Profiled-cross-section hollow polyfiber reinforced emulsified asphalt slurry seal

A technology of emulsified asphalt and special-shaped section, which is applied to the coagulation pavement, roads, roads and other directions paved on site to achieve the effects of improving mechanical properties and low-temperature crack resistance, reducing embrittlement point temperature and reducing reflection cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Emulsified asphalt: BC-1 type, which meets the technical requirements of emulsified asphalt for roads in "Technical Specifications for Construction of Highway Asphalt Pavement". The amount of asphalt is 10%.

[0024] Fiber: Not added.

[0025] Filler: 425# ordinary Portland cement is used, and the blending amount is 3%. All performances meet the requirements of "Technical Specifications for Highway Asphalt Pavement Construction" (JTGF40-2004).

[0026] Primary aggregate: sand. All properties meet the requirements of "Technical Specifications for Construction of Highway Asphalt Pavement" (JTG F40-2004).

[0027] The mineral material gradation is as follows:

[0028] Sieve hole(mm)

Embodiment 2

[0030] Emulsified asphalt: BC-1 type, which meets the technical requirements of emulsified asphalt for roads in "Technical Specifications for Construction of Highway Asphalt Pavement". The amount of asphalt is 10%.

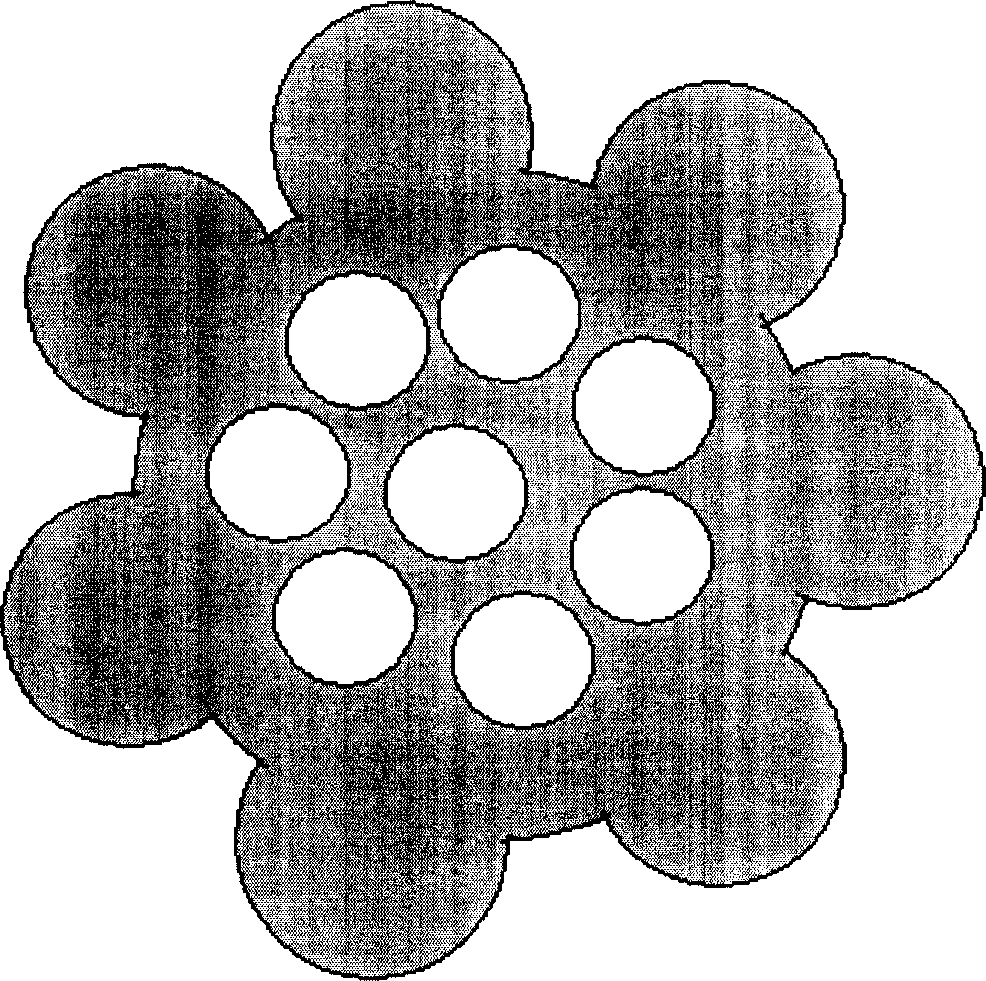

[0031] Fiber: it is the porous polyester fiber with quincunx cross-section shown in the accompanying drawing, and the dosage is 0.10% of the total mass of the mixture.

[0032] Filler: 425# ordinary Portland cement is used, and the blending amount is 3%. All performances meet the requirements of "Technical Specifications for Highway Asphalt Pavement Construction" (JTGF40-2004).

[0033] Primary aggregate: sand. All properties meet the requirements of "Technical Specifications for Construction of Highway Asphalt Pavement" (JTG F40-2004).

[0034] The mineral material gradation is as follows:

[0035] Sieve hole(mm)

Embodiment 3

[0037] Emulsified asphalt: BC-1 type, which meets the technical requirements of emulsified asphalt for roads in "Technical Specifications for Construction of Highway Asphalt Pavement", and the dosage is 10%.

[0038] Fiber: it is the porous polyester fiber with quincunx cross-section shown in the accompanying drawing, and the dosage is 0.15% of the total mass of the mixture.

[0039] Filler: 425# ordinary Portland cement is used, and the blending amount is 3%. All performances meet the requirements of "Technical Specifications for Highway Asphalt Pavement Construction" (JTGF40-2004).

[0040] Primary aggregate: sand. All properties meet the requirements of "Technical Specifications for Construction of Highway Asphalt Pavement" (JTG F40-2004).

[0041] The mineral material gradation is as follows:

[0042] Sieve hole(mm)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com