Glass plating film cleaning liquid and preparation method thereof

A technology for cleaning liquid and glass, which is applied in the direction of chemical instruments and methods, detergent compounding agents, detergent compositions, etc. It can solve the problems of low flash point, high cost, ozone destruction, etc., and achieve good cleaning effect and good infiltration Ability, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

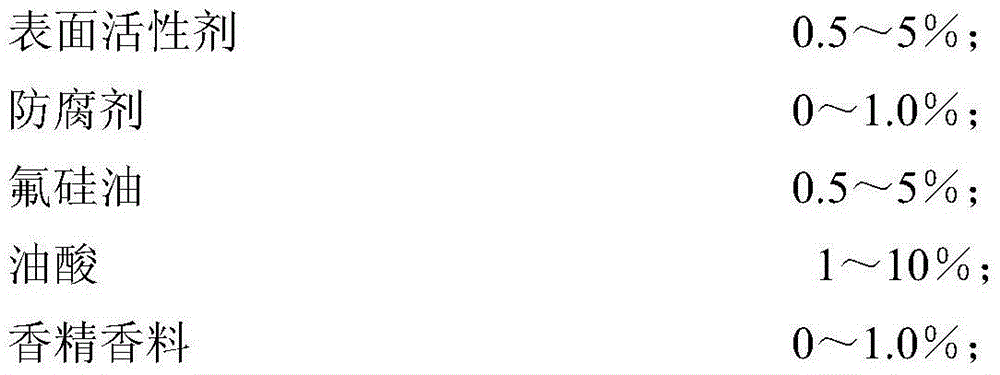

[0028] A glass coating cleaning solution is characterized in that the components of the glass coating cleaning solution are:

[0029]

[0030] The above percentages are percentages by weight.

[0031] During preparation, add deionized water into the reaction kettle, heat up to 60°C while stirring, and stir for 80 minutes; slowly and evenly add surfactant while stirring; then add preservatives, lemonade essence, fluorosilicone oil, oil acid, the stirring time is 120 minutes, so that the mixture is stirred evenly; the temperature is lowered to 35°C, and the material is discharged for inspection.

Embodiment 2

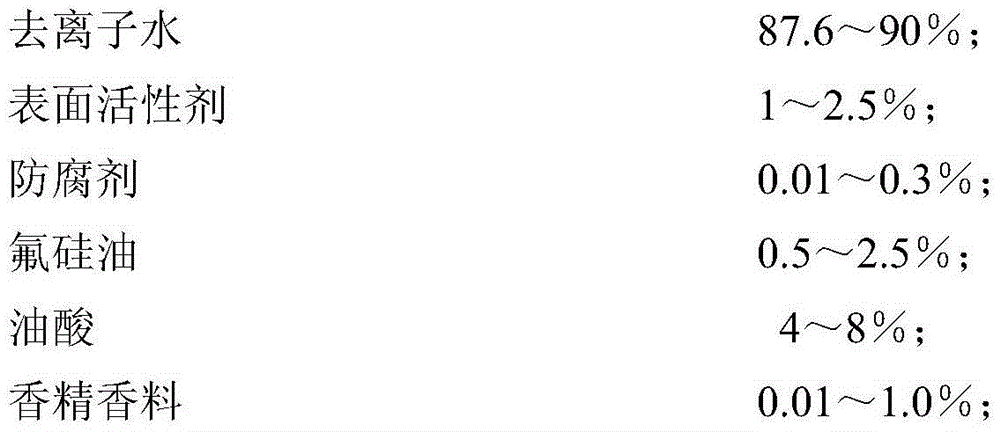

[0033] A glass coating cleaning solution is characterized in that the components of the glass coating cleaning solution are:

[0034]

[0035] The above percentages are percentages by weight.

[0036] During preparation, add deionized water into the reaction kettle, heat up to 45°C while stirring, and stir for 120 minutes; slowly and evenly add surfactant while stirring; then add preservatives, lemonade essence, fluorosilicone oil, oil acid, the stirring time is 80 minutes, so that the mixture is stirred evenly; the temperature is lowered to 20°C, and the material is discharged for inspection.

Embodiment 3

[0038] A glass coating cleaning solution is characterized in that the components of the glass coating cleaning solution are:

[0039]

[0040] The above percentages are percentages by weight.

[0041] During preparation, add deionized water into the reaction kettle, heat up to 80°C while stirring, and stir for 30 minutes; slowly and evenly add surfactant while stirring; then add preservatives, lemonade essence, fluorosilicone oil, oil acid, the stirring time is 30 minutes, so that the mixture is stirred evenly; the temperature is lowered to 40°C, and the material is discharged for inspection.

[0042] In the above examples, the surfactant is a composite of polyethylene glycol series ethers, fatty alcohol polyoxyethylene ether series, and lauramide propyl betaine series. The compound mass ratio is:

[0043] Polyethylene glycol series ether: 10-50 parts;

[0044] Fatty alcohol polyoxyethylene ether series: 10 to 50 parts;

[0045] Lauryl amidopropyl betaine series: 10-50 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com