High purity andalusite brick for high blast temperature and preparation method thereof

A technology for andalusite and pillar stone bricks, which is applied in the field of high-purity andalusite bricks and their preparation, can solve the problem that creep resistance and thermal shock resistance cannot meet the use requirements of hot blast stoves, quality differences of mullite bricks, and thermal shock resistance. In order to achieve the effect of complete mullite chemicalization, reduced material consumption and energy consumption, and good thermal shock resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

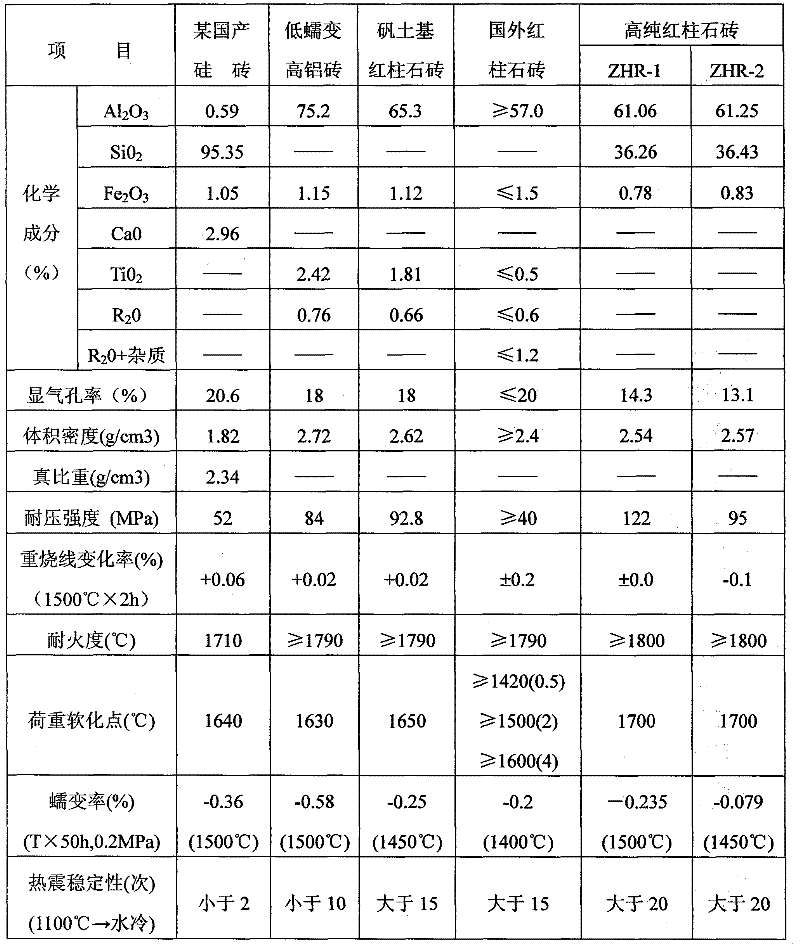

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: A high-purity andalusite brick used in a high-wind temperature hot blast stove and its preparation method

[0038] The ingredients of high-purity andalusite bricks used in high-temperature hot blast stoves are:

[0039] 50% andalusite with a particle size of 3.5-1mm, 5% andalusite with a particle size ≤1mm, 25% andalusite with a particle size ≤0.088mm, 10% activated alumina powder, 5% sillimanite sand and 5% Suzhou kaolin.

[0040] The preparation method of high-purity andalusite bricks used in high wind temperature hot blast stoves:

[0041] The method includes the following detailed steps:

[0042] a. Weigh various raw materials according to the above high-purity andalusite brick ingredients, and premix the powder part, namely andalusite powder with a particle size of ≤0.088mm, activated alumina powder and Suzhou kaolin powder, and the premixing time is 30 to 50 minutes , mixed evenly to make powder;

[0043] b. First add the granular material, that is, ...

Embodiment 2

[0047] Embodiment two: basically the same as embodiment one, the similarity is no longer described, and the difference is:

[0048] The ingredients of high-purity andalusite bricks used in high-temperature hot blast stoves are:

[0049] 40% of andalusite with a particle size of 3.5-1mm, 15% of andalusite with a particle size of ≤1mm, 20% of andalusite with a particle size of ≤0.088mm, 8% of activated alumina powder, 7% of sillimanite sand and 10% of Suzhou kaolin.

[0050] Preparation method of high-purity andalusite brick:

[0051] The total amount of pulp waste liquid added in step b accounts for 4% of the total raw material amount of high-purity andalusite bricks;

[0052] In the step c, a vibratory press machine is used to press into adobe;

[0053] In step d, the total drying time is 22 hours from the inlet temperature of the drying kiln being ≤70°C to the outlet temperature being 150°C±10°C;

[0054] In step e, it takes 34 hours to raise the temperature from normal te...

Embodiment 3

[0055] Embodiment three: basically the same as embodiment one, the similarity is no longer described, and the difference is:

[0056] The ingredients of high-purity andalusite bricks used in high-temperature hot blast stoves are:

[0057] 48% of andalusite with a particle size of 3.5-1mm, 10% of andalusite with a particle size of ≤1mm, 22% of andalusite with a particle size of ≤0.088mm, 9% of activated alumina powder, 9% of sillimanite sand and 2% of Suzhou kaolin.

[0058] Preparation method of high-purity andalusite brick:

[0059] The total amount of pulp waste liquid added in step b accounts for 5% of the total raw material amount of high-purity andalusite bricks;

[0060] In step d, the total drying time is 18 hours from the inlet temperature of the drying kiln being ≤70°C to the outlet temperature being 150°C±10°C;

[0061] In step e, it takes 30 hours to raise the temperature from normal temperature to the firing temperature of 1580°C, and it takes 30 hours to raise t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com