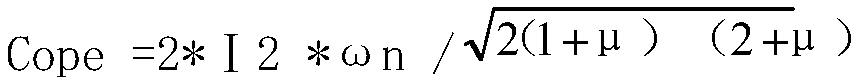

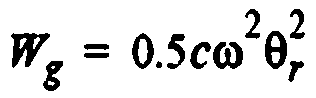

Silicon oil for torsional vibration damper of internal combustion engine

A technology for torsional vibration dampers and internal combustion engines, applied in springs/shock absorbers, mechanical equipment, vibration suppression adjustment, etc., can solve problems such as the unsuitability of methylphenyl silicone oil, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

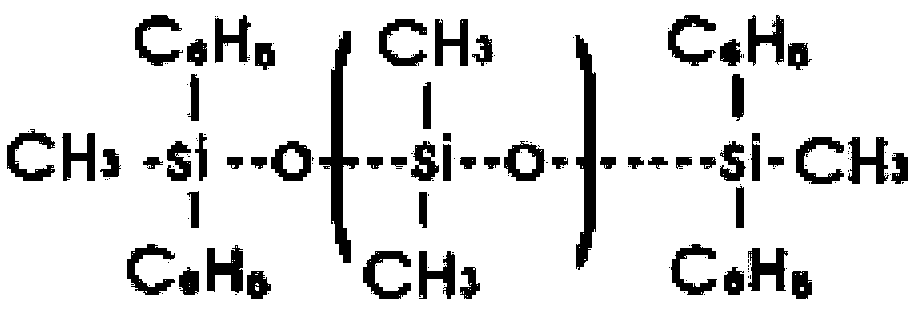

[0049] Embodiment one: a kind of silicone oil that is used for internal combustion engine torsional vibration damper, is formed after mixing and stirring by methyl silicone oil and iron triacetylacetonate, and its molecular formula is [(CH3)2SiO]n. The structural formula is

[0050]

[0051] The number of n-series polysiloxane chains, iron triacetylacetonate is metal ion ferric iron and ferrous iron and organic group acetylacetonate ion CH 3 -CO-CH--CO-CH 3 Combined organic iron compound, molecular formula: C15H21FeO6, molecular weight: 353.1686, melting point 184°C, molecular structure formula:

[0052]

[0053] The iron triacetylacetonate is 0.1%-0.3% of the methyl silicone oil by mass fraction. Its performance is shown in the table below:

[0054]

[0055] It can be seen from the above table that the silicone oil of the present invention has not been gelled at 250°C for 60 days X24=1440 hours, the minimum gel temperature has reached 460°C, and the viscosity-temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com