Non-water-based magnetorheological polishing solution and preparation method thereof

A magnetorheological polishing, non-water-based technology, applied in the field of magnetorheological polishing, can solve the problems that non-water-based magnetorheological polishing fluids have not been found, the rheological properties of magnetorheological fluids are not strong, and the processing range is limited. Achieve the effects of ensuring long-term stability, maintaining characteristic stability, and improving anti-settling and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of non-aqueous magnetorheological polishing liquid of the present invention, by mass fraction, by 31% diethylene glycol monobutyl ether (alkoxy alcohol base carrier liquid), 59% carbonyl iron powder (magnetic sensitive particle ), 5% surfactant and 5% deionized water. The viscosity of the non-water-based magnetorheological polishing fluid at 20° C. is 0.5 Pa·s.

[0034] In this example, the viscosity of diethylene glycol monobutyl ether at 20° C. is 6.49 mPa·s.

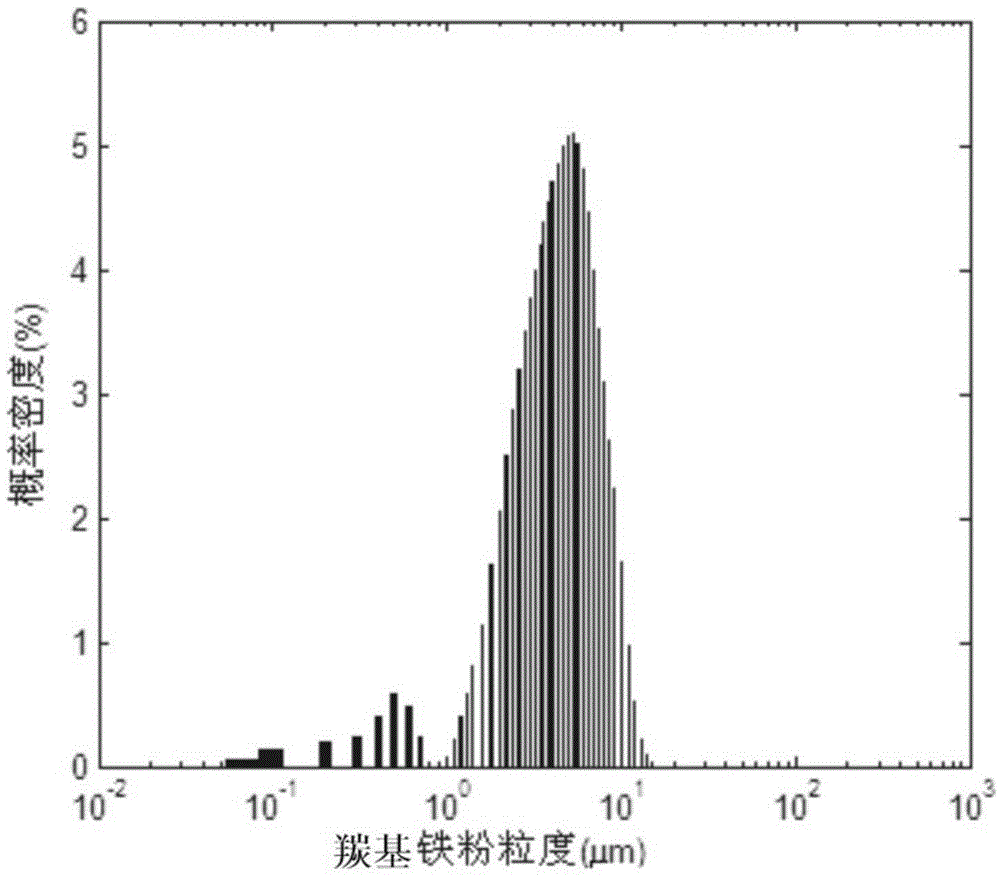

[0035] In the present embodiment, the particle size distribution of carbonyl iron powder is as follows figure 1 As shown, the particle size is mainly in the range of 1 μm to 10 μm, the average particle size of carbonyl iron powder is 5 μm, the purity of Fe is greater than 97%, the relative quality factor is greater than 1.75, and the effective magnetic permeability is greater than 3. The carbonyl iron powder can be purchased in the market. .

[0036] In this embodiment, the surfactant is a mixture of st...

Embodiment 2

[0048] A kind of non-water-based magnetorheological polishing fluid of the present invention is substantially the same as the non-water-based magnetorheological polishing fluid of embodiment 1, the difference is only: by mass fraction, diethylene glycol monobutyl ether (base carrier liquid ) is 40%, carbonyl iron powder (magnetic sensitive particles) is 50%, surfactant is 5%, and deionized water is 5%.

[0049] A preparation method of the non-water-based magnetorheological polishing fluid of this embodiment, the preparation steps are basically the same as in Example 1, the difference is only that in terms of mass fraction, diethylene glycol monobutyl ether (base carrier liquid) is 40 %, carbonyl iron powder (magnetic sensitive particles) is 50%, surfactant is 5%, and deionized water is 5%.

[0050] As shown in Table 2, it is the viscosity and long-term stability test results of the non-water-based magnetorheological polishing fluid prepared in this embodiment. It can be seen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com