Asphalt mixture modfied with polyester and polyamide fiber possessing irregular cross section and its prepn

A technology of asphalt mixture and polyester polyamide, which is applied in the direction of building insulation materials, building components, buildings, etc., can solve the problems of poor durability, improve mechanical properties, reduce embrittlement point temperature, compatibility and durability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

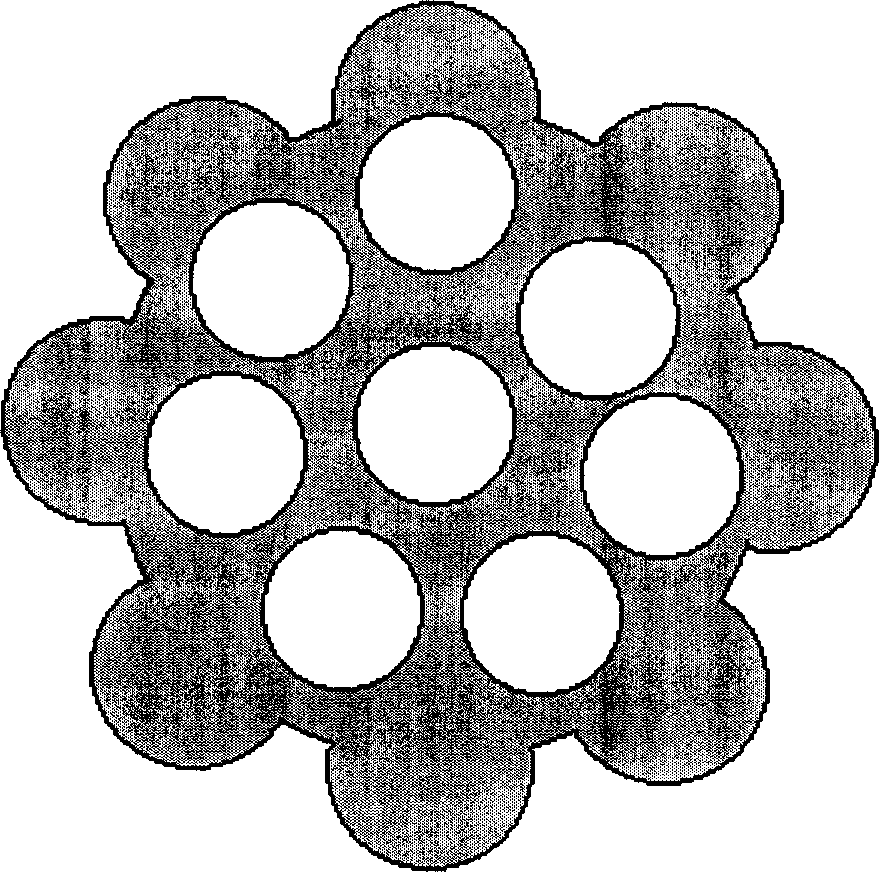

[0023] The conventional SMA formula is adopted: among them, the asphalt is 6%, the weight ratio of fiber and asphalt is 1:20, the weight ratio of fiber and stone is 0.4%, and the fiber is figure 2 Shown are the profiled multi-hollow polyester polyamide fibers.

[0024] According to the above ratio, put several kinds of raw materials in the mixer, mix well, then add fiber, dry mix for 1 minute, add asphalt heated to the mixing temperature, wet mix for 1 minute, finally add mineral powder, continue mixing Until it is uniform, the special-shaped cross-section polyester polyamide fiber modified asphalt mixture of the present invention is obtained.

[0025] Add the well-mixed asphalt mixture into the preheated mold, compact it 50 times on both sides with an automatic compactor, and then cool it at room temperature (not less than 12 hours). Remove the sample from the mold. The test performance is shown in Table 1.

Embodiment 2

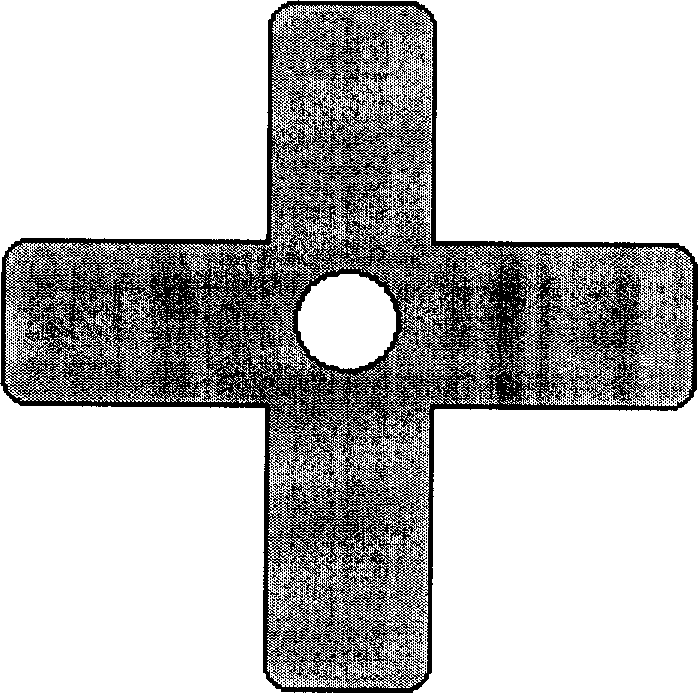

[0027] The special-shaped multi-hollow polyester polyamide fiber of embodiment 1 is changed into figure 1 For the special-shaped single hollow polyester polyamide fiber shown, other steps are the same as in Example 1, and the test performance is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com