High-strength thermal-shock-resistant wear-resistant silicon mullite brick and production process thereof

A production process and thermal shock resistance technology, applied in the field of refractory bricks, can solve the problem of insufficient thermal shock resistance of refractory bricks, and achieve the effects of strong thermal shock resistance, high thermal shock resistance, and high softening point under load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

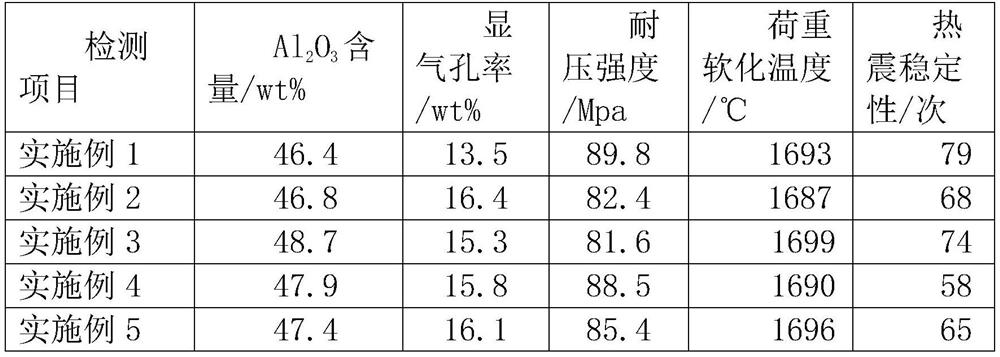

Examples

Embodiment 1

[0038]A high-strength thermal shock and wear-resistant silica brick, comprising:

[0039] 6wt% of natural sintered mullite with a particle size of 3-5mm;

[0040] 10 wt% of natural sintered mullite particles with a particle size of 1-3 mm;

[0041] 24wt% of andalusite particles with a particle size of 1-3mm;

[0042] 15 wt% of andalusite particles with a particle size of 0-1 mm;

[0043] 5 wt% of silicon carbide particles with a particle size of 0-1 mm;

[0044] Granularity is 200 mesh andalusite fine powder 10wt%;

[0045] Particle size is 250 mesh sillimanite fine powder 5wt%;

[0046] Granularity is 200 mesh refractory mud 5wt%;

[0047] The particle size is 5wt% of natural sintered mullite fine powder of 200 mesh;

[0048] Particle size is 10wt% of silicon carbide fine powder of 150 mesh;

[0049] Dextrin 0.5 wt%.

[0050] The production process of the above-mentioned high-strength thermal shock-resistant and wear-resistant silica bricks includes the following step...

Embodiment 2

[0057] A high-strength thermal shock and wear-resistant silica brick, including:

[0058] 7wt% of natural sintered mullite with a particle size of 3-5mm;

[0059] 11 wt% of natural sintered mullite particles with a particle size of 1-3mm;

[0060] 23wt% of andalusite particles with a particle size of 1-3mm;

[0061] 14wt% of andalusite particles with a particle size of 0-1mm;

[0062] 6 wt% of silicon carbide particles with a particle size of 0-1mm;

[0063] The particle size is 200 mesh andalusite fine powder 8wt%;

[0064] The particle size is 250 mesh sillimanite fine powder 6wt%;

[0065] Granularity is 200 mesh refractory mud 4wt%;

[0066] The particle size is 6wt% of natural sintered mullite fine powder of 200 mesh;

[0067] Particle size is 11wt% of silicon carbide fine powder of 150 mesh;

[0068] Dextrin 0.8wt%.

[0069] The production process of the above-mentioned high-strength thermal shock-resistant wear-resistant silica brick includes the following steps...

Embodiment 3

[0076] A high-strength thermal shock and wear-resistant silica brick, including:

[0077] 7wt% of natural sintered mullite with a particle size of 3-5mm;

[0078] 12 wt% of natural sintered mullite particles with a particle size of 1-3mm;

[0079] 22wt% of andalusite particles with a particle size of 1-3mm;

[0080] 13wt% of andalusite particles with a particle size of 0-1mm;

[0081] 7 wt% of silicon carbide particles with a particle size of 0-1 mm;

[0082] Particle size is 200 mesh andalusite fine powder 6wt%;

[0083] Particle size is 250 mesh sillimanite fine powder 7wt%;

[0084] Particle size is 200 mesh refractory mud 3wt%;

[0085] The particle size is 7wt% of natural sintered mullite fine powder of 200 mesh;

[0086] Particle size is 12wt% of silicon carbide fine powder of 150 mesh;

[0087] Dextrin 1wt%.

[0088] The production process of the above-mentioned high-strength thermal shock-resistant wear-resistant silica brick includes the following steps:

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com