenly, then add an appropriate amount of water and stir for ten minutes, then add Guangxi white mud and mix for ten minutes; then add Guangxi white mud and mix for ten minutes After 10 minutes, the mixed mud was obtained. The finished product can be obtained by pressing the mixed mud into shape, drying and sintering. Preferably, after the mixed mud is pressed into shape, it is first dried at 130 degrees Celsius for eight hours, and then fired at a high temperature of 1430-1470 degrees Celsius for 12 hours to obtain a finished high-alumina brick.

[0032] The high alumina brick prepared in thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Normal temperature compressive strength | aaaaa | aaaaa |

| Normal temperature compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com