True tri-axial hydraulic fracture test machine and test method

A hydraulic fracturing and true triaxial technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of inconvenient maintenance, broken deformation, large triaxial pressure difference, etc., to achieve The effect of low physiological inertia, high compression resistance, and low viscosity-temperature coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

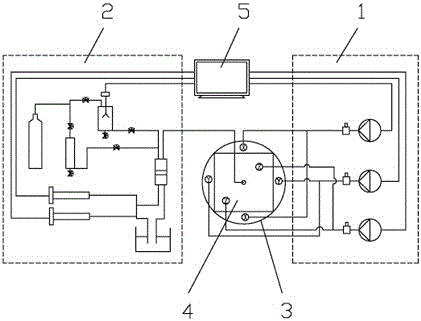

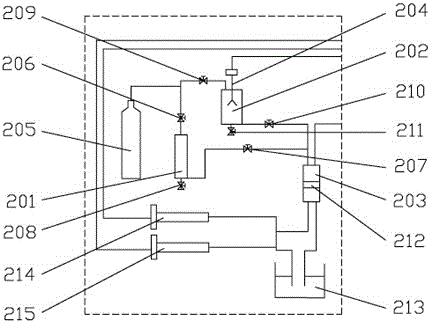

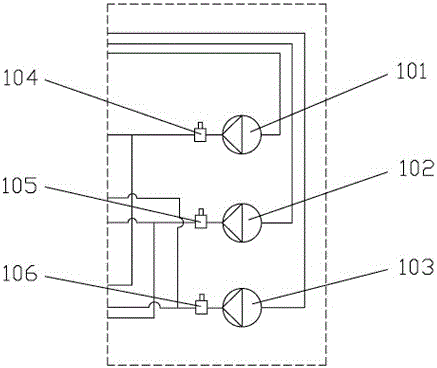

[0051] Such as figure 1 As shown, according to an embodiment of the true triaxial hydraulic fracturing testing machine of the present invention, it includes a confining pressure system 1, an injection system 2 and a true triaxial test frame 3, the confining pressure system 1 and the injection system 2 Connected with the true triaxial test frame 3, the downhole core 4 is placed in the true triaxial test frame 3; the injection system 2 and the confining pressure system 1 are connected with a computer 5, and the injection system 2 includes fracturing A fluid container I 201 , a fracturing fluid container II 202 and a piston container 203 . The fracturing fluid container II 202 is equipped with a stirring mechanism 204 connected to the computer 5 .

[0052] The fracturing fluid container and the injection container (that is, the piston container) of the true triaxial hydraulic fracturing testing machine of this embodiment are designed separately, which facilitates replacement of f...

Embodiment 2

[0067] According to another embodiment of the true triaxial hydraulic fracturing testing machine of the present invention, its structure, connection relationship between components, working principle and beneficial effects are all the same as those of the first embodiment. Using the testing machine of this embodiment to carry out another embodiment of the true triaxial hydraulic fracturing test method, it includes the following steps in sequence:

[0068] Step 1: Close all switch valves and drain valves, inject clean water and additives into the fracturing fluid container II in a certain proportion, set the stirring time, and start the stirring mechanism to stir to form a uniform fracturing solution;

[0069] Step 2: Open the on-off valve III and the on-off valve IV first, and then open the high-pressure gas cylinder. At this time, the fracturing solution enters the cavity above the piston plate in the piston container;

[0070] Step 3: After all the fracturing solution enters...

Embodiment 3

[0079] According to another embodiment of the true triaxial hydraulic fracturing testing machine of the present invention, its structure, connection relationship between various components, working principle and beneficial effects are the same as those of Embodiment 2, the difference is: the fracturing fluid container The size of the pipeline connected between II and the piston container, and between the piston container and the downhole core should be large enough to ensure the smooth injection of sand-carrying fracturing fluid into the downhole core.

[0080] Using the testing machine of this embodiment to carry out another embodiment of the true triaxial hydraulic fracturing test method, the process steps are the same as in the second embodiment, except that the clear water and additives in step one are replaced with fracturing fluid and proppant . The fracturing fluid and proppant are injected into the fracturing fluid container II according to a certain ratio, the stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com