Method for synthesizing silane modified waterborne polyurethane-acrylic resin

A water-based polyurethane and acrylic resin technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as adhesion, water resistance, solvent resistance, fullness, hardness, wear resistance, and durability that are not as good as oil-based coatings. Good oxidation resistance and weather resistance, improved stability, and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

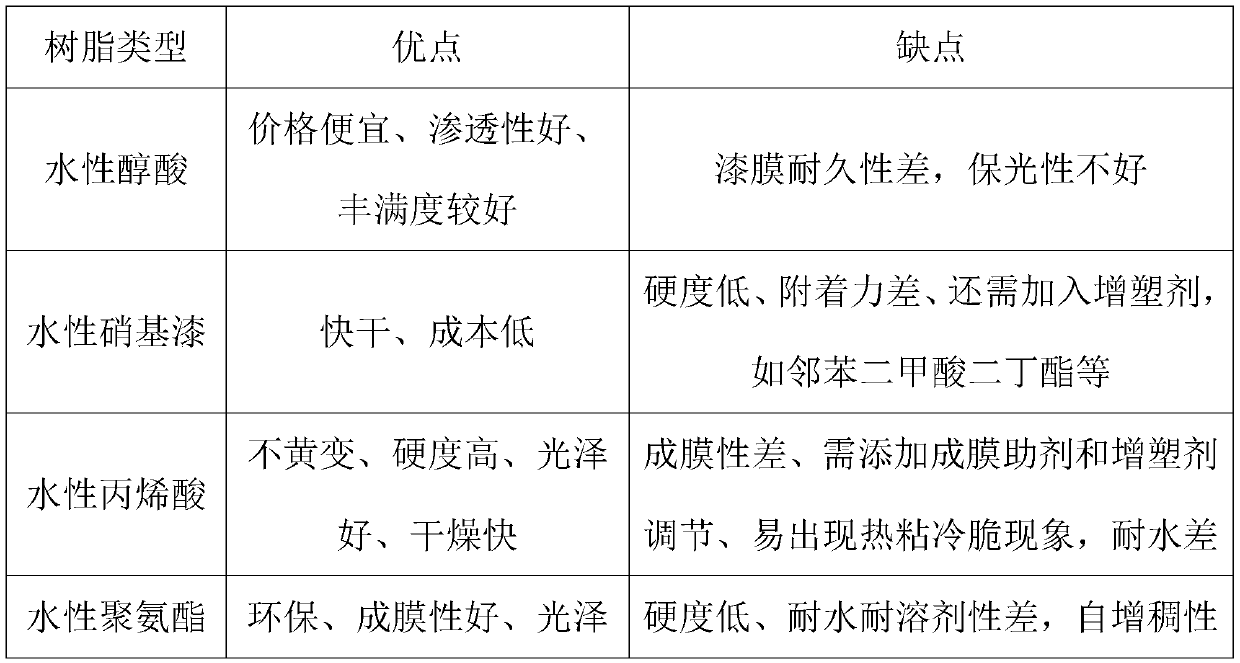

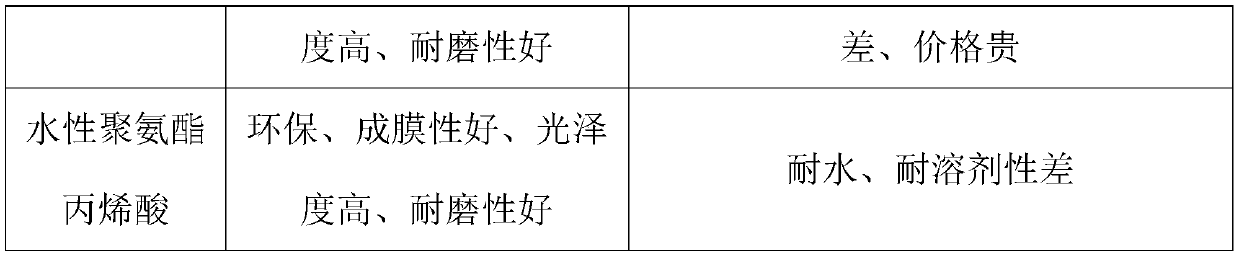

Problems solved by technology

Method used

Image

Examples

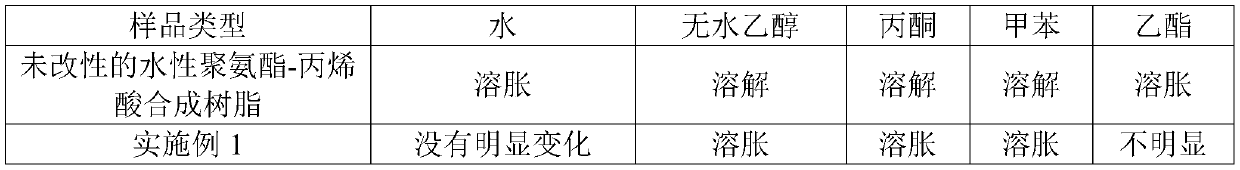

Embodiment 1

[0032] First, add 33g polydibutyl adipate (M=2000), 14g isophorone diisocyanate (IPDI) into the reaction flask for vacuum dehydration, then add 1.5g dimethylol propionic acid (DMPA), and 30g Methyl methacrylate and 8g butyl acrylate, add 0.01g catalyst DBTDL, react at 80°C for 2.5h, then add 4g silane coupling agent γ-aminopropyltriethoxysilane KH-550 for polyurethane modification reaction for 1h , and then add 3g of hydroxyethyl methacrylate for double bond capping, then slowly dropwise add 1.5g of organic amine neutralizer triethanolamine (TEA) to neutralize and form a salt, react for 25min, cool the temperature to 40°C, and stir at a high speed Add water to self-emulsify to obtain a silane-modified PU prepolymer with a double bond as the shell, methyl methacrylate and butyl acrylate as the core, and then raise the temperature to 80°C and add 0.2g of the initiator APS aqueous solution dropwise , and 8g of functional monomer glycidyl methacrylate (GMA), reacted at 80°C for 2h...

Embodiment 2

[0035] First, add 32.5g polydibutyl adipate (M=2000), 12g hexamethylene diisocyanate into the reaction bottle for vacuum dehydration, then add 1.5g hydrophilic chain extender DMPA, and 30g methyl methacrylate And 8g butyl acrylate, add 0.01g catalyst DBTDL, react at 80°C for 2.5h, then add 4g silane coupling agent KH-550 for polyurethane modification reaction for 1h, then add 3g hydroxyethyl methacrylate for double bond capping , then slowly add 1.5g of organic amine neutralizer TEA to neutralize and form salt, react for 25min, cool down to 40°C, add water under high-speed stirring to self-emulsify to obtain a silane-modified PU prepolymer terminated with double bonds. shell, methyl methacrylate and butyl acrylate as the core self-emulsifying body, and then heated to 80 ° C, dropwise added 0.2 g initiator APS aqueous solution, and 8 g functional monomer glycidyl methacrylate (GMA), at 80 React at ℃ for 2 hours, and cool down to obtain silane-modified water-based polyurethane-a...

Embodiment 3

[0038]At first 33g polydibutyl adipate (M=2000), 14g IPDI are added in the reaction flask for vacuum dehydration, then add 0.5g hydrophilic chain extender DMPA, and 30g methyl methacrylate and 8g butyl acrylate, Add 0.01g catalyst DBTDL, react at 80°C for 1h, then add 1.2g sodium 1,2-dihydroxy-3-propanesulfonate for further hydrophilic chain extension for 1.5h, add 4g silane coupling agent KH-550, The mixture of A-174 and Coatosil1757 was subjected to polyurethane modification reaction for 1 hour, then 3g of hydroxyethyl methacrylate was added for double bond capping, and then 1.5g of organic amine neutralizer AMP-95 (2-amino-2 -Methyl isopropanol) to neutralize to form a salt, react for 25 minutes, cool to 40°C, add water under high-speed stirring to self-emulsify to obtain a silane-modified PU prepolymer terminated with a double bond as the shell, methyl methacrylate The self-emulsifying body with butyl acrylate as the core, then heated to 80°C, added dropwise 0.2g of initia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com