Thermoset plastics infiltration strengthened powdery plant fiber material and preparation method thereof

A plant fiber material and plant fiber technology, which is applied in the field of modified plant fiber powder and its preparation, can solve the problems that affect the corrosion resistance and moisture resistance of plant fiber powder particles, the mechanical properties of composite materials cannot be obtained, and the plant fiber powder particles are loose. , to achieve the effects of easy promotion and application, excellent anti-corrosion and high affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

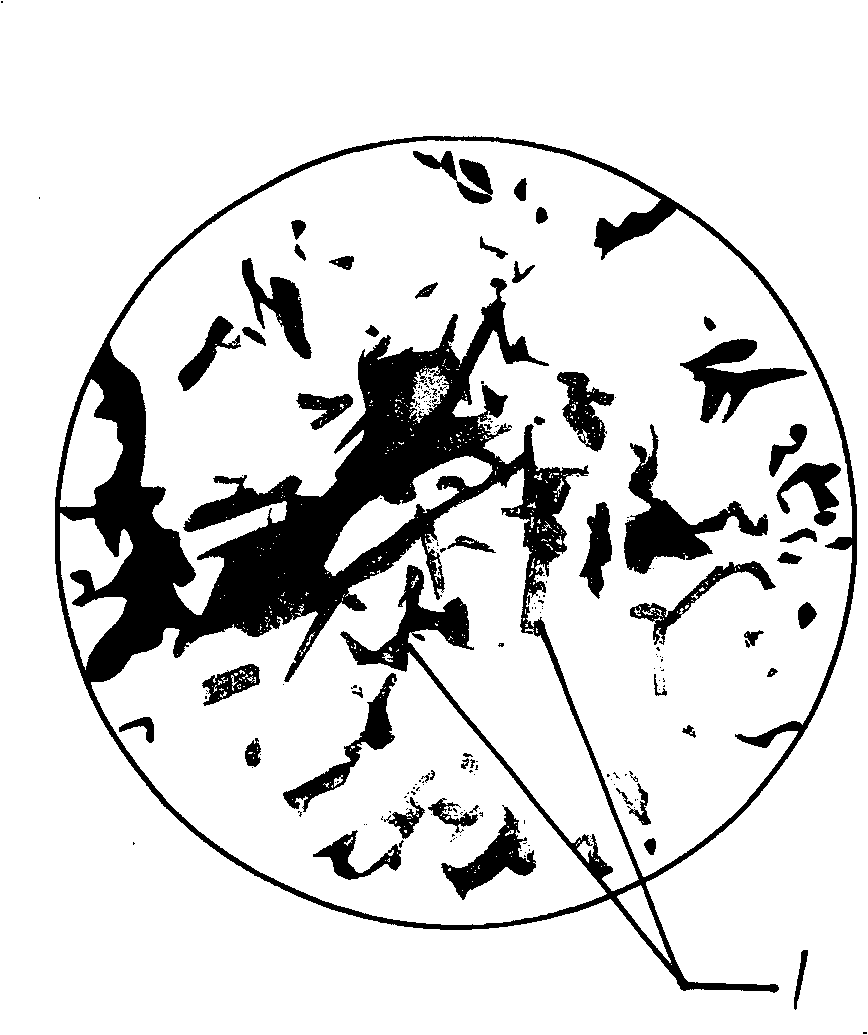

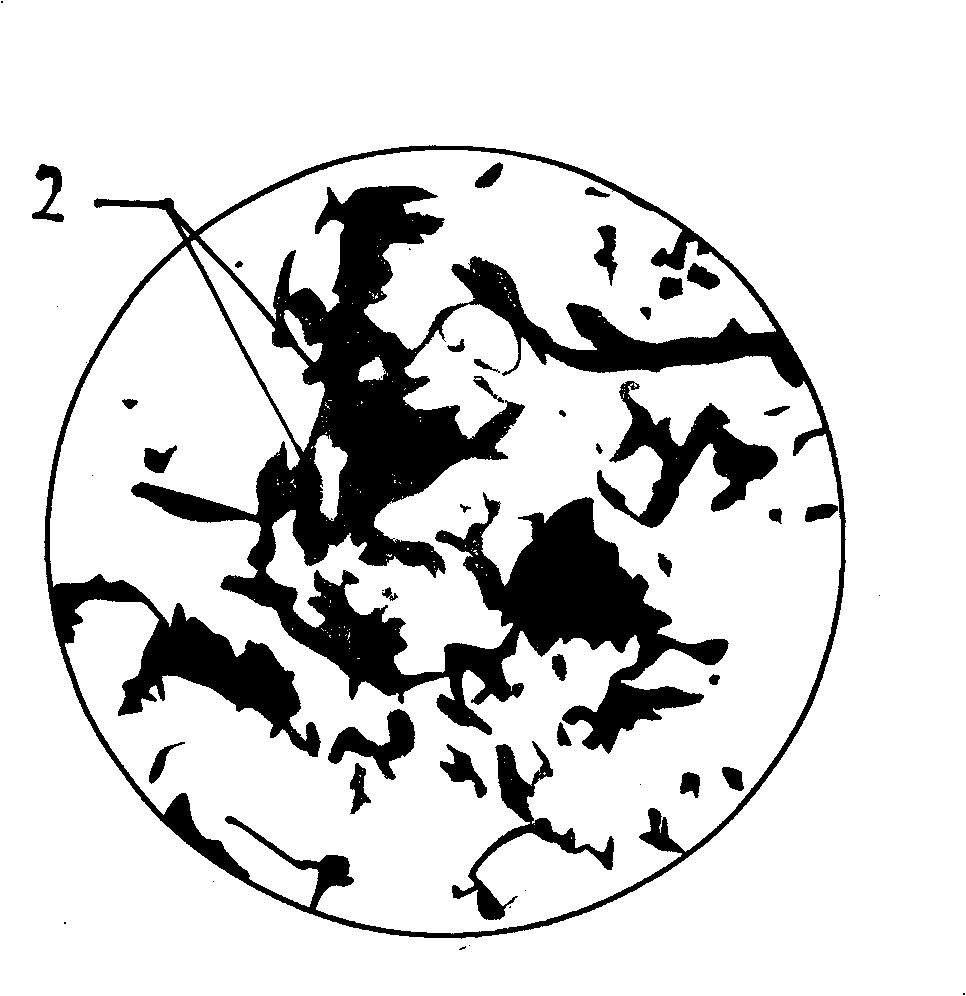

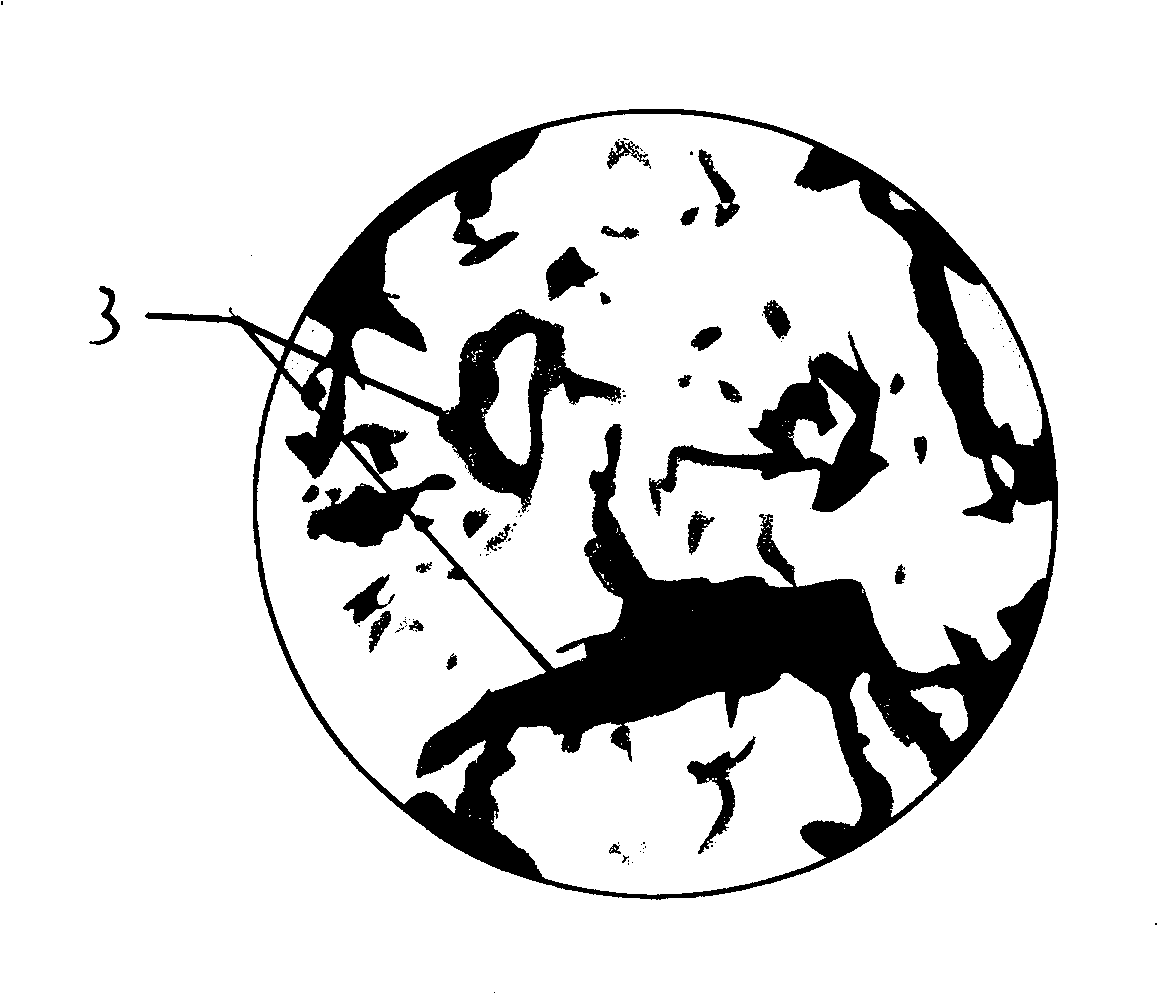

Image

Examples

Embodiment 1

[0028] The formula of the modified fiber powder material contains the following components: 100 parts of waste wood chips with a water content of 8% are ground into 100 mesh powders, 2 parts of vinyl ester resins and 0.02 parts of the corresponding SG- 1 curing agent, 2 parts of stearic acid and 2 parts of PE wax.

[0029] The preparation method of this material is the following steps:

[0030] A. At room temperature, grind the waste wood chips with a water content of 8% into a powder over 100 meshes, then take 100 parts and put them into a high-speed mixer with a speed of 700 rpm to continuously stir, then Add 2 parts of vinyl ester resin and 0.02 parts of SG-1 curing agent corresponding to vinyl ester resin;

[0031] B. After completing A, heat up to 120°C after 20 minutes, and add 2 parts of stearic acid and 2 parts of PE wax at the same time;

[0032] C. After the completion of B, heat up to 125°C after 9 minutes, and at the same time, stir and cool to room temperature a...

Embodiment 2

[0034] With embodiment 1, the prescription of the modified fiber powder material contains following components: water content is that 2% shavings are ground into 100 parts of 150 mesh powders, 30 parts of epoxy resin and 0.3 part of methyl ethyl ketone peroxide curing agent, 0.4 parts of white oil.

[0035] In the preparation step, the waste sawdust with a water content of 8% in reaction A is ground into a powder over 100 mesh and replaced with shaving wood chips with a water content of 2% and ground into a powder over 150 mesh, and the stirring speed is selected at 1200 rpm; 2 parts of vinyl resin and 0.02 parts of SG-1 curing agent corresponding to vinyl resin, replaced by adding 30 parts of epoxy resin and 0.3 parts of methyl ethyl ketone peroxide curing agent.

[0036] In reaction B, the original 20 minutes was replaced by 60 minutes, the temperature was raised to 80°C, and 0.4 parts of white oil was added as a dispersant and lubricant.

[0037] In reaction C, replace the...

Embodiment 3

[0039] With embodiment 1, the formula of the fiber powder material of modification contains following components: water content is that 5% sawdust is ground into powder of 125 meshes, 12 parts of phenolic resins and 0.15 parts of phenolic resins NL curing agent, the BOP of 1.1 parts and 1.1 parts white oil.

[0040] In the preparation step, the waste sawdust with a water content of 8% in reaction A was ground into a powder over 100 mesh and replaced with sawdust with a water content of 5% and ground into a powder over 125 mesh, and the stirring speed was selected at 950 rpm; the original added 2 12 parts of vinyl resin and 0.02 parts of SG-1 curing agent corresponding to vinyl resin, replaced by adding 12 parts of phenolic resin and 0.15 parts of phenolic resin NL curing agent.

[0041] In reaction B, replace the original 20 minutes with 40 minutes, raise the temperature to 100°C, add 1.1 parts of BOP as a dispersant and 1.1 parts of white oil as a lubricant.

[0042] In reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com