High-strength wear-resistant composite packaging material and preparation method thereof

A composite packaging material, high-strength technology, applied in the field of packaging materials, can solve the problems of heat resistance, electrical insulation and weather resistance, poor compression resistance, wear resistance and antistatic properties, etc., to achieve excellent heat resistance, high Compression resistance, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

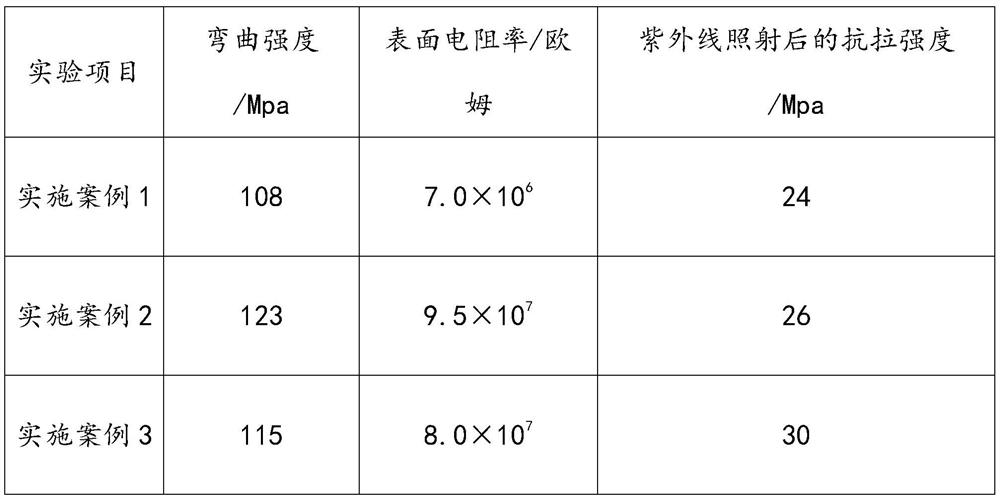

Examples

preparation example Construction

[0021] A high-strength wear-resistant composite packaging material and a preparation method thereof, comprising the following raw materials in parts by weight: 80-120 parts of chlorinated butyl rubber, 60-80 parts of polyvinyl chloride resin, 20-40 parts of nano-carbon fiber, graphene 4-8 parts, glass fiber 8-12 parts, carbon fiber 18-22 parts, ultra-high molecular weight polyethylene fiber 16-20 parts, plasticizer 3-9 parts, methyl silicone oil 4-8 parts, bamboo fiber 8-12 parts parts, compatibilizer 4 to 8 parts.

[0022] The plasticizer is acetyl tributyl citrate.

[0023] The compatibilizer is maleic anhydride.

[0024] 80 parts of chlorinated butyl rubber, 60 parts of polyvinyl chloride resin, 20 parts of nano-carbon fiber, 4 parts of graphene, 8 parts of glass fiber, 18 parts of carbon fiber, 16 parts of ultra-high molecular weight polyethylene fiber, 3 parts of plasticizer, and 4 parts of base silicone oil, 8 parts of bamboo fiber, 4 parts of compatibilizer.

[0025]...

Embodiment 1

[0033] Embodiment 1: take each raw material component according to weight and number ratio: 80 parts of chlorinated butyl rubber, 60 parts of polyvinyl chloride resins, 20 parts of carbon nanofibers, 4 parts of graphene, 8 parts of glass fibers, 18 parts of carbon fibers, 16 parts of ultra-high molecular weight polyethylene fiber, 4 parts of methyl silicone oil, and 8 parts of bamboo fiber. Put the weighed raw materials into the reactor for mixing and stirring. The speed is 300-500r / min, and the heating temperature is 100-130 ℃, stirring for 15-25min; then 3 parts of acetyl tributyl citrate as the plasticizer and 4 parts of maleic anhydride as the compatibilizer are successively added into the reaction kettle at a temperature of 160-180 °C and a speed of 450-500r / min, stirring for 25-30 minutes to obtain a composite mixture; extrude the composite mixture through a twin-screw extruder, the head temperature of the twin-screw extruder is 250-260°C, the barrel temperature is 230-2...

Embodiment 2

[0034] Embodiment 2: take each raw material component according to the ratio of parts by weight: 100 parts of chlorinated butyl rubber, 70 parts of polyvinyl chloride resin, 30 parts of carbon nanofibers, 6 parts of graphene, 10 parts of glass fibers, 20 parts of carbon fibers, 18 parts of ultra-high molecular weight polyethylene fiber, 6 parts of methyl silicone oil, and 10 parts of bamboo fiber; put the weighed raw materials into the reactor for mixing and stirring, the speed is 300-500r / min, and the heating temperature is 100-130 ℃, stirring for 15-25 minutes; then 6 parts of acetyl tributyl citrate as the plasticizer and 6 parts of maleic anhydride as the compatibilizer are successively added into the reaction kettle at a temperature of 160-180 °C and a rotation speed of 450-500r / min, stirring for 25-30 minutes to obtain a composite mixture; extrude the composite mixture through a twin-screw extruder, the head temperature of the twin-screw extruder is 250-260°C, the barrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com