Saggar for roller kiln for soft ferromagnet production and preparation method of saggar

A technology of soft magnets and roller kiln, which is applied in applications, household utensils, ceramic products, etc. It can solve the problems of affecting the appearance quality of ferrite soft magnets, circular cracks on the surface, and the inability to continue to use. The preparation method is simple and feasible. , less reaction, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

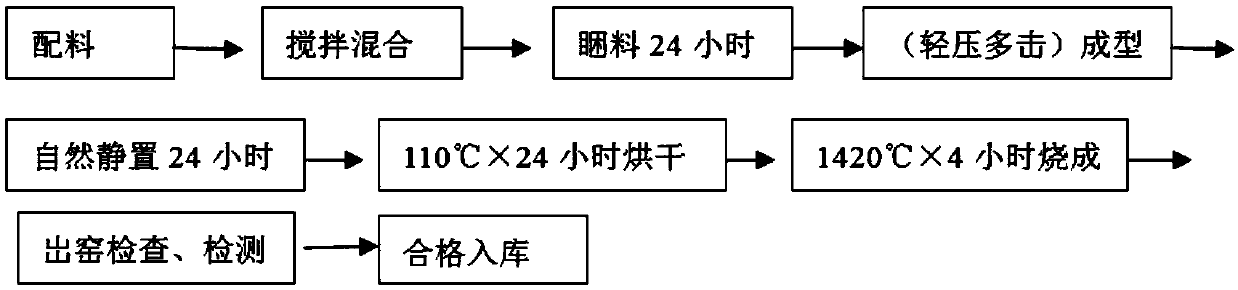

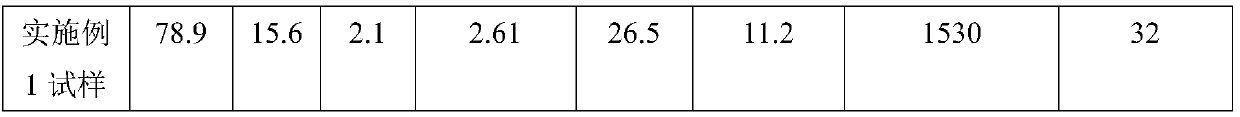

[0026] Weigh 30 parts of 2-1mm sintered mullite, 10 parts of 1-0mm sintered mullite, 15 parts of 1-0mm andalusite, 2.5 parts of 325 mesh kaolin, 19 parts of 325 mesh low-sodium alumina, 1500 mesh active oxidation 8 parts of aluminum, 15 parts of 325-mesh aluminum-rich spinel, 0.5 part of zirconia refractory fiber, plus 0.4 part of dextrin and 0.5 part of calcium lignosulfonate, put it into the mud mixer, at 15 rpm Speed, stir for 5-10 minutes, add 12 parts of water, stir and mix for 20 minutes, discharge, put into the raw material barrel, and leave for 24 hours to trap the material. Use a friction press to form, with a pressure of 2-5 tons, and hit 10-15 times to form. After standing for 24 hours to dry naturally, the green body enters the drying room for drying at 110°C for 24 hours. Then put the sagger into a high-temperature kiln for firing at 1420°C for 4 hours. For the entire process, see figure 1 .

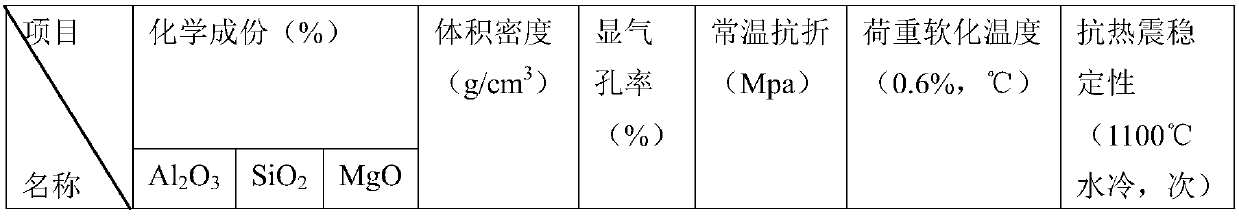

[0027]It can be seen from Table 1 that the proportion of raw materi...

Embodiment 2

[0032] Weigh 30 parts of 2-1mm sintered mullite, 10 parts of 1-0mm sintered mullite, 15 parts of 1-0mm andalusite, 2.5 parts of 325 mesh kaolin, 19 parts of 325 mesh low-sodium alumina, 1500 mesh active oxidation 8 parts of aluminum, 25 parts of 325-mesh alumina-rich spinel, 0.5 part of zirconia refractory fiber, 0.4 part of dextrin and 0.5 part of calcium lignosulfonate are put into the mud mixer, and the Speed, stir for 5-10 minutes, add 12 parts of water, stir and mix for 20 minutes, discharge, put into the raw material barrel, and leave for 24 hours to trap the material. The raw material becomes dry due to the hydration of aluminum-rich spinel, and its fluidity is poor. After replenishing 1% of the water, it is formed by a friction press with a pressure of 2-5 tons and 10-15 blows. The green body is left to stand for 24 hours, and then enters the drying room for drying at 110°C for 24 hours. Then put the sagger into a high-temperature kiln for firing at 1420°C for 4 hours...

Embodiment 3

[0037] Weigh 30 parts of 2-1mm sintered mullite, 10 parts of 1-0mm sintered mullite, 15 parts of 1-0mm andalusite, 2.5 parts of 325 mesh kaolin, 12 parts of 325 mesh low-sodium alumina, 1500 mesh active oxidation 15 parts of aluminum, 15 parts of 325-mesh aluminum-rich spinel, 0.5 part of zirconia refractory fiber, plus 0.4 part of dextrin and 0.5 part of calcium lignosulfonate, put it into the mud mixer, at 15 rpm Speed, stir for 5-10 minutes, add 12 parts of water, stir and mix for 20 minutes, discharge, put into the raw material barrel, and leave for 24 hours to trap the material. Use a friction press to form, with a pressure of 2-5 tons, and hit 10-15 times to form. The green body is left to stand for 24 hours, and then enters the drying room for drying at 110°C for 24 hours. Then put the sagger into a high-temperature kiln for firing at 1420°C for 4 hours.

[0038] This example mainly investigates the impact of low-sodium alumina and activated alumina on product perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com