Refractory bricks for flue walls of carbon anode baking furnaces and preparation method thereof

A carbon anode and refractory brick technology, applied in the field of roasting furnaces, can solve the problems of high softening temperature under load, low porosity of refractory bricks, low creep rate at high temperature, etc. low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. After the calcined kaolin is crushed, it is screened into two grades with a particle size of 3-1mm and 1-0mm.

[0019] 2. After mixing 20% of sillimanite, 15% of alumina powder and 10% of bonded clay, grind them into a co-grinding powder with a fineness of ≤0.088mm.

[0020] 3. Mix the co-ground powder with 38% calcined kaolin of 3-1mm grade and 17% calcined kaolin of 1-0mm grade according to the above ratio, and add pulp waste liquid and mix together for 10-15 minutes.

[0021] 4. The mixed mud is pressed and formed into adobes, dried at 80-160°C, put into a tunnel kiln, and calcined at 1480-1500°C to make refractory materials.

[0022] 5. Compression molding, using 315T pneumatic press to press the mud into a density > 2.55g / cm 3 of adobe.

Embodiment 2

[0024] 1. After the calcined kaolin is crushed, it is screened into two grades with a particle size of 3-1mm and 1-0mm.

[0025] 2. After mixing 25% sillimanite, 8% alumina powder and 12% bonded clay, grind it into a co-milled powder with a fineness of ≤0.088mm.

[0026] 3. Mix the co-ground powder with 30% calcined kaolin of 3-1mm grade and 23% calcined kaolin of 1-0mm grade according to the above ratio, and add pulp waste liquid and mix together for 10-15 minutes.

[0027] 4. The mixed mud is pressed and formed into adobes, dried at 80-160°C, put into a tunnel kiln, and calcined at 1480-1500°C to make refractory materials.

[0028] 5. Compression molding, using 315T pneumatic press to press the mud into a density > 2.55g / cm 3 of adobe.

Embodiment 3

[0030] 1. After the calcined kaolin is crushed, it is screened into two grades with a particle size of 3-1mm and 1-0mm.

[0031] 2. After mixing 23% of sillimanite, 13% of alumina powder and 8% of bonded clay, grind them into a co-grinding powder with a fineness of ≤0.088mm.

[0032] 3. Mix the co-ground powder with 35% calcined kaolin of 3-1mm grade and 21% calcined kaolin of 1-0mm grade according to the above ratio, and add pulp waste liquid and mix together for 10-15 minutes.

[0033] 4. The mixed mud is pressed and formed into adobe, dried at 80-160°C, put into a tunnel kiln, and calcined at 1480-1500°C to make a refractory material.

[0034] 5. Compression molding, using 315T pneumatic press to press the mud into a density > 2.55g / cm 3 of adobe.

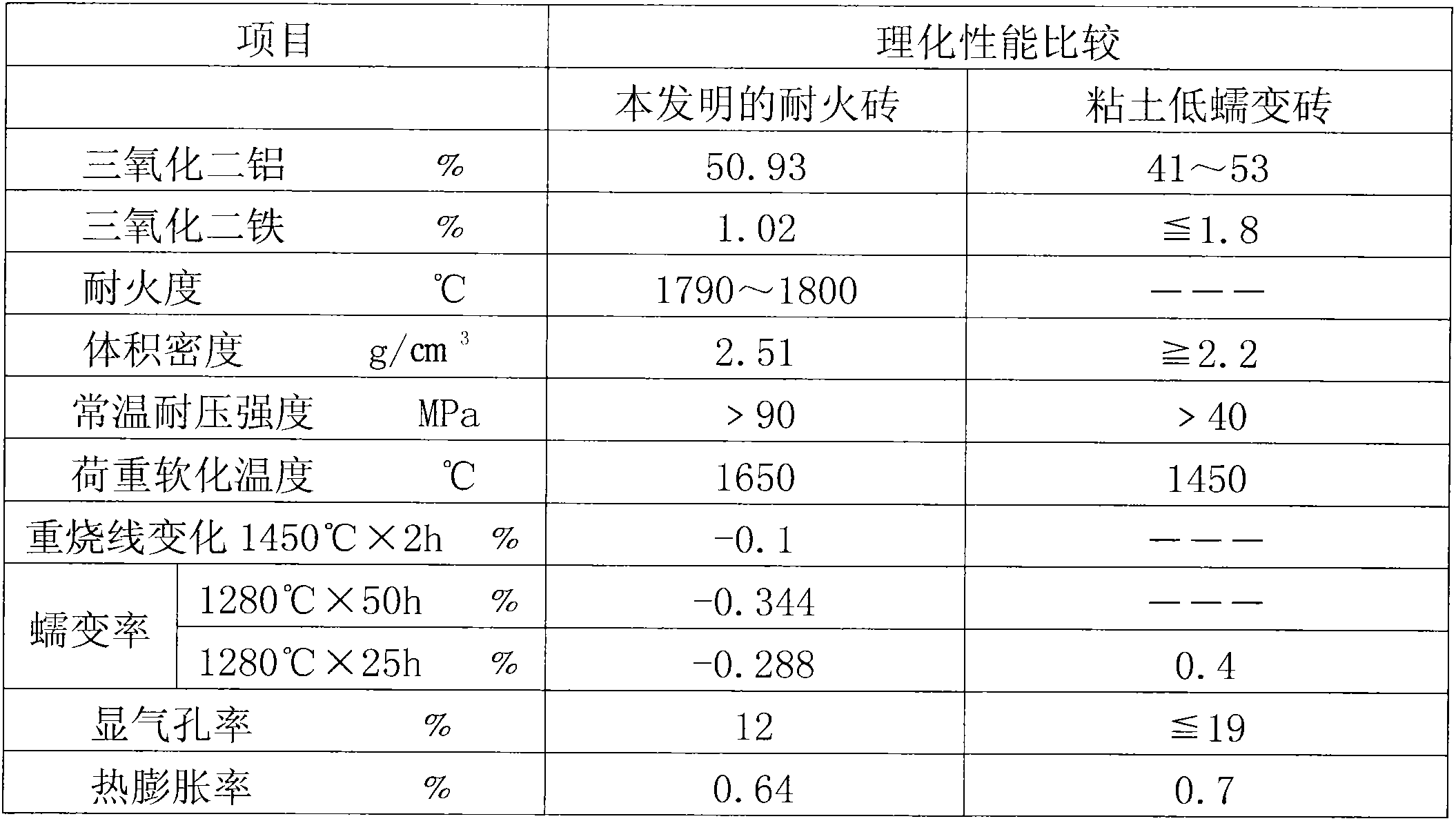

[0035] The physical and chemical properties of the special brick for the flue wall of the carbon roasting furnace of the present invention are compared with refractory bricks and high-alumina bricks, as shown in Table 1

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com