Weatherproof inorganic exterior wall coating based on graphene and mullite and preparation method thereof

A technology of exterior wall coatings and mullite, which is applied in the direction of anti-corrosion coatings, fire-proof coatings, anti-fouling/underwater coatings, etc., can solve the problem of adhesion and other properties that need to be improved, affect the application effect of graphene, and the dispersion effect of graphene is not good Good and other problems, to achieve the effect of light apparent density, good thermal shock stability, and improved anti-corrosion and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

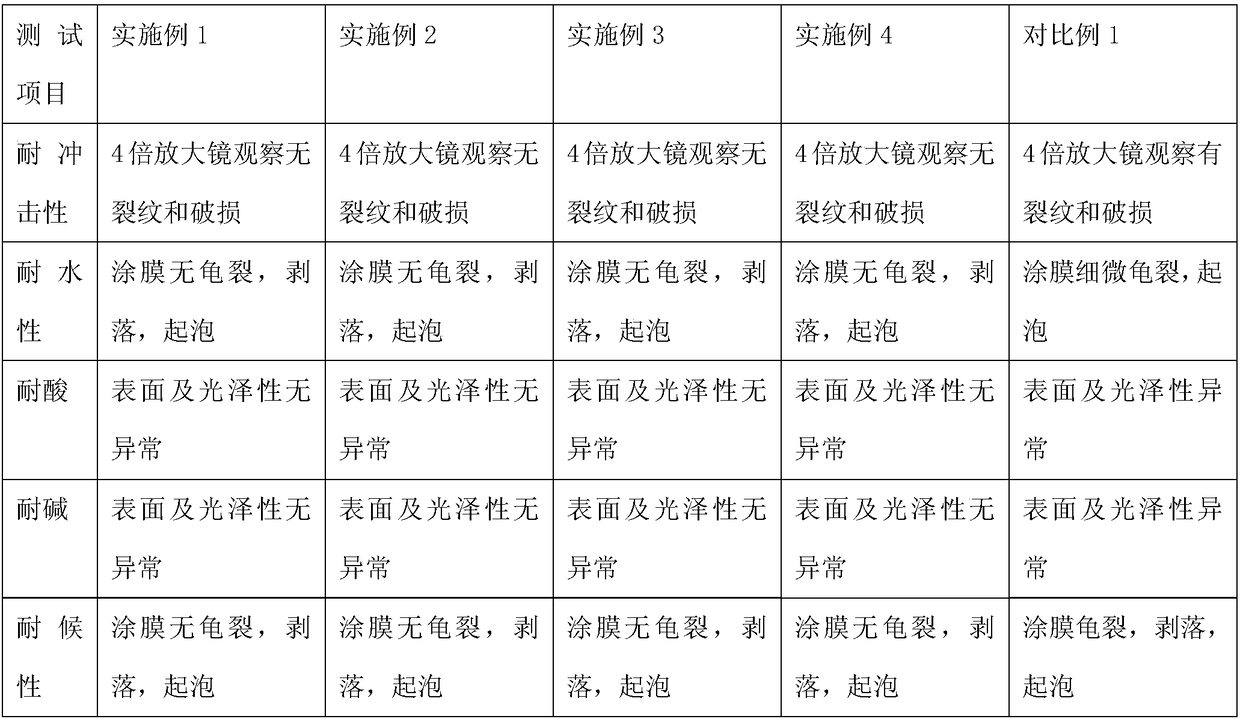

Embodiment 1

[0030] The weather-resistant inorganic exterior wall coating based on graphene and mullite includes the following components according to mass percentage: 5% mullite, 10% perlite, 10% graphene, 5% vitrified microbeads, 7% sepiolite, Albite 14%, light calcium carbonate 5%, bauxite 5%, nano-titanium dioxide 2%, nano-silica sol 10%, additives 23%, pure acrylic emulsion 4%; among them,

[0031]The auxiliary agent includes the following components in terms of mass percentage: 75% sodium silicate, 24% zinc phosphate, and 1% sodium hexametaphosphate;

[0032] The nano-silica sol is first modified by adding γ-methacryloxypropyltrimethoxysilane into the nano-silica sol and stirring at room temperature for 10 hours; the γ-methacryloyl The usage amount of oxypropyltrimethoxysilane is 2.0wt% of the nano-silica sol quality;

[0033] The particle size of the light calcium carbonate is 0.02 μm;

[0034] The preparation method of described inorganic exterior wall paint, comprises the follow...

Embodiment 2

[0040] The weather-resistant inorganic exterior wall coating based on graphene and mullite includes the following components in terms of mass percentage: 10% mullite, 6% perlite, 6% graphene, 3% vitrified microbeads, 5% sepiolite, Albite 12%, light calcium carbonate 8%, bauxite 8%, nano-titanium dioxide 4%, nano-silica sol 15%, additives 20%, pure acrylic emulsion 3%; among them,

[0041] The auxiliary agent includes the following components in terms of mass percentage: 80% sodium silicate, 18% zinc phosphate, and 2% sodium hexametaphosphate;

[0042] The nano-silica sol is first modified by adding γ-methacryloxypropyltrimethoxysilane into the nano-silica sol and stirring at room temperature for 11 hours; the γ-methacryloyl The usage amount of oxypropyltrimethoxysilane is 3.0wt% of the nano-silica sol quality;

[0043] The particle size of the light calcium carbonate is 0.10 μm;

[0044] The preparation method of described inorganic exterior wall paint, comprises the followi...

Embodiment 3

[0050] The weather-resistant inorganic exterior wall coating based on graphene and mullite includes the following components in terms of mass percentages: 12% mullite, 8% perlite, 15% graphene, 3% vitrified microbeads, 9% sepiolite, Albite 6%, light calcium carbonate 5%, bauxite 5%, nano-titanium dioxide 3%, nano-silica sol 10%, additives 20%, pure acrylic emulsion 4%; among them,

[0051] The auxiliary agent includes the following components according to mass percentage: 77% of sodium silicate, 20% of zinc phosphate, and 3% of sodium hexametaphosphate;

[0052] The nano-silica sol is first modified by adding γ-methacryloxypropyltrimethoxysilane into the nano-silica sol and stirring at room temperature for 10.5 hours; the γ-methacrylic acid The usage amount of acyloxypropyltrimethoxysilane is 2.5wt% of the nano-silica sol quality;

[0053] The particle size of the light calcium carbonate is 0.06 μm;

[0054] The preparation method of described inorganic exterior wall paint, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com