Tackifying resin and preparation method and application thereof

A technology of tackifying resin and rosin resin, applied in chemical modification of natural resin, rosin adhesive, etc., can solve the problems of poor adhesion of surface energy materials, poor water resistance, etc., and achieve low surface tension, cost reduction, viscosity-temperature coefficient small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

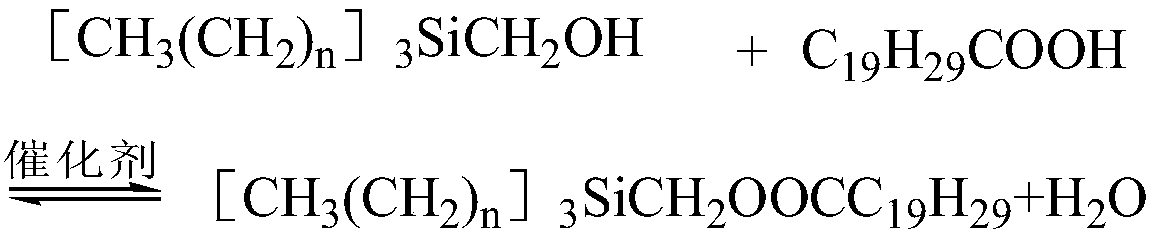

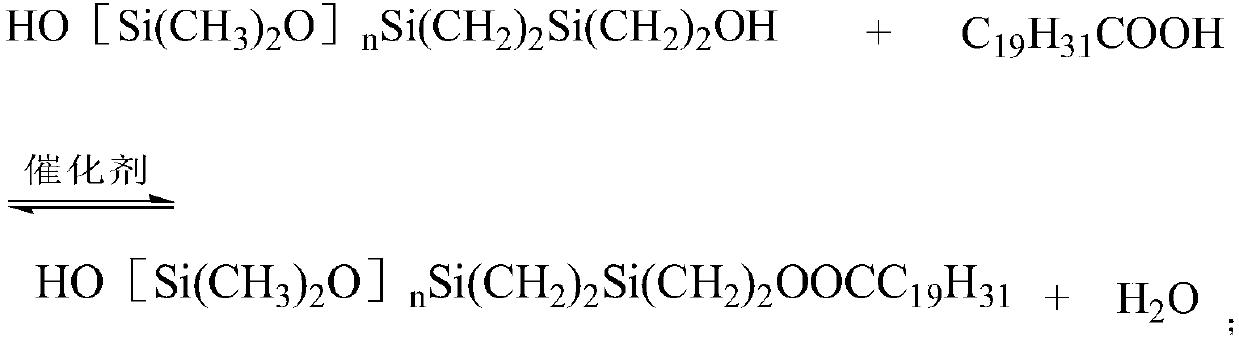

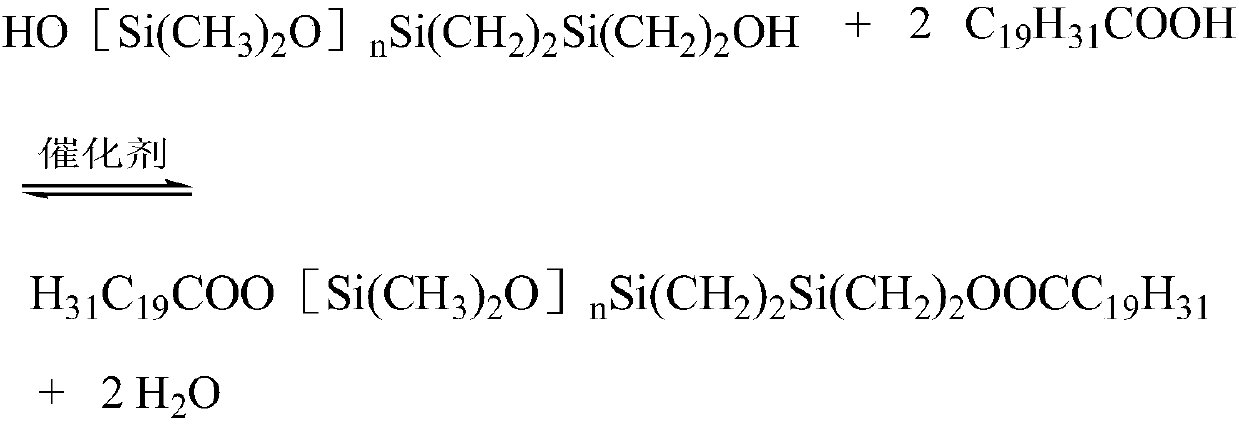

Method used

Image

Examples

Embodiment 1

[0041] The tackifying resin of this embodiment is prepared from the following parts by weight of raw materials:

[0042]

[0043] The specific preparation steps of the tackifying resin are as follows:

[0044] (1) Weigh the above raw materials by weight:

[0045] (2) Crush the rosin resin, add the pulverized rosin resin, antioxidant, nitrogen gas, stir to dissolve, and heat to 120°C for complete dissolution in a drying reactor equipped with a thermometer, agitator, and reflux condenser;

[0046] (3) Add catalyst and disperse for another 5 minutes, then add alcohol to react for 30 minutes, and the temperature is controlled at 250-270℃;

[0047] (4) Add hydroxysilane dropwise to start the esterification reaction, the temperature is controlled at 250-270°C, the dropwise addition is completed in 4 hours, and the temperature is kept for 1.5 hours;

[0048] (5) Vacuum (20mmHg) to reduce pressure to distill out low-boiling components;

[0049] (6) Cooling and discharging.

[0050] The tackifying ...

Embodiment 2

[0052] The tackifying resin of this embodiment is prepared from the following parts by weight of raw materials:

[0053]

[0054] The specific preparation steps of the tackifying resin are as follows:

[0055] (1) Weigh the above raw materials by weight;

[0056] (2) Crush the rosin resin, add the pulverized rosin resin to a drying reactor equipped with a thermometer, agitator, and reflux condenser, stir and dissolve the antioxidant, pass nitrogen, and heat to 70°C to completely dissolve;

[0057] (3) Add catalyst and disperse for 5 minutes;

[0058] (4) Add hydroxysilane dropwise to start the esterification reaction, the temperature is controlled at 240-260°C, the dropwise addition is completed in 4 hours, and the temperature is kept for 1.5 hours;

[0059] (5) Vacuum (20mmHg) to reduce pressure to distill out low-boiling components;

[0060] (6) Cooling and discharging.

[0061] The tackifying resin prepared in this embodiment can be used directly as a hot melt adhesive, or as a tackifie...

Embodiment 3

[0063] The tackifying resin of this embodiment is prepared from the following parts by weight of raw materials:

[0064]

[0065] The specific preparation steps of the tackifying resin are as follows:

[0066] (1) Weigh the above raw materials by weight;

[0067] (2) Crush the rosin resin, add the pulverized rosin resin to a drying reactor equipped with a thermometer, agitator, and reflux condenser, stir and dissolve the antioxidant, pass nitrogen, and heat to 100°C to completely melt;

[0068] (3) Add catalyst and disperse for 5 minutes;

[0069] (4) Add hydroxysilane dropwise to start the esterification reaction, the temperature is controlled at 200-220°C, the dropwise addition is completed in 3 hours, and the temperature is kept for 1 hour;

[0070] (5) Vacuum (20mmHg) to reduce pressure to distill out low-boiling components;

[0071] (6) Cooling and discharging.

[0072] The tackifying resin prepared in this embodiment can be used directly as a hot melt adhesive, or as a tackifier for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com