A new type of prefabricated iron ditch and its preparation method

A new type of iron tapping trough technology, applied in the field of ironmaking, can solve the problems of increased construction difficulty and time, replacement, difficult replacement, etc., and achieve the effect of improving safe use performance, convenient replacement process, and short time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with specific examples, further illustrate the present invention, the examples are implemented under the premise of the technical solutions of the present invention, it should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

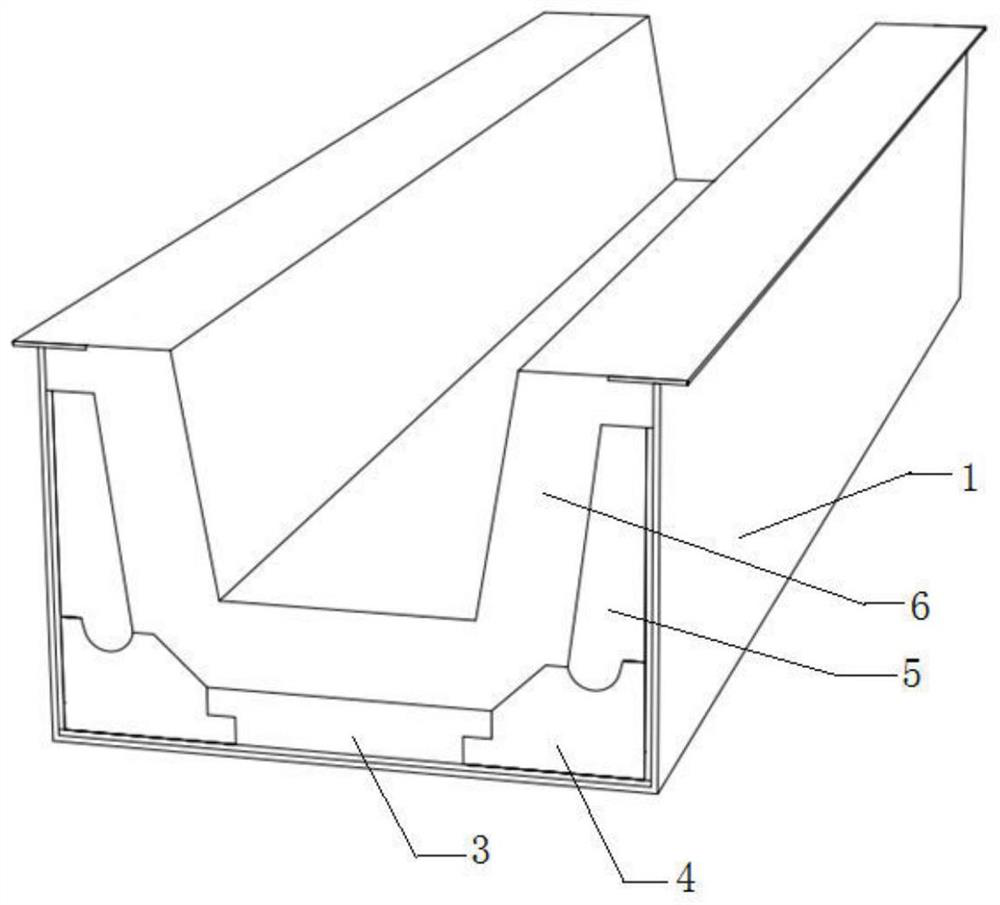

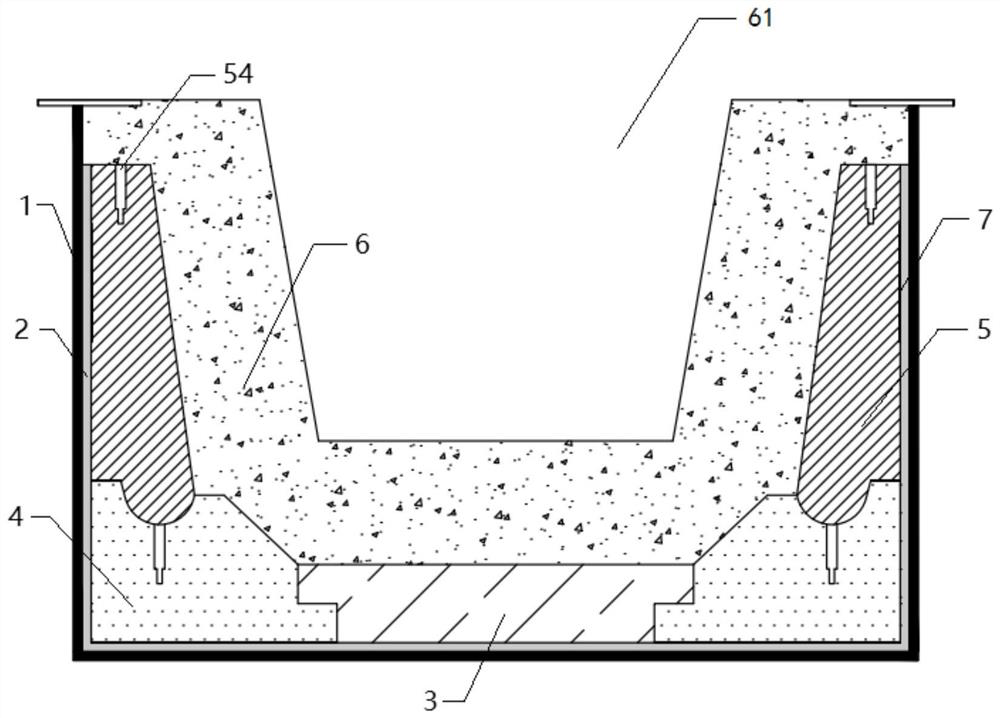

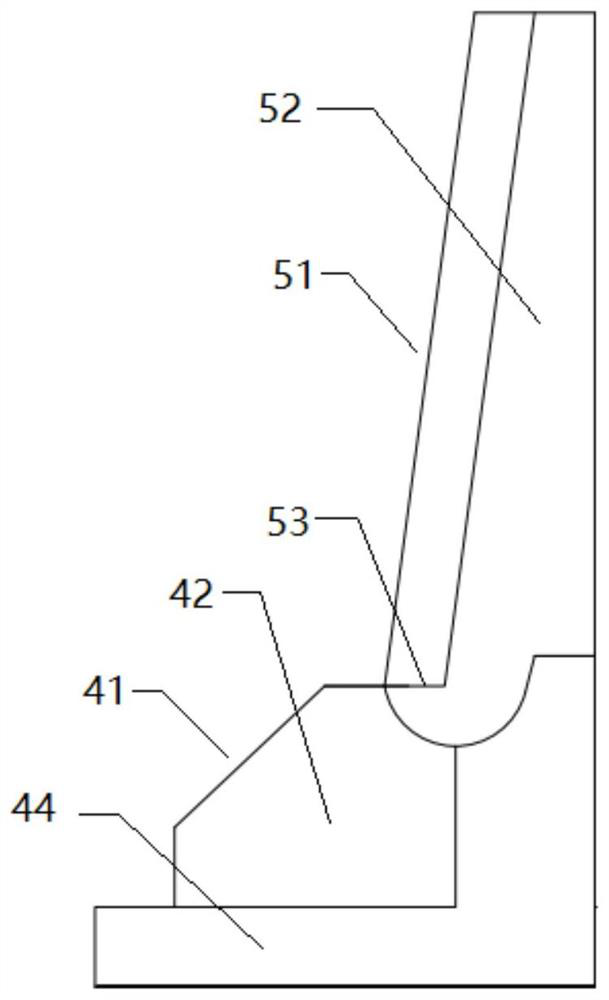

[0036] Such as Figure 1-6 As shown, a new type of prefabricated iron trough includes an outer steel shell 1, a permanent layer set inside the outer steel shell 1, and a working layer 6 set on the permanent layer. The working layer 6 is provided with a groove for molten iron to flow through 61. The outer steel shell 1 is made of a heat-resistant steel plate with a thickness of 25 mm. The outside of the outer steel shell 1 maintains a natural air circulation or forced air cooling structure design. A heat insulation layer 2 with a thickness of 30 mm is installed on the inner wall of the outer steel shell 1. Thermal layer 2 adopt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com