High-strength abrasive brick for aviation garbage furnace

A technology for waste incinerators and wear-resistant bricks, applied in incinerators, combustion chambers, combustion methods, etc., can solve the problems of poor thermal shock resistance and erosion resistance, poor creep performance, and low porosity, and achieve thermal shock resistance Strong corrosion resistance, low porosity, and good creep performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A high-strength wear-resistant brick for an aviation waste incinerator, characterized in that it consists of the following components and the mass percentage of the components is:

[0063] 3 ~ 1mm mullite 25%

[0064] 1~0.1mm mullite 10%

[0065] <0.1mm mullite 25%

[0066] 1~0.074mm brown corundum or white corundum 12%

[0067] <0.074 brown or white corundum 12%

[0068] 2 o 3 Micronized 2%

[0069] Silica powder <1mm 2%

[0070] Industrial phosphoric acid 12%.

[0071] Manufacturing process:

[0072] Preparation of 50% industrial phosphoric acid:

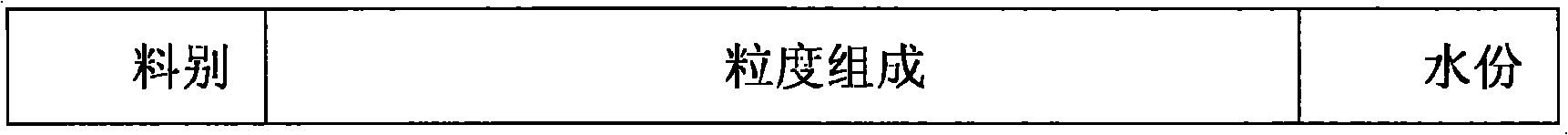

[0073]The general concentration of industrial phosphoric acid sold on the market is 85%, and the same concentration as castable binder is generally 45%-60%, so industrial phosphoric acid can be diluted with tap water, and the water consumption can be diluted by adding water as shown in the table below.

[0074] Phosphoric acid dilution water consumption

[0075] Phosphoric acid concentration%

Density ...

Embodiment 2

[0132] A high-strength wear-resistant brick for an aviation waste incinerator, characterized in that it consists of the following components and the mass percentage of the components is:

[0133] 3~1mm mullite 37%

[0134] 1-0.1mm mullite 8%

[0135] <0.1mm mullite 23%

[0136] 1~0.074mm brown corundum or white corundum 10%

[0137] <0.074mm brown or white corundum 10%

[0138] 2 o 3 Micronized powder 1%

[0139] Silica powder <1mm 1%

[0140] Industrial phosphoric acid 10%.

[0141] Its manufacturing process is the same as in Embodiment 1.

Embodiment 3

[0143] A high-strength wear-resistant brick for an aviation waste incinerator, characterized in that it consists of the following components and the mass percentage of the components is:

[0144] 3-1mm mullite 33%

[0145] 1-0.1mm mullite 9%

[0146] <0.1mm mullite 23%

[0147] 1~0.074mm brown corundum or white corundum 10%

[0148] <0.074mm brown or white corundum 10%

[0149] 2 o 3 Micronized 2%

[0150] Silica powder <1mm 2%

[0151] Industrial phosphoric acid 11%.

[0152] Its manufacturing process is the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com