Neodymium iron boron rare-earth permanent magnet heavy rare-earth thermal diffusion coating liquid and preparation method and application thereof

A rare earth permanent magnet, NdFeB technology, applied in inductor/transformer/magnet manufacturing, coating, transportation and packaging, etc., can solve the lack of process stability, cost increase, and limit the wide use of rare earth permanent magnet thermal diffusion technology And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

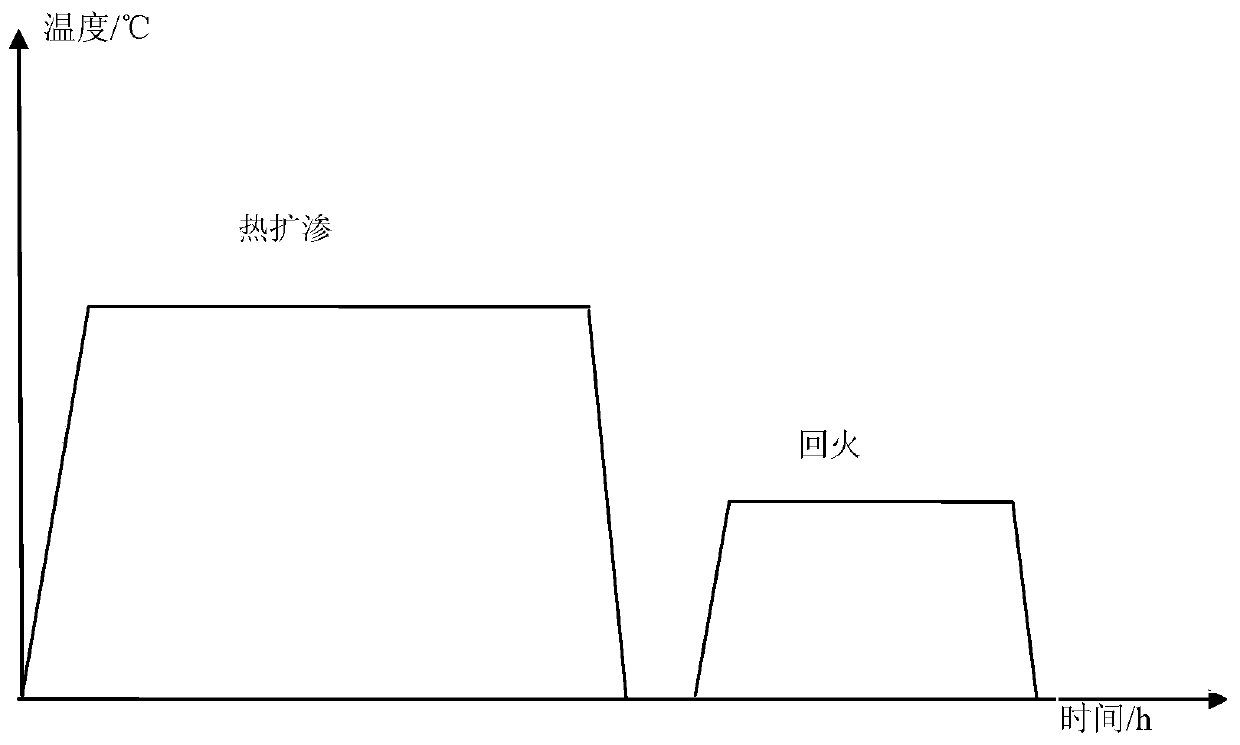

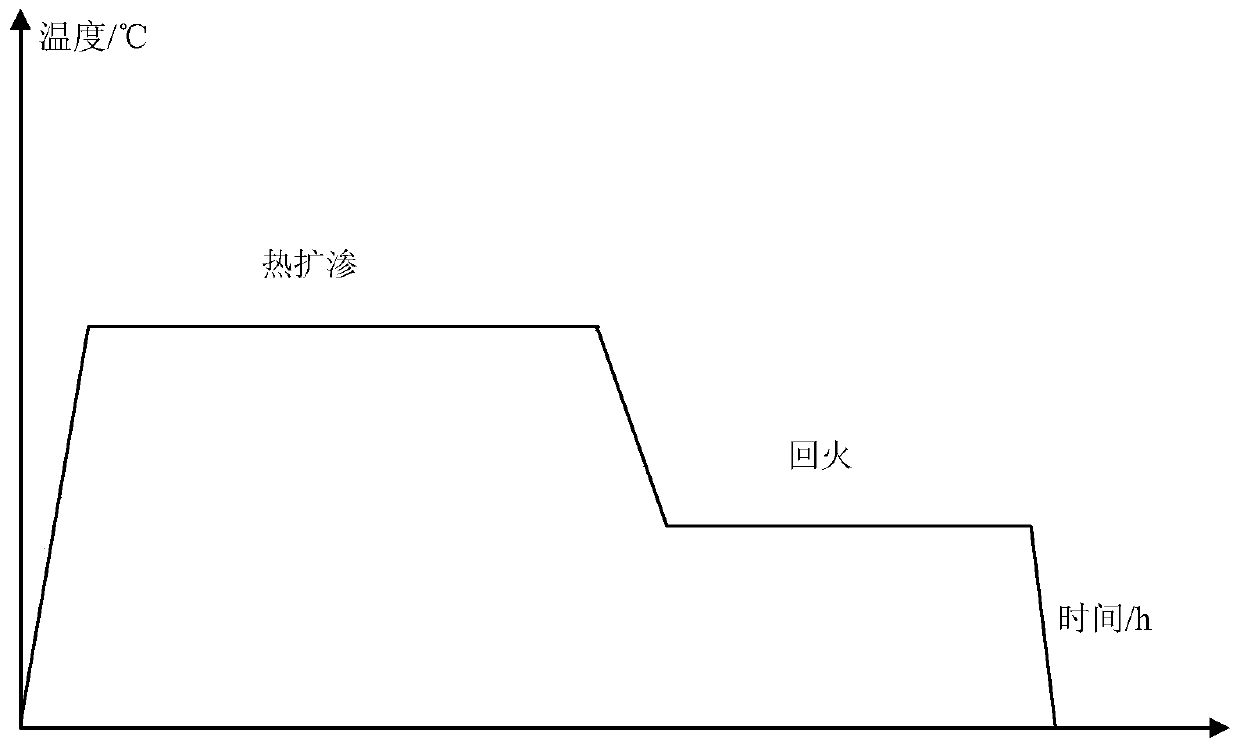

Method used

Image

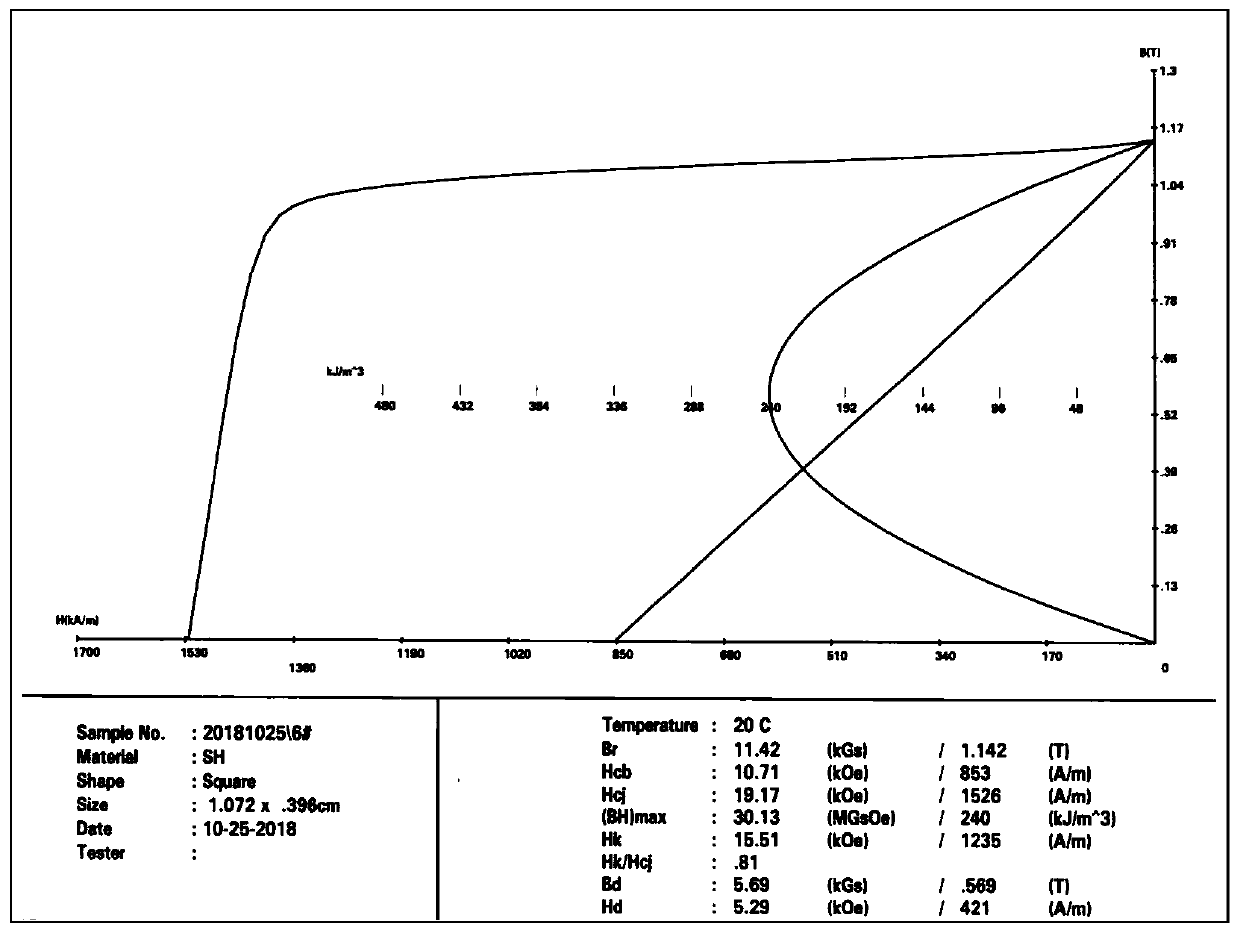

Examples

Embodiment 1

[0086] A kind of NdFeB rare earth permanent magnet heavy rare earth thermal expansion and penetration coating liquid, the components included and the mass percentage of each component are: DyF 3 Powder 35%, binder 10%, diluent 50%, surfactant 3%, dispersant 2%;

[0087] Among them, DyF 3 The particle size is 1-20 μm (commercially purchased DyF 3 powder, using ball milling); the binder is epoxy resin; the diluent is a mixture of N,N-dimethylformamide, toluene, and cyclohexanone, and N,N-dimethylformamide Amide: toluene: cyclohexanone = 1:1:1; surfactant is OP-9; dispersant is silane coupling agent KH550.

[0088] A method for preparing a NdFeB rare earth permanent magnet heavy rare earth thermal expansion and infiltration coating solution, comprising the following steps:

[0089] Step 1: Heavy rare earth powder pretreatment

[0090] DyF 3 Powder ball milling to obtain DyF with a particle size of 1-20 μm 3 powder;

[0091] Step 2: Preparation of thermal expansion penetran...

Embodiment 2

[0104] A kind of NdFeB rare earth permanent magnet heavy rare earth thermal expansion and penetration coating liquid, the components included and the mass percentage of each component are: DyF 3 Powder 35%, binder 10%, diluent 50%, surfactant 3%, dispersant 2%;

[0105] Among them, DyF 3 The particle size is 1-20 μm (commercially purchased DyF 3 powder, using ball milling); the binder is epoxy resin; the diluent is a mixture of N,N-dimethylformamide, toluene, and cyclohexanone, and N,N-dimethylformamide Amide, toluene, cyclohexanone=2:1:1; surfactant is OP-9; dispersant is silane coupling agent KH550.

[0106] A method for preparing a NdFeB rare earth permanent magnet heavy rare earth thermal expansion and infiltration coating solution, comprising the following steps:

[0107] Step 1: Heavy rare earth powder pretreatment

[0108] DyF 3 Powder ball milling to obtain DyF with a particle size of 1-20 μm 3 powder;

[0109] Step 2: Preparation of thermal expansion penetrant ...

Embodiment 3

[0122] A kind of NdFeB rare earth permanent magnet heavy rare earth thermal expansion and penetration coating liquid, the components included and the mass percentage of each component are: DyF 3 Powder 30%, binder 15%, diluent 50%, surfactant 2%, dispersant 3%;

[0123] Among them, DyF 3 The particle size of the powder is 10-20μm; the binder is mixed resin P-200; the diluent is N,N-dimethylformamide; the surfactant is OP-9; the dispersant is silane coupling agent KH560.

[0124] A method for preparing a NdFeB rare earth permanent magnet heavy rare earth thermal expansion and infiltration coating solution, comprising the following steps:

[0125] Step 1: Heavy rare earth powder pretreatment

[0126] DyF 3 Powder ball milling to obtain DyF with a particle size of 10-20 μm 3 powder;

[0127] Step 2: Preparation of thermal expansion penetrant

[0128] (1) According to the ratio of NdFeB rare earth permanent magnet weight rare earth thermal expansion and infiltration coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com