Contact lens material, contact lenses and method for manufacturing contact lenses

A technology of contact lenses and manufacturing methods, applied in glasses/goggles, instruments, optics, etc., capable of solving problems such as uncomfortable wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

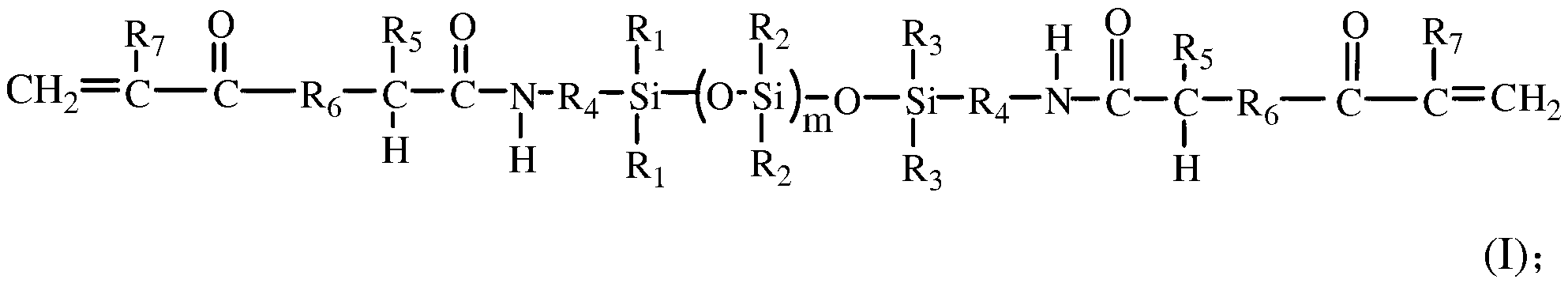

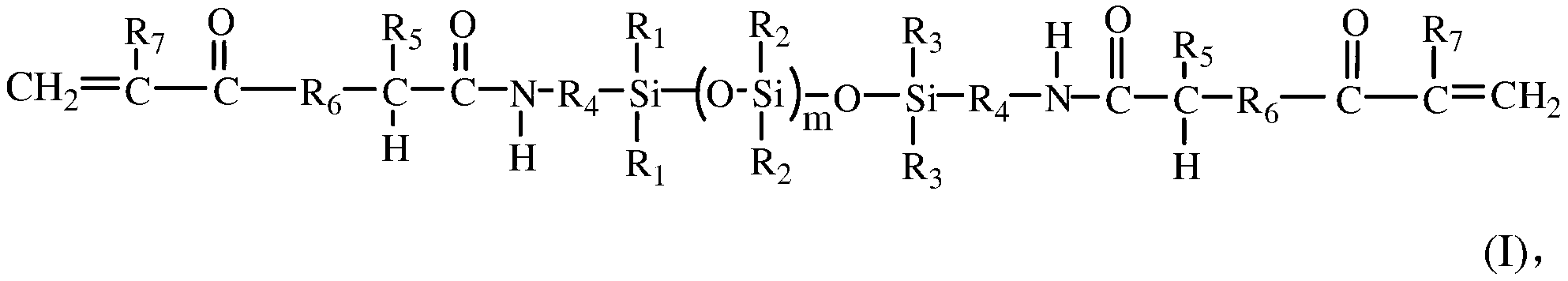

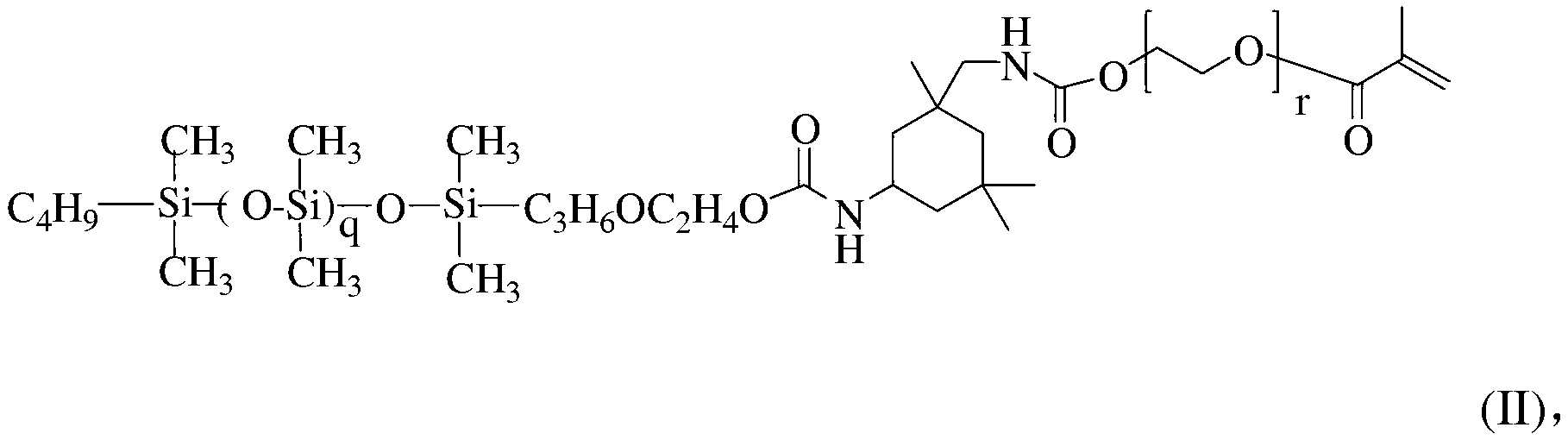

Method used

Image

Examples

preparation example Construction

[0094] 5. Preparation of Contact Lenses

[0095] (1) detailed preparation steps of embodiment 1-embodiment 15

Embodiment 1

[0096] Detailed preparation steps of embodiment 1

[0097]Silicone polymer (I-1), silicone polymer (II), N-vinylpyrrolidone (NVP), 2-hydroxyethyl methacrylate (HEMA), N,N-dimethyl Acrylamide (DMA), thermal initiator azobisisoheptanonitrile (ADVN) and solvent ethanol were mixed in the proportions shown in Table 1 and stirred for about 1 hour to form a mixture.

[0098] The mixture was then added to the PP mold and cured in an oven at 80°C for 10 hours. After the polymerization reaction is complete, soak the model and lens in isopropanol for 1 hour and remove the contact lens. The contact lens lenses were then heated in water for 4 hours before being placed in buffered saline.

Embodiment 2

[0099] Detailed preparation steps of embodiment 2

[0100] Silicone polymer (I-1), silicone polymer (II), N-vinylpyrrolidone (NVP), 2-hydroxyethyl methacrylate (HEMA), thermal initiator azobis Isoheptanonitrile (ADVN) and solvent ethanol were mixed in the proportions shown in Table 1 and stirred for about 1 hour to form a mixture.

[0101] The mixture was then added to the PP mold and cured in an oven at 80°C for 10 hours. After the polymerization reaction is complete, soak the model and lens in isopropanol for 1 hour and remove the contact lens. The contact lens lenses were then heated in water for 4 hours before being placed in buffered saline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com