Patents

Literature

32results about How to "Strong infiltration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vacuum infusion forming method for carbon fiber composite structure member

The invention discloses a vacuum infusion forming method for a carbon fiber composite structure member. The method comprises the steps as follows: making a large-size carbon fiber composite wind power blade structure member by a vacuum infusion forming technology; bonding and fixing a guide net to a mould by a transparent double-sided tape for preventing deformation of carbon fiber fabrics due to deformation of the guide net to guarantee that carbon fiber sheet is consistent in orientation so as to obtain a composite structure member with higher mechanical performance; preheating a resin mixing solution with a carbon fiber preforming body at first to guarantee the resin mixing solution to be quickly infused in a low-viscosity state; and sealing the upper surface of the carbon fiber preforming body with a unidirectional breathable film to form a surface breathable channel, and enabling the resin mixing solution to permeate from surface and to fill fully under vacuum, thus completing the vacuum infusion forming process. The method is suitable for the carbon fiber fabrics which are shaped by hot melting lines and have different surface densities; and compared with the carbon fiber prepreg forming process, the method has the advantages of long material availability period, high process stability and low product cost, and is favorable for popularization and application.

Owner:SINOMATECH WIND POWER BLADE

Refining agent for aluminum and aluminum alloy

ActiveCN101967565AAffect the service lifeWill not corrodeProcess efficiency improvementSlagPotassium

The invention relates to a refining agent for aluminum and aluminum alloy. The refining agent is characterized by mainly comprising the following components in percentage by mass: 30 to 85 percent of NaCl, 5 to 40 percent of Na2SiF6, 5 to 40 percent of Na2SO4, 2 to 20 percent of CaF2 and 0.5 to 5 percent of C6C16; and the refining agent also can comprise one or more of CaMg(CO3)2, Na3AlF6, Na2S2O3 and NaF. The potassium-free refining agent provided by the invention has good slag forming performance, strong gas and impurity removing capability and low cost; and the aluminum ash produced by refining the aluminum and the aluminum alloy through the refining agent can realize recycle.

Owner:江西广恒铝业有限公司

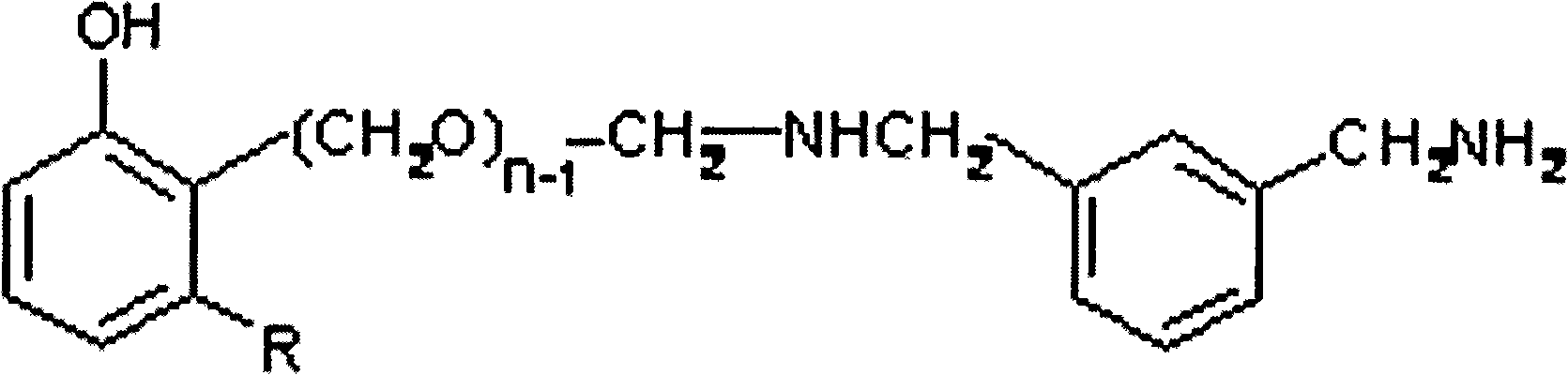

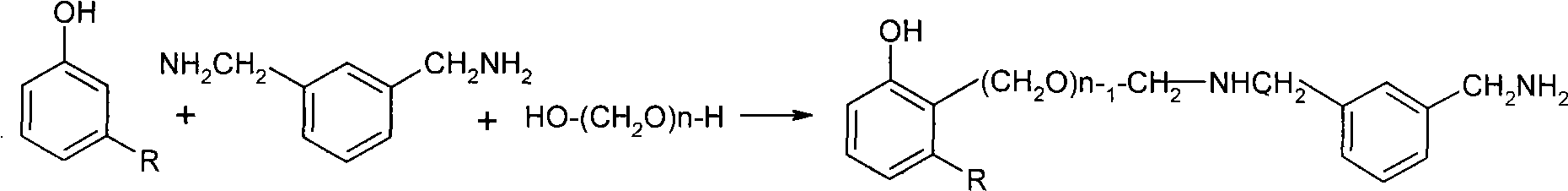

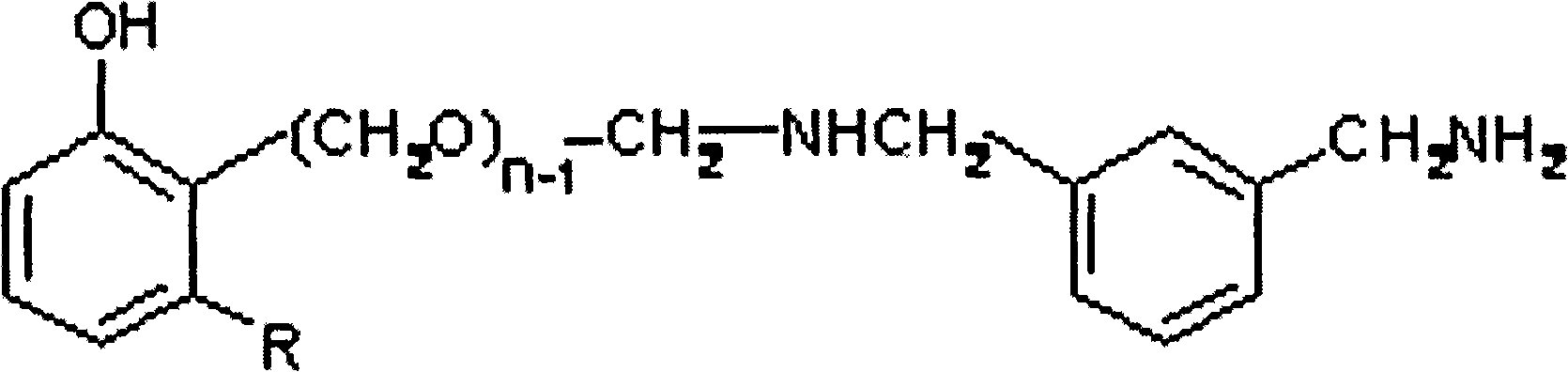

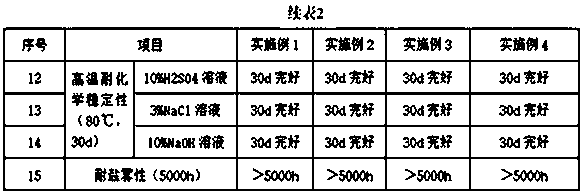

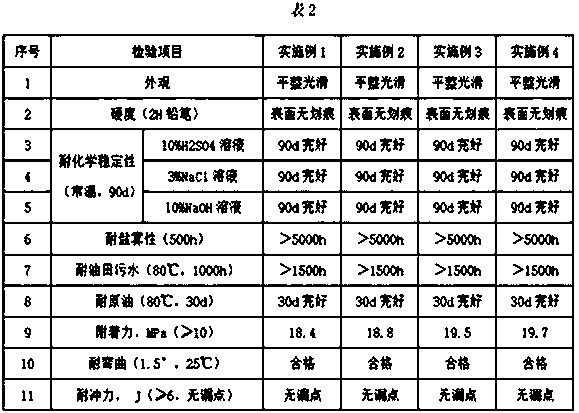

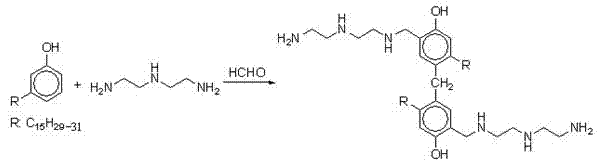

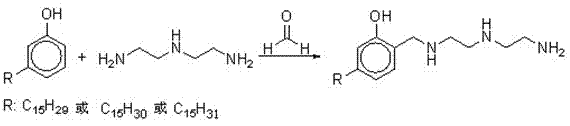

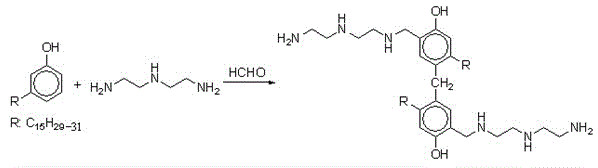

Low-viscosity cardanol solidifying agent of epoxy resin and preparation method thereof

The invention relates to a low-viscosity cardanol epoxy resin curing agent which has a structural formula shown on the right. The method for preparing the low-viscosity cardanol epoxy resin curing agent utilizes reaction of cardanol, p / m-benzene dimethylamine and paraformaldehyde to prepare the low-viscosity cardanol epoxy resin curing agent. The low-viscosity cardanol epoxy resin curing agent has no solvent, has no irritation, is nontoxic and environment-friendly, is mild in heat release, low in color, low in viscosity, and moderate in curing speed, can be cured at a low temperature, and simultaneously has superior anti-corrosive and protective properties; and cured products have superior toughness, good strength, superior adhesion and invasive ability on substrates, and superior low surface construction performance, and are normally used on wet and rusty surfaces.

Owner:上海美东生物材料股份有限公司

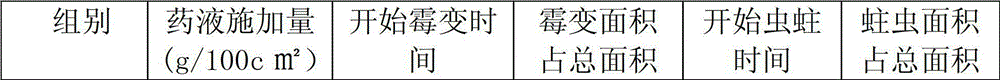

Wood preservative

InactiveCN102941606AImprove bindingGood insect repellentWood impregnation detailsPreservativePolyethylene glycol

The invention discloses a wood preservative. The preservative comprises the following components, by weight, borate 15-45%, quaternary ammonium salt 6-15%, chlorothalonil 5-10%, cosolvent 4-10% and the balance solvent, wherein the solvent is one or a plurality of dimethylbenzene, glycerol and water, and the cosolvent is polyethylene glycol, urea formaldehyde preshrinking liquid or ethylene. The wood preservative is colorless, odorless, safe and environment-protection, simultaneously has the functions of corrosion prevention, mold prevention, insect prevention and antitarnish, and can rest assured use indoor and outdoor.

Owner:东兴市观福古典红木家具有限公司

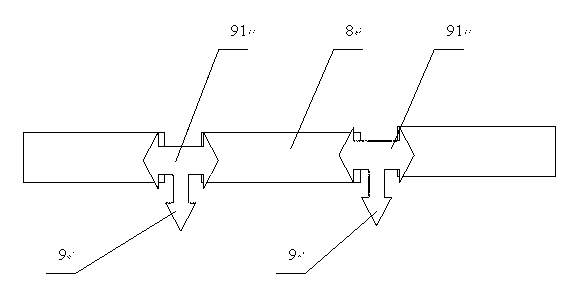

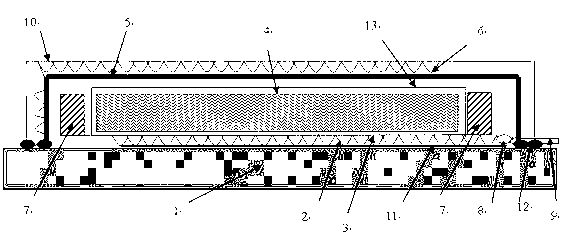

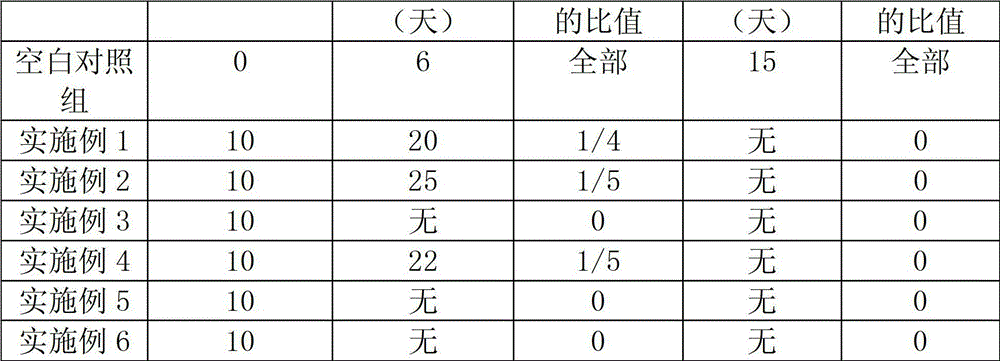

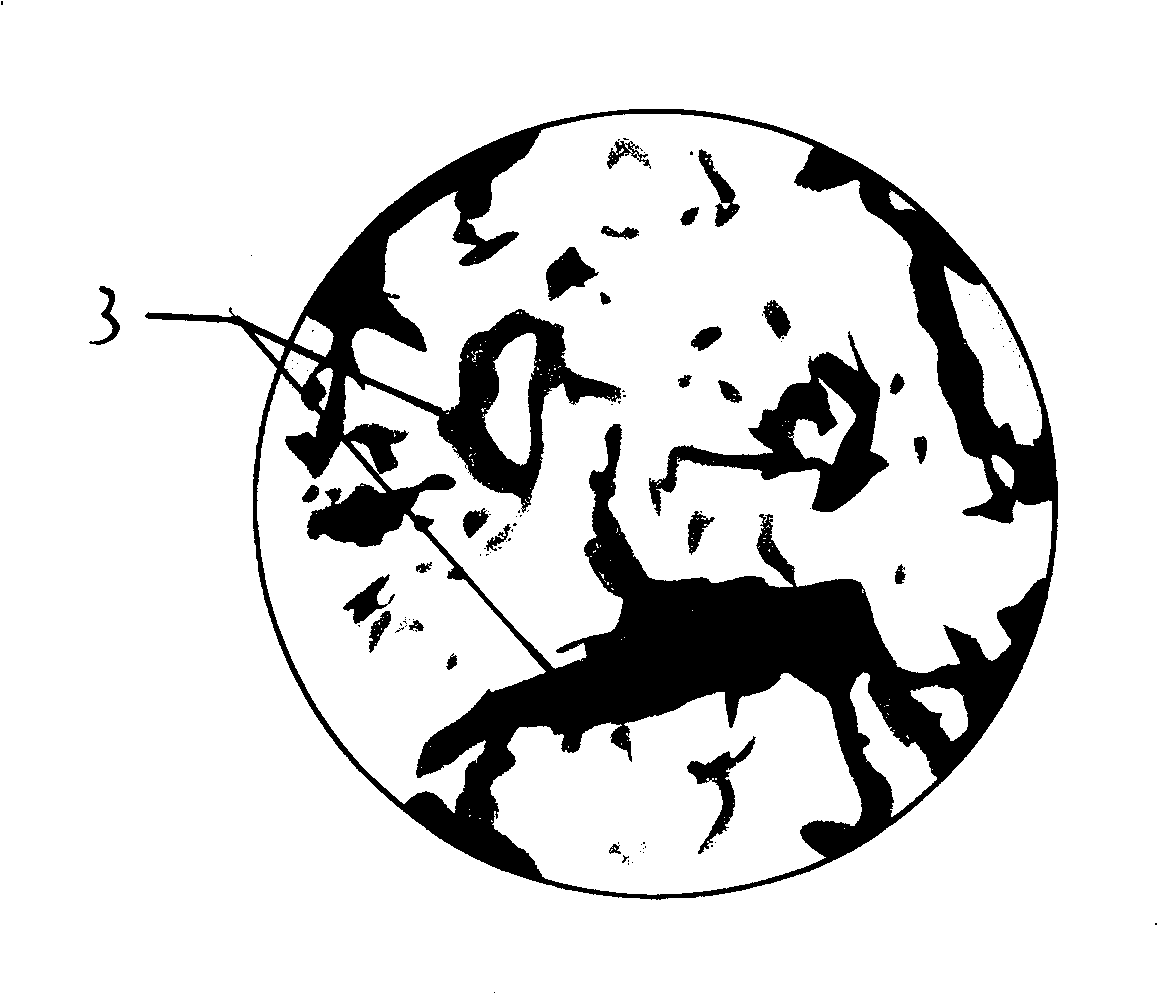

Self-adhesive and preparation method thereof and anti-pollution self-adhesive asphalt waterproofing membrane

ActiveCN108003833AGood adhesionStrong infiltrationSynthetic resin layered productsBituminous material adhesivesPolymer modifiedBituminous waterproofing

The invention discloses a self-adhesive and a preparation method of the self-adhesive and an anti-pollution self-adhesive asphalt waterproofing membrane. The self-adhesive comprises the following components: petroleum asphalt, aromatic oil, naphthenic oil, synthetic wax, styrene-isoprene-styrene, styrene-butadiene-styrene, a tackifier, a stabilizer, a coupling agent and an inorganic filler. The anti-pollution self-adhesive asphalt waterproofing membrane comprises three layers which are a reinforced layer, a self-adhesive layer and an isolation layer successively; or five layers which are an isolation layer, a self-adhesive layer, a reinforced layer, a self-adhesive layer, and an isolation layer successively. According to the anti-pollution self-adhesive asphalt waterproofing membrane prepared by the invention, physical properties can meet product standard requirements in GB 23441-2009 Self-adhesive Polymer Modified Asphalt Waterproofing Membrane, and the peel strength of the membrane and an aluminum plate reaches 2.8 N / mm, and is higher than the standard by 1.5 N / mm.

Owner:YUEYANG ORIENTAL YUHONG WATERPROOF TECH

Thermoset plastics infiltration strengthened powdery plant fiber material and preparation method thereof

The invention relates to a powdery plant fiber material soaked and intensified by thermosetting plastic, and a preparation method thereof. The powdery plant fiber material is the raw material of a wood and plastic composite material. The plant fiber material disclosed by the invention comprises powdery plant fiber with more than 100 meshes in an amount of 100 parts, the thermosetting plastic in an amount of 2 to 30 parts, a curing agent adapted to the thermosetting plastic in an amount of 0.02 to 0.3 parts, a dispersant in an amount of 0.2 to 2 parts, and a lubricant in an amount of 0.2 to 2 parts. After the broken fiber surface and the interior of the powdery material of the powdery plant fiber are soaked with the thermosetting plastic, the prepared wood and plastic product not only has a high affinity for PVC, but also has better mechanical property compared with the prior wood and plastic product under the condition of equal loading. In addition, the prepared wood and plastic product has excellent anticorrosion property, humidity resistance, and high and low temperature resistance. The production of the powder is easy, convenient, and environment-friendly with low cost, thereby being easy to popularize and apply.

Owner:张国栋

Plaster using paper as carrier for treating beriberi

InactiveCN1383879AHeal fastStrong infiltrationAntimycoticsUnknown materialsLiquid layerTissue protein

The paper-based plaster for treating beriberi is produced through the process of making Chinese medicine liquid with 24 kinds of Chinese medicinal materials including flavescent sophora root, gallnut, alum, cnidium fruit, sessile stemona root, etc.; producing paper carrier with husk, wheat b bran and Chinese medicine residue and through conventional papermaking process; painting thiamine and the medicine liquid to the paper carrier and stoving; and covering the medicine liquid layer with water absorbing paper layer. It has the functions of killing bacteria, stopping itch, eliminating wetness,promoting blood circulation, healing tissue protein, killing free dmould spores and replenishing vitamin B1.

Owner:邵建国 +2

Solvent-free oil pipeline anti-corrosion and anti-drag special coating and preparation method thereof

ActiveCN111205746AImprove thixotropyEvenly dispersedAnti-corrosive paintsEpoxy resin coatingsFatty amineSolvent free

The invention discloses a solvent-free oil pipeline anti-corrosion and anti-drag special coating and a preparation method thereof, belongs to the field of anti-corrosion coatings, and solves the problems that an existing solvent-free anti-corrosion coating is high in construction difficulty, a coating is prone to scale formation and the like. The coating is prepared from two components, wherein the component I is prepared from bisphenol A epoxy resin, polyethersulfone modified epoxy resin, aromatic hydrocarbon resin, glass fiber powder, polytetrafluoroethylene wax powder, potassium hexatitanate whiskers, silica powder, a dispersing agent, a leveling agent, an epoxy active diluent, polyethylene wax powder, talcum powder, phthalocyanine blue, lemon yellow and an antifoaming agent, and the component II consists of a cashew nut shell oil modified phenolic aldehyde amine curing agent and a resin type modified fatty amine curing agent. The preparation method comprises the following steps: mixing the component I and the component II according to a mass ratio of (4-12): 1, and uniformly stirring. The coating has the advantages of favorable long-acting property, favorable flexibility, favorable temperature resistance, favorable chemical resistance, favorable drag reduction effect, environment friendliness and easiness in construction. The preparation method is simple, and the productionefficiency can be obviously improved.

Owner:西北永新涂料有限公司

Cashew amine epoxy curing agent for marine heavy anti-corrosion coating and preparation method for curing agent

ActiveCN102898623AThe composition ratio is scientific and reasonableHigh viscosityAnti-corrosive paintsEpoxy resin coatingsSolubilityAlcohol

The invention discloses a cashew amine epoxy curing agent for a marine heavy anti-corrosion coating. The curing agent is sequentially prepared from the following raw materials in parts by weight: 20 to 23 parts of cardanol, 1 to 1.2 parts of diethylenetriamine, 12 to 15 parts of 37 percent formaldehyde aqueous solution, 9 to 10 parts of diethylenetriamine, and 7 to 8 parts of 37 percent formaldehyde aqueous solution. According to the cashew amine epoxy curing agent for the marine heavy anti-corrosion coating, the raw material composition and the optimal proportion and the adding sequence of the raw materials are selected through a large quantity of experiments, and the proportion of each component is scientific and reasonable; acetal is catalyzed by adopting diethylenetriamine to control the viscosity parameter, and then Mannich addition is carried out on the periphery of molecules to improve the alcohol solubility; and the cashew amine curing agent prepared by the method is high in activity, viscosity and solid content and good in compatibility, does not release oil, and can overcome many defects of the cashew amine epoxy curing agent prepared by the method in the prior art.

Owner:JIANGSU SANMU GROUP CORPORATION

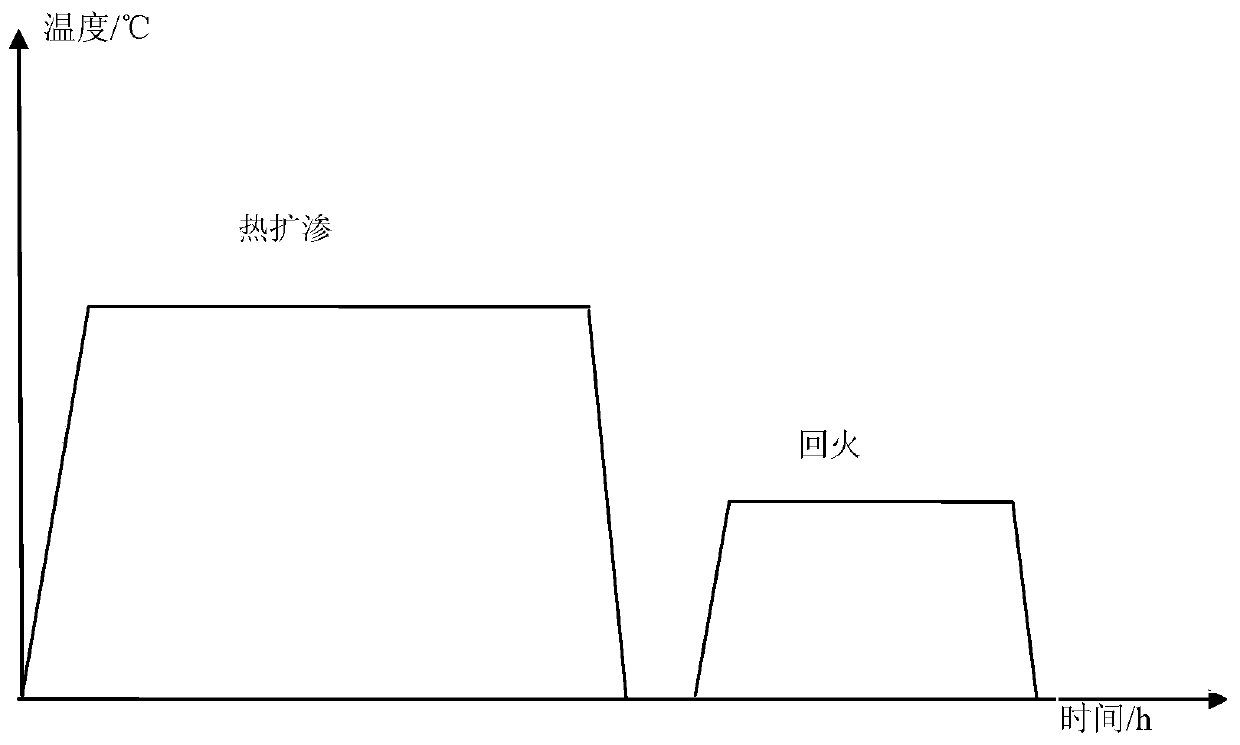

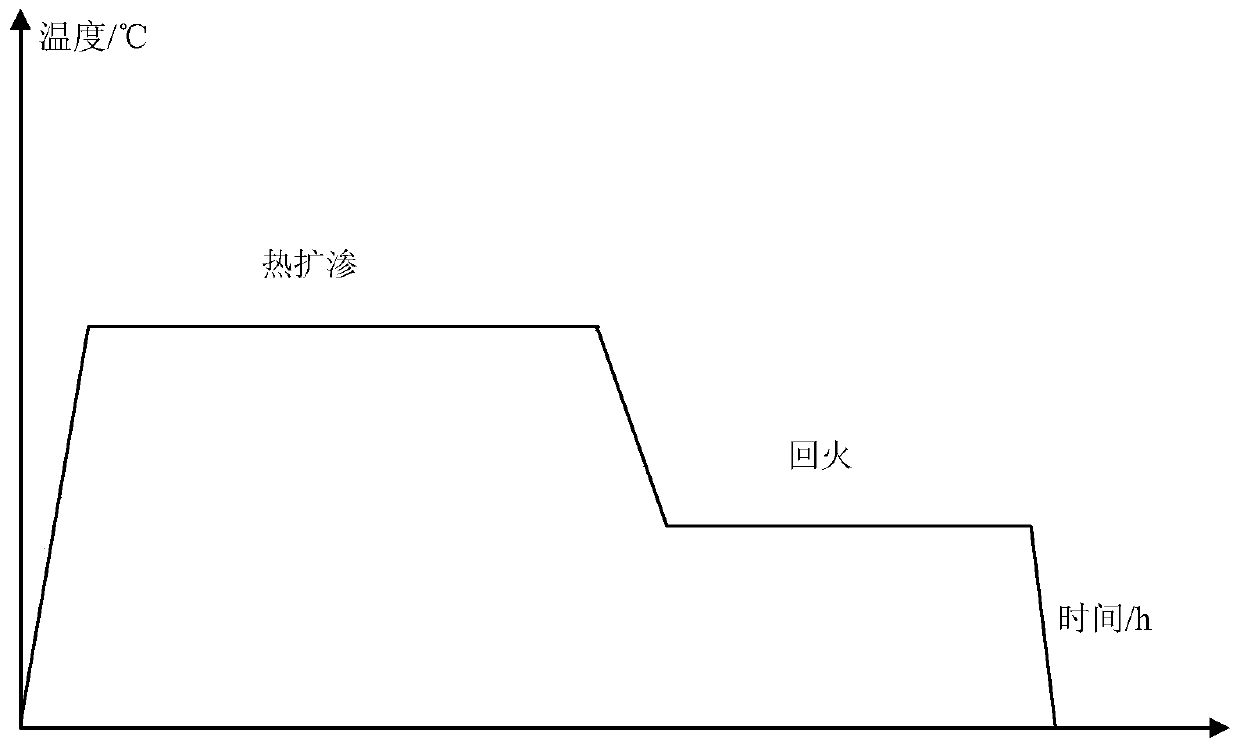

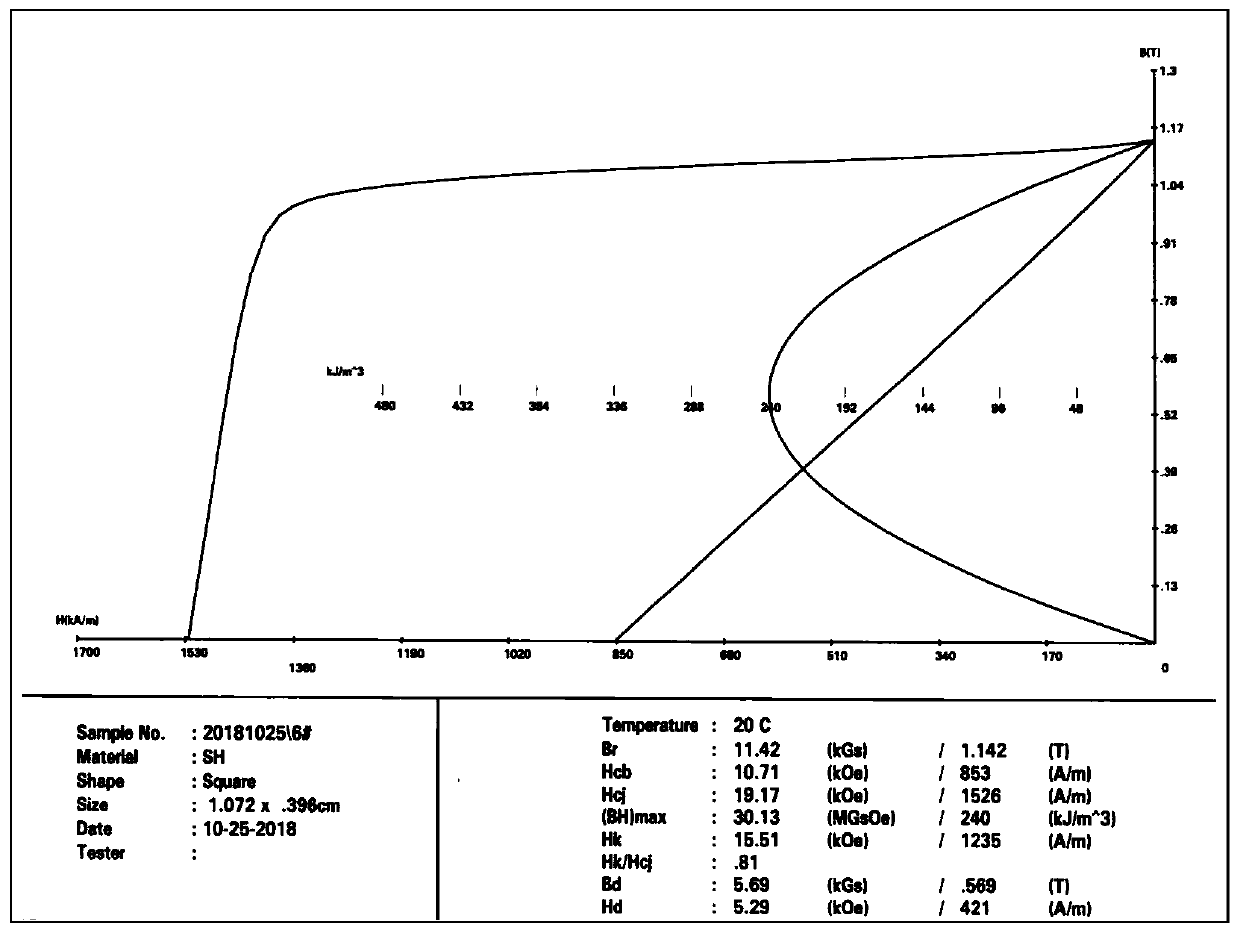

Neodymium iron boron rare-earth permanent magnet heavy rare-earth thermal diffusion coating liquid and preparation method and application thereof

InactiveCN109695015AStickyAdjustable thicknessTransportation and packagingMetal-working apparatusSurface cleaningRare earth

The invention relates to neodymium iron boron rare-earth permanent magnet heavy rare-earth thermal diffusion coating liquid and a preparation method and application thereof, and belongs to the technical field of rare-earth permanent magnet surface treatment. The neodymium iron boron rare-earth permanent magnet heavy rare-earth thermal diffusion coating liquid is prepared from the components: 25-50% of heavy rare-earth powder, 0-5% of a penetration-promoting agent, 2-15% of a binder, 1-3% of a surfactant, 1-3% of a dispersing agent and the balance of a diluent. The preparation method comprisesthe steps of mixing the heavy rare-earth powder, the penetration-prompting agent and the diluent, and adding residual raw materials. The method is applied to a neodymium iron boron rare-earth permanent magnet heavy rare-earth thermal diffusion process, and the process comprises the specific steps that surface cleaning treatment is carried out on the neodymium iron boron rare-earth permanent magnet, surface coating treatment is carried out by centrifugal immersion or spraying, and then thermal expansion is carried out. According to the neodymium iron boron rare-earth permanent magnet heavy rare-earth thermal diffusion coating liquid, the coercive force can be greatly improved after the thermal diffusion, meanwhile, the coating efficiency is improved, the waste of the heavy rare-earth powderis reduced, and a bottleneck of the prior coating art is broken.

Owner:NORTHEASTERN UNIV

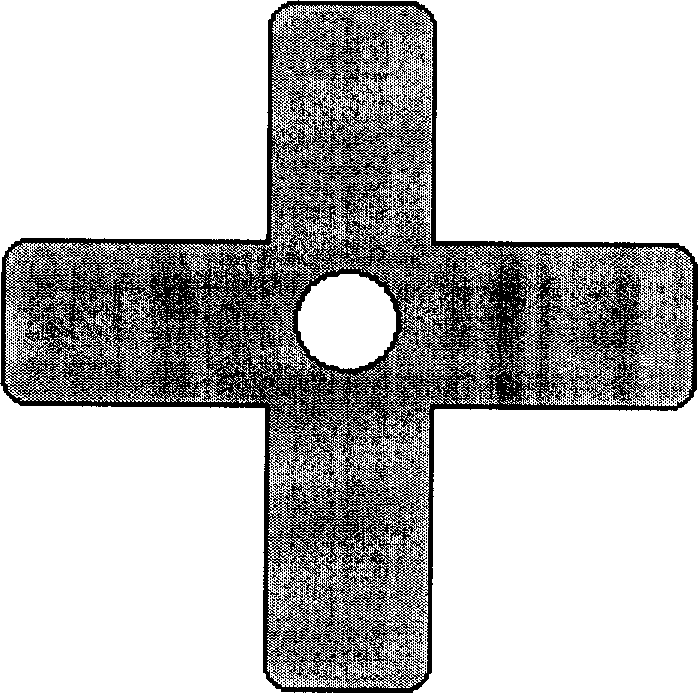

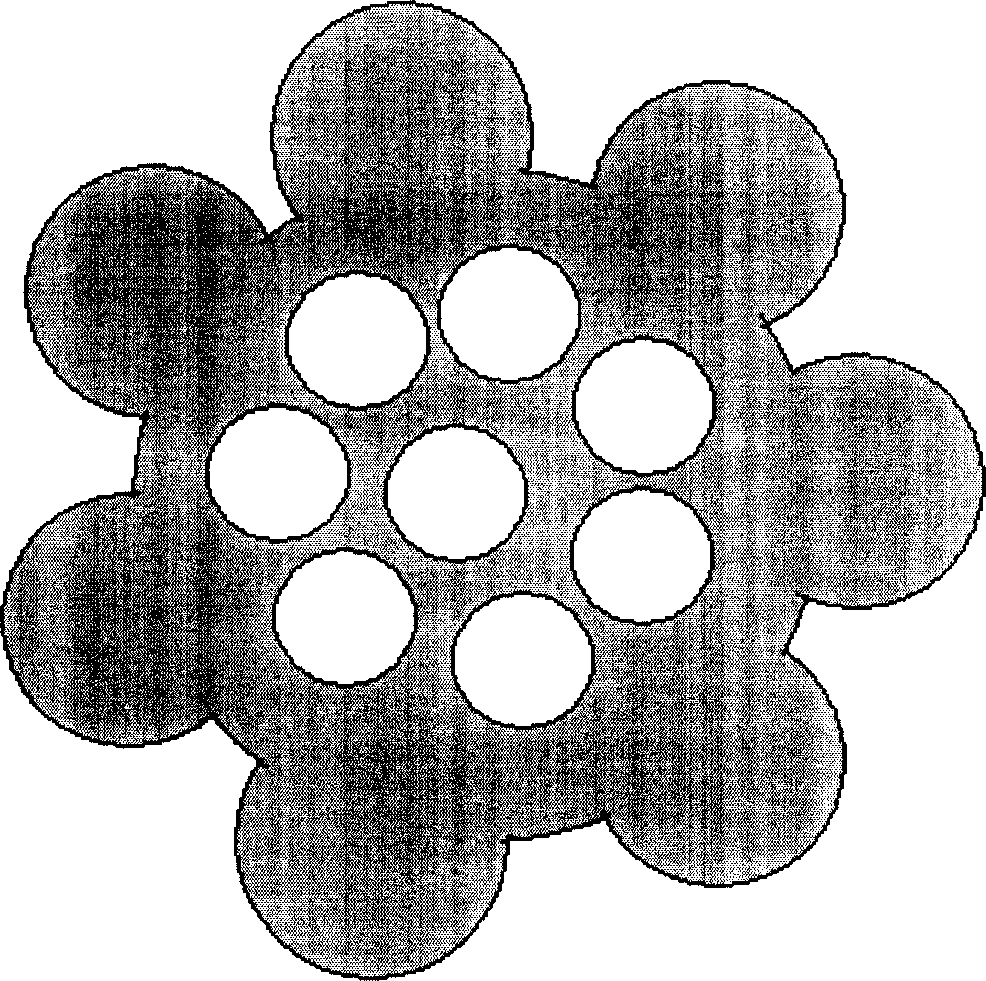

Asphalt mixture modfied with polyester and polyamide fiber possessing irregular cross section and its prepn

InactiveCN1526767AImprove lipophilicityImprove high temperature resistanceIn situ pavingsBuilding insulationsHollow fibrePetroleum

The asphalt mixture modified with polyester and polyamide fiber possessing irregular cross section consists of conventional SMA and hollow polyester and polyamide fiber possessing irregular cross section consists, with the fiber content being 0.01-15 wt%. The present invention is superior in that the hollow polyester and polyamide fiber possesses good lipophilicity to infiltrate and adsorb asphalt, so as to prevent separation of asphalt in the mixture, raise the mechanical performance of the mixture, lower the brittle point, raise the anticracking performance of the mixture and toughen. The present invention is simple and practical and the asphalt mixture may be prepared in available asphalt mixing apparatus.

Owner:DONGHUA UNIV

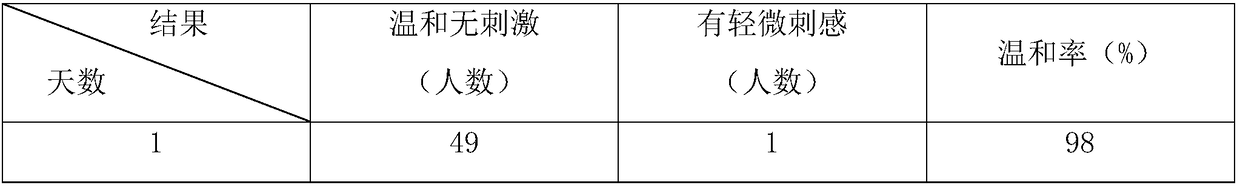

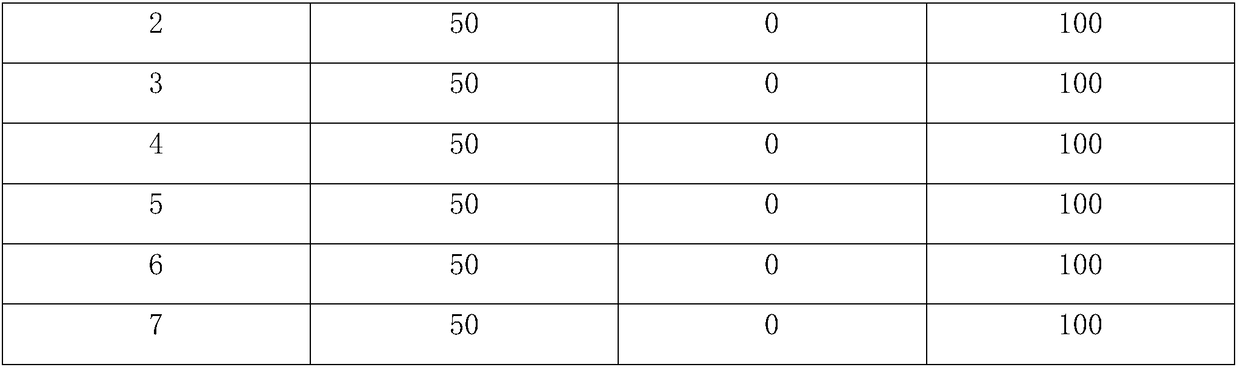

Makeup removing lotion and preparation method thereof

InactiveCN108969402AStrong infiltrationStrong makeup removerCosmetic preparationsMake-upIrritationOil phase

The invention discloses a makeup removing lotion and a preparation method thereof. The makeup removing lotion comprises an oil phase component and a water phase component; on the basis of total weightof the makeup removing lotion, the oil phase component contains 15 to 25% of grease, and 20 to 25% of an oil phase emulsifier; the water phase component comprises 15 to 25% of a polyol moisturizer, 10 to 15% of a water phase emulsifier, and 10 to 50% of water. By adopting the type, the makeup removing lotion has the advantages that the appearance is fully transparent, the makeup removing abilityis strong, and the excellent makeup removing effect is realized for the heavy makeup; the makeup removing lotion is mild, free from irritation, cool and not greasy, and the skin feel is good; the anti-corrosive ability is strong, and the quality warranty period is long.

Owner:SHENZHEN LANTERN SCI

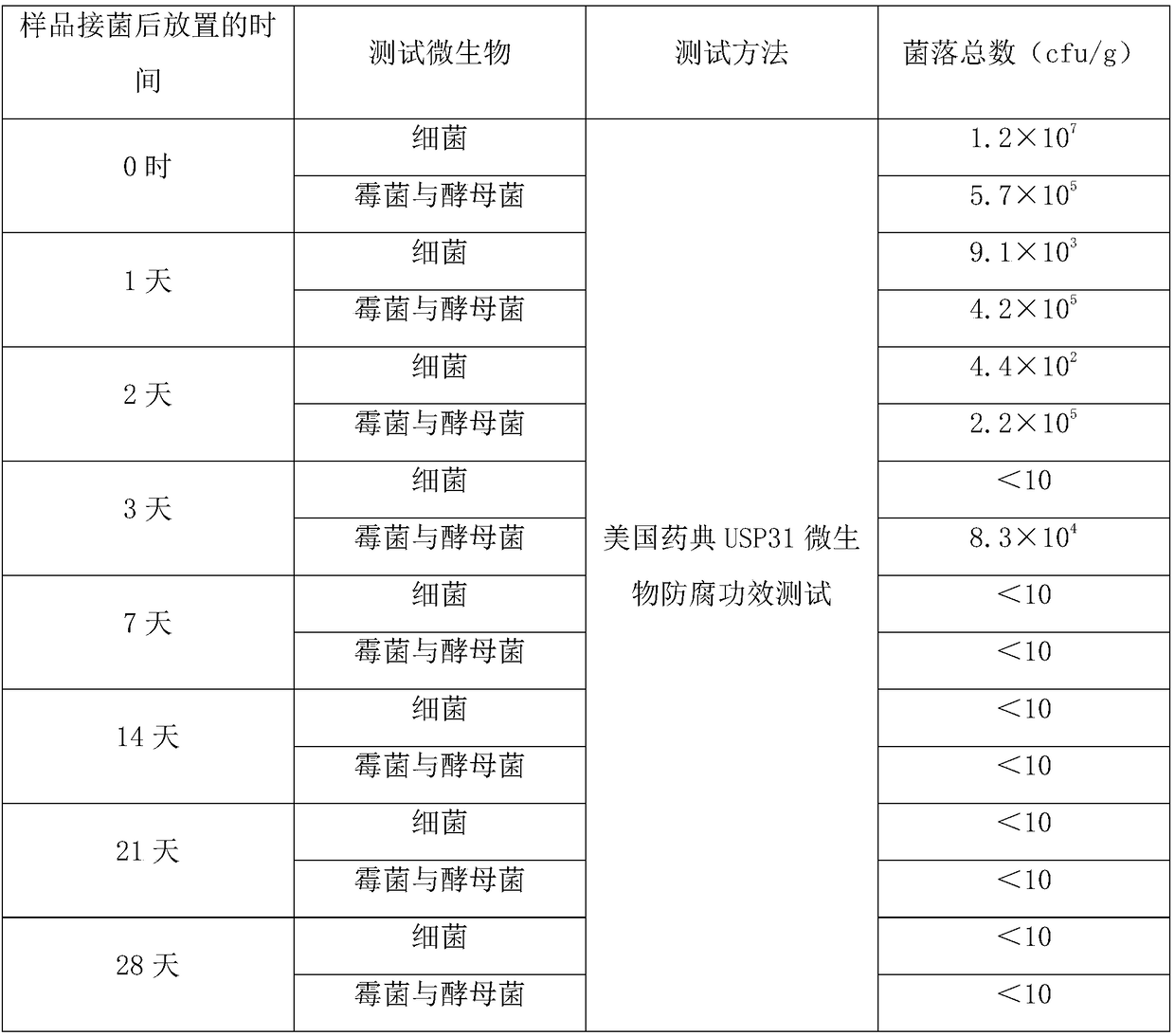

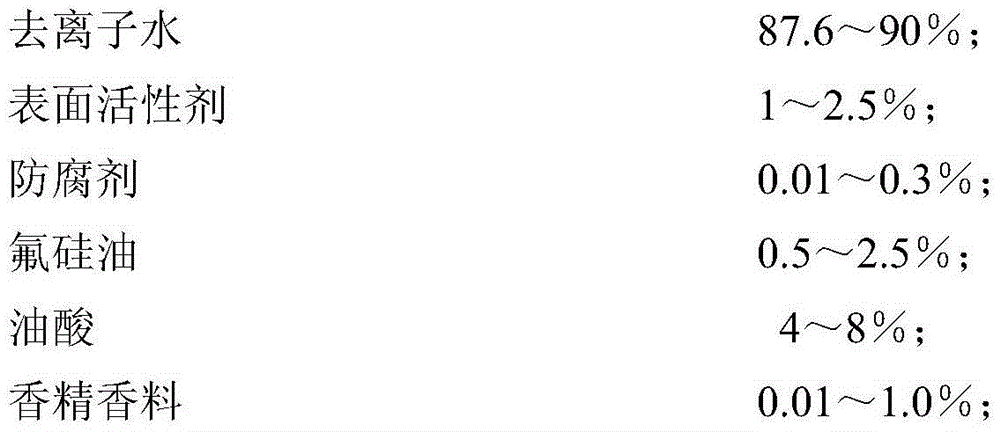

Glass plating film cleaning liquid and preparation method thereof

InactiveCN104928063AStrong infiltrationEasy to cleanInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSolventCleansing Agents

A glass plating film cleaning liquid is characterized by comprising the components by the weight percentage: 80-90% of deionized water, 0.5-5% of a surfactant, 0-1.0% of a preservative, 0.5-5% of fluorosilicone oil, 1-10% of oleic acid, and 0-1.0% of an essence and spice. A preparation method comprises the steps: during preparation, adding deionized water into a reaction vessel, stirring and heating up to 45-80 DEG C, and stirring for 30-120 minutes; adding the surfactant; and adding the preservative, the essence and spice, the fluorine silicone oil and oleic acid, with the stirring time of 30-240 minutes, stirring evenly and cooling to 20-50 DEG C, discharging, and detecting. With use of water as a solvent to replace alcohol, the cleaning liquid is environmentally friendly and has no pollution; in addition, the cleaning agent is adjusted in view of the surfactant wettability, has good infiltration capacity on all kinds of plastics and metal parts, is good in cleaning effect and low in cost, and has three efficacies of cleaning, hydrophobility, and film formation and acid rain prevention combined; the product is neutral, transparent, uniform and stable, and cannot damage the surface of washed materials; and the cleaning liquid is antistatic and can prevent dust retention.

Owner:NINGBO PASCO UNITED IND

Refining agent for aluminum and aluminum alloy

ActiveCN101967565BAffect the service lifeWill not corrodeProcess efficiency improvementSlagPotassium

The invention relates to a refining agent for aluminum and aluminum alloy. The refining agent is characterized by mainly comprising the following components in percentage by mass: 30 to 85 percent of NaCl, 5 to 40 percent of Na2SiF6, 5 to 40 percent of Na2SO4, 2 to 20 percent of CaF2 and 0.5 to 5 percent of C6C16; and the refining agent also can comprise one or more of CaMg(CO3)2, Na3AlF6, Na2S2O3 and NaF. The potassium-free refining agent provided by the invention has good slag forming performance, strong gas and impurity removing capability and low cost; and the aluminum ash produced by refining the aluminum and the aluminum alloy through the refining agent can realize recycle.

Owner:江西广恒铝业有限公司

Environment-friendly cashew amine epoxy curing agent for low volatile organic compound (VOC) anticorrosive coating and preparation method for curing agent

ActiveCN102898884ALow viscosityHigh activityOrganic compound preparationAnti-corrosive paintsSolvent freeAqueous solution

The invention discloses an environment-friendly cashew amine epoxy curing agent for a low volatile organic compound (VOC) anticorrosive coating and a preparation method for the curing agent. The curing agent is prepared from the following raw materials in parts by weight: 1.5 to 2.5 parts of cardanol, 1 to 1.5 parts of diethylenetriamine, and 1.5 to 2 parts of 37 percent formaldehyde aqueous solution. The raw material composition and the optimal proportion of the raw materials are selected through a large quantity of experiments, so that the proportion of each component is scientific and reasonable. The curing agent synthesized by adopting excessive amine and a low-temperature reaction method is high in activity, low in viscosity, good in mixing property, light in color, oil-free, convenient in construction, environment-friendly and solvent-free, can meet various requirements of low VOC anticorrosion, and can overcome many defects of the cashew amine epoxy curing agent prepared by the method in the prior art.

Owner:JIANGSU SANMU GROUP CORPORATION

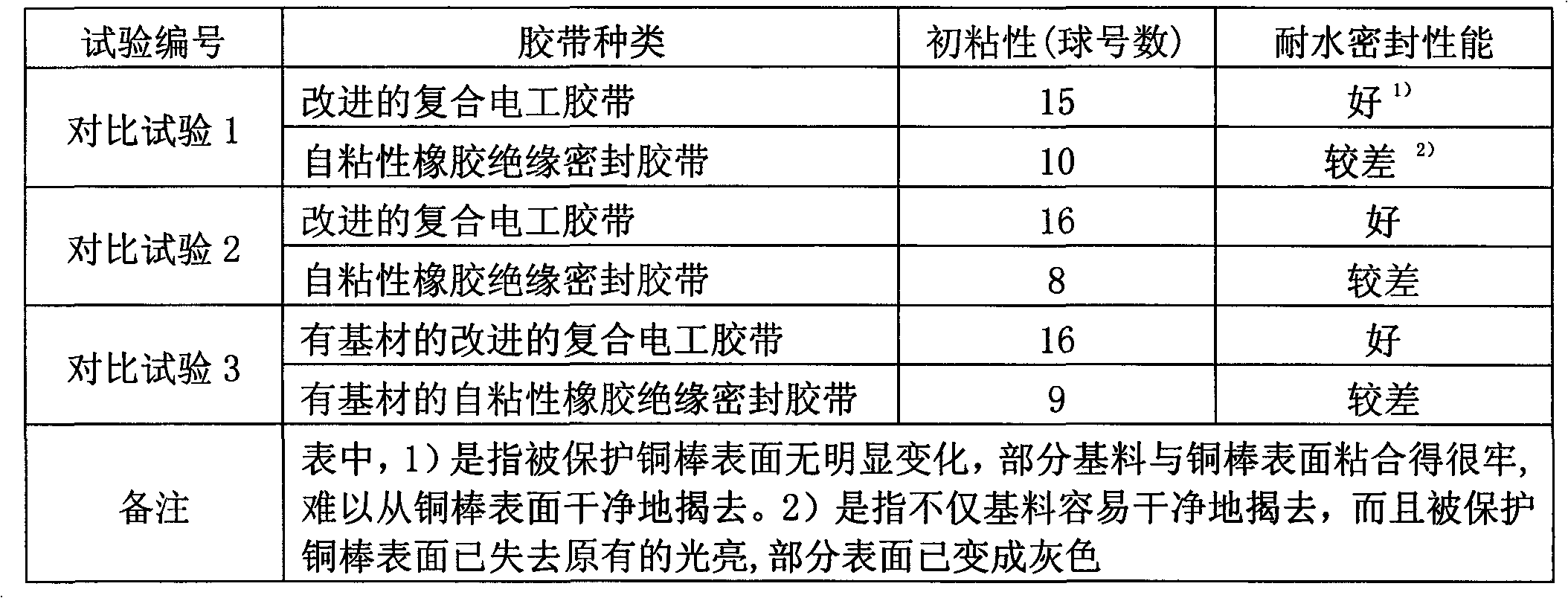

Improved composite electrical adhesive tape and processing method thereof

ActiveCN101602920AStrong infiltrationImprove wettabilityFilm/foil adhesivesEster polymer adhesivesHigh pressureViscosity

The invention discloses improved composite electrical adhesive tape, which comprises a base material formed by calendaring rubber gelatine. A key improvement is to coat the surface of the base material with a layer of pressure-sensitive adhesive having diffusion-fusion performances. A processing method for the improved composite electrical adhesive tape is direct blade coating or transfer coating. As the initial viscosity and water resistance of the adhesive tape are remarkably improved by adopting the processing method, the problem that the prior self-adhesive insulating sealing tape which is wet or soaked in water is easy to lose effectiveness is solved so as to provide a strong guarantee for the insulation seal protection of high-voltage wires and cables.

Owner:HEBEI YONGLE TAPE CO LTD

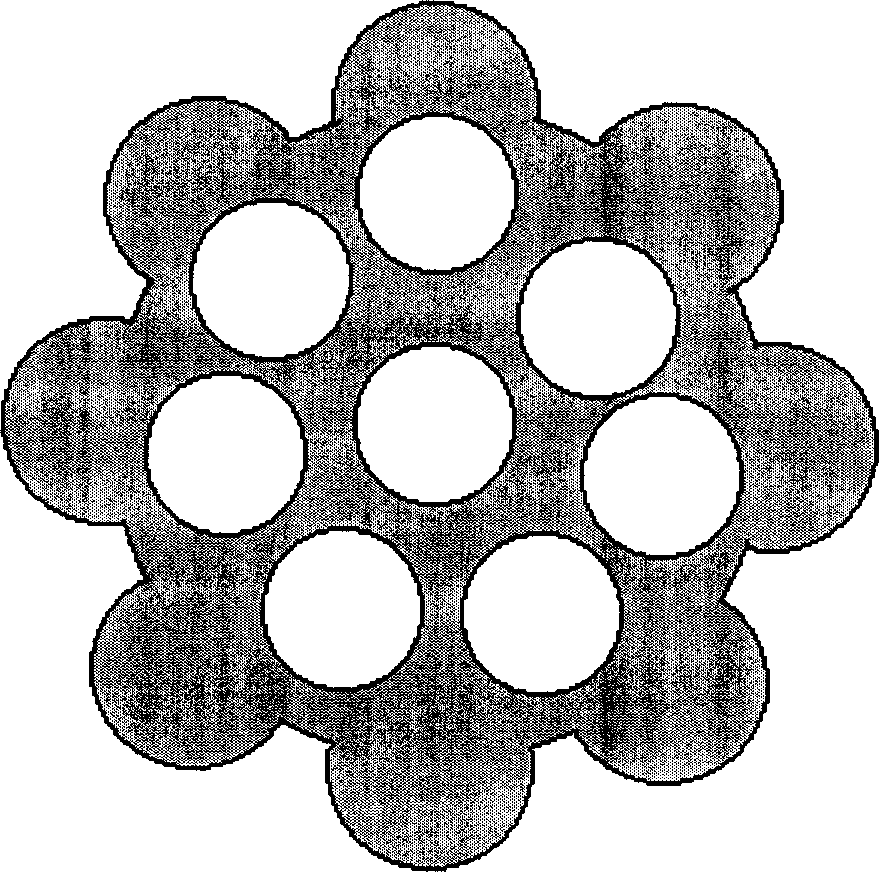

Profiled-cross-section hollow polyfiber reinforced emulsified asphalt slurry seal

InactiveCN1963023AImprove lipophilicityImprove high temperature resistanceIn situ pavingsPolymer scienceSlurry

The invention discloses a sealer which prepared by special-shaped section hollow polymer fiber reinforced emulsified asphalt slurry and it comprises of regular emulsified asphalt slurry sealer and special-shaped section single hole or porous polymer. Among them, the content of special-shaped section single whole or porous polymer is 0.1-0.3% of the total weight of bitumen slurries mixture. The polymer fibers are polyester fibers, polyacrylic fiber or polyamide fiber, or mixed fiber comprised of said fibers in causal proportion. The 'special-shaped section' of polymer fibers is the lateral section of fibers which could be regular or irregular geometric shapes, for example, cross-shaped, trilobular, well-shaped, star-shaped, quincunx etc. The 'hollow'' means the fiber is not solid, but with one or more holes structure along the axis. The special-shaped section hollow polymer fiber reinforced emulsified asphalt slurry sealer has many advantages, such as fine toughness, and it does not occur cracks, local decortication and breakage easily. It can be applied to maintenance and conservation of various levels of road widely, especially the high-grade highways, ordinary roads which asphalt pavement is in larger deformation, large communications, heavy communications and other engineering areas.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD

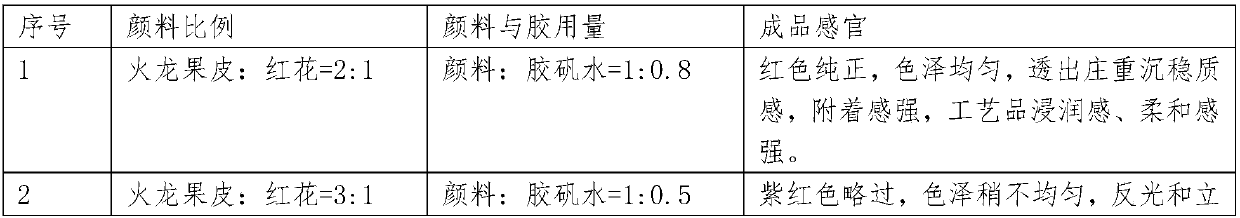

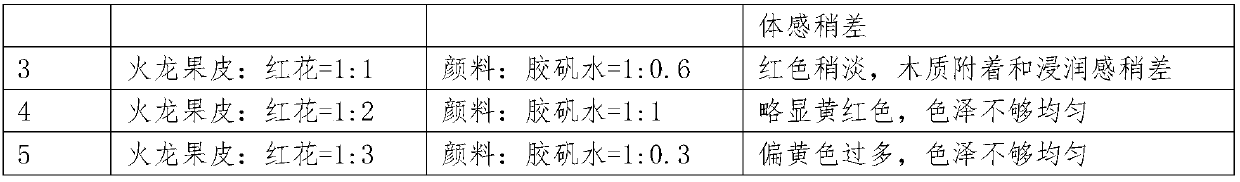

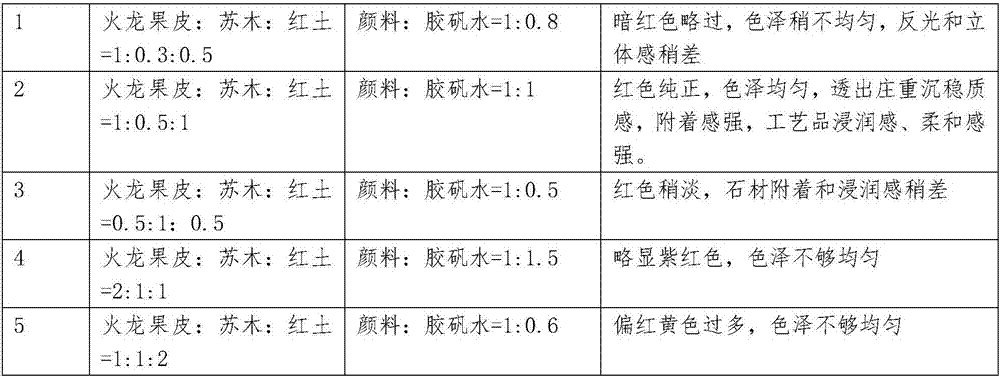

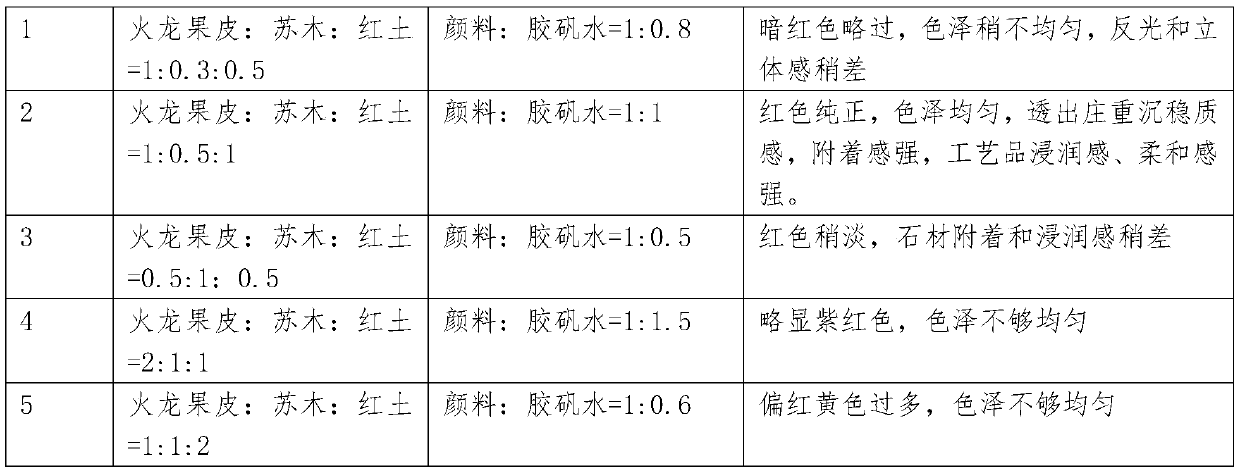

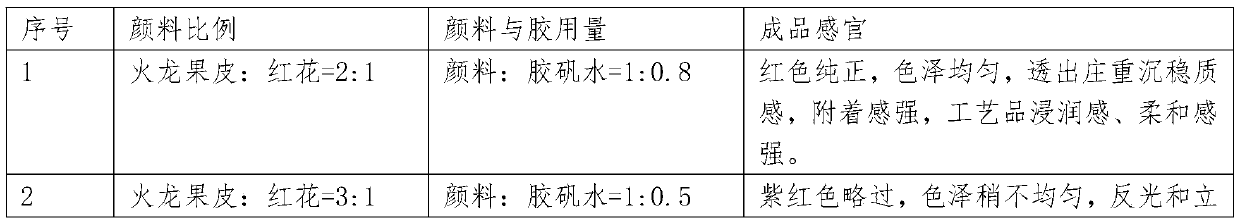

Processing and making method of cinnabar relief painting

ActiveCN107672376AStrong three-dimensional senseReduce usageOrnamental structuresSpecial artistic techniquesResource protectionCinnabar

The invention discloses a processing and making method of a cinnabar relief painting. Basic pigment bottoming and cinnabar contouring are combined and performed on a relief painting blank to form thecinnabar relief painting. The blank is colored through plant color mucilage, pigments are fully permeated into the blank and well attached to the surface of the blank, and then the blank line segmentsand outstanding positions are drawn through cinnabar pigments. The cinnabar relieve painting obtained through the method is uniform in color and luster, styled with layers and capable of vividly, lively and three-dimensionally showing the veins and other delicate details in the relief painting. Through reasonable combination of cinnabar powder, natural dyestuff and the like, the using amount of cinnabar is reduced, the reasonable resource protection and utilization are performed, the effect that the relief painting is not discolored and faded for a long time can be maintained, and then the cinnabar relief painting has color, luster, three-dimensional style and attractiveness.

Owner:铜仁市万山区天下红朱砂工艺有限责任公司

Preparation method of novel Chinese herbal medicine pyroligneous liquor-containing anticancer drug

InactiveCN104083470AInhibition of Survival DiffusionEfficient killingAntineoplastic agentsPlant ingredientsSide effectCurative effect

The invention discloses a preparation method of a novel Chinese herbal medicine pyroligneous liquor-containing anticancer drug. The preparation method comprises the following steps of 1, extracting pyroligneous liquor, 2, carrying out aggregation separation, 3, carrying out adsorption separation, 4, carrying out Chinese herbal medicine acidification extraction and 5, filtering a finished product. The novel Chinese herbal medicine pyroligneous liquor anticancer drug is safe and reliable, has no toxic or side effect and definite anticancer effects, can obviously improve symptoms, can gradually recover health and can prolong a life.

Owner:李永君

Processing and manufacturing method for cinnabar stone carving handicraft picture

InactiveCN107571676AStrong three-dimensional senseReduce usageDecorative surface effectsSpecial ornamental structuresCinnabarResource protection

The invention discloses a processing and manufacturing method for a cinnabar stone carving handicraft picture. The cinnabar stone carving handicraft picture is formed through the mode that basic pigment underpainting and cinnabar outlining are combined and conducted on an embossment blank; firstly coloring is conducted on the blank through mixed color paste of plants and soil, so that pigment sufficiently permeates into the blank and is well adhered to the surface of the blank; and then blank line segments and emphases are outlined through the cinnabar pigment. According to the cinnabar stonecarving handicraft picture obtained through the method, the color is uniform and layered, and textures and other subtle details in the embossment picture can be displayed in lifelike, vivid and three-dimensional modes; and through reasonable matching of cinnabar powder, natural dyestuffs, base materials and the like, the use amount of cinnabar is reduced, reasonable resource protection and utilization are conducted, and the embossment picture can keep nondiscoloring and fadeless for a long time, so that the cinnabar stone carving handicraft picture has the colors, three-dimensional feeling andaesthetic feeling.

Owner:贵州筑信达创科技有限公司

Excernally applied plaster using paper as paper as carrier for treating beriberi

InactiveCN1193780CStrong infiltrationAntipruriticAntimycoticsUnknown materialsLiquid layerTissue protein

The paper-based plaster for treating beriberi is produced through the process of making Chinese medicine liquid with 24 kinds of Chinese medicinal materials including flavescent sophora root, gallnut, alum, cnidium fruit, sessile stemona root, etc.; producing paper carrier with husk, wheat b bran and Chinese medicine residue and through conventional papermaking process; painting thiamine and the medicine liquid to the paper carrier and stoving; and covering the medicine liquid layer with water absorbing paper layer. It has the functions of killing bacteria, stopping itch, eliminating wetness, promoting blood circulation, healing tissue protein, killing free dmould spores and replenishing vitamin B1.

Owner:邵建国 +2

A kind of processing and manufacturing method of cinnabar stone carving craft painting

InactiveCN107571676BStrong three-dimensional senseReduce usageDecorative surface effectsSpecial ornamental structuresCinnabarStone carving

The invention discloses a processing and manufacturing method for a cinnabar stone carving handicraft picture. The cinnabar stone carving handicraft picture is formed through the mode that basic pigment underpainting and cinnabar outlining are combined and conducted on an embossment blank; firstly coloring is conducted on the blank through mixed color paste of plants and soil, so that pigment sufficiently permeates into the blank and is well adhered to the surface of the blank; and then blank line segments and emphases are outlined through the cinnabar pigment. According to the cinnabar stonecarving handicraft picture obtained through the method, the color is uniform and layered, and textures and other subtle details in the embossment picture can be displayed in lifelike, vivid and three-dimensional modes; and through reasonable matching of cinnabar powder, natural dyestuffs, base materials and the like, the use amount of cinnabar is reduced, reasonable resource protection and utilization are conducted, and the embossment picture can keep nondiscoloring and fadeless for a long time, so that the cinnabar stone carving handicraft picture has the colors, three-dimensional feeling andaesthetic feeling.

Owner:贵州筑信达创科技有限公司

A kind of processing method of cinnabar relief painting

ActiveCN107672376BStrong three-dimensional senseReduce usageOrnamental structuresSpecial artistic techniquesVeinResource protection

The invention discloses a processing and making method of a cinnabar relief painting. Basic pigment bottoming and cinnabar contouring are combined and performed on a relief painting blank to form thecinnabar relief painting. The blank is colored through plant color mucilage, pigments are fully permeated into the blank and well attached to the surface of the blank, and then the blank line segmentsand outstanding positions are drawn through cinnabar pigments. The cinnabar relieve painting obtained through the method is uniform in color and luster, styled with layers and capable of vividly, lively and three-dimensionally showing the veins and other delicate details in the relief painting. Through reasonable combination of cinnabar powder, natural dyestuff and the like, the using amount of cinnabar is reduced, the reasonable resource protection and utilization are performed, the effect that the relief painting is not discolored and faded for a long time can be maintained, and then the cinnabar relief painting has color, luster, three-dimensional style and attractiveness.

Owner:铜仁市万山区天下红朱砂工艺有限责任公司

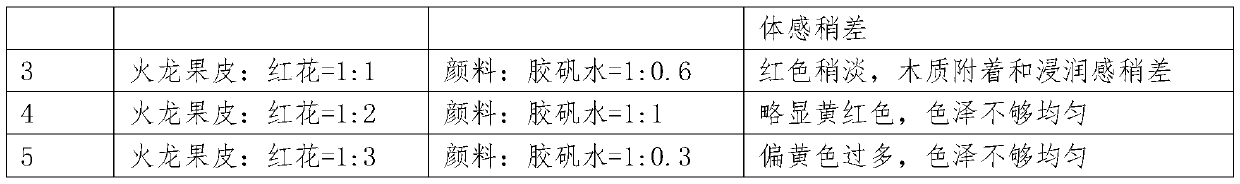

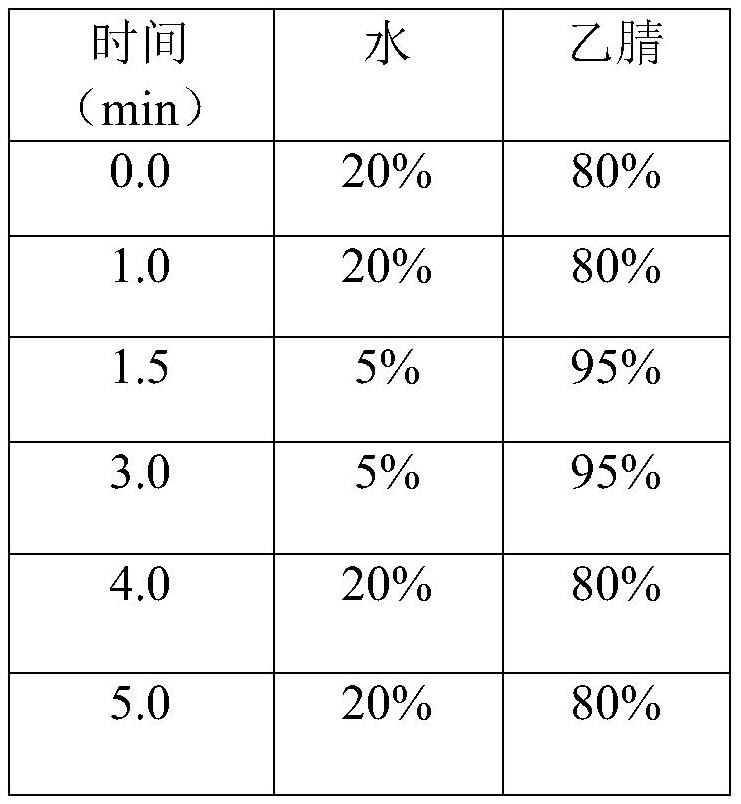

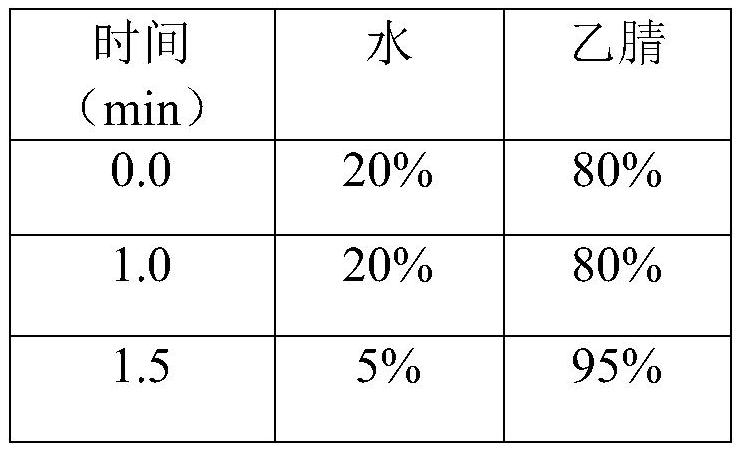

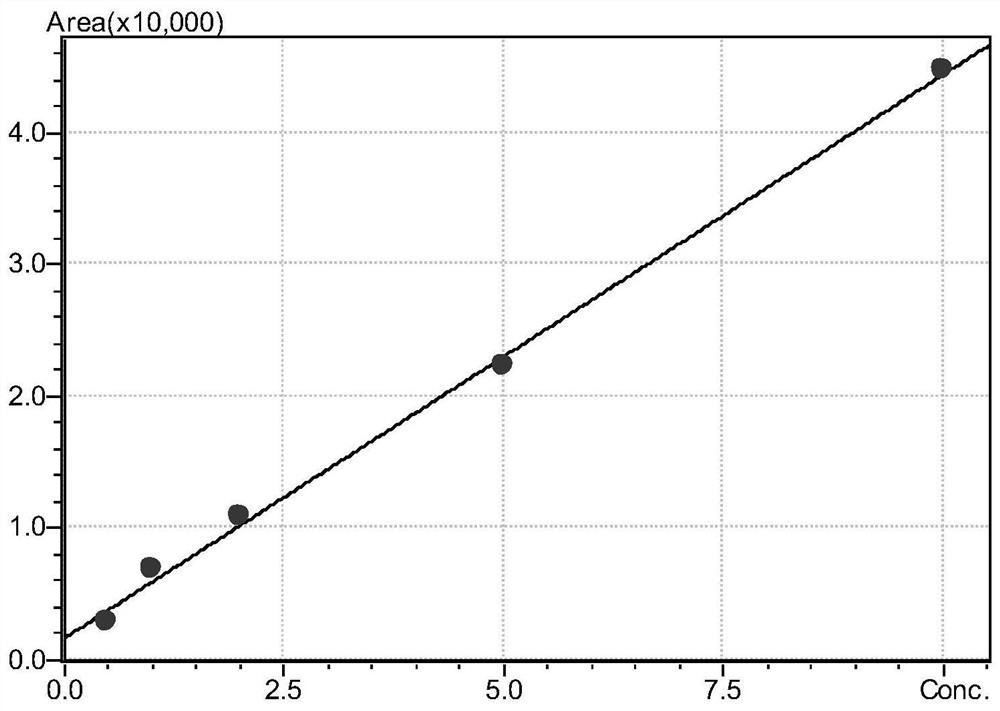

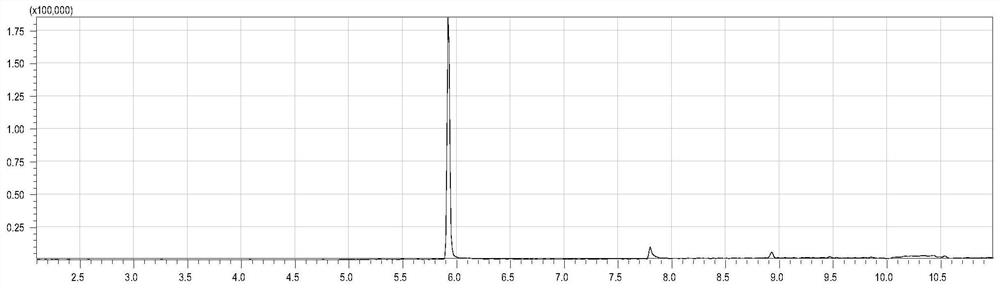

A kind of detection method of octyl p-methoxycinnamate in textiles

ActiveCN107860842BStrong infiltrationEfficient extractionComponent separationMegasonic cleaningMaterials science

The invention belongs to the technical field of detection methods and in particular relates to a method for detecting iso-octyl p-methoxycinnamate in textiles. The method comprises the following steps: 1, sampling textiles; 2, weighing a certain amount of samples to be added into a container, adding methanol into the container, and performing ultrasonic extraction on the container in an ultrasoniccleaner for 10 minutes to an hour so as to obtain an extracting solution; 3, filtering the extracting solution obtained in the second step so as to obtain a to-be-detected solution; 4, analyzing theto-be-detected solution obtained in the third step by using an ultra-high performance liquid chromatography-tandem mass spectrometry (UPLC-MSMS). Compared with the prior art, the method disclosed by the invention can simply, rapidly, accurately and reliably detect the content of the iso-octyl p-methoxycinnamate in textiles and meet detection requirements of the iso-octyl p-methoxycinnamate in Washington Child Product Safety Act.

Owner:广东省中鼎检测技术有限公司

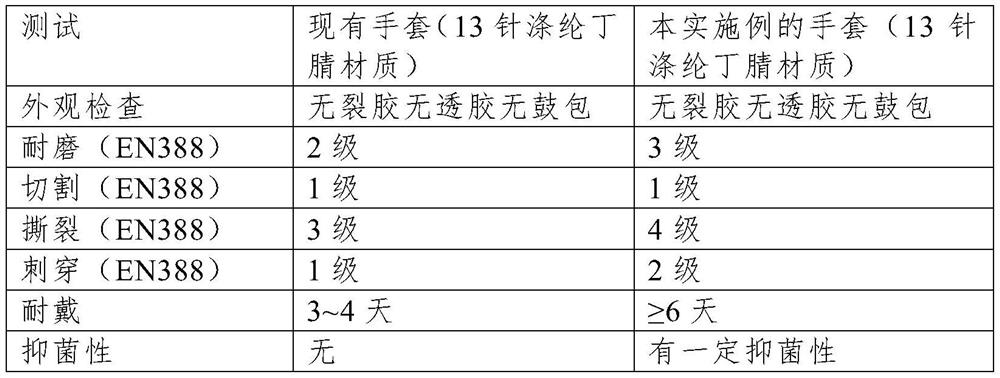

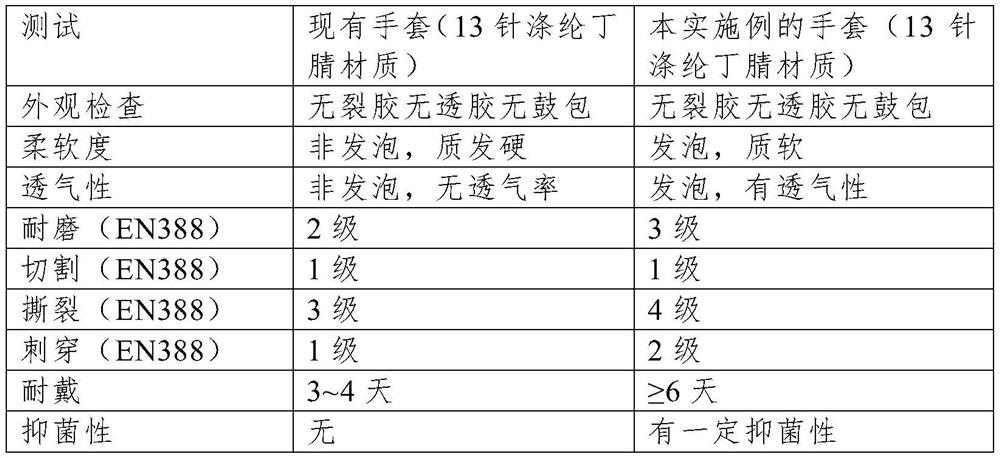

A kind of graphene-coated rubber gloves and preparation method thereof

ActiveCN108486902BImproved cut and tear resistanceBacteriostaticGlovesConjugated diene hydrocarbon coatingsPolymer scienceGraphene coating

The invention relates to a graphene-coated rubber glove, which comprises: a glove embryo, a rubber layer attached to the outer surface of the glove embryo, and a graphene film layer covering the outer surface of the rubber layer; the rubber layer is not Graphene-containing foamed rubber or non-foamed rubber. The preparation method of the gloves includes: preparing a graphene-free glue, impregnating the knitted glove blank with the glue; preparing a graphene-latex dispersion, and impregnating the glued glove blank impregnated with the glue. Described graphene-latex dispersion liquid; Sulphurization drying, makes described graphene-coated rubber gloves. In the present invention, after secondary dipping, the rubber body structure part of the glove is formed after the glue dipped in the first step is cured, so as to ensure that the quality of the body structure meets the relevant standards (EN388) and the basic labor protection function of the glove; the graphene coating is formed by the second dipping , can protect the rubber surface formed by one-time dipping, and improve the overall performance of glove products.

Owner:SHANDONG XINGYU GLOVES

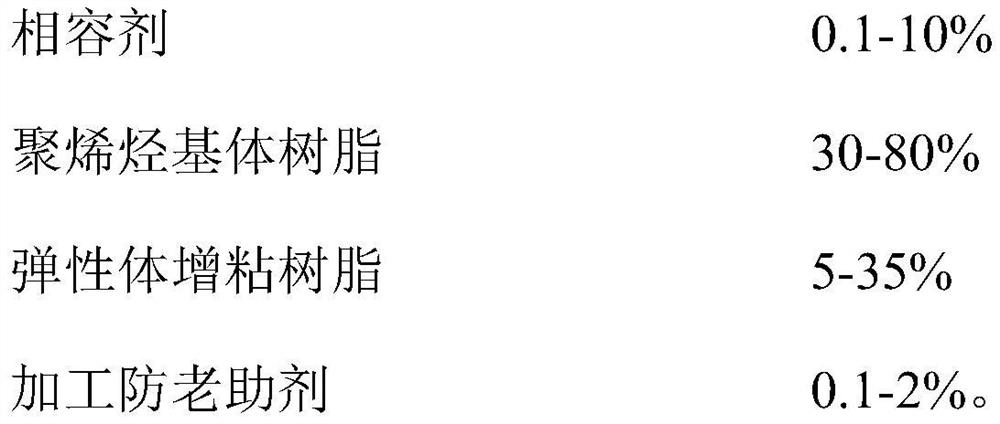

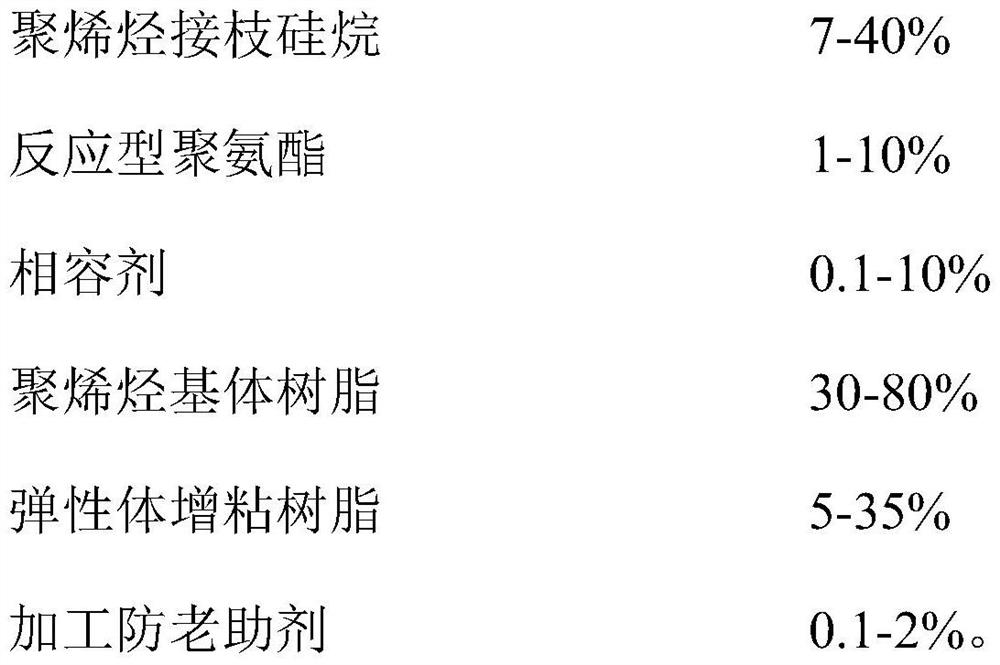

Adhesive resin for continuous fiber reinforced plastic composite pipe and preparation method thereof

ActiveCN109749663BGood adhesionHigh molecular weightPolyureas/polyurethane adhesivesMacromolecular adhesive additivesElastomerPolyester

The invention discloses an adhesive resin for continuous fiber-reinforced plastic composite pipes, which is prepared from the following components in percentage by weight: polyolefin grafted silane 7-40%, reactive polyurethane 1-10%, 0.1-10% compatibilizer, 30-80% polyolefin matrix resin, 5-35% elastomer tackifying resin, 0.1-2% processing anti-aging additive. The invention also provides a preparation method of the adhesive resin for the continuous fiber reinforced plastic composite pipe. The bonding resin of the present invention has a good bonding effect on continuous fiber materials such as continuous glass fiber, polyester fiber, nylon fiber, aramid fiber, carbon fiber, etc., and the continuous fiber reinforced thermoplastic pipe prepared by it has a multi-layer structure, many The bonding between the layers is firm, the pressure bearing capacity is high, and the weight is light. It is an excellent choice in the field of high-pressure pipes.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

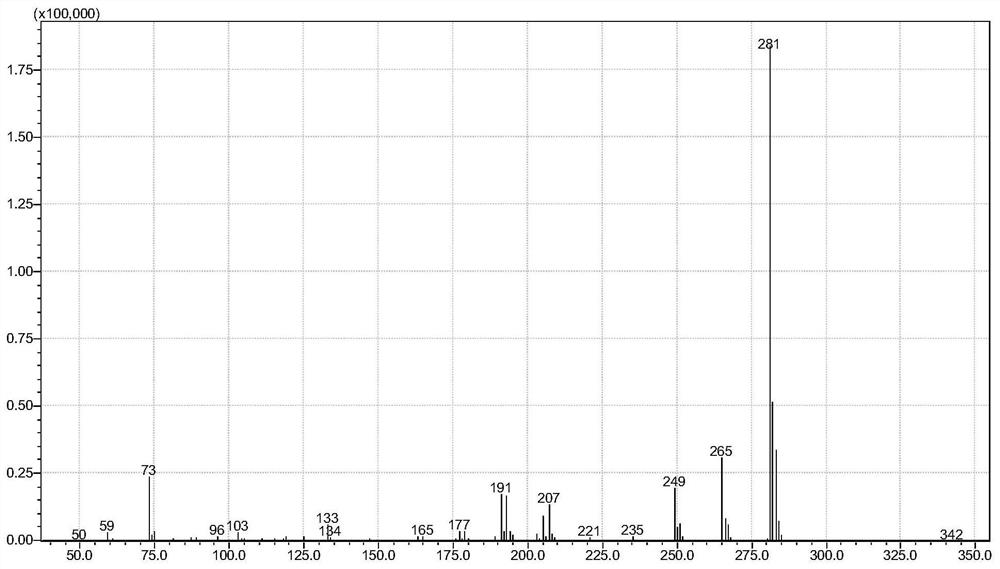

A method for detecting octamethylcyclotetrasiloxane content in textiles by gas chromatography-mass spectrometry

ActiveCN107632081BStrong infiltrationEfficient extractionComponent separationMeth-Gas liquid chromatographic

The invention discloses a method for detecting otcamethylcyclotetrasiloxane content in a textile by a gas chromatography-mass spectrometer. The method comprises the following steps: 1) taking a samplefrom the textile, and cutting the sample; 2) weighing 1.0 g of the cut sample, placing the sample in a 40 mL reaction tube, adding 10 mL analytically pure methanol, performing ultrasonic extraction in a ultrasonic cleaner at the temperature of 50 DEG C for 30 min, using an organic filter membrane for filtering a 1 mL extract to a sample bottle to obtain a sample solution, using the gas chromatography-mass spectrometer for analysis of the sample solution, and 3) using an external standard method for quantification. The method can rapidly and accurately perform qualitative and quantitative analysis on otcamethylcyclotetrasiloxane in the textile.

Owner:浙江中鼎检测技术有限公司

Cashew amine epoxy curing agent for marine heavy anti-corrosion coating and preparation method for curing agent

ActiveCN102898623BThe composition ratio is scientific and reasonableHigh viscosityAnti-corrosive paintsEpoxy resin coatingsSolubilityAlcohol

The invention discloses a cashew amine epoxy curing agent for a marine heavy anti-corrosion coating. The curing agent is sequentially prepared from the following raw materials in parts by weight: 20 to 23 parts of cardanol, 1 to 1.2 parts of diethylenetriamine, 12 to 15 parts of 37 percent formaldehyde aqueous solution, 9 to 10 parts of diethylenetriamine, and 7 to 8 parts of 37 percent formaldehyde aqueous solution. According to the cashew amine epoxy curing agent for the marine heavy anti-corrosion coating, the raw material composition and the optimal proportion and the adding sequence of the raw materials are selected through a large quantity of experiments, and the proportion of each component is scientific and reasonable; acetal is catalyzed by adopting diethylenetriamine to control the viscosity parameter, and then Mannich addition is carried out on the periphery of molecules to improve the alcohol solubility; and the cashew amine curing agent prepared by the method is high in activity, viscosity and solid content and good in compatibility, does not release oil, and can overcome many defects of the cashew amine epoxy curing agent prepared by the method in the prior art.

Owner:JIANGSU SANMU GROUP CORPORATION

Halogen-free and flame-retardant polyethylene cable material

InactiveCN109971068AStrong infiltrationFast fillPlastic/resin/waxes insulatorsPolymer sciencePhosphate

The invention discloses a halogen-free and flame-retardant polyethylene cable material. The halogen-free and flame-retardant polyethylene cable material comprises 70-80% of polyethylene resin, 12-25%of phosphate ester-modified ultrafine calcium carbonate, 1-2% of oleamide, 2-5% of triglycidyloxyphenyl silane and 0.5-1.0% of stearic acid. All assistants are weighed according to the above formula proportions, and are uniformly mixed in high-speed mixer, and the obtained mixture is granulated by plasticization shaping by using an extruder. The prepared halogen-free and flame-retardant polyethylene cable material has the advantages of low cost, good mechanical properties and outstanding flame retardant performance.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

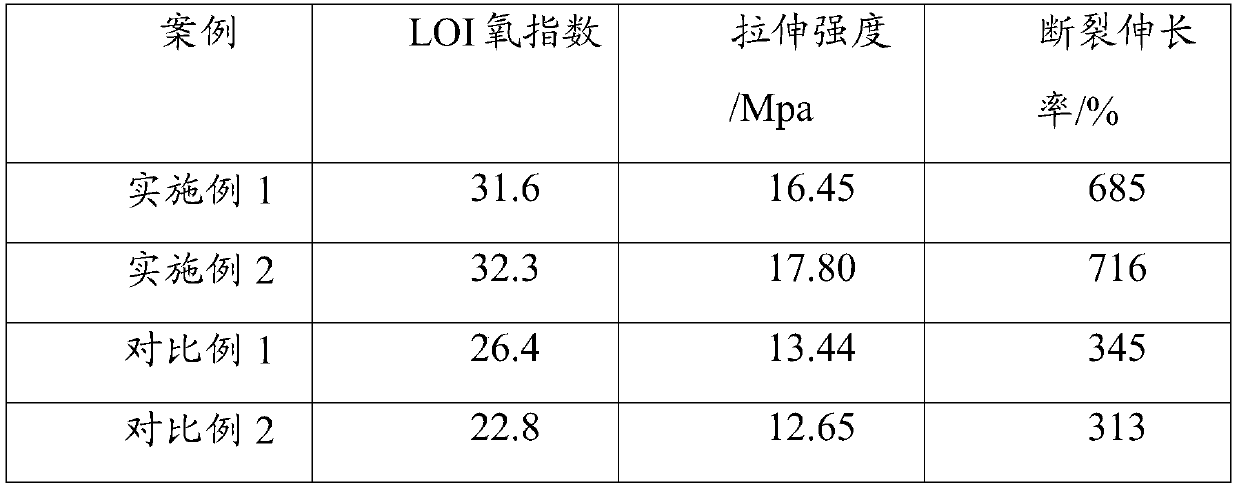

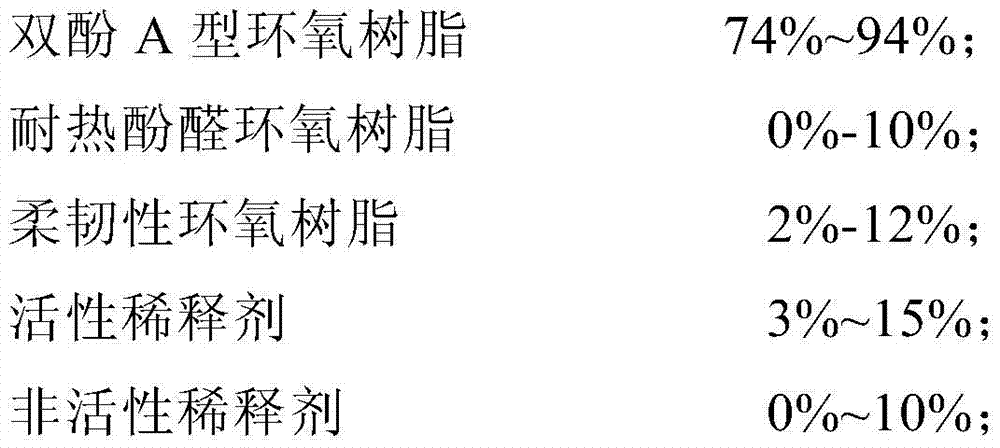

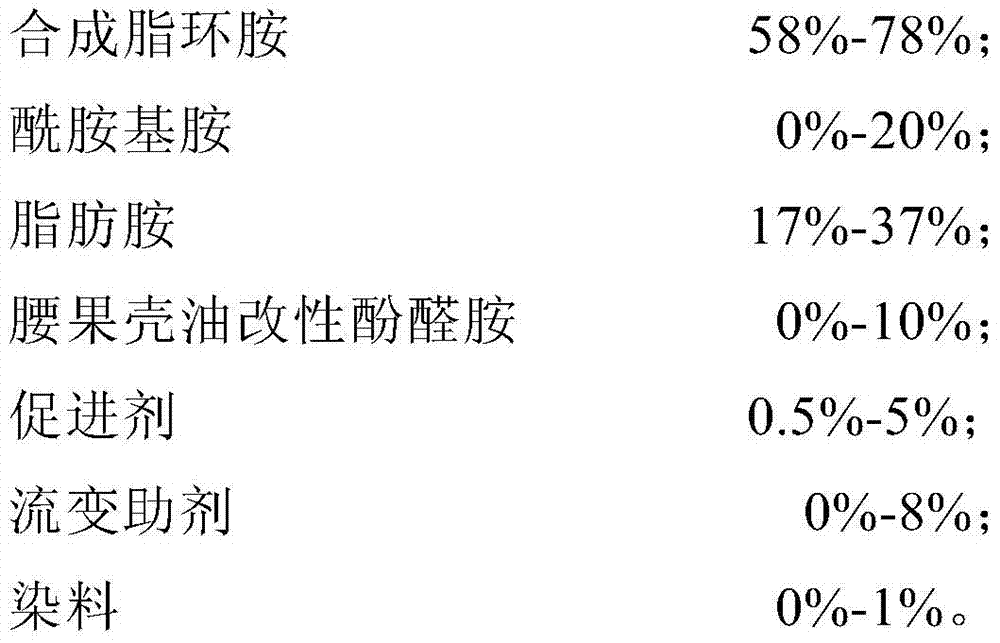

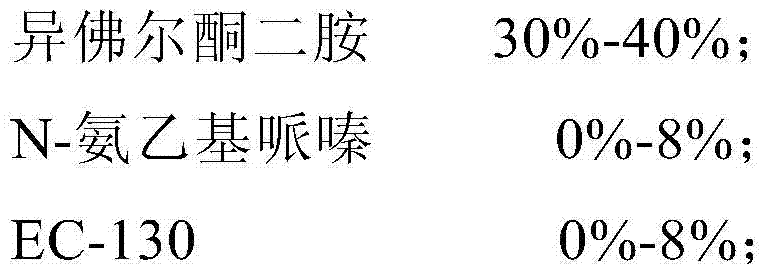

An anti-sag and anti-crystallization wind power grade hand lay-up resin system and its preparation method

The invention discloses an anti-sagging and anti-crystallization wind power grade hand lay-up resin system and a preparation method thereof. The hand lay-up resin system is prepared by mixing compounded epoxy resin component A and denatured curing agent component B. The compounded epoxy resin component A is prepared from bisphenol A epoxy resin, heat-resistant novolac epoxy resin, flexible epoxy resin, reactive diluent, and non-reactive diluent; the denatured curing Agent component B is prepared from synthetic alicyclic amines, amidoamines, fatty amines, cashew nut shell oil modified phenalkamines, accelerators, rheological additives, and dyes. The anti-sagging and anti-crystallization properties of the present invention are significantly enhanced, excellent in wettability to fibers, relatively less affected by the working environment, and the cured product has excellent comprehensive properties such as mechanical properties, toughness, heat resistance and water resistance, which can meet Practical requirements for hand lay-up and repair of various composite materials, especially suitable for large-area high-strength composite materials such as wind power blades.

Owner:上海康达新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com