Electric cast mullite brick and preparation method thereof

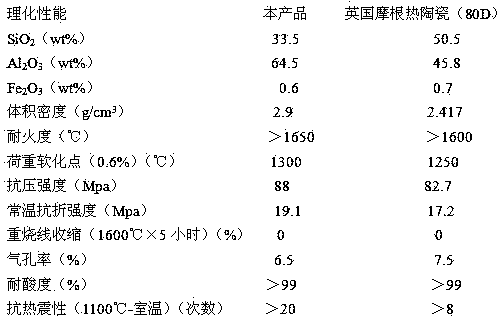

A technology for fused mullite and mullite bricks, applied in the field of refractory materials, can solve the problems of low compressive strength at room temperature, unsatisfactory use, high market price, etc., and achieves high thermal shock mechanical strength and thermal shock stability. The effect of good performance and strong chemical corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The particle size of each component after the raw material component used in this embodiment and pulverizing is as shown in table 1:

[0032] Table 1

[0033]

[0034] The present embodiment is prepared according to the following steps:

[0035] A, pulverizing the raw material components to obtain the particle size distribution of the raw material components, and then removing iron impurities in the raw material components through magnetic separation;

[0036] B, kyanite, quartz and 20% fused mullite (1.6 kilograms) obtained in step A were mixed with oleic acid, and ball milled in a ball mill for 20 hours to obtain a ball mill, and the particle size distribution of the ball mill obtained was: The mass percentage of the ball mill with a particle size of 0.088 mm is 90%, so that it can pass through a 200-mesh sieve; after dissolving methylcellulose in water, mix it with 80% fused mullite (6.4 kg) to obtain granules Material;

[0037] C. After mixing the ball mill an...

Embodiment 2

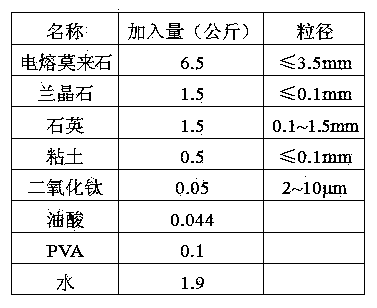

[0041] The particle size of each component after the raw material component used in this embodiment and pulverizing is as shown in table 2:

[0042] Table 2

[0043]

[0044] The present embodiment is prepared according to the following steps:

[0045] A, pulverizing the raw material components to obtain the particle size distribution of the raw material components, and then removing iron impurities in the raw material components through magnetic separation;

[0046] B, kyanite, quartz, clay, titanium dioxide and 30% fused mullite (1.95 kilograms) obtained in step A were mixed with oleic acid, and ball milled in a ball mill for 24 hours to obtain a ball mill, and the obtained ball mill The particle size distribution is: the mass percentage of the ball abrasive with a particle size of 0.088 mm is 92%, so that it can pass through a 200-mesh sieve; after dissolving PVA in water, mix it with 70% fused mullite (4.55 kg) to obtain pellets;

[0047] C. After mixing the ...

Embodiment 3

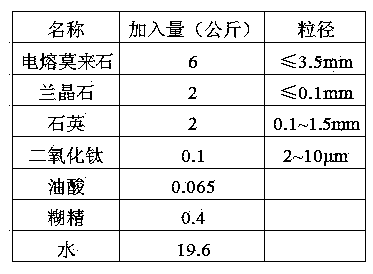

[0051] The particle size of each component after the raw material component used in this embodiment and pulverizing is as shown in table 3:

[0052] table 3

[0053]

[0054] The present embodiment is prepared according to the following steps:

[0055] A, pulverizing the raw material components to obtain the particle size distribution of the raw material components, and then removing iron impurities in the raw material components through magnetic separation;

[0056] B, kyanite, quartz, clay, titanium dioxide and 40% fused mullite (2.4 kilograms) obtained in step A were mixed with oleic acid, and ball milled in a ball mill for 28 hours to obtain a ball mill, and the obtained ball mill The particle size distribution is: the mass percentage of the ball abrasive with a particle size of 0.088 mm is 95%, so that it can pass through a 200-mesh sieve; after dissolving dextrin in water, mix it with 60% (3.6 kg) of fused mullite evenly, get pellets;

[0057] C. After mixi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com