Water-based magneto-rheological polishing liquid for optical processing and preparation method thereof

A technology of magnetorheological polishing and optical processing, applied in the direction of polishing composition containing abrasives, magnetic liquid, etc., can solve the problems of shear stress reduction, complicated process, expensive price, etc., and achieve large shear yield stress, preparation The effect of simple process and high static stability

Inactive Publication Date: 2010-08-11

NAT UNIV OF DEFENSE TECH

View PDF2 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the use of water as the base carrier liquid has the following problems: 1. Poor compatibility with the magnetically sensitive particles, the magnetically sensitive particles are easy to settle and agglomerate, making the coagulation stability and sedimentation stability of the magnetorheological polishing fluid worse; 2. Sensitive particles are easily oxidized, resulting in reduced shear stress and poor rheology

This method is complicated in process and high in production cost. It will be very expensive for the polishing of optical parts that require a large amount of magnetorheological polishing fluid.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

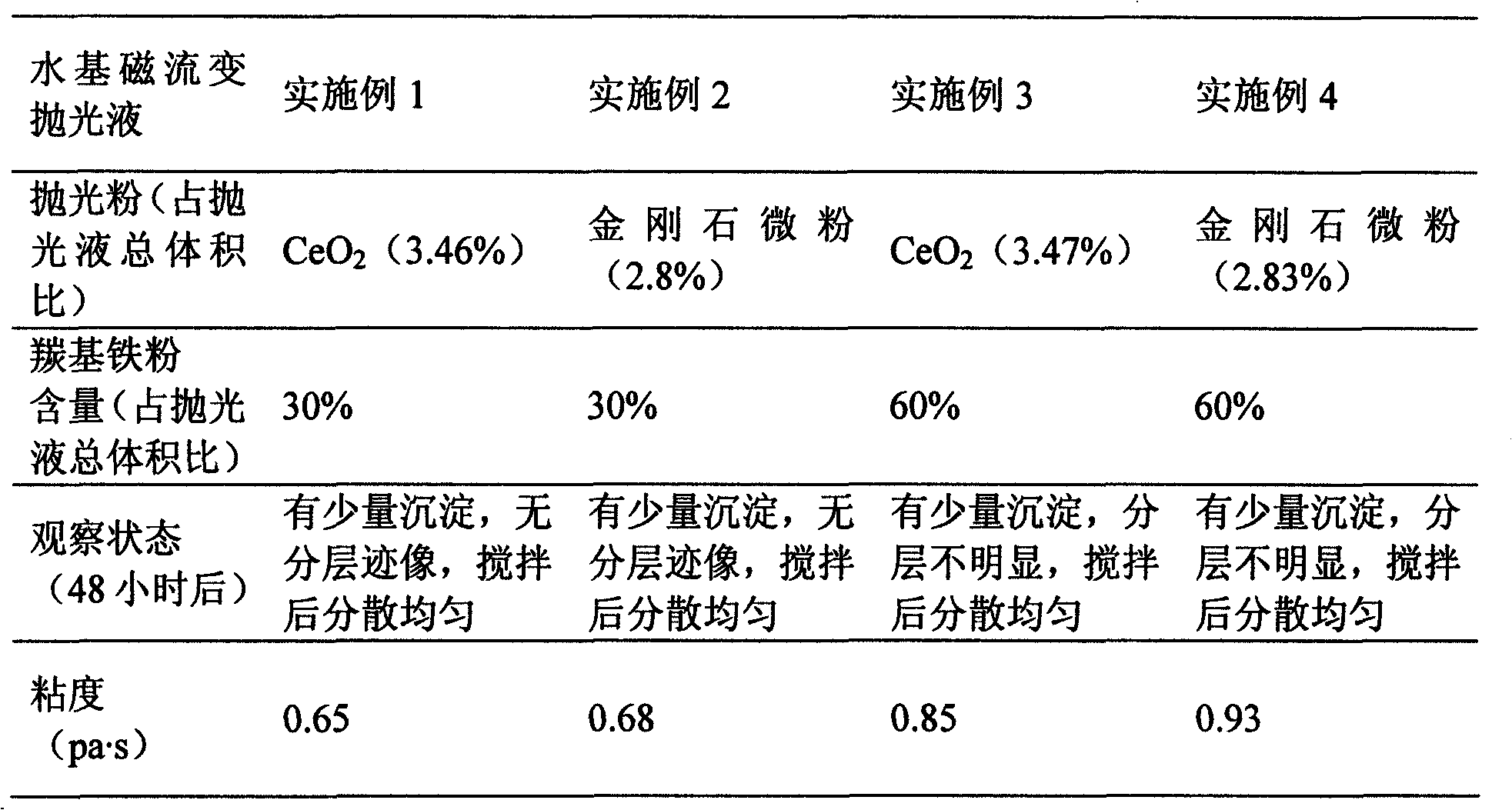

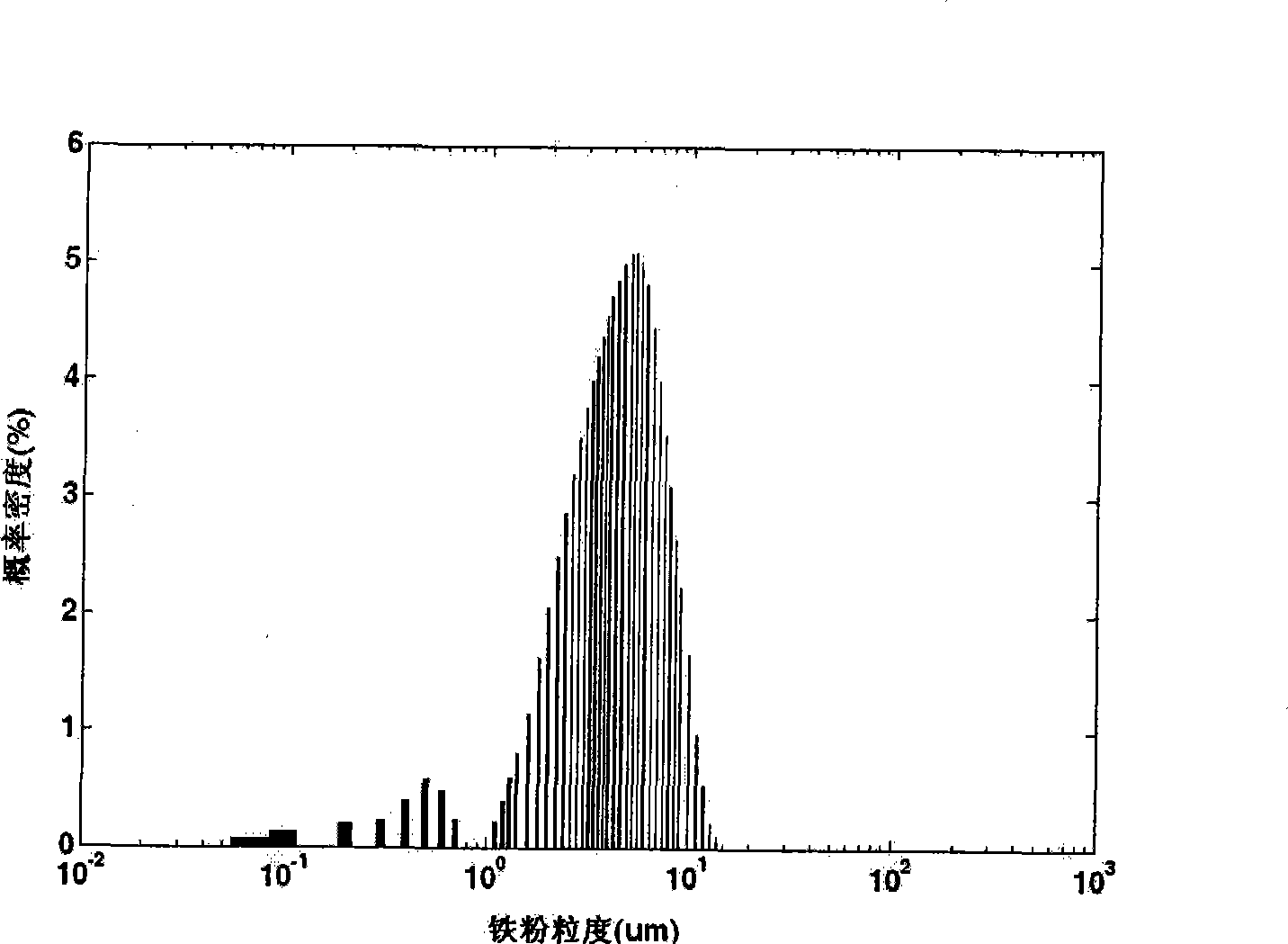

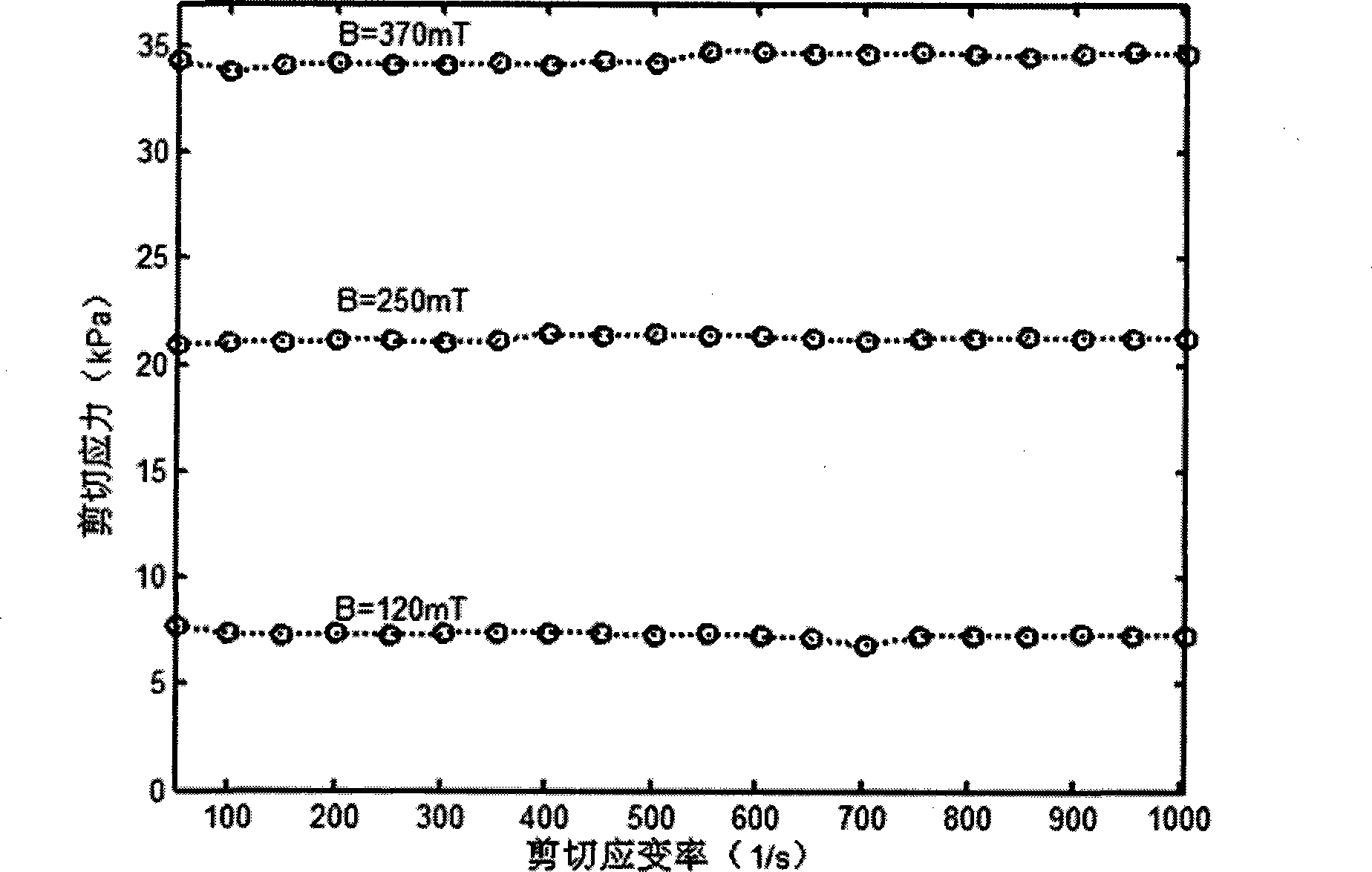

The invention relates to a water-based magnetorheological polishing solution for optical manufacture, which is formed by the following volume components, water-based remixed carrier liquid 25%-75% and additive component 25%-75%, wherein the additive component is dispensed by the following volume percentage, carbonyl iron powder 80%-90%, nanometer iron powder 4%-10% and polishing powder 4%-10%, the water-based remixed carrier liquid which is measured according to volume percentage comprises deionized water 85%-90%, dispersing agent 3%-5%, wetting agent 2%-5% and thixotropic agent 3%-5%, the method for preparing comprises the following steps: mixing deionized water and thixotropic agent, stirring in indoor temperature for 1-2 hours, and adding dispersing agent, stirring in indoor temperature for 0.5-1 hour, and then adding wetting agent, stirring in indoor temperature for 0.5-1 hour, getting water-based remixed carrier liquid, mixing additive component and water-based remixed carrier liquid, adding into a ball-milling tank, adding into a steel ball according to mass ratio which is 1:10, grinding for 3-5 hours in the speed which is 20-30r / m, separating out a steel ball, and getting products. The polishing solution of the invention has the advantages of excellent stability, high rheological property, excellent oxidation resistance property and simple and environmental-friendly preparation technology.

Description

technical field The invention belongs to the field of processing and manufacturing of precision optical parts, and in particular relates to a water-based magnetorheological polishing liquid for manufacturing optical parts and a preparation method thereof. Background technique Magnetorheological polishing technology is a deterministic advanced optical manufacturing technology. It uses the solid-liquid phase transient characteristics of magnetorheological fluid under high-intensity gradient magnetic field, and the shear yield stress and Due to the influence of local shape, a "flexible polishing mold" that can match the processed surface is formed, so as to realize the deterministic, high-precision and quantitative modification and polishing of optical components, while ensuring the surface processing quality of sub-nanometer roughness, tiny Workpiece subsurface damage and high machining efficiency. To achieve high-precision and high-efficiency magnetorheological polishing, on...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09G1/02H01F1/44

Inventor 李圣怡戴一帆彭小强宋辞石峰陈善勇郑子文

Owner NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com