Improving process for hydrophobicity of external insulation of power equipment

A technology for power equipment and external insulation, applied in the field of power, can solve the problems of poor anti-pollution flashover effect, poor surface adsorption of super-hydrophobic coatings and power equipment, and achieve firm adsorption, stable insulation, and improved surface roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

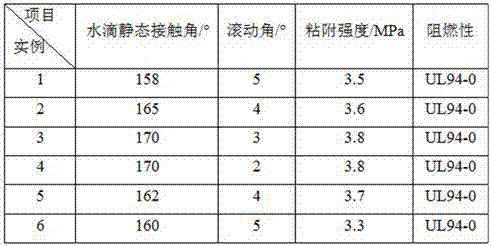

Examples

Embodiment 1

[0026] A process for improving the hydrophobicity of the external insulation of electric equipment, comprising the following steps:

[0027] (1) Surface roughening of electrical equipment;

[0028] (2) Prepare 15 parts of polyperfluoroethylene propylene, 10 parts of vinyl-terminated silicone oil, 5 parts of dimethyl silicone oil, 5 parts of polyetheretherketone and 20 parts of diluent acetone into a viscous solution, and cast it on the surface of the power equipment. 300μm thick solution film, followed by vacuum defoaming;

[0029] (3) Spread 10 parts of hydrophobic nano-silica powder with a particle size of 100nm through a 200-mesh sieve evenly on the surface of the solution film in step (2), keep it for 20 hours, then bake at 80°C for 6 hours to form a film;

[0030] (4) Rinse off the residual powder on the surface of the film in step (3) with clean water and dry.

[0031] The viscosity of the vinyl-terminated silicone oil is 500 mPa·s.

[0032] The molecular weight of de...

Embodiment 2

[0034] A process for improving the hydrophobicity of the external insulation of electric equipment, comprising the following steps:

[0035] (1) Surface roughening of electrical equipment;

[0036] (2) Prepare 16 parts of polyperfluoroethylene propylene, 12 parts of vinyl-terminated silicone oil, 6 parts of dimethyl silicone oil, 6.5 parts of polyetheretherketone and 30 parts of diluent anhydrous ethanol into a viscous solution, and place it on the surface of electric equipment Casting into a solution film with a thickness of 500μm, followed by vacuum degassing;

[0037] (3) Spread 15 parts of hydrophobic nano-silica powder with a particle size of 50nm through a 270-mesh sieve evenly on the surface of the solution film in step (2), keep it for 22 hours, then bake at 90°C for 4 hours to form a film;

[0038] (4) Rinse off the residual powder on the surface of the film in step (3) with clean water and dry.

[0039] The viscosity of the vinyl-terminated silicone oil is 1000mPa·...

Embodiment 3

[0042] A process for improving the hydrophobicity of the external insulation of electric equipment, comprising the following steps:

[0043] (1) Surface roughening of electrical equipment;

[0044] (2) Prepare 18 parts of polyperfluoroethylene propylene, 13 parts of vinyl-terminated silicone oil, 7 parts of dimethyl silicone oil, 8 parts of polyetheretherketone and 40 parts of diluent n-hexane to form a viscous solution, and cast it on the surface of electric equipment Form a solution film with a thickness of 600 μm, followed by vacuum degassing;

[0045] (3) Spread 20 parts of hydrophobic nano-silica powder with a particle size of 20nm through a 400-mesh sieve evenly on the surface of the solution film in step (2), keep it for 25 hours, and bake at 100°C for 3 hours to form a film;

[0046] (4) Rinse off the residual powder on the surface of the film in step (3) with clean water and dry.

[0047] The viscosity of the vinyl-terminated silicone oil is 2000mPa·s.

[0048] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com