Cashew amine epoxy curing agent for marine heavy anti-corrosion coating and preparation method for curing agent

A cashew amine epoxy and heavy-duty anti-corrosion technology, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of difficult promotion and application, high product cost, deep product color, etc., and achieve excellent adhesion and low cost Good balance of strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of cardanol amine epoxy curing agent for marine heavy-duty coatings, according to the order of feeding, it is made of the following raw materials in parts by weight: 23 parts of cardanol, 1.2 parts of diethylenetriamine, 15 parts of aqueous solution of 37% formaldehyde: two 10 parts of ethylene triamine, 8 parts of 37% formaldehyde aqueous solution.

Embodiment 2

[0027] A kind of cardanol amine epoxy curing agent for marine heavy-duty coatings, according to the order of feeding, it is made of the raw materials in the following parts by weight: 20 parts of cardanol, 1 part of diethylenetriamine, 12 parts of aqueous solution of 37% formaldehyde: 2 9 parts of ethylene triamine, 7 parts of 37% formaldehyde aqueous solution.

Embodiment 3

[0029] Preparation method of cashew amine epoxy curing agent for marine heavy-duty anti-corrosion coatings:

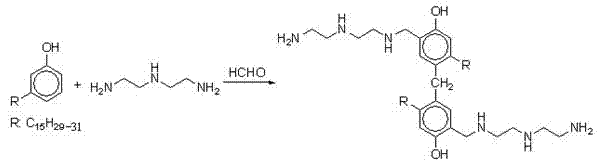

[0030] The reaction process is as figure 1 Shown:

[0031] Introduce a nitrogen tube into a 1000mL four-necked bottle for nitrogen purging, then put in 300g cardanol and 13g diethylenetriamine in sequence, and then continue nitrogen purging. After purging, under mechanical stirring and nitrogen protection, slowly Add 162g of 37% formaldehyde aqueous solution dropwise, control the system temperature below 70oC, and keep it at about 80oC for 2 hours. Then add 120g of diethylenetriamine dropwise, and control the system temperature below 80oC. After adding diethylenetriamine dropwise, continue to drop 85g of 37% formaldehyde aqueous solution, control the system temperature below 80oC, and keep the temperature at about 80oC for 2 hours , vacuum dehydration, the initial vacuum temperature is 80oC, the maximum temperature in the later stage is not more than 100oC, and the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| impact resistance | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com