Patents

Literature

48results about How to "Small viscosity-temperature coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

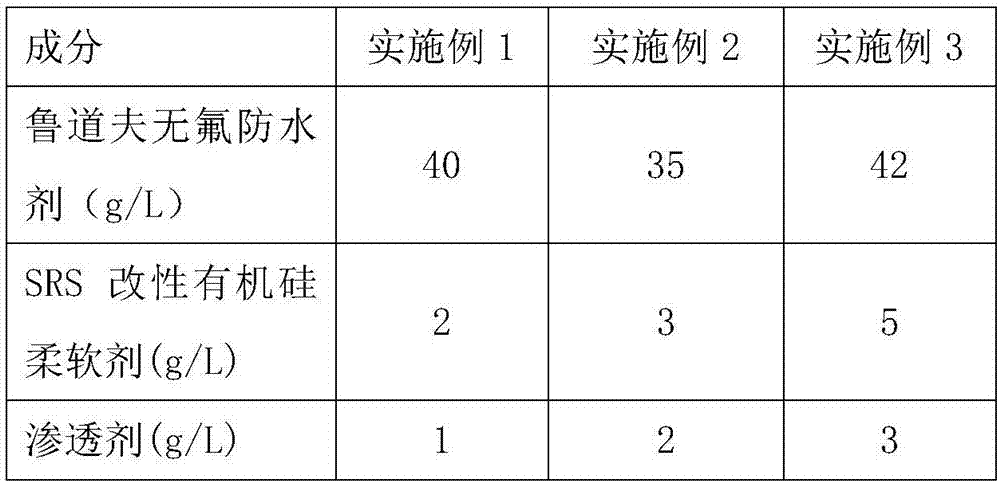

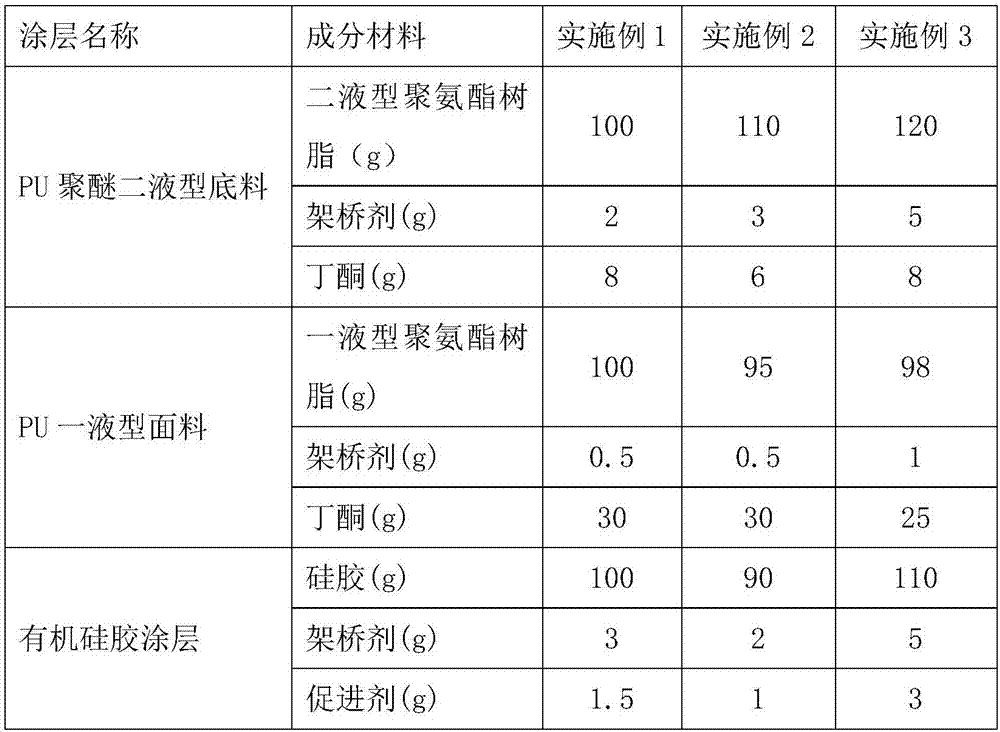

Production technology of medical fabric

ActiveCN107299540ASoft touchImprove tear resistanceMedical preparationsCoatingsEngineeringResin coating

The invention discloses a production technology of a medical fabric. The technology comprises the following steps of grey fabric weaving, desizing, drying, splashing and sizing, calendering treatment, and coating of a double-sided coating, wherein the calendered surface of the fabric is coated with a PU resin coating with water pressure resistance; the PU resin coating is divided into a PU polyether two-component base material and a PU one-component fabric for separate coating; after the calendered surface is coated, the fabric is dried through high-temperature oven until being rolled up, and the other side of the fabric is coated with an organic silicone coating, and high-temperature drying is carried out to obtain the medical fabric. The tissue style characteristics of the woven fabric are integrated, and coating finishing is carried out on the front and reverse sides of the fabric, so that the fabric has the characteristics of being waterproof, easy to decontaminate and high in tenacity, and the production technology is suitable for the medical fabric.

Owner:HUAMAO (XIAMEN) WEAVING DYEING & FINISHING CO LTD

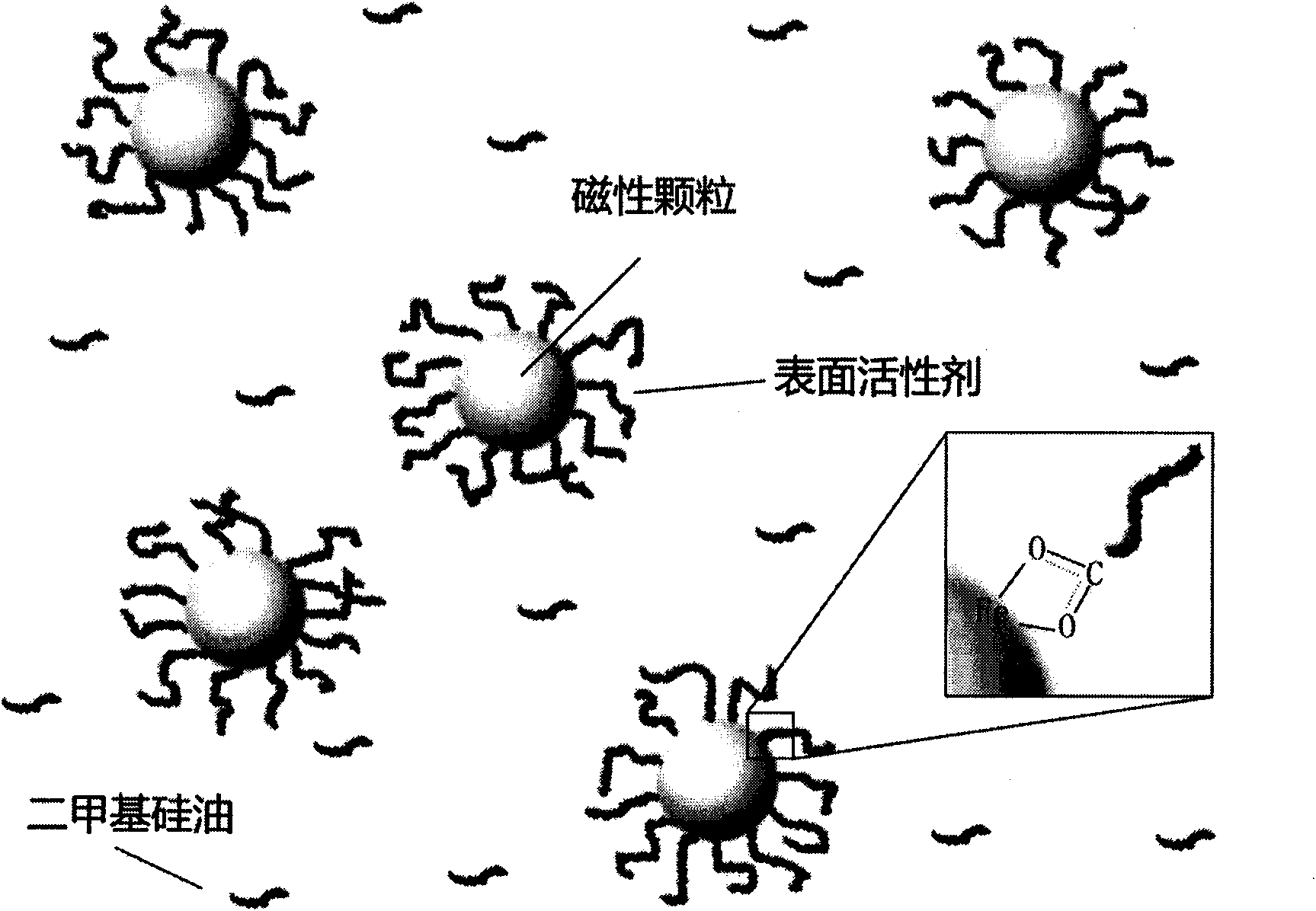

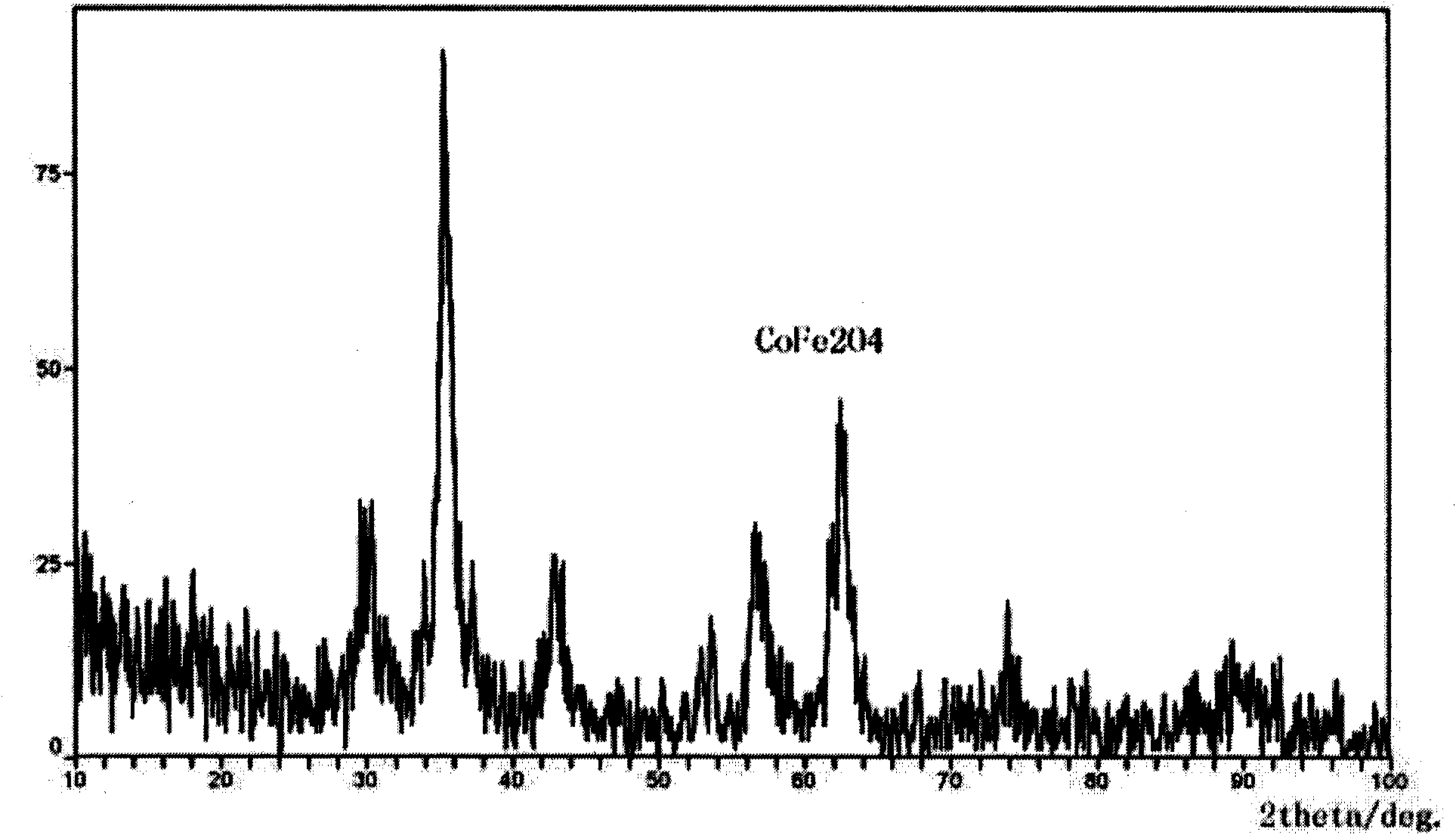

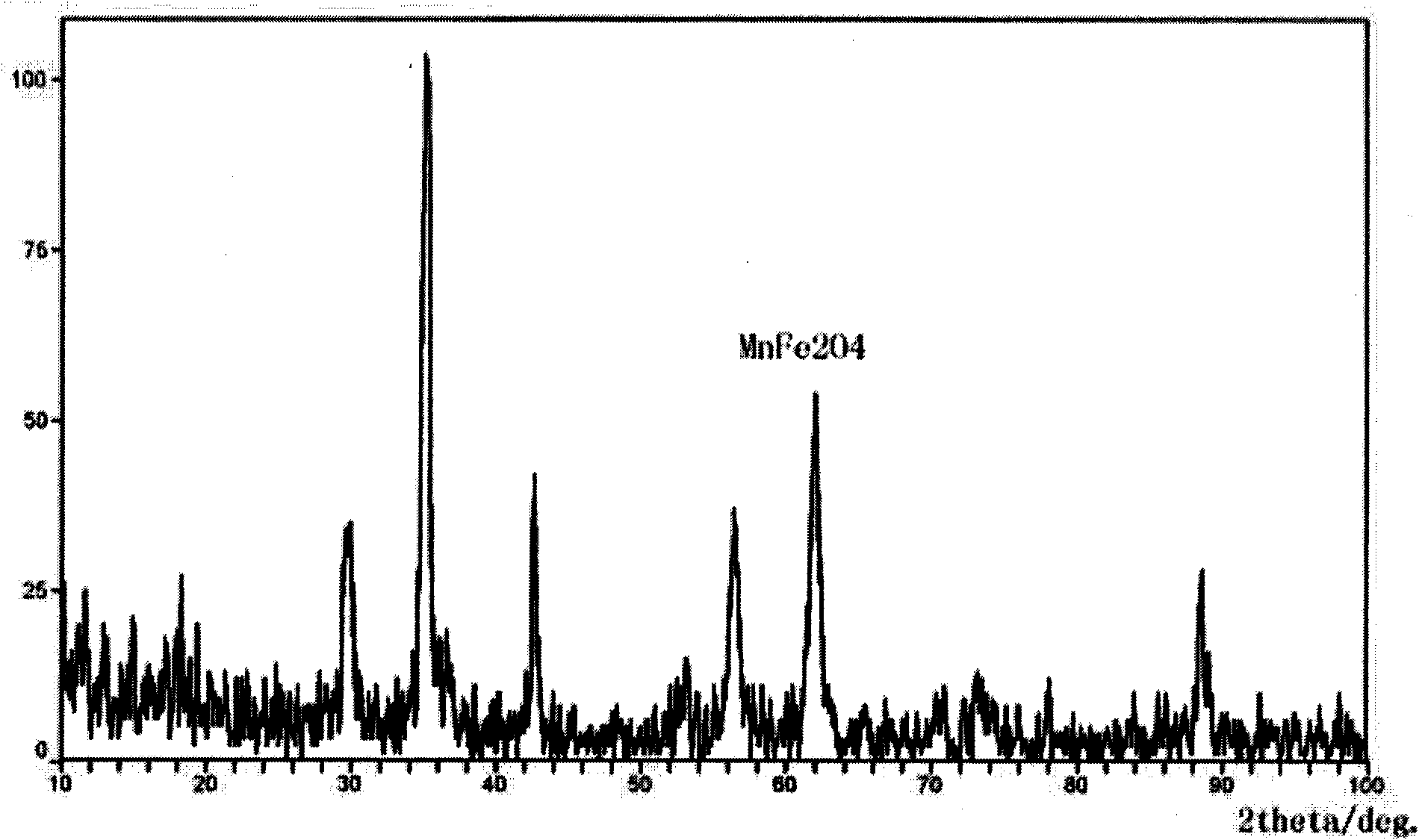

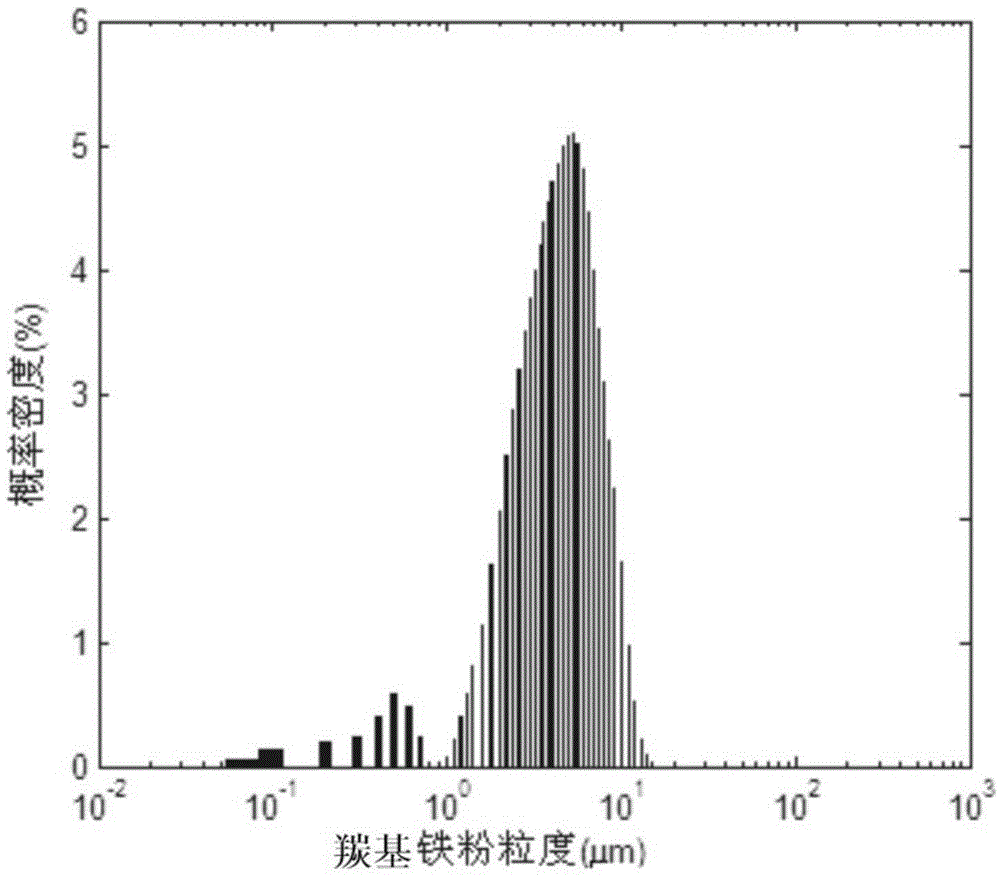

Oxidation resistant dimethyl silicon oil based magnetic fluid and preparation method thereof

InactiveCN101599335ASmall viscosity-temperature coefficientLow compression resistanceMagnetic liquidsOrganic/organic-metallic materials magnetismMethylene DichlorideMagnetic liquids

The invention provides oxidation resistant dimethyl silicon oil based magnetic fluid and a preparation method thereof; the dimethyl silicon oil based magnetic fluid is prepared by nano-magnetic particles, a surface modifier and carrier fluid, and the carrier fluid is the dimethyl silicon oil. The preparation method of the dimethyl silicon oil based magnetic fluid comprises the following steps: preparing the nano-magnetic particles; treating the nano-magnetic particles in an activated way; preparing the nano-magnetic particles which are modified by the surface modifier; adding the modified nano-magnetic particles which are purified into methylene dichloride, dispersing and filtering the mixture to obtain the methylene dichloride based magnetic fluid; adding the magnetic fluid into the dimethyl silicon oil to be stirred and dispersed, heating the mixture and maintaining the temperature between 50 and 90 DEG C, separating and precipitating the mixture to obtain the dimethyl silicon oil based magnetic fluid. The dimethyl silicon oil based magnetic fluid in the invention has the advantages of high stability, low temperature resistance and high temperature resistance. The preparation method is simple, high in efficiency and low in requirement on equipments, thus being easy to be applied in various fields and having wide application prospect.

Owner:SUN YAT SEN UNIV

Graphene reinforced organic silicon heat-conductive material and preparation method thereof

InactiveCN104530706AReduce surface tensionSmall viscosity-temperature coefficientSilicone resinOrganosilicon

The invention discloses a graphene reinforced organic silicon heat-conductive material. The material is prepared from 15-35 parts of organic silicon resin, 25-55 parts of a heat-conductive agent, 1-7 parts of graphene, 0.1-2 parts of a platinum catalyst, 0.1-2 parts of hydrogen-containing silicone oil, 3-11 parts of a coupling agent, 0.5 parts of a flame retardant and 0-3 parts of a release agent. According to the invention, the graphene, the heat-conductive agent and the organic silicon resin are combined in a certain proportion, and the coupling agent, the hydrogen-containing silicone oil curing agent or other auxiliaries are added to form a formula, so that the heat conducting performance of the organic silicon material can be improved, the mechanical performance of the organic silicon material is improved, and the heat conducting performance of the product is further improved due to addition of the graphene, surfaces of the heat-conductive agent particles can be completely covered by the coupling agent due to the surface treatment mode of the heat-conductive agent in the preparation process, the compatibility of the heat-conductive agent and the organic silicon resin can be improved, and a high-quality high-performance product can be obtained.

Owner:HUIZHOU KINGBALI TECH

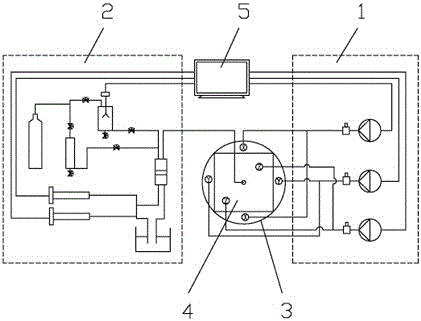

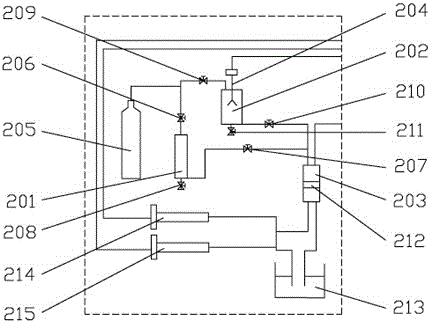

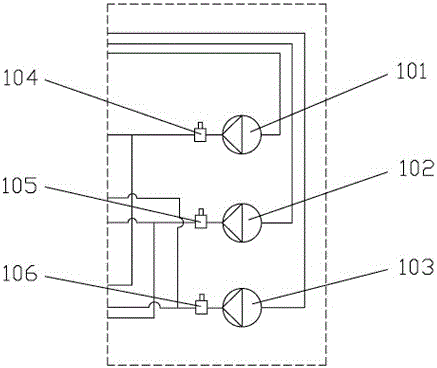

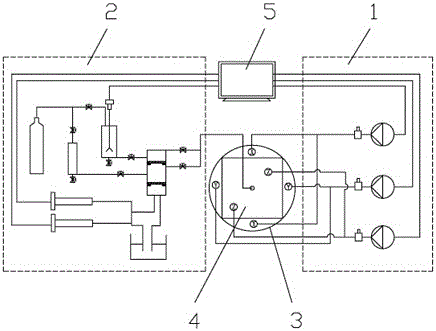

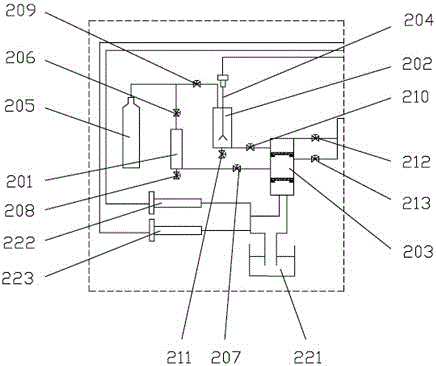

True tri-axial hydraulic fracture test machine and test method

InactiveCN106644734AImprove heat resistanceImprove insulation performanceMaterial strength using tensile/compressive forcesFracturing fluidEngineering

The invention relates to a true tri-axial hydraulic fracture test machine which comprises a confining pressure system, an injection system and a true tri-axial test stand, wherein the injection system comprises a fracturing solution container I, a fracturing solution container II and a piston container, and a stirring mechanism is mounted in the fracturing solution container II. A test method comprises the following steps: injecting clear water and an additive into the fracturing solution container II according to a certain proportion, and starting the stirring mechanism to stir; injecting a fracturing solution into a cavity body above a piston plate in the piston container by utilizing pressure; respectively applying confining pressures onto three axial directions of a downhole rock core simultaneously through three high-pressure advection pumps; draining into a cavity body under the piston plate in the piston container through a constant-pressure constant-speed plunger pump I and / or a constant-pressure constant-speed plunger pump II; injecting the fracturing solution into the rock core to start to fracture and taking out the downhole rock core after the end of fracturing to observe fracture expansion condition. The true tri-axial hydraulic fracture test machine provided by the invention has the benefits that the technical scheme is simple and easy to understand, the operation is convenient and fast, the unified control of the confining pressure system and the injection system can be realized, and the fracturing solution is convenient to replace.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Waterproof coating of carton

ActiveCN102704330AGood chemical stabilityImprove insulation performanceCoatingsPaper forming aids additionParaffin waxEmulsion

The invention relates to a waterproof coating, in particular to a waterproof coating of a carton, which comprises the following components in weight part: 30-120 parts of paraffin micro-emulsion, 50-90 parts of simethicone, and 4-8 parts of emulsifier. The waterproof coating is prepared according to a method as follows: (1) heating the paraffin micro-emulsion to 50-180 degree C; (2) adding simethicone and stirring for 0.5-3 hours; and (3) adding the emulsifier, stirring at a high speed for 10-40 minutes, and cooling to the room temperature. The waterproof coating of the carton, disclosed by the invention, has no pollution on the human body and the environment, can be combined with the base material firmly, and has excellent waterproof property.

Owner:ANHUI JINDUN PAINT

Crystal whisker reinforced organic silicon heat conducting material and preparation method thereof

InactiveCN104530707AReduce surface tensionSmall viscosity-temperature coefficientInorganic crystalsSurface finishing

The invention discloses a crystal whisker reinforced organic silicon heat conducting material and a preparation method thereof. The crystal whisker reinforced organic silicon heat conducting material is prepared from organic silicon resin, heat conducting insulating filler, crystal whiskers, a platinum catalyst, hydrogen-containing silicon oil, a coupling agent and other additives which are subjected to processes such as surface treatment, vacuum smelting and rolling. By adding the inorganic crystal whiskers and the heat conducting insulating filler, the heat conductivity coefficient of the organic silicon material can be increased, the mechanical properties of the organic silicon material can be improved as well, and the organic silicon material has better toughness and more balanced mechanical properties and can be widely applied to electronic heat conduction fields of electrons, automobiles, LED lamps and the like.

Owner:HUIZHOU KINGBALI TECH

High-performance heat conduction material

InactiveCN104530708AReduce surface tensionSmall viscosity-temperature coefficientHeat-exchange elementsHexagonal boron nitrideCompressibility

The invention discloses a high-performance heat conduction material. The high-performance heat conduction material contains organic silicon resin, hexagonal boron nitride, aluminum oxide, graphene, platinum catalyst, hydrogen-containing silicone oil with hydrogen content of 0.5 to 0.8 percent, silane coupling agent, organosiloxane surface modifier, organic silicone oil and antioxidant 168; the organic silicon resin is low in surface tension, small in viscosity-temperature coefficient, high in compressibility and high in gas permeability, and the hexagonal boron nitride is high in precision and excellent in heat conduction performance and heat radiation performance, so that when the hexagonal boron nitride material is used for preparing an LED heat radiator, a high effect of heat resistance transfer and heat radiation for the LED can be realized; the hexagonal boron nitride and the aluminum oxide are used as heat conduction fillers, so that the cost performance is high; the graphene and the heat conduction fillers are combined with organic silicon resin in the formula, so that the reaction performance of the hexagonal boron nitride in the preparation process can be enhanced through the surface modifier, the compatibility and mechanical properties among the materials can be coordinately improved by virtue of the coupling agent, hydrogen-containing silicone oil and other additives, and a product with high quality and high performance can be obtained.

Owner:HUIZHOU KINGBALI TECH

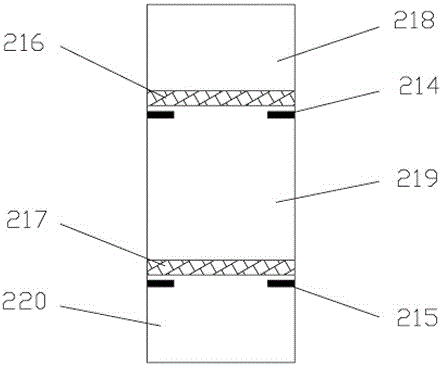

True triaxial sand fracturing testing machine and testing method

The invention relates to a true triaxial sand fracturing testing machine, which comprises a confining pressure system and an injecting system, wherein the injecting system comprises a first fracturing fluid container, a second fracturing fluid container and a piston container; two piston sheet baffle plates are arranged in the piston container. A true triaxial sand fracturing testing method comprises the following steps that stirring is performed in the second fracturing fluid container to form sand-carrying fracturing fluid; prepositive fracturing fluid is injected into the first fracturing fluid container; the prepositive fracturing fluid and the sand-carrying fracturing fluid are respectively injected into a middle cavity and an upper cavity of the piston container by pressure; through a first constant-pressure constant-speed plunger pump and / or a second constant-pressure constant-speed plunger pump, water is discharged into a lower cavity of the piston container; the prepositive fracturing fluid, the sand-carrying fracturing fluid and displacement fracturing fluid sequentially enter a downhole core for fracturing; after the fracturing is finished, the downhole core is taken out; the crack expanding condition is observed. The technical scheme is simple and is easy to understand; the operation is convenient and fast; the unified control on the confining pressure system and the injecting system can be realized; the fracturing fluid replacement is convenient.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

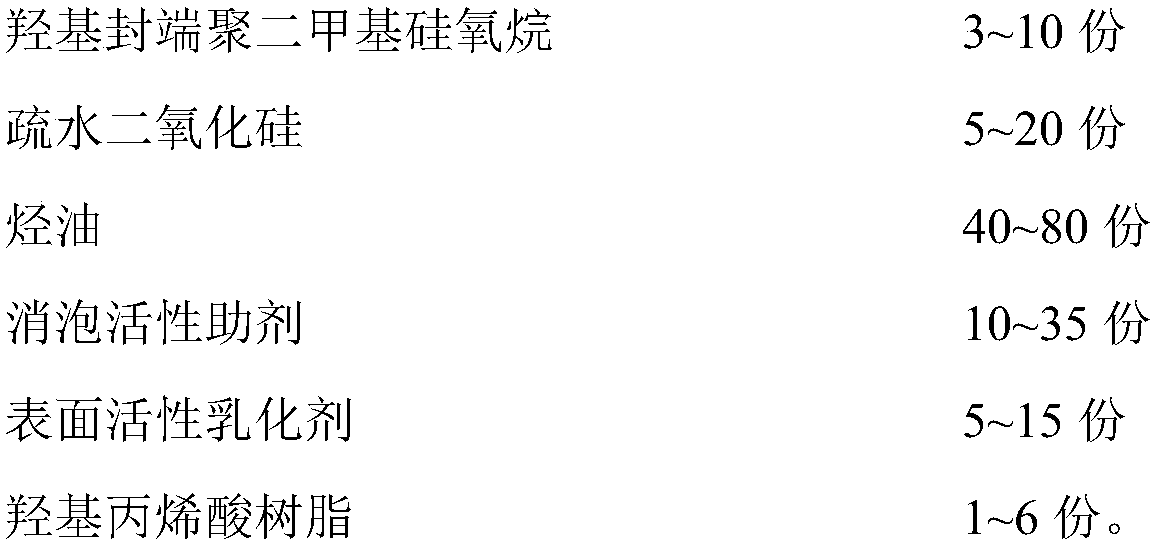

Mineral oil defoaming agent and preparation method thereof

The invention discloses a mineral oil defoaming agent and a preparation method thereof, and belongs to the technical field of fine chemical auxiliaries. The mineral oil defoaming agent provided by theinvention comprises the following components in parts by weight: 3-10 parts of hydroxyl-terminated polydimethylsiloxane; 5-20 parts of hydrophobic silicon dioxide; 40-80 parts of hydrocarbon oil; 10-35 parts of a defoaming coagent; 5-15 parts of a surface active emulsifier; and 1-6 parts of hydroxy acrylic resin. By adopting the mineral oil defoaming agent prepared by the invention, not only arethe polymerization, steam stripping and filling of harmful foam during a styrene-butadiene latex production process effectively inhibited, but also the effective control on oil shrinkage, pinhole, fisheye and foam inhibition of a subsequent coating is realized; at the same time, the mineral oil defoaming agent has the advantages of good stability, less addictive amount and the like.

Owner:安徽銮威化工科技开发有限公司

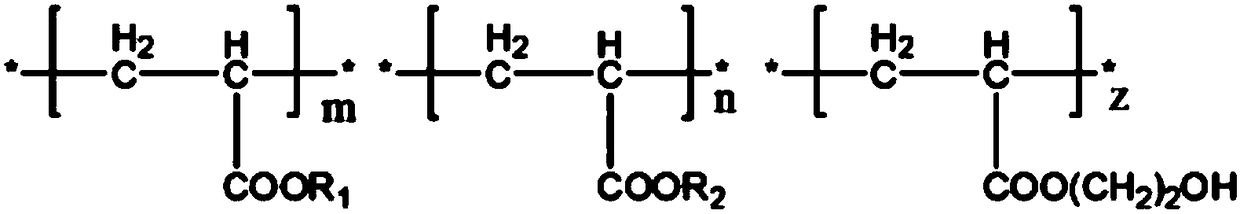

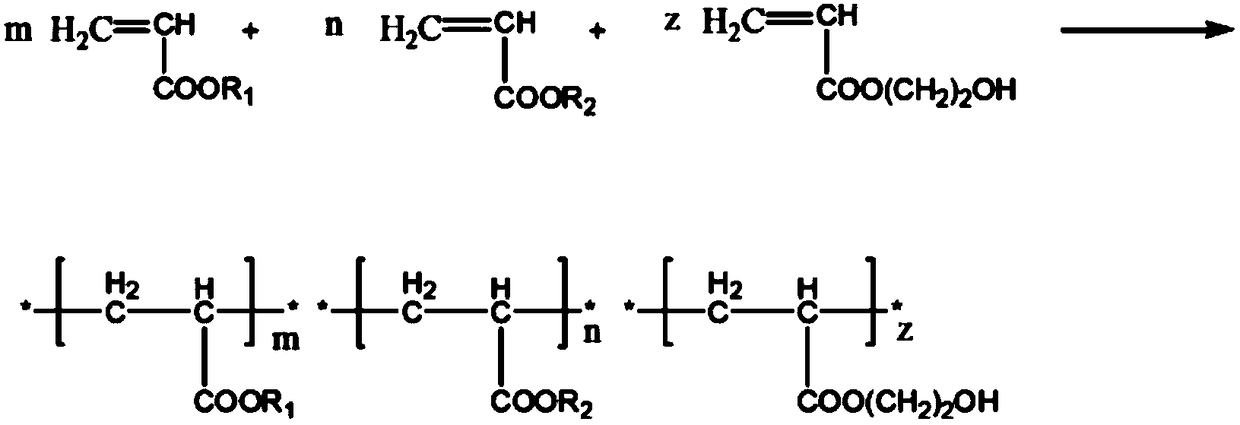

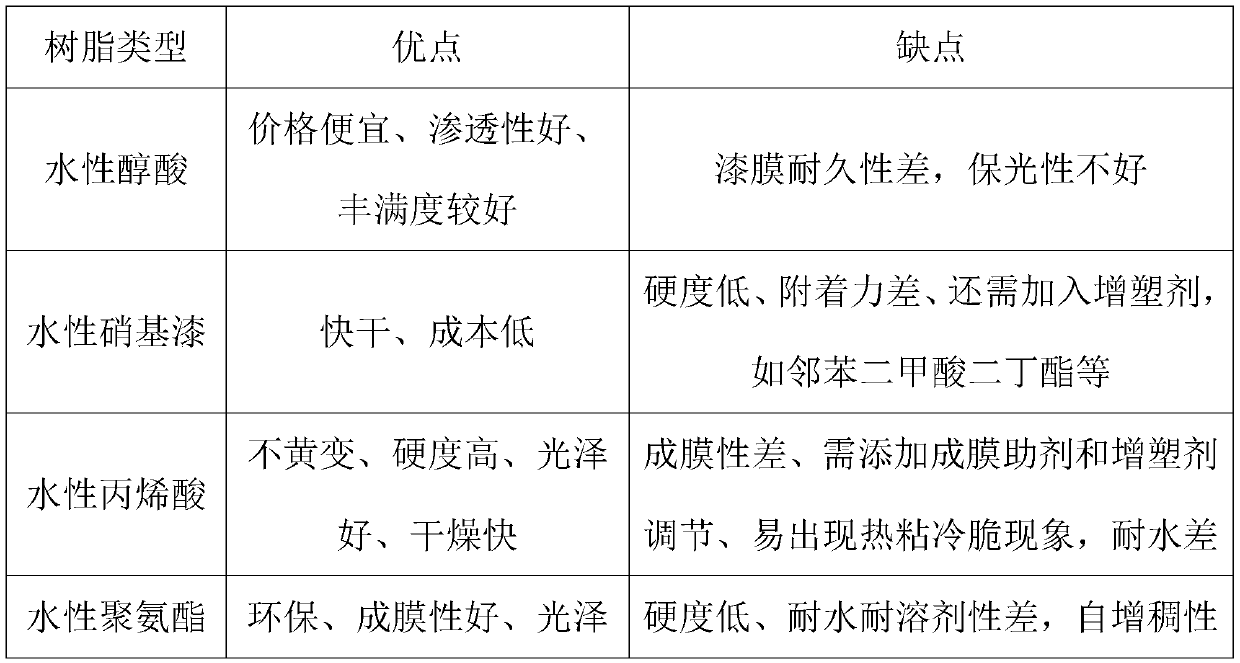

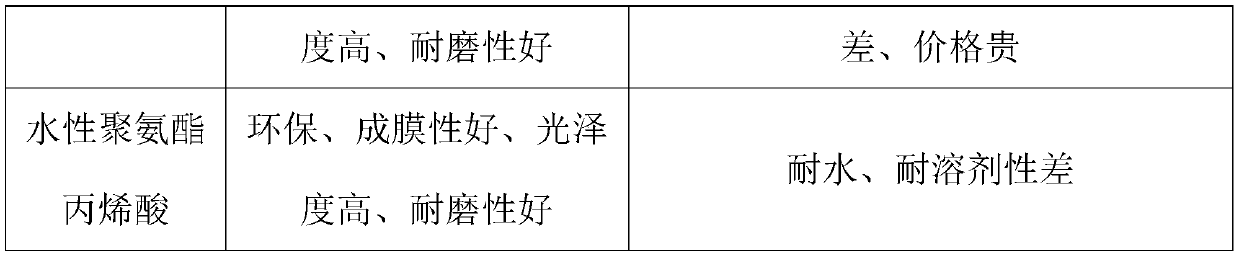

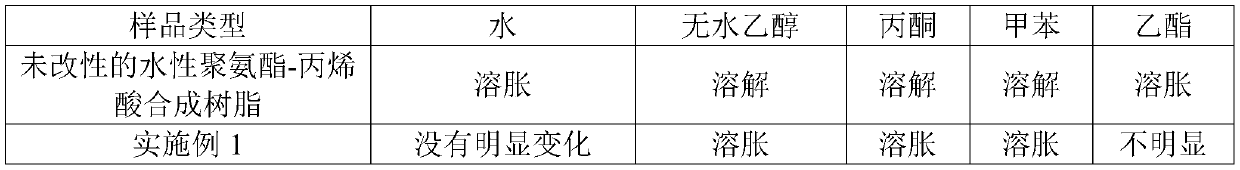

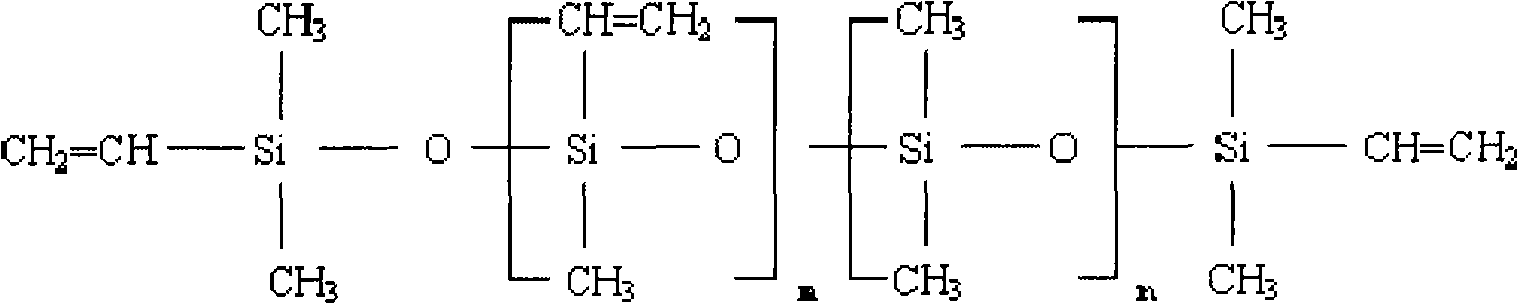

Method for synthesizing silane modified waterborne polyurethane-acrylic resin

InactiveCN110078868ACompact structureIncrease chemical bond energyPolyurea/polyurethane coatingsPolyesterFunctional monomer

The invention relates to the synthesis of waterborne resin, in particular discloses a method for synthesizing silane modified waterborne polyurethane-acrylic resin, and aims to solve the problem thatconventional aqueous resin is poor in water resistance and solvent resistance. The preparation method comprises the following steps: carrying out vacuum dehydration on polyester polyol and diisocyanate, and adding a hydrophilic chain extender, an acrylate mixed monomer and a catalyst to carry out a reaction so as to obtain a polyurethane prepolymer I; adding a silane coupling agent into the prepolymer I to carry out a polyurethane modification reaction, and carrying out double-bond end sealing, neutralization salting and self emulsification to obtain a self emulsifier II; adding an initiator solution and a functional monomer glycidyl methacrylate into the self emulsifier II to carry out a reaction for 2-4 hours, and cooling to obtain the silane modified waterborne polyurethane-acrylic resin. The obtained resin is good in water resistance and solvent resistance and good in adhesion property, and can be used for aqueous wooden instrument coatings applied to furniture such as cabinets, wooden doors, floors, wardrobes, tables, chairs, beds and the like.

Owner:广东伟明涂料有限公司

Heat shrinkable casing pipe and preparation method thereof

The invention discloses a heat shrinkable casing pipe. The casing pipe comprises the following components in parts by weight: 50-70 parts of an ethylene-vinyl acetate copolymer, 30-50 parts of polyethylene, 5-15 parts of an ethylene-octylene copolymer, 2-5 parts of a compatilizer, 50-100 parts of an inorganic filler or a flame retardant, 5-10 parts of a lubricant, 1-3 parts of a composite antioxidant and 0-3 parts of color master batches. The casing pipe provided by the invention has a self-adhesion prevention effect, and even when the heat shrinkable casing pipe is used in batches, and used in a high-temperature machining state or other high-temperature environments, the phenomena of mutual adhesion or adhesion with metal materials which is in contact with the casing pipe can be avoided,so that the production efficiency is ensured and the appearance quality of products is prevented from being damaged.

Owner:SHANGHAI CHANGYUAN ELECTRONICS MATERIAL

Ice and snow resistant, anti-corrosion paint and uses thereof

InactiveCN101270261AWith high and low temperature resistanceHigh viscosity temperature coefficientOther chemical processesAnti-corrosive paintsPolymer scienceHigh pressure

The invention discloses ice and snow resistant, and corrosion-proof coating which comprises the following materials by weight: 1.0 to 1.5 portion of silicone oil, 1.0 to 1.5 portion of organosilicon water repellent compound, 2.0 to 2.5 portion of calcium chloride, 0.8 to 1.2 portion of organosilicon defoamer, and1.0 to 1.5 portion of methylvinylsilicone rubber. The coating has the properties both as inorganic material and organic material, both can resist high and low temperature; insulate electric appliances; resist ozone, flame; is hydrophobic, corrosion-proof, weatherable, innoxious, tasteless, physiologically inert with small surface tension; and has low viscosity-temperature coefficient and can resist compression well. The coating can effectively prevent outdoor facilities, such as high voltage electric steel towers, communication equipment and so on, from being frozen. In addition, the coating further has radiation resistance.

Owner:刘国强

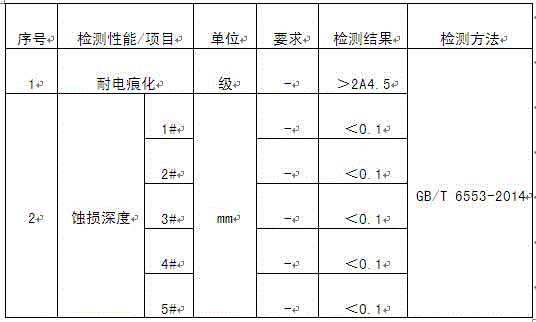

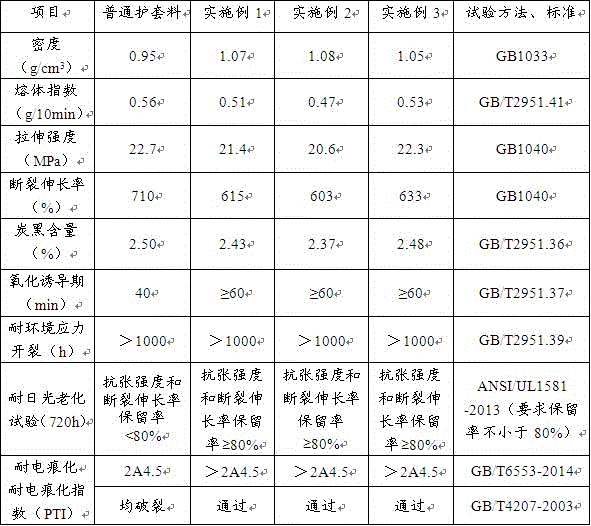

Anti-track uvioresistant ADSS optical cable jack material

The invention discloses an anti-track uvioresistant ADSS optical cable jack material which comprises the following raw materials by weight part: 65-70 parts of high density polyethylene resins, 15-20 parts of ethylene acrylic copolymers, 9-10 parts of polyethylene grafting materials, 5-6 parts of polydimethylsiloxane, 15-20 parts of magnesium hydrate, 5.0-5.5 parts of carbon black master batches, 0.5-1.0 part of ultraviolet light absorber and 0.5-1.0 part of antioxidant. In a preparation process, the raw materials are put into a high-speed mixing machine and are uniformly mixed, and then are continuously extruded by a double-screw extruder for two times, and are cooled, cut into grains and dried, so that the jack material provided by the invention is acquired; the temperature of the double-screw extruder is at 160-230 DEG C. The anti-track uvioresistant ADSS optical cable jack material can serve as the jack material special for 220KV and above ADSS optical cable, can realize high-altitude suspending remote conveying, can resist corona and electric track, can resist ultraviolet irradiation, can bear the cold environment test under wind, rain, snow and frost environments and has excellent physical and mechanical properties.

Owner:HUANGMEI KEPUDA INDAL

Heat-conducting silicone grease composition

InactiveCN104530714AImproves compression resistanceLittle physiological inertiaPolymer scienceHexagonal boron nitride

The invention discloses a heat-conducting silicone grease composition which is prepared from methyl ethoxy silicone oil, hexagonal boron nitride, aluminum oxide, scrap rubber nano-powder, a silane-based quaternary ammonium salt phase transfer catalyst, organic silicone oil, a silane coupling agent, an organic siloxane surface modification agent, an antioxidant 168 and an antioxidant 1010. According to the heat-conducting silicone grease composition, a product is high in performance cost ratio by compounding the hexagonal boron nitride, the aluminum oxide and the scrap rubber nano-powder as heat-conducting insulating fillers; in addition, the scrap rubber nano-powder with a small particle diameter can be used for enhancing the flowability of the product in a preparation process and filling a gap to obtain larger heat-transfer specific surface area, so that a final heat-conducting silicone grease composition product has the advantages of excellent heat conductivity, electrical insulation, weather resistance, hydrophobicity, physiological inertia and less surface tension, lower viscosity-temperature coefficient, higher compression resistance and no corrosion effect, can be used for well filling the gap between an electronic element and a radiating fin and is a very good medium material of the electronic element.

Owner:HUIZHOU KINGBALI TECH

Fireproof rubber

The invention relates to fireproof rubber which comprises the following raw materials in part by weight: 100 to 150 parts of chloroprene rubber, 100 to 130 parts of natural rubber, 5 to 10 parts of zinc oxide, 2 to 5 parts of hydrogen silicon oil, 2 to 5 parts of stearic acid, 15 to 30 parts of magnesium hydroxide, 2 to 5 parts of an accelerant, 2 to 5 parts of a vulcanizing agent, 3 to 10 parts of aluminum phosphate, 3 to 10 parts of sodium silicate, 3 to 10 parts of silicon carbide, 1 to 5 parts of an anti-aging agent, 5 to 10 parts of calcium carbonate, 1 to 5 parts of hydroxyl silicone oil, 1 to 5 parts of dimethicone and 1 to 5 parts of dibutyl phthalate. The fireproof rubber has good fire resistance, can perform a certain protection effect in a big fire and can reduce loss which is caused by the big fire and is brought to people.

Owner:CHONGQING XUXING CHEM

Finish gloss oil for manufacturing of glass and preparation method of marbled glass

ActiveCN108753165AGood flexibilityHigh hardnessAntifouling/underwater paintsPaints with biocidesDiluentColor saturation

The invention discloses a finish gloss oil for manufacturing of glass. The finish gloss oil comprises a host agent and a diluent at the mass ratio of 5 : 4 to 2:1. The host agent comprises, by mass, 25-30% of organic silicon resin, 55-65% of silicone modified epoxy resin, 4-8% of fluorosilicon resin, 0.5-2% of leveling agent, 0.5-2% of surfactant, and 1-2% of defoamer. The invention further discloses a preparation method of marbled glass. The preparation method includes directly printing natural marble patterns onto glass, sealing the glass with the finish gloss oil to obtain the marbled glass. The marbled glass has excellent wear resistance and scratch resistance capacity, good hydrophobic and antifouling performance, good weather fastness, high color saturation and fine and beautiful patterns, and can be used for long time.

Owner:东莞市尚艺玻璃制品有限公司

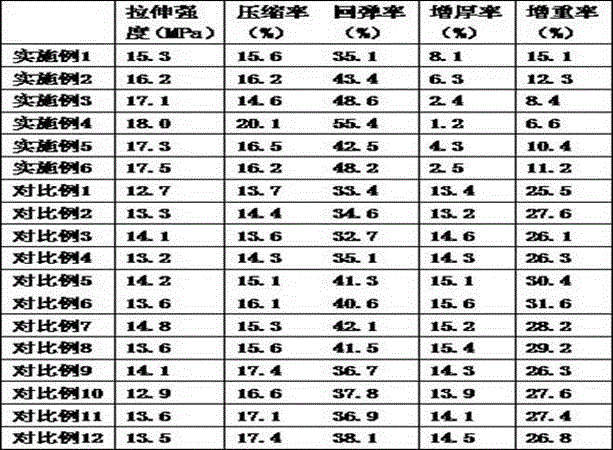

Antifreeze liquid resisting water pump gasket and preparation method of antifreeze liquid resisting water pump gasket

ActiveCN106750669AAchieve strengthImprove mechanical propertiesEngine sealsCoatingsFiberUltimate tensile strength

The invention relates to an antifreeze liquid resisting water pump gasket and a preparation method of the antifreeze liquid resisting water pump gasket. The antifreeze liquid resisting water pump gasket is prepared from a main material and an auxiliary material in parts by weight and is prepared from the following components in parts by weight: 100 parts of the main material, 3 to 15 parts of mica powder, 20 to 30 parts of kaolin, 10 to 20 parts of talcum powder and 5 to 10 parts of a coloring agent; the main material is prepared from an antifreeze liquid resisting hydroxyl silicone oil substance, butadiene styrene rubber and fibers at the mass ratio of (3 to 5) to 40 to (55 to 57); the antifreeze liquid resisting hydroxyl silicone oil substance is prepared from the following components in parts by weight: 30 to 40 parts of hydroxyl silicone oil, 2.5 to 3 parts of a vulcanizing agent, 2 to 3 parts of a vulcanizing accelerant and 1 to 3 parts of an anti-ageing agent. By researching antifreeze liquid, antifreeze liquid resisting materials are pertinently selected; all the raw materials have mutual effect through a special process, so that a prepared sealing gasket has good resilience rate, tensile strength and compression ratio, and also has an excellent antifreeze liquid resisting performance; the weight gain of the sealing gasket is less than 20 percent and the thickening rate of the sealing gasket is less than 10 percent within 22h at the temperature of 100 DEG C.

Owner:南阳天一密封股份有限公司

Composite heat conductive material for LEDs

InactiveCN105086461AReduce surface tensionSmall viscosity-temperature coefficientTemperature coefficientSilicone resin

The invention provides a composite heat conductive material for LEDs. The heat conductive material comprises components in parts by weight as follows: 10-20 parts of organic silicone resin, 10-20 parts of branched silicone oil, 15-25 parts of linear silicone oil, 1-10 parts of an antioxidant, 10-20 parts of graphene, 5-15 parts of nanoscale heat conductive metal fibers, 15-25 parts of an inorganic filling material and 15-25 parts of 95% aluminum oxide ceramic fibers. Filling materials such as the graphene with excellent heat conductivity, mechanical and chemical stability and the like, the nanoscale heat conductive metal fibers and the like are introduced into organic silicone resin which is low in surface tension, low in viscosity-temperature coefficient, high in compressibility and high in gas permeability and the branched silicone oil which is long in service life, free of sun crack and hardening and good in heat conduction effect, all the components are matched scientifically and reasonably, and the prepared composite heat conductive material is excellent in aging performance, stable in property, good in heat resistance, good in heat conductivity and particularly applicable to LED lamps.

Owner:桂林健评环保节能产品开发有限公司

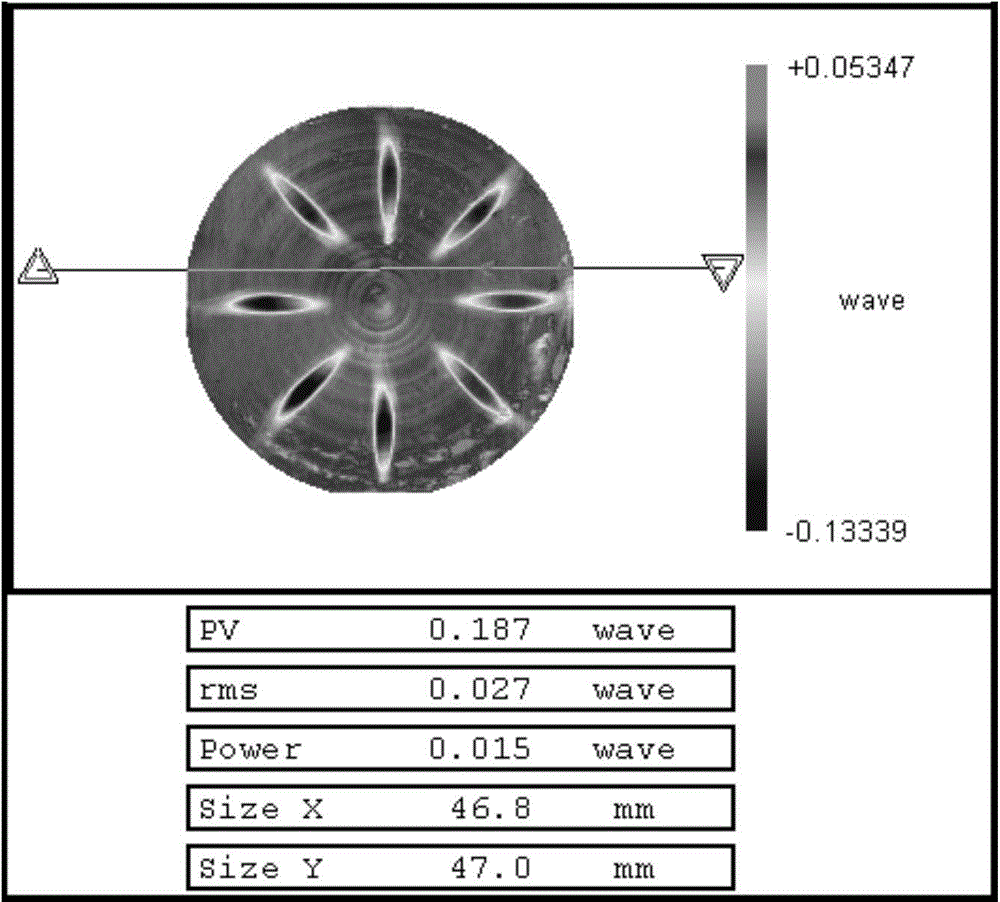

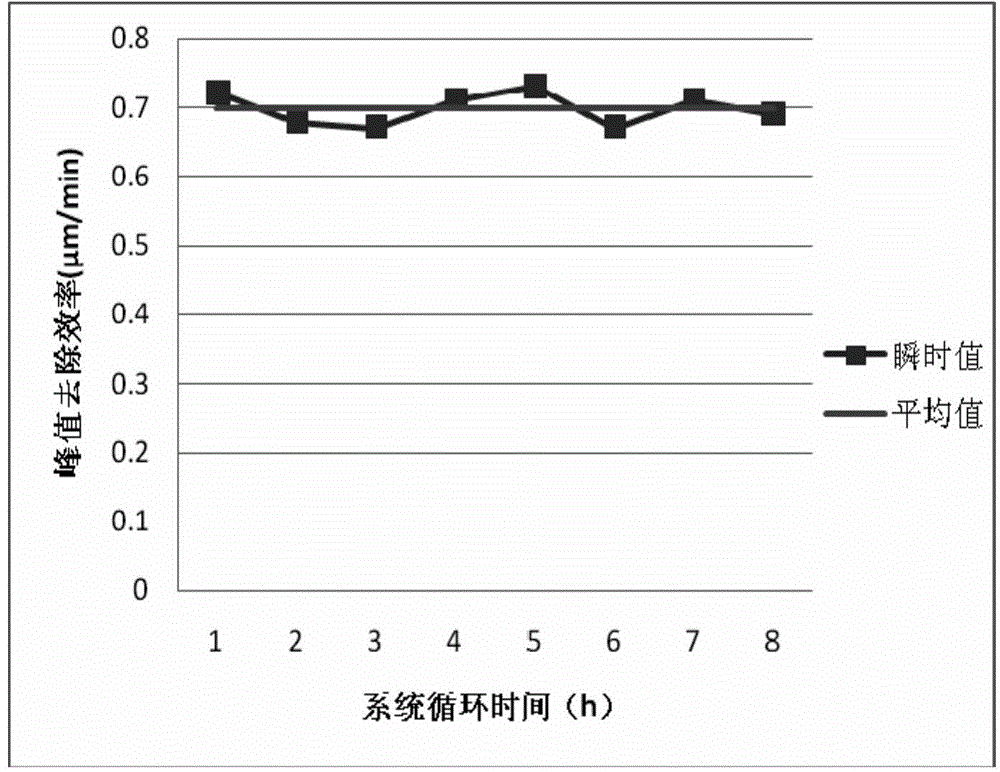

Non-water-based magnetorheological polishing solution and preparation method thereof

ActiveCN104017503ALow magnetic field viscosityImprove rheologyPolishing compositions with abrasivesWater basedAlcohol

The invention discloses a non-water-based magnetorheological polishing solution and a preparation method thereof. The non-water-based magnetorheological polishing solution comprises the following components in percentage by mass: 30-60% of alkoxy alcohol, 30-60% of magnetic-sensitive particle, 3-8% of surfactant and 3-6% of deionized water. The preparation method comprises the following steps: (1) weighing the alkoxy alcohol, magnetic-sensitive particle, surfactant and deionized water; (2) heating the alkoxy alcohol, mixing with the surfactant to form a compound solution, and adding the magnetic-sensitive particle to obtain a mixed solution; and (3) pouring the mixed solution into a ball milling tank, carrying out ball milling, adding deionized water, and carrying out ball milling to obtain the non-water-based magnetorheological polishing solution. The non-water-based magnetorheological polishing solution has the advantages of low zero magnetic field viscosity, favorable rheological behavior, high long-term stability, no precipitation and no caking; and the preparation method is simple and convenient, and is low in cost.

Owner:NAT UNIV OF DEFENSE TECH

Waterproof material for toilet and preparation method of waterproof material

The invention discloses a waterproof material for a toilet and a preparation method of the waterproof material and relates to the technical field of waterproof materials. The waterproof material comprises the following raw materials in parts: 70-80 parts of modified starch, 55-65 parts of inorganic powder fillers, 45-50 parts of cis-1,4-polyisoprene rubber, 35-40 parts of aluminum stearate, 30-35 parts of fly ash, 25-30 parts of nano particles, 15-25 parts of organic fibers, 15-20 parts of dimethyl silicone, 10-15 parts of aids, 5-10 parts of pigments and 120-150 parts of water. The waterproof material disclosed by the invention has excellent waterproof, anti-permeability and antibacterial and anti-mold properties, the raw materials are environmental-friendly and high in affinity, water leakage in the toilet can be effectively prevented, and the waterproof material is difficult to age.

Owner:HEFEI FENGTENG ENERGY SAVING TECH CO LTD

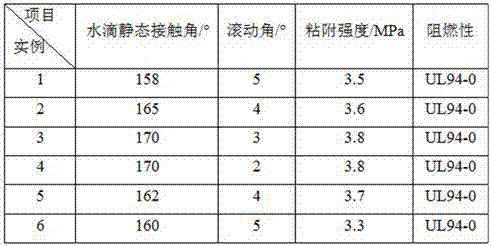

Improving process for hydrophobicity of external insulation of power equipment

InactiveCN107365536AGood high and low temperature resistanceImprove wear resistanceCoatingsThermal insulationEngineering

The invention belongs to the technical field of power and particularly relates to an improving process for the hydrophobicity of external insulation of power equipment. The improving process comprises the following steps: (1) roughening the surface of the power equipment; (2) preparing a viscous solution from 15-20 parts of fluoroethylenepropylene, 10-15 parts of vinyl-terminated silicon oil, 5-10 parts of dimethyl silicon oil, 5-10 parts of polyetheretherketone and 20-60 parts of a diluent, pouring a solution film with the thickness of 300-800mu m on the surface of the power equipment, and then, carrying out vacuum defoamation; (3) uniformly scattering 10-30 parts of hydrophobic nanopowder on the surface of the solution film in the step (2) by a sieve, keeping the scattering for 20-26h, and then, carrying out baking at 80-150 DEG C for 2-6h to form a film; and (4) removing residual powder on the surface of the film in the step (3) by flushing with clear water, and drying the film. The improving process disclosed by the invention is low in cost, safe and convenient to operate and high in adhesion strength of the film on the outer edge of the equipment and a substrate.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY

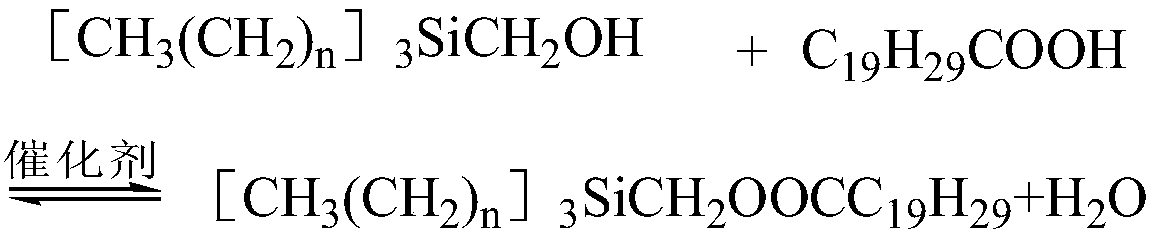

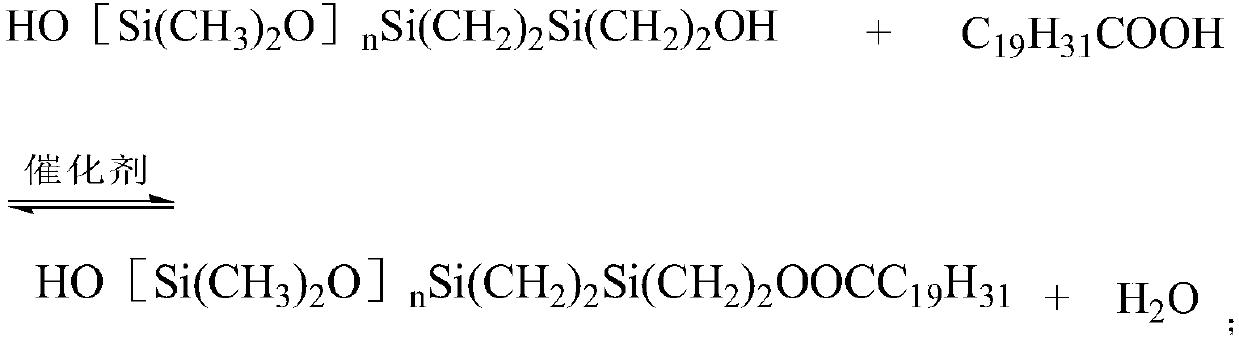

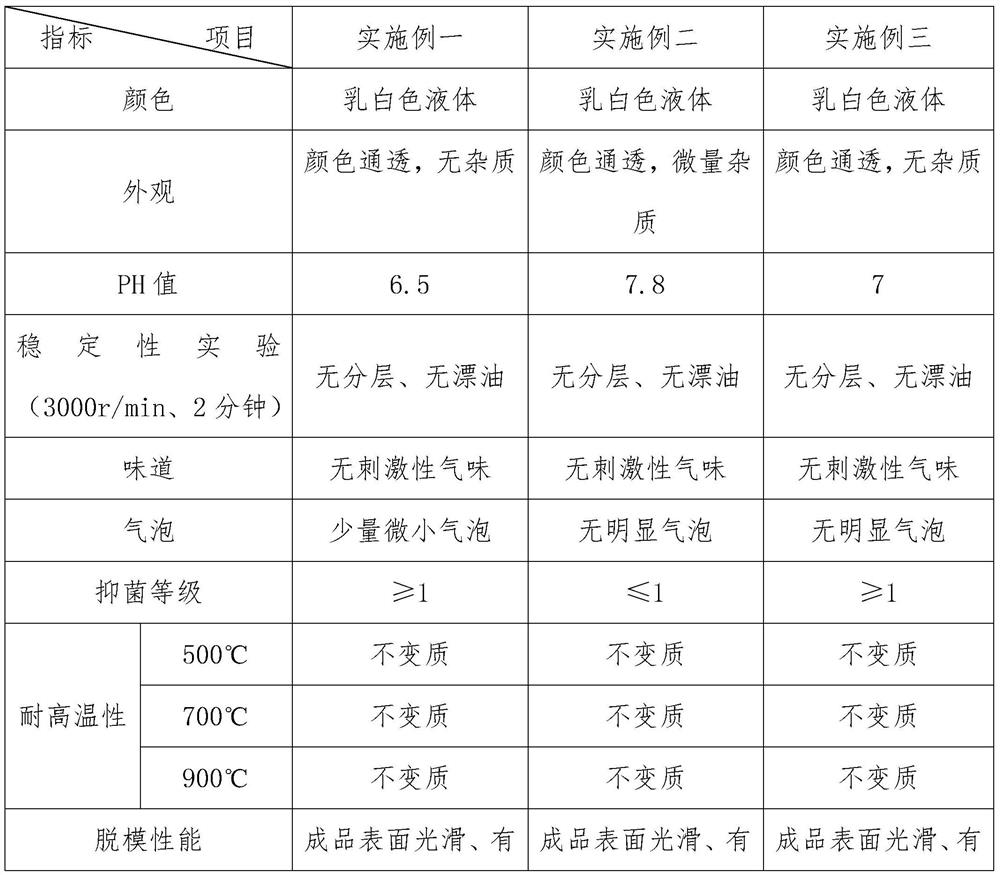

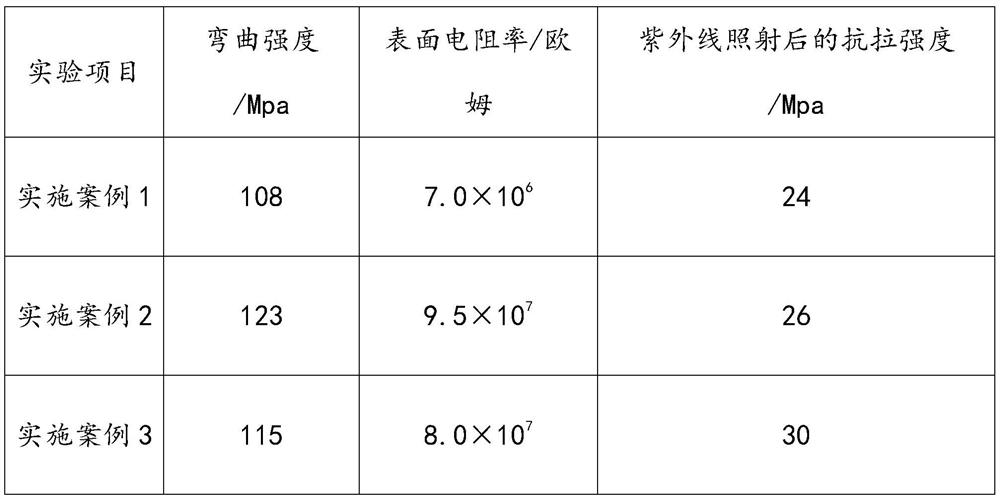

Organosilicon microemulsion antisticking agent and preparation method thereof

InactiveCN101406928BSolution to short lifeHigh particleFoundry mouldsFoundry coresSilanesFatty alcohol

Owner:武汉亿强科技开发股份有限公司

Tackifying resin and preparation method and application thereof

ActiveCN109627984AReduce surface tensionSmall viscosity-temperature coefficientNatural resin chemical modificationRosin adhesivesSurface energyRosin

The invention provides tackifying resin. The tackifying resin is characterized by being prepared from, by weight, 100 parts of rosin resin, 0.1-80 parts of hydroxyl silane, 0-50 parts of alcohol, 0.2-0.4 part of a catalyst and 0.3-0.6 part of an antioxidant. The invention further provides a preparation method and application of the tackifying resin. The preparation method includes the following steps that 1, the raw materials are weighed; 2, the rosin resin is smashed, the antioxidant is added, stirring is conducted to dissolve the rosin resin, and heating is conducted until the rosin resin iscompletely dissolved; 3, the catalyst is added and disperses for 5 minutes, and then alcohol is added to react for 30 minutes; 4, hydroxyl silane is added dropwise to start esterification reaction; 5, when no water is discharged any more, vacuum decompression is conducted to distill off fractions with low boiling points; 6, cooling is conducted to discharge the tackifying resin. The tackifying resin has excellent bonding performance for materials with low surface energy, can independently serve as hot melt adhesive resin, can also be added into other hot melt adhesive systems to serve as a tackifying agent to be in mixed usage and can serve as a compatilizer in the hot melt adhesive systems.

Owner:广东省邦得利新材料技术有限公司

Silicon oil for torsional vibration damper of internal combustion engine

InactiveCN109578511AWell mixedEasy to useVibration suppression adjustmentsExternal combustion engineTorsional vibration

The invention discloses silicon oil for a torsional vibration damper of an internal combustion engine. The silicon oil for the torsional vibration damper of the internal combustion engine is characterized in that methyl silicone oil and ferric acetylacetonate are mixed and stirred to form the silicon oil, and the mass fraction of the ferric acetylacetonate is 0.1-0.3% of the methyl silicone oil. The silicon oil has the advantages that the ferric acetylacetonate with the specific mass fraction is added into the methyl silicone oil and is uniformly mixed, compared with a methyl silicone oil which is not add the ferric acetylacetonate components, the gelatinization temperature of the methyl silicon oil added with the ferric acetylacetonate and the methyl silicon oil not added with the ferricacetylacetonate is measured, a gel is generated at the temperature of 250 DEG C for 10 hours in the prior art, the methyl silicone oil mixed solution with 0.1%-0.3% of the ferric acetylacetonate of the invention is added, gelation does not occur yet after 60 days * 24 = 1440 hours at the temperature of 250 DEG C, when the mass percent of the doped ferric acetylacetonate is changed between 0.1-0.3%, the viscosity-temperature coefficient changes between 0.61-0.62, the viscosity-temperature coefficient is basically the same as that of the methyl silicone oil, and the silicon oil is completely suitable for a torsional vibration damper product of the internal combustion engine.

Owner:NINGBO SEDSUN VIBRATION DAMPER CO LTD

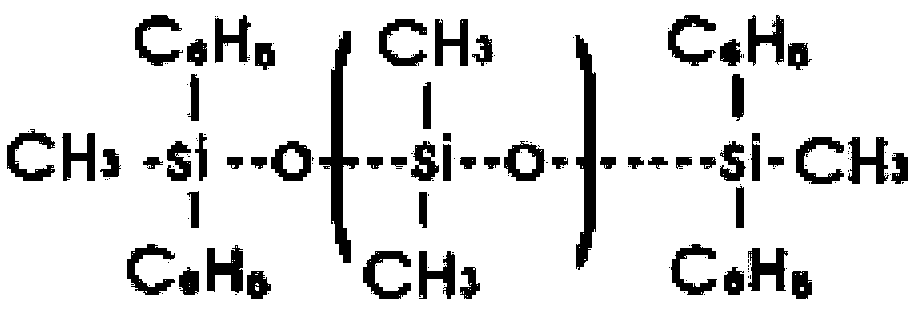

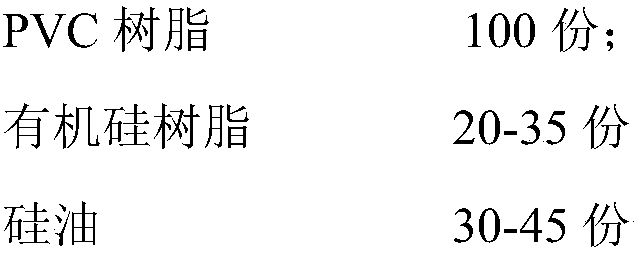

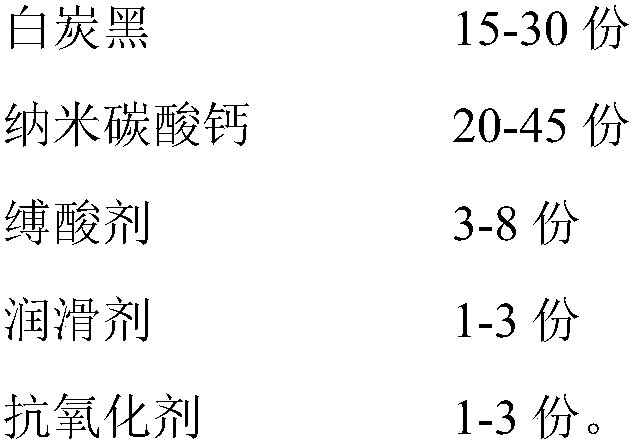

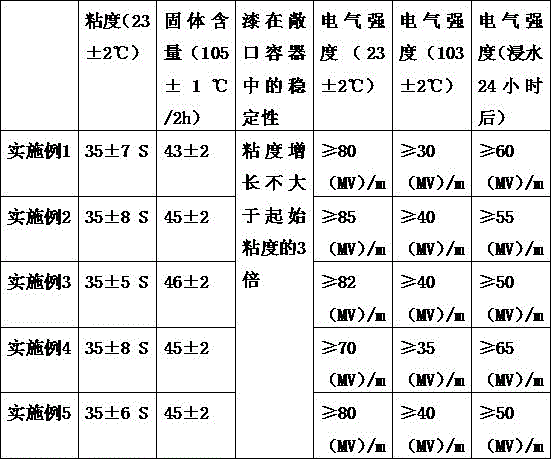

Low temperature-resistant PVC (Polyvinyl Chloride) cable material

InactiveCN108707298AWith high and low temperature resistanceWith electrical insulationPlastic/resin/waxes insulatorsAntioxidantPolyvinyl chloride

The invention relates to a cable material, in particular to a low temperature-resistant PVC (Polyvinyl Chloride) cable material and a preparation method thereof. The low temperature-resistant PVC cable material is prepared from the following components in parts by weight: 100 parts of PVC resin, 20 to 35 parts of organosilicone resin, 30 to 45 parts of silicone oil, 15 to 30 parts of white carbonblack, 20 to 45 parts of nano calcium carbonate, 3 to 8 parts of acid-binding agent, 1 to 3 parts of lubricating agent and 1 to 3 parts of antioxidant. The low temperature-resistant PVC cable materialdisclosed by the invention has the following beneficial effects that (1) through a plasticizing effect of the organosilicone resin and the silicone oil, low temperature resistance of the low temperature-resistant PVC cable material can be effectively improved; (2) a formula and a preparation technology of the low temperature-resistant PVC cable material are simple, are low in cost, are capable ofproducing without changing existing equipment and are suitable for large-scale production; (3) the obtained low temperature-resistant PVC cable material also is good in mechanical property, weather fastness and flame resistance.

Owner:ZHEJIANG WELLSCOM PLASTIC CO LTD

New radiation-proof material

The invention relates to a new radiation-proof material. The new radiation-proof material is used to make a TV main board and / or a power board, the TV main board and / or the power board comprises a radiation-proof layer, a bonding layer and a heat dissipation layer in order from inside to outside, and the radiation-proof layer is pasted with the heat dissipation layer into one through the bonding layer. The chemical composition of the radiation-proof layer is: polyvinyl chloride; organosilicon; cis-polybutadiene; silk fiber; a waterborne acrylic emulsion; silver powder; a compatibilizer; a plasticizer; a thermal stabilizer; and an antioxidant, wherein a mass ratio of polyvinyl chloride to the silk fiber to the silver powder is 5-9:1:1-1.5, the antioxidant is a mixture of zinc dialkyl dithiophosphate and zinc dialkyl dithiocarbamate mixed according to 1:1, and a mass ratio of the organosilicon to the cis-polybutadiene to the waterborne acrylic emulsion is 1:1:0.8. The new radiation-proofmaterial can effectively prevent electromagnetic wave radiation, can avoid an excessive thickness of the TV main board and the power board, and at the same time can ensure the strength, so that the performance of the TV main board and the power board is greatly improved.

Owner:苏州韵之秋智能科技有限公司

Alkyd paint with excellent yellowing resistance and preparation method of alkyd paint

InactiveCN106634489APromote oxidationPromote aggregationFireproof paintsPolyester coatingsAntioxidantViscosity

The invention discloses alkyd paint with excellent yellowing resistance and a preparation method of the alkyd paint. The alkyd paint is prepared from the following components in percentage by mass: 55-65% of alkyd resins, 1-5% of pigments, 1-3% of fillers, 0.5-1.5% of aids, 0.5-1.5% of a catalyst, 0.05-0.25% of a wetting agent, 0.05-0.25% of an anti-skining agent, 1.5-3.5% of antioxidant and 25-35% of a solvent. The preparation method comprises the following steps: adding alkyd resins into a mixer, stirring, adding aids, pigments, an antioxidant and fillers, stirring for 20-30 minutes, adding one of the solvents so as to obtain a mixture; adding the mixture into a grinding machine for grinding; adding a dryer, the wetting agent and the anti-skining agent into the ground mixture, stirring for 20-30 minutes, adding the residual solvents for adjusting the viscosity, stirring for 20-30 minutes, and packaging after detection qualification, so as to obtain the product. The alkyd paint disclosed by the invention has the advantages of high yellowing resistance, excellent overall performance and the like.

Owner:安徽凤凰涂料科技有限公司

Formula of negative ion antibacterial antimite sponge

The invention discloses a formula of a negative ion antibacterial antimite sponge, the negative ion antibacterial antimite sponge is prepared from the following raw materials: 85-90% of a sponge solution, 6-7% of an antibacterial agent, 2-6% of negative ion powder and 1-3% of a blowing promoter, the sponge solution is prepared from the following raw materials: 5-10% of silicone oil, 75-80% of polyester resin, 3-10% of fiber and 2-5% of a resin binder, The negative ions are confirmed to be an effective means for purifying air during use of thenegative ion antibacterial antimite sponge , and the antibacterial agent has the functions of killing germs and preventing bacteria breeding, so that the sponge has the effects of promoting metabolism of a human body, improving the immunity of the human body, enhancing the muscle energy of the human body, regulating the functional balance of the human body, resisting bacteria and preventing mite breeding; and the silicone oil has heat resistance, electrical insulating property, weather resistance, hydrophobicity, physiological inertia and small surface tension, so that the surface of the sponge prepared according to the formula is smoother, the pore diameter of bubbles in the sponge is reduced, and the elasticity of the sponge is better.

Owner:佛山市爱思诺家具有限公司 +1

Microemulsion demolding brightener

PendingCN114480004AGood release effectPrevent spoilageLubricant compositionActive agentSurface-active agents

The invention discloses a microemulsion demolding brightener, and aims to solve the technical problems that in the prior art, oil stains and oxidized and unoxidized surface impurities remaining on the surface of a mold cannot be removed, the glossiness of the mold cannot be maintained, burrs exist on the surface of a finished product, and the texture of the finished product is reduced. The demolding brightener comprises the following components in parts by weight: 50 to 200 parts of paraffin, 100 to 200 parts of silicone oil, 50 to 80 parts of an emulsifier, 100 to 150 parts of borax, 200 to 300 parts of glass powder, 70 to 150 parts of a surfactant, 10 to 30 parts of an alkaline agent, 10 to 30 parts of ethylparaben, 60 to 100 parts of deionized water, 30 to 50 parts of a defoaming agent, 100 to 200 parts of a mixed copolymer, 50 to 100 parts of polymerized olefin, 80 to 160 parts of saccharin sodium salt, 30 to 60 parts of ethoxylated butynediol and 30 to 60 parts of copper sulfate. And 10-30 parts of sodium dodecyl benzene sulfate. The demolding brightener adopts the silicone oil and the paraffin as main materials, so that the demolding brightener has a better demolding effect, the glossiness of a finished product is ensured, the demolding brightener is prevented from going bad, the scratch resistance of the demolding brightener is improved, and bubbles in the demolding brightener are effectively reduced.

Owner:马鞍山中集瑞江润滑油有限公司

High-strength wear-resistant composite packaging material and preparation method thereof

The invention relates to the technical field of packaging materials, in particular to a high-strength wear-resistant composite packaging material and a preparation method thereof. The high-strength wear-resistant composite packaging material is prepared from, by weight, 80-120 parts of chlorinated butyl rubber, 60-80 parts of polyvinyl chloride resin, 20-40 parts of carbon nanofibers, 4-8 parts of graphene, 8-12 parts of glass fibers, 18-22 parts of carbon fibers, 16-20 parts of ultra-high molecular weight polyethylene fibers, 3-9 parts of plasticizer, 4-8 parts of methyl silicone oil. 8-12 parts of bamboo fiber, 4-8 parts of a compatibilizer. Through the carbon nanofibers, the glass fibers, the carbon fibers and the ultra-high molecular weight polyethylene fibers, the strength, the stability and the wear resistance of the composite packaging material can be relatively high; and through the methyl silicone oil and the bamboo fibers, the composite packaging material has excellent heat resistance, electrical insulating property, weather resistance, hydrophobicity, physiological inertness and small surface tension, and also has a low viscosity-temperature coefficient and high compression resistance, so that the overall using effect is better.

Owner:上海方乾科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com