Production technology of medical fabric

A production process and fabric technology, which is applied in pharmaceutical formulations, coatings, textiles and papermaking, etc., can solve the problems of high fabric cost, unsuitable for medical fabrics, poor decontamination, etc., and achieve soft hand feeling, good resistance to hydrostatic pressure, The effect of low surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in further detail below in conjunction with specific embodiments.

[0027] The invention discloses a production process of medical fabric, which comprises the following steps:

[0028] 1. Gray cloth weaving, select low-denier nylon yarn material, and weave on the loom. In this embodiment, 20-70 denier fully stretched cotton fiber 66 yarn material (single filament meeting 4G / D) is selected. The weave is designed as a plaid cloth with a warp and weft density of 145*132 and a width of 63 inches, which is woven on a loom. The weave design considers plaid, double-grid or multi-line plaid with 2 or 3 grid sides, or dobby-style prismatic fabric. Using this kind of weave design can improve the tear resistance and overall strength of the fabric .

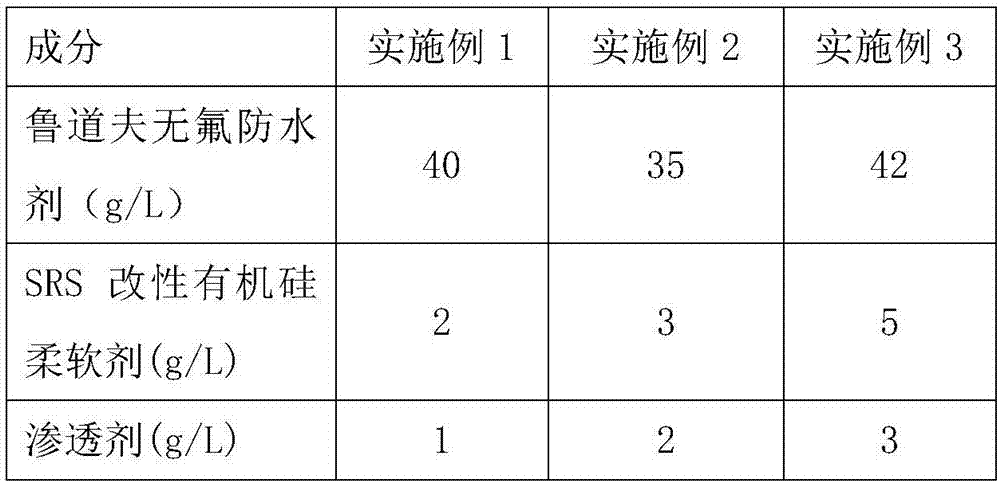

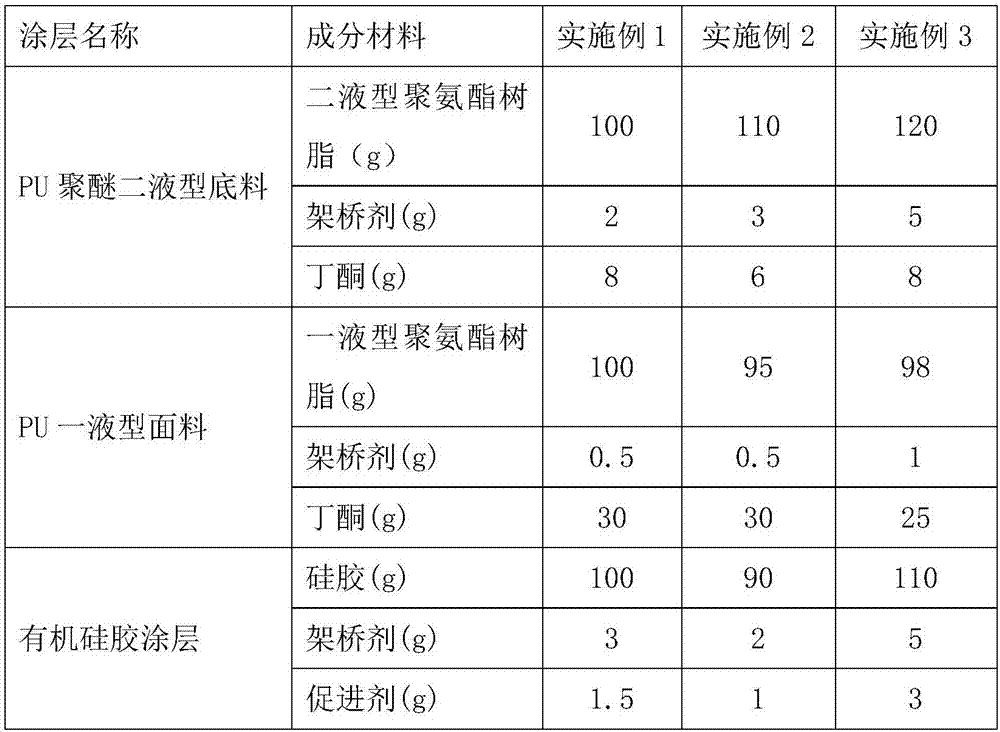

[0029] 2. Desizing, desizing the woven gray fabric on the desizing machine, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com