Microemulsion demolding brightener

A brightener and mold release technology, applied in lubricating compositions, petroleum industry, etc., can solve problems such as inability to remove mold oil stains, oxidized and unoxidized surface impurities, inability to maintain mold gloss, and burrs on the surface of finished products. Improved scratch resistance, high compression resistance, reduced air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

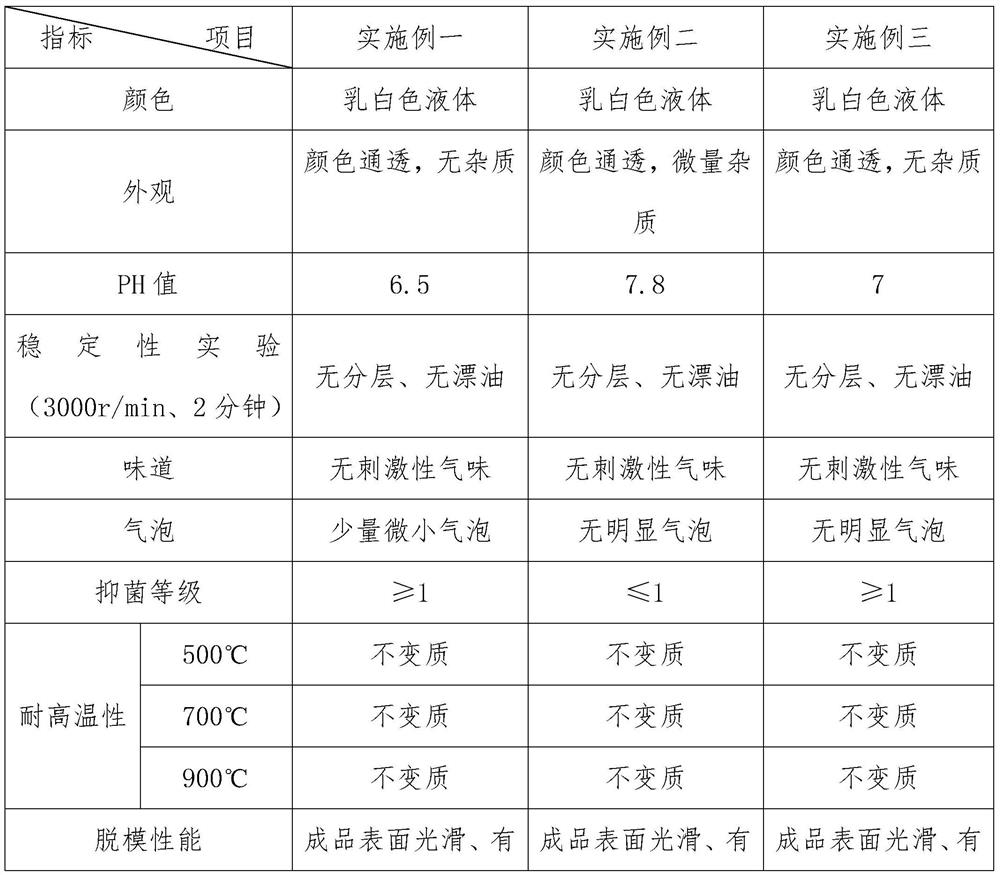

Embodiment 1

[0024] This specific embodiment is a microemulsion release brightener, which includes the following components by weight: 150 parts of paraffin, 100 parts of silicone oil, 50 parts of emulsifier, 130 parts of borax, 200 parts of glass powder, and surfactant 80 parts, 10 parts of alkali agent, 30 parts of ethyl paraben, 80 parts of deionized water, 30 parts of defoamer, 120 parts of mixed copolymer, 80 parts of polymerized olefin, 160 parts of sodium saccharin, ethoxylated butynediol 50 parts, copper sulfate 50 parts, sodium dodecylbenzene sulfate 10 parts.

[0025] Further, the mixed copolymer contains 2 parts by weight of pentaerythritol, 6 parts by weight of stearic acid, 2 parts by weight of acrylic acid, and 3 parts by weight of maleic anhydride.

[0026] Further, the alkaline agent is sodium hydroxide, potassium hydroxide, ammonium hydroxide, sodium carbonate, sodium phosphate, sodium orthosilicate, sodium silicate, sodium hydroxide-sodium orthosilicate, sodium hydroxide-...

Embodiment 2

[0037]This particular embodiment is a microemulsion release brightener, which includes the following components by weight: 180 parts of paraffin, 120 parts of silicone oil, 80 parts of emulsifier, 120 parts of borax, 250 parts of glass powder, surfactant 100 parts, 10 parts of alkali agent, 10 parts of ethyl paraben, 60 parts of deionized water, 40 parts of defoamer, 150 parts of mixed copolymer, 50 parts of polymerized olefin, 120 parts of sodium saccharin, ethoxylated butynediol 60 parts, 40 parts of copper sulfate, 20 parts of sodium dodecylbenzene sulfate.

[0038] Further, the mixed copolymer contains 1 part by weight of pentaerythritol, 3 parts by weight of stearic acid, 3 parts by weight of acrylic acid, and 2 parts by weight of maleic anhydride.

[0039] Further, the alkaline agent is sodium hydroxide, potassium hydroxide, ammonium hydroxide, sodium carbonate, sodium phosphate, sodium orthosilicate, sodium silicate, sodium hydroxide-sodium orthosilicate, sodium hydroxi...

Embodiment 3

[0050] This specific embodiment is a microemulsion release brightener, which includes the following components by weight: 180 parts of paraffin, 180 parts of silicone oil, 80 parts of emulsifier, 130 parts of borax, 220 parts of glass powder, surfactant 130 parts, 15 parts of alkaline agent, 15 parts of ethyl paraben, 100 parts of deionized water, 40 parts of defoamer, 150 parts of mixed copolymer, 90 parts of polymerized olefin, 130 parts of sodium saccharin, ethoxylated butynediol 50 parts, copper sulfate 40 parts, sodium dodecylbenzene sulfate 20 parts.

[0051] Further, the mixed copolymer contains 2 parts by weight of pentaerythritol, 6 parts by weight of stearic acid, 2 parts by weight of acrylic acid, and 3 parts by weight of maleic anhydride.

[0052] Further, the alkaline agent is sodium hydroxide, potassium hydroxide, ammonium hydroxide, sodium carbonate, sodium phosphate, sodium orthosilicate, sodium silicate, sodium hydroxide-sodium orthosilicate, sodium hydroxide-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com