Low temperature-resistant PVC (Polyvinyl Chloride) cable material

A cable material, low temperature resistance technology, applied in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of inability to quantitatively determine the low temperature resistance limit, insufficient low temperature resistance performance, complex formula components, etc., and achieve the viscosity temperature coefficient. Small, low surface tension, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

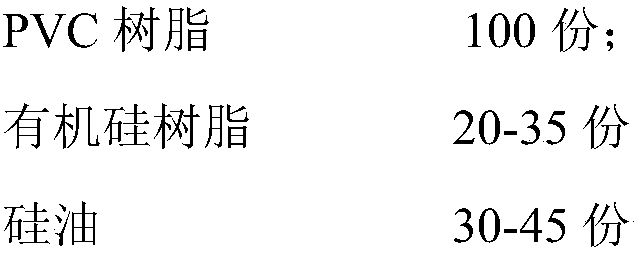

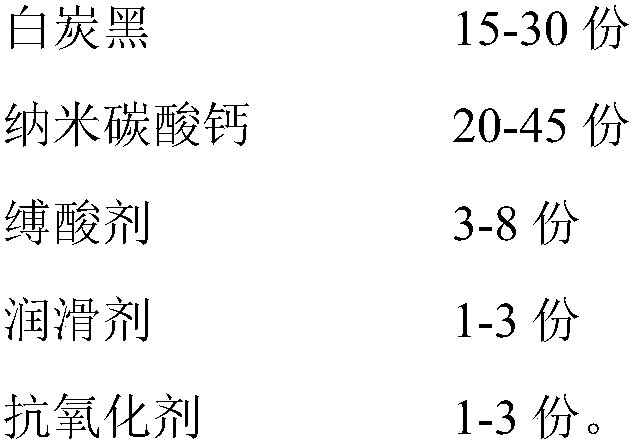

[0039] A low-temperature-resistant PVC cable material, said cable material comprising the following components in parts by weight:

[0040] The PVC resin is 100 parts of a mixture of three different PVC resins with a polymerization degree of 1800-1650, 1650-1500 and 1500-1350 in a mass ratio of 3:5:2; the phenyl content is 350%, and the number-average mole 20 parts of silicone resin with a mass of 1500g / mol; viscosity of 1000mm 2 30 parts of simethicone oil per s; 15 parts of hydrophobic superfine precipitated white carbon black with a particle size of 500nm; 20 parts of nano-calcium carbonate; 3 parts of acid-binding ammonium polyphosphate; 1 part of lubricant magnesium stearate ;Antioxidant bisphenol A 1 part.

Embodiment 2

[0042] A low-temperature-resistant PVC cable material, said cable material comprising the following components in parts by weight:

[0043] The PVC resin is 100 parts of a mixture of three different PVC resins with a polymerization degree of 1800-1650, 1650-1500 and 1500-1350 in a mass ratio of 3:5:2; the phenyl content is 50%, and the number-average mole Quality is 35 parts of silicone resin of 3500g / mol; Viscosity is 1500mm 2 45 parts of long-chain alkyl modified silicone oil per s; 30 parts of hydrophobic superfine precipitated white carbon black with a particle size of 1500nm; 45 parts of nano-calcium carbonate; 8 parts of acid-binding agent diammonium hydrogen phosphate; lubricant stearin Calcium acid 3 parts; Antioxidant CA, 3 parts.

Embodiment 3

[0045] A low-temperature-resistant PVC cable material, said cable material comprising the following components in parts by weight:

[0046] The PVC resin is 100 parts of a mixture of three different PVC resins with a polymerization degree of 1800-1650, 1650-1500 and 1500-1350 in a mass ratio of 3:5:2; the phenyl content is 40%, and the number-average mole Quality is 2500g / mol silicone resin 30 parts; Viscosity is 1200mm 2 35 parts of aminoalkyl silicone oil per s; 20 parts of hydrophobic superfine precipitated white carbon black with a particle size of 1000nm; 30 parts of nanometer calcium carbonate; 4 parts of acid-binding ammonium dihydrogen phosphate; 2 parts of paraffin; 264 parts of antioxidant 2 servings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com