Patents

Literature

62results about How to "Good insect repellent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rubber-wood-cement composite material

ActiveCN101298379AShorten the production cycleHigh degree of continuitySolid waste managementWear resistantAdhesive

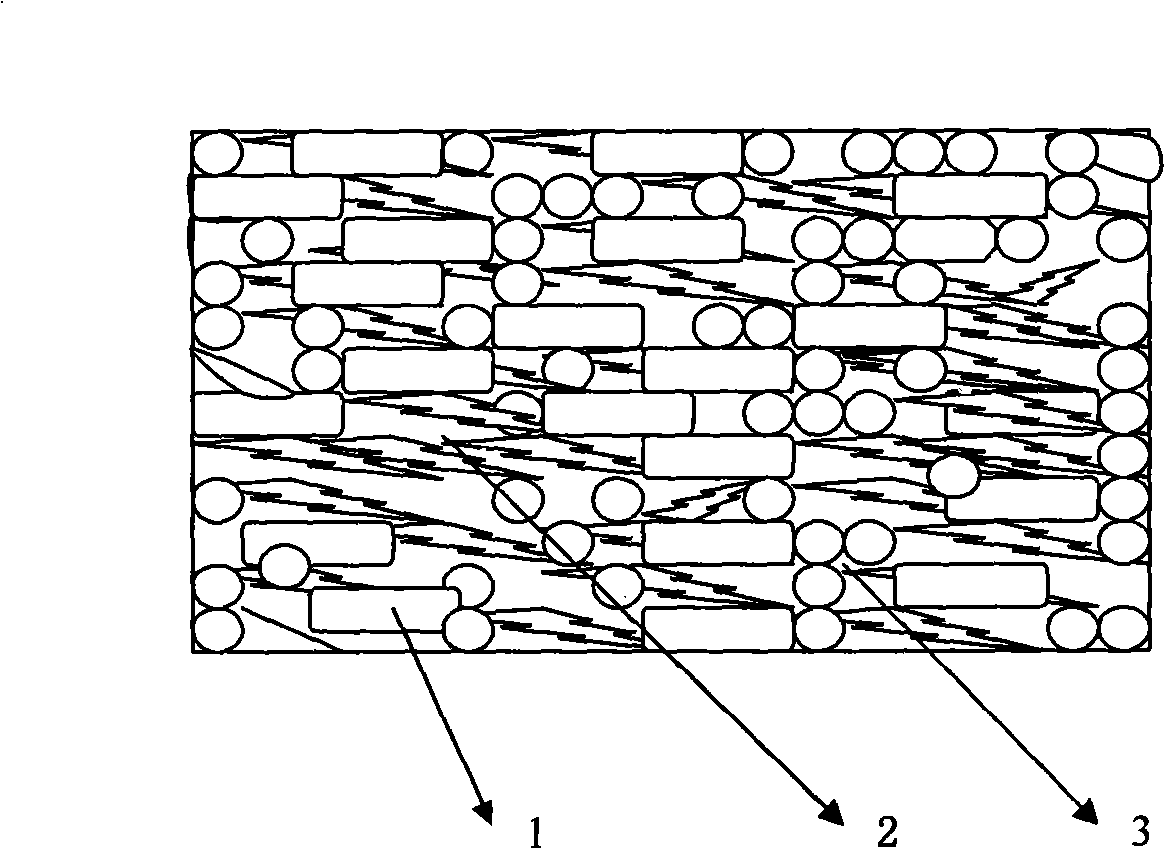

The invention provides a rubber-timber-cement functional environment-friendly compound material, which belongs to the field of cement-base compound material. The material adopts the waste tire rubber, waste rubber products, woody material and silicate cement as raw materials, an isocyanate-based adhesive is coated on the surface of the waste rubber particles, then the woody material is soaked and dried, and the treated rubber particles, the woody material and cement are mixed to form a blank material, which is finally laid, pressed and cured so as to obtain the compound material. The compound material provided by the invention can absorb and insulate sound, has high shock resistance and damping property, and is wear-resistant, antistatic, mothproof, waterproof and anticorrosive; also the material is heat-insulating and friendly to the environment, etc.; the production process has no chemical pollution source, no radioactivity, no light pollution and no noise. The invention blazes a new path for solving the 'black pollution' of increasing waste tires, which is a global problem; additionally, the compound material can be used for producing structural lumber.

Owner:BEIJING ZHONGYANYI ENG TECH DEV CENT

Wood wax oil and preparation technology thereof

The invention discloses wood wax oil for maintenance and decoration of buildings, furniture and the like and preparation technology thereof. The wood wax oil contains wood oil, linseed oil, catalpa oil, perilla oil, pine oil, castor oil, rosin modified resin, bee wax or wood wax and turpentine oil, wherein the content of each component is 5 to 10 percent; and each component is a pure natural extract. The preparation technology for the wood wax oil comprises the following steps: polymerizing the wood oil, the linseed oil, the catalpa oil, the perilla oil, the pine oil, the castor oil, the rosin modified resin and the bee wax or the wood wax at a high temperature of between 290 and 300 DEG; adding the turpentine oil into the polymerized product to dilute; filtering the mixture; and adding a drier into the filtered product to adjust. The wood wax oil has the advantages of natural health, good durability and permeability, and recoverability.

Owner:董学明

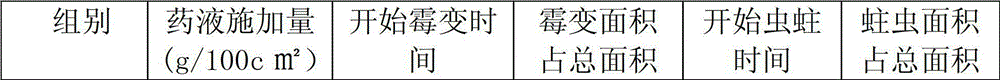

Wood preservative

InactiveCN102941606AImprove bindingGood insect repellentWood impregnation detailsPreservativePolyethylene glycol

The invention discloses a wood preservative. The preservative comprises the following components, by weight, borate 15-45%, quaternary ammonium salt 6-15%, chlorothalonil 5-10%, cosolvent 4-10% and the balance solvent, wherein the solvent is one or a plurality of dimethylbenzene, glycerol and water, and the cosolvent is polyethylene glycol, urea formaldehyde preshrinking liquid or ethylene. The wood preservative is colorless, odorless, safe and environment-protection, simultaneously has the functions of corrosion prevention, mold prevention, insect prevention and antitarnish, and can rest assured use indoor and outdoor.

Owner:东兴市观福古典红木家具有限公司

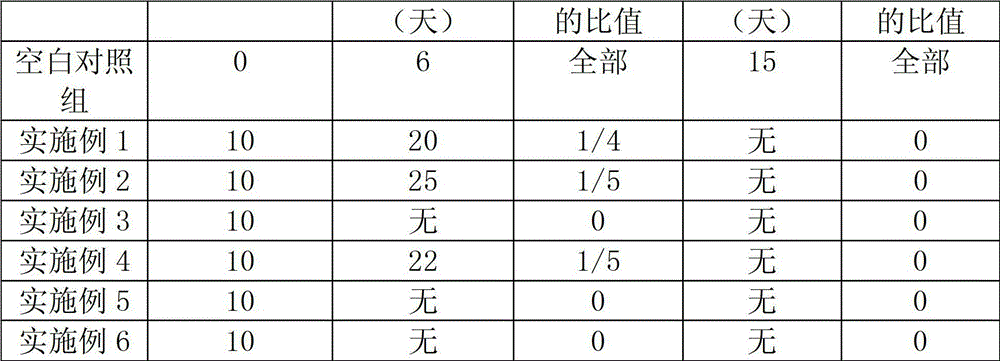

Photocatalystc composite floor board and production process of photocatalystc composite floor board

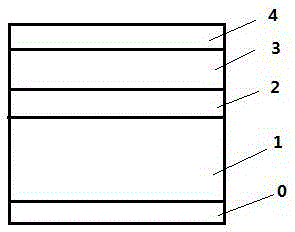

InactiveCN104989066ADoes not affect bond strengthAffect bond strengthLaminationLamination apparatusWood shavingsSurface layer

The invention relates to a photocatalystc composite floor board, and belongs to the field of a functional environment-friendly healthy floorboard. The formaldehyde emission content of the composite floorboard is less than 0.3mg / L; the antibacterial rate is higher than or equal to 90 percent; the surface wear-resistant coefficient is less than or equal to 0.08g / 100r; a substrate layer is an oriented shaving board layer; the oriented shaving board layer comprises an upper surface layer and a lower surface layer which are formed by glue mixing wood shavings in longitudinal arrangement according to the fiber direction and a core layer shaving layer formed by glue mixing wood shavings in transverse arrangement according to the fiber direction; and a decoration layer, a wear-resistant primer layer and a photocatalystc antibacterial paint decoration layer are sequentially arranged on the substrate layer. A production process of the photocatalystc composite floor board comprises the steps of shaving board layer sorting, glue preparation, glue distribution and assembling for the first time, cold pressing for the first time, core trimming, glue distribution and assembling for the second time, cold pressing for the second time, hot pressing for the first time, fixed-thickness sanding, edge cutting, puttying, polishing, sorting, reconditioning, glue distribution and veneering, cold pressing for the third time, hot pressing for the second time, multi-blade sawing, sanding, double-end milling, priming, finish paint preparing and finish paint painting. The composite floorboard has the advantages of good antibacterial function, high strength, good wear-resistant performance and comfortable foot feeling.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

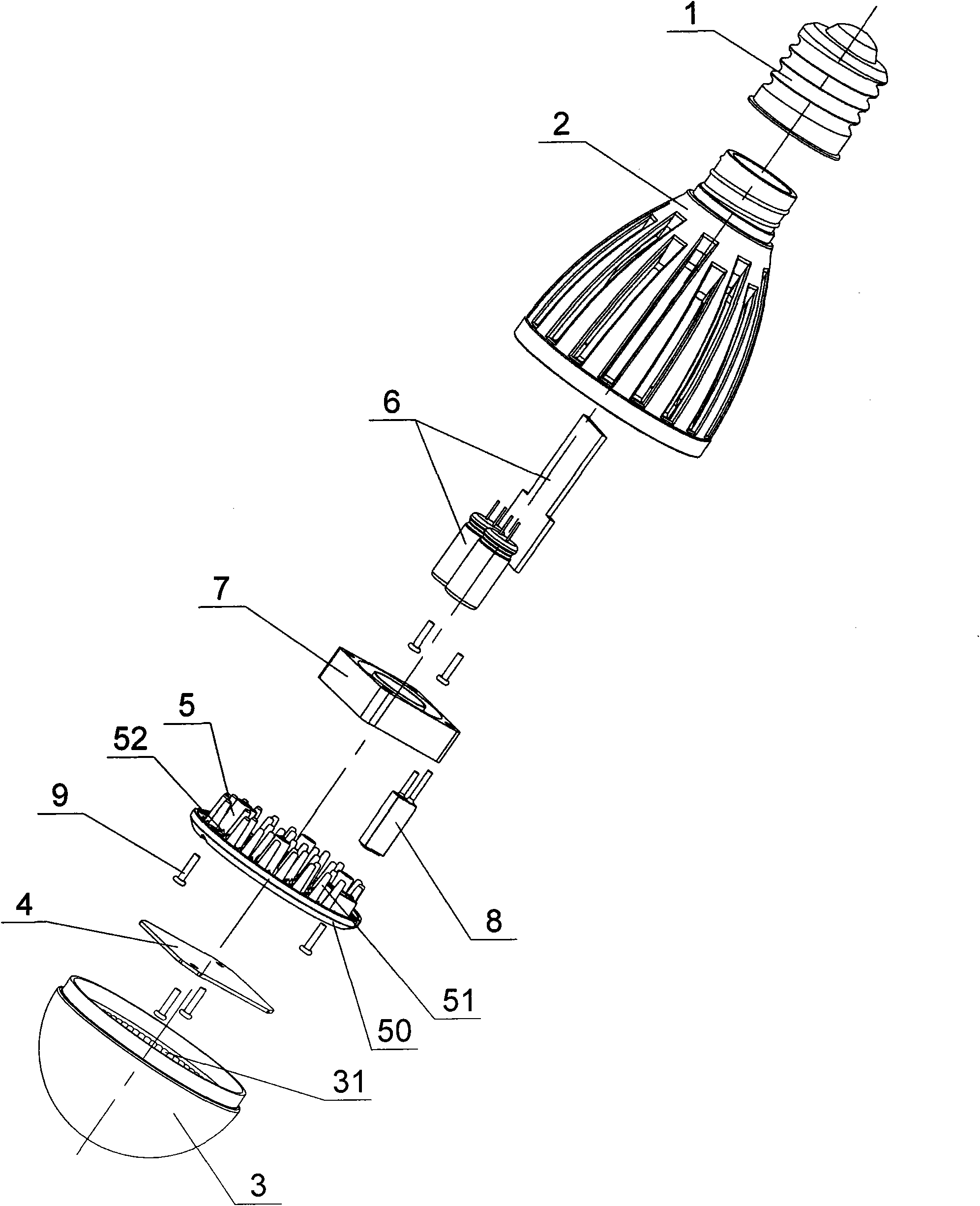

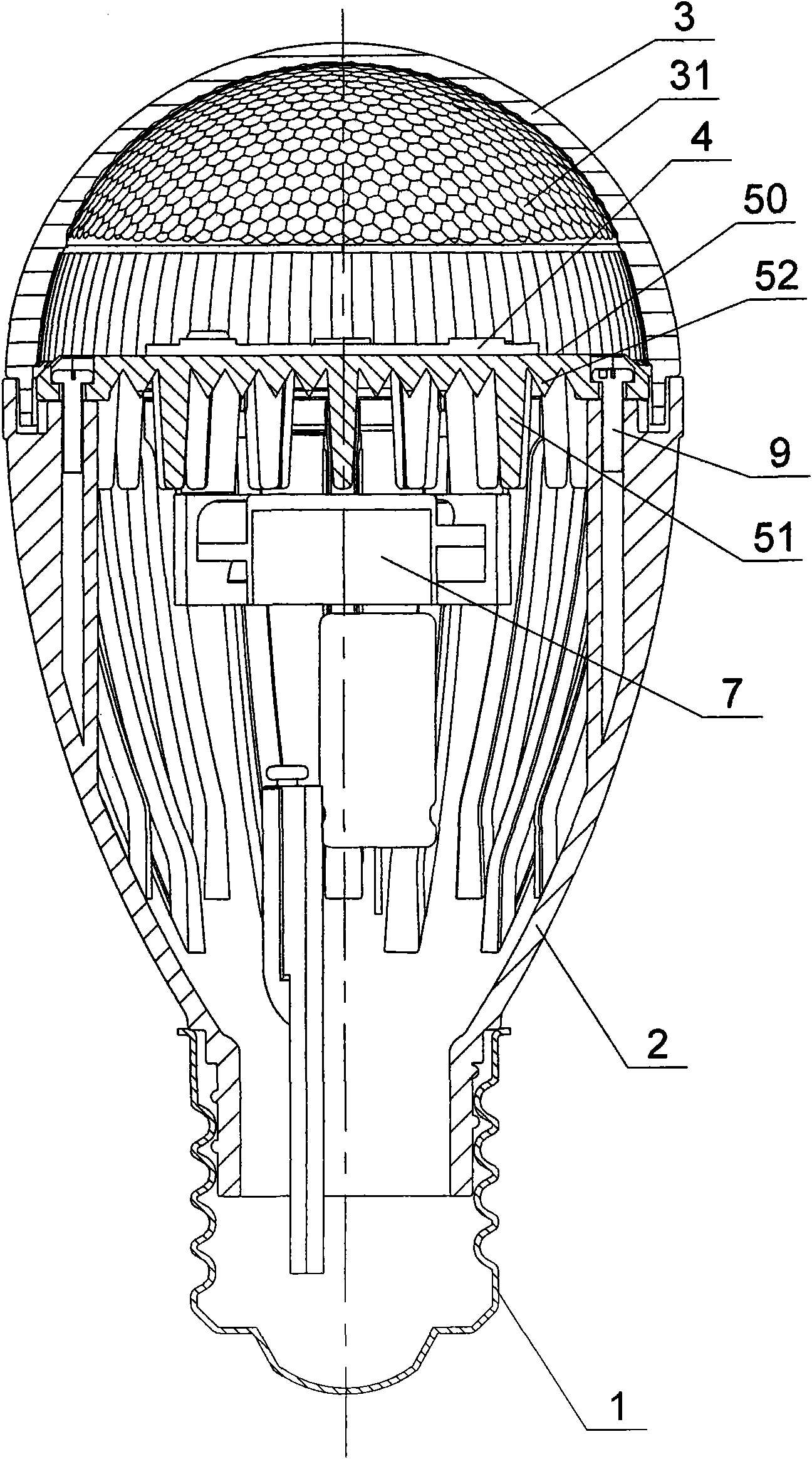

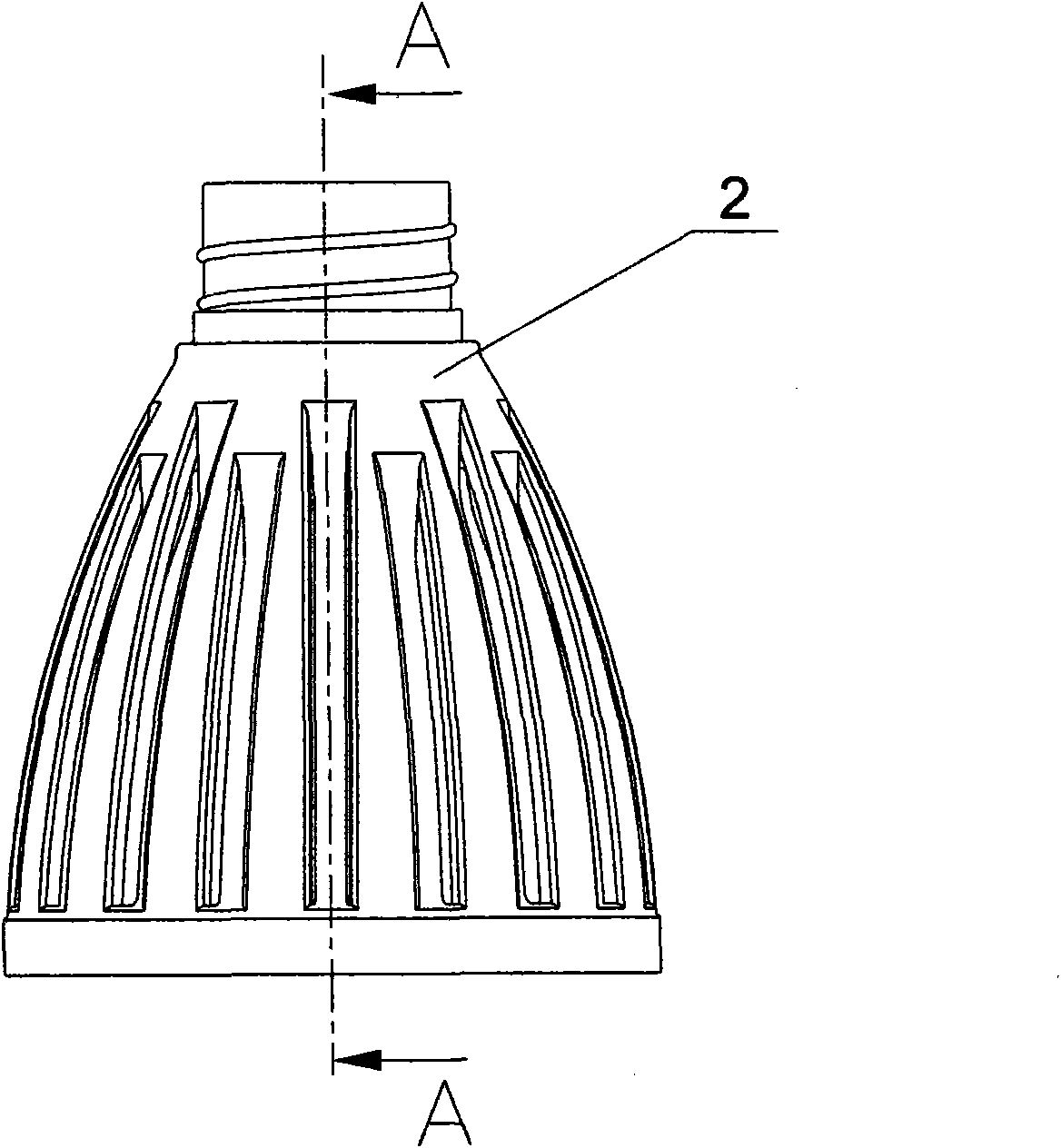

High-power LED bulb

InactiveCN102109104AIncrease cooling areaAvoid safety hazardsPoint-like light sourceLighting heating/cooling arrangementsElectric shockHigh power leds

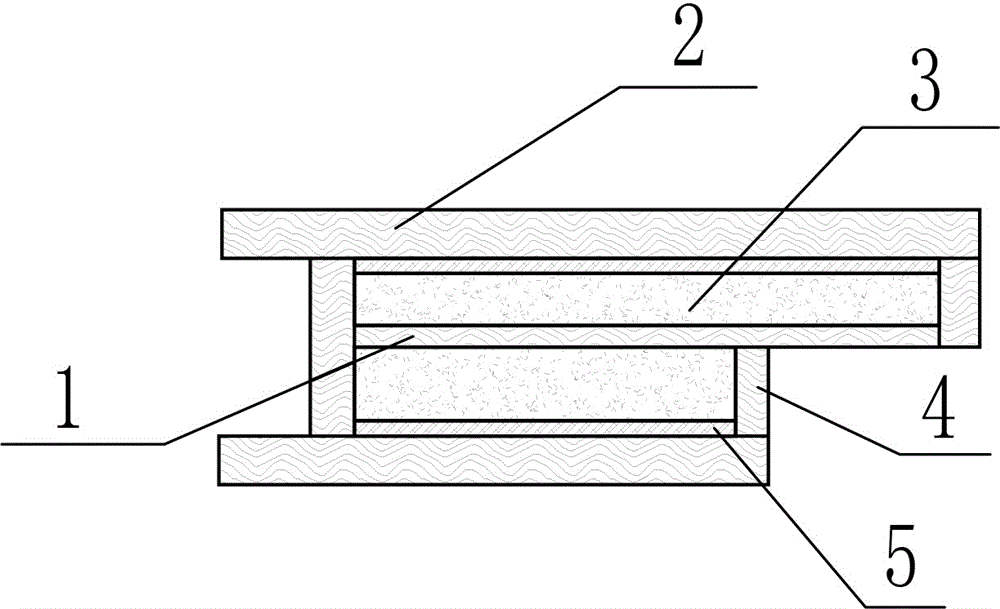

The invention discloses a high-power LED bulb with electric shock preventing performance, high safety and long service life. The high-power LED bulb comprises a bulb cap (1), an insulating casing (2), an insulating light-transmitting front bulb shade (3), a light source plate (4) integrated with an LED chip, a radiator (5), a power supply drive component (6) and a thermo-sensitive switch (8), wherein the thermo-sensitive switch (8) is used for cutting off a power supply when the bulb is under high temperature; the front end of the insulating casing (2) is fixedly connected with the insulating light-transmitting front bulb shade (3), so as to form an accommodating cavity; all the light source plate (4), the radiator (5), the power supply drive component (6) and the thermo-sensitive switch (8) are arranged in the accommodating cavity; the radiator (5) comprises a baseplate (50); the bottom surface of the baseplate (50) is a plane surface part tightly clung to the light source plate (4); a heat radiation pillar (51) is arranged on the top surface of the baseplate (50); a lug boss (52) or sunken part which is used for enlarging the radiation area is arranged on the top surface of the baseplate (50); and a plurality of heat radiation grooves (21) communicated with the inner cavity of the insulating casing (2) are formed on the side wall of the insulating casing (2). The high-power LED bulb can be extensively applied to the field of LED illumination.

Owner:NANKER GUANGZHOU SEMICON MFG

Bio-organic fertilizer produced in quick fermentation manner by adopting crop stalks as main material and preparation method for bio-organic fertilizer

The present invention discloses a bio-organic fertilizer produced in a quick fermentation manner by adopting crop stalks as a main material and a preparation method for the bio-organic fertilizer, and relates to the technical field of agricultural fertilizers. The bio-organic fertilizer is prepared by mixing and granulation of the following materials in parts by weight: 40-60 parts of crop stalks, 20-30 parts of live stock excrement, 10-20 parts of humic acid, 0.4-0.6 part of microbe fungus, 2-6 parts of ammonium chloride, 1-3 parts of potassium chloride, 2-4 parts of calcium superphosphate, and 0.4-0.6 part of medium and microelements. The bio-organic fertilizer has the advantages of being relatively low in production cost, relatively high in biological activity, high in fertilizing value, and broad in raw material sources, can be taken as paddy rice fertilizers, upland crop, vegetable, amphisarca and fruit tree fertilizers, and flower fertilizers.

Owner:HUNAN ZHONGKE AGRI

Photocatalyst flame-retardant antibacterial floor and production process thereof

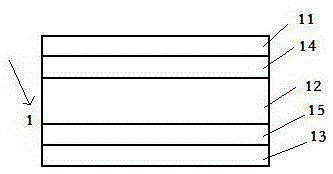

InactiveCN105298077ADoes not affect bond strengthAffect bond strengthWood working apparatusFlooring insulationsSurface layerWear resistant

The invention relates to a photocatalyst flame-retardant antibacterial floor and belongs to the field of functional environment-friendly health floors. The floor has a formaldehyde release limit less than 0.3 mg / L, an antibacterial rate not less than 90%, and surface wear resistance not less than 0.08 g / 100r. A base layer is a flame-retardant directional chipboard layer, comprising upper and lower surface layers of glue-mixed shavings, a core shaving layer, a first flame-retardant layer and a second flame-retardant layer; a decorative layer, a wear-resistant undercoat layer and a photocatalyst antibacterial oil facing layer are disposed in order above the base layer; a balance layer is disposed below the base layer. A production process of the floor comprises chipboard layer regulating; glue mixing; first gluing and assembly; first cold pressing; core dressing; second gluing and assembly; second cold pressing; first hot pressing; fixed thickness sanding; edging; puttying; polishing; sorting; curing; gluing and facing; third cold pressing; second hot pressing; multi-piece sawing; sanding; double end milling; undercoating; top coat blending; top-coating. The composite floor has high antibacterial performance, high strength, good wear resistance and good foot comfort.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

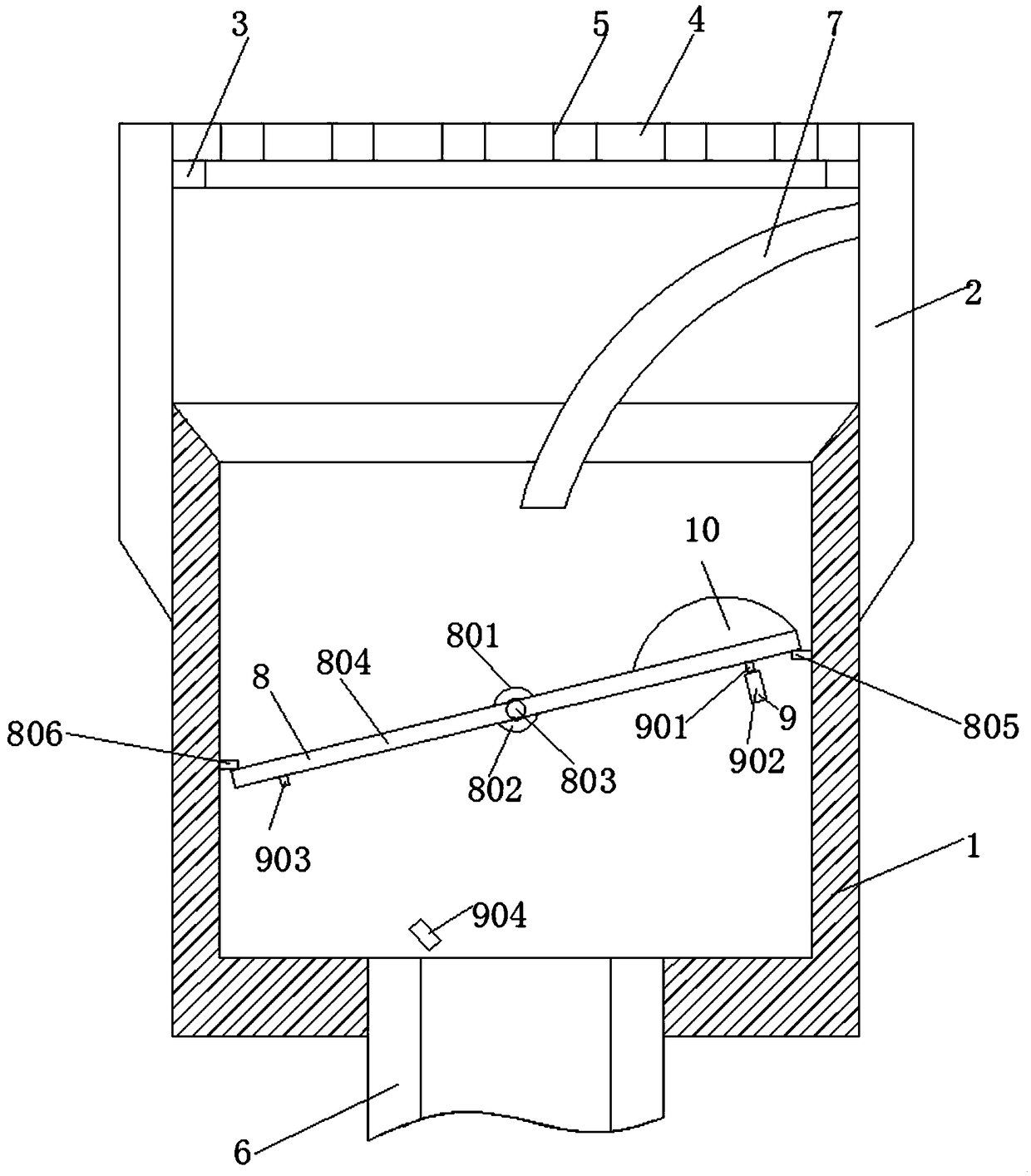

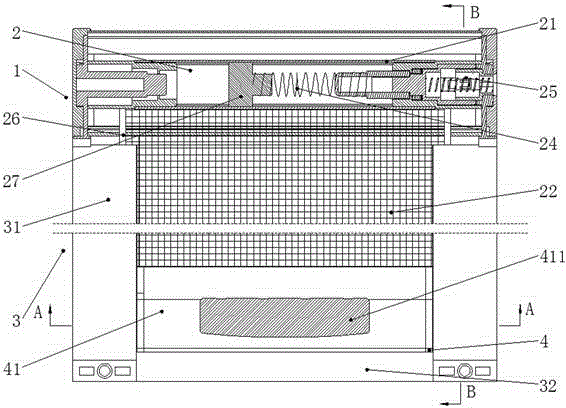

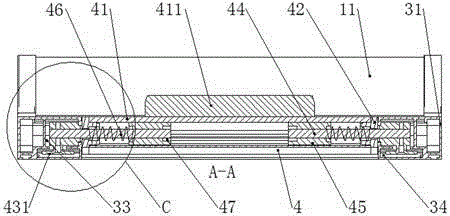

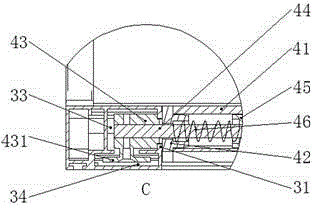

Insect-proof odor-resistant floor drain

The invention provides an insect-proof odor-resistant floor drain, and relates to the field of drainage appliances. The insect-proof odor-resistant floor drain comprises a cavity, wherein the outer wall of the cavity is fixedly welded with a shell body, a fixed ring is fixedly welded at the inner wall of the shell body and located above the cavity, a filter plate is embedded in the fixed ring, thetop plane of the filter plate is flush with the end of the shell body, the top of the filter plate is provided with a water leakage hole, and the bottom of the cavity is communicated with a drainagepipe. The insect-proof odor-resistant floor drain has the advantages that an arc-shaped guide plate is arranged to introduce water flowing under the filter plate to a baffle plate at the left side ofa bearing, and the baffle plate is oblique under a sealed state; by introducing the water flowing under the filter plate to the baffle plate at the left side of the bearing, when the water gravity borne by the baffle plate is larger than the magnetic force of a first sealing permanent magnet block and a second sealing permanent magnet block, the baffle plate can rotate anticlockwise around a connecting shaft, so that the anticlockwise rotation of the baffle plate can form a gap between the baffle plate and the cavity to facilitate the discharge of water in the cavity.

Owner:孟永强

Wood surface corrosion control method

InactiveCN104723424AImprove anti-corrosion performanceImprove mildew resistanceBiocideWood treatment detailsBronopolPolyvinyl chloride

The invention discloses a wood surface corrosion control method. The method comprises the following steps: (1) drying the wood until the water content is about 18%; (2) injecting the preservatives, namely 2-4 parts of propylene glycol, 30-48 parts of propene carbonate, 1-2.3 part of DCOIT, 10-25 parts of p-chloroxylenol, 1-4 parts of alkyl dimethyl benzyl ammonium chloride, 1-2.8 part of sodium chloride, 1-3 parts of sodium chlorate, 1-3 parts of potassium bromide, 5-8 parts of bronopol, 35-46 parts of dithiocyano-methane and 108-116 parts of fatty alcohol polyvinyl chloride ether in part by weight, into the wood under the vacuum high pressure condition; (3) performing high-temperature qualitative treatment for 6-12 hours on the wood after the preservatives are added; and (4) carrying out air drying on the high-temperature qualitatively treated wood to obtain the wood subjected to preservative treatment. The corrosion control method disclosed by the invention is good in corrosion control effect, the preservatives can permeate into the part being 1-2mm of the wood surface, and good mold prevention and corrosion resistance are obtained; the wood is strong in waterproof durability, is loss resistant and long in residual action, the raw materials is easily available, and the cost can be saved.

Owner:HAIMEN JINQILIN REDWOOD INVESTMENT DEV

Anticorrosive wood production method

InactiveCN104858964ASimple processEfficient treatment processBiocideWood treatment detailsBronopolMethyl carbamate

The invention discloses an anticorrosive wood production method including five steps of wood pretreatment, preservative preparation, preservative liquid preparation, dipping treatment and post-drying treatment, a preservative comprises polyethylene glycol (peg), bronopol, 4, 5-dichloro-N-octyl-4-isothiazoline-3-one, imidacloprid, 2-chloro-5-hydroxy meta-xylene, dithiocyano-methane, dodecyl dimethyl benzyl ammonium chloride and N-(2-benzimidazole)-methyl carbamate and fatty alcohol polyvinyl chloride (PVC) ether. The beneficial effects are that the anticorrosive wood production method has the advantages of simple process, high efficiency, and easy operation, and the like, the processed wood maintains the original features, meanwhile has excellent anti-corrosion, mouldproof, insect-resistant, antibacterial and other effects, and is good in environmental protection property, stable in performance, and durable.

Owner:王玉燕

Mothproof and waterproof coating for garden wooden bridge and preparation method thereof

InactiveCN107141949AGood waterproofGood insect repellentAntifouling/underwater paintsPaints with biocidesCarbon blackPolyacrylamide

The invention discloses a mothproof and waterproof coating for a garden wooden bridge and a preparation method thereof. The coating comprises the following components: polyacrylamide, polyurethane, graphene, superfine talc powder, nano silicon dioxide, nano aluminum oxide, white carbon black, high-viscosity attapulgite clay, pyrethrum, radix angelicae, cortex cinnamomi, fructus quisqualis, radix euphorbiae lantu, anise, and radix sanguisorbae. The preparation method comprises: extracting the traditional Chinese medicine components respectively to obtain an extracting solution, and making the extracting solution into freeze-dried powder; adding polyacrylamide and a polyurethane aqueous solution into a reaction kettle, adding a graphene aqueous solution, and performing stirring reaction for 0.5-1.5h; and adding the superfine talc powder, the nano silicon dioxide, the nano aluminum oxide, the white carbon black and the high-viscosity attapulgite clay, mixing the materials uniformly, then adding the freeze-dried powder, and mixing the materials uniformly to obtain the coating. The coating is applied to decoration of the garden wooden bridge, and enables the wooden bridge to not only have good waterproof and anticorrosive effect but also have excellent mothproof and mildewproof properties, so that the coating has a good application value.

Owner:HEFEI XUELIXIN AGRI TECH CO LTD

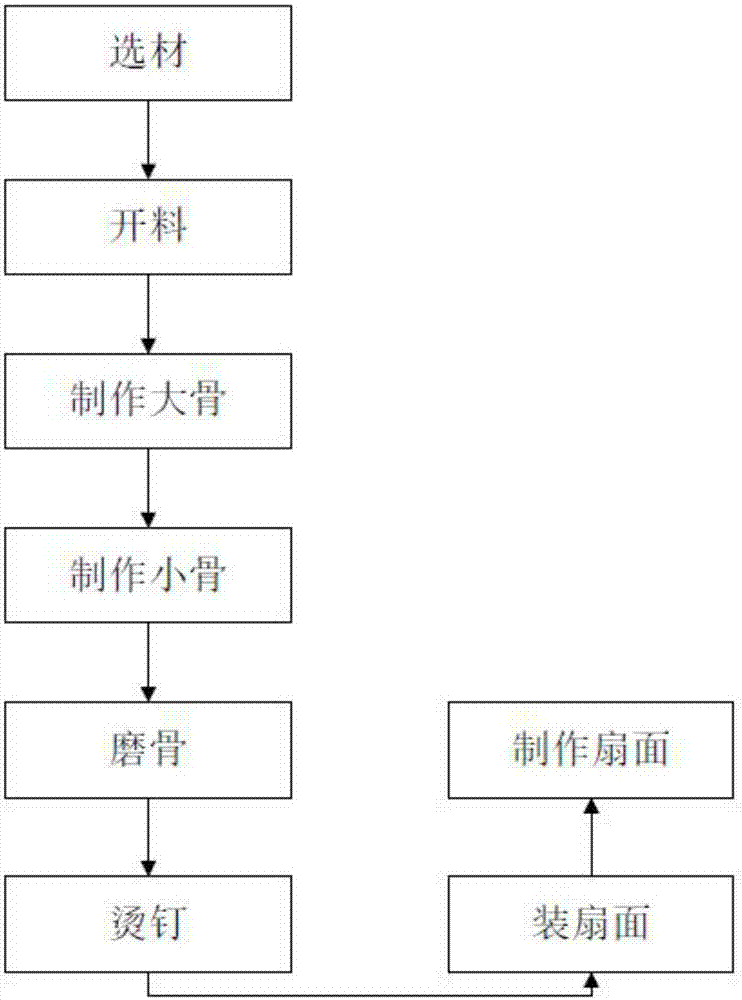

Folding fan manufacture method

InactiveCN107997323AExtend your lifeGood insect repellentUmbrellasWood working apparatusAgricultural engineeringLife time

The invention discloses a folding fan manufacture method which includes the steps: material selection; cutting; large framework manufacturing; small framework manufacturing; framework grinding; nail installation; fan surface manufacturing; fan surface installation and the like. According to the method, frameworks of a folding fan are boiled, dried and the like, so that the anti-insect and anti-corrosion effects of the frameworks are good, the frameworks are baked at the temperature about 300 DEG C, so that the strength of a fan frame is quite high and enhanced by double more than as comprisedwith the strength of a fan frame manufactured by a common grinding tool, and the service life of the whole folding fan is greatly prolonged.

Owner:苏州梅香雅筑工艺品有限公司

Wood fire retardant anticorrosive processing method

InactiveCN104858958ASimple processEasy to controlBiocideWood treatment detailsMethyl carbamateKetone

The invention discloses a wood fire retardant anticorrosive processing method including five steps of wood preprocessing, preparation of a flame retardant preservative, preparation of a flame retardant preservative solution, impregnation and post-drying processing. The fire retardant preservative is prepared from propylene glycol, bronopol, 4, 5-dichloro-N-octyl-4-isothiazolin-3-one, 2-chloro-5-hydroxy meta-xylene, dithiocyano methane, dodecyl dimethyl benzyl ammonium chloride, N-(2-benzimidazole)-methyl carbamate, diammonium phosphate, zinc borate, ammonium molybdate and fatty alcohol polyoxyethylene ether compound. The beneficial effect is that the wood fire retardant anticorrosive processing method is simple in process, practical, efficient, environmentally-friendly, and easy to control, and the like, the processed wood maintains the original features, meanwhile has excellent flame retardant, anti smoke, anti-corrosion, anti mildew, pest control, antibacterial, anti erosion and other muti-function modification effect, is stable in performance, non-toxic, and environmentally-friendly, and can be widely used in indoor and outdoor decoration, building material, furniture material and other fields.

Owner:王玉燕

Self-control positioning rewinding screen window

ActiveCN105781388AEasing inertia forceExtended service lifeInsect protectionEngineeringInertia force

A self-control positioning rewinding screen window comprises a housing device, a reel screen window device, a window frame device and a positioning pull rod device, wherein the window frame device comprises side pillars and a bottom rod, and slideways are disposed in the side pillars; the positioning pull rod device comprises a pull rod, and an outer clamping heads are disposed on end parts of the pull rod; the positioning pull rod device also comprises inner clamping heads and a screw rod, the screw rod successively passes through the inner clamping head and the outer clamping heads and reaches inside of the pull rod, the screw rod is equipped with spring stopping blocks on the outer sides of the outer clamping heads, the spring stopping blocks are clamped inside the pull rod, the screw rod is sleeved by springs between the spring stopping blocks and the outer clamping heads, and the screw rod is equipped with bolts embedded in the spring stopping blocks are disposed on outer sides of the spring stopping blocks; and the inner clamping heads are located in the slideways of the window frame device, the outer clamping heads are disposed outside the slideways, and the outer clamping heads and the inner clamping heads generate clamping force to the side pillars. The screen window provided by the invention has the advantages that a screen mesh can be positioned and unfolded at any position in the window frame; rewinding inertia force of the rewinding screen window is small; the structure is simple; and installation and disassembly are convenient, etc.

Owner:钜峰窗饰江苏有限公司

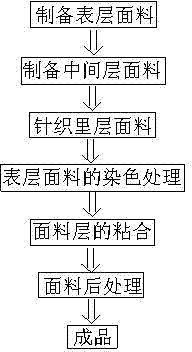

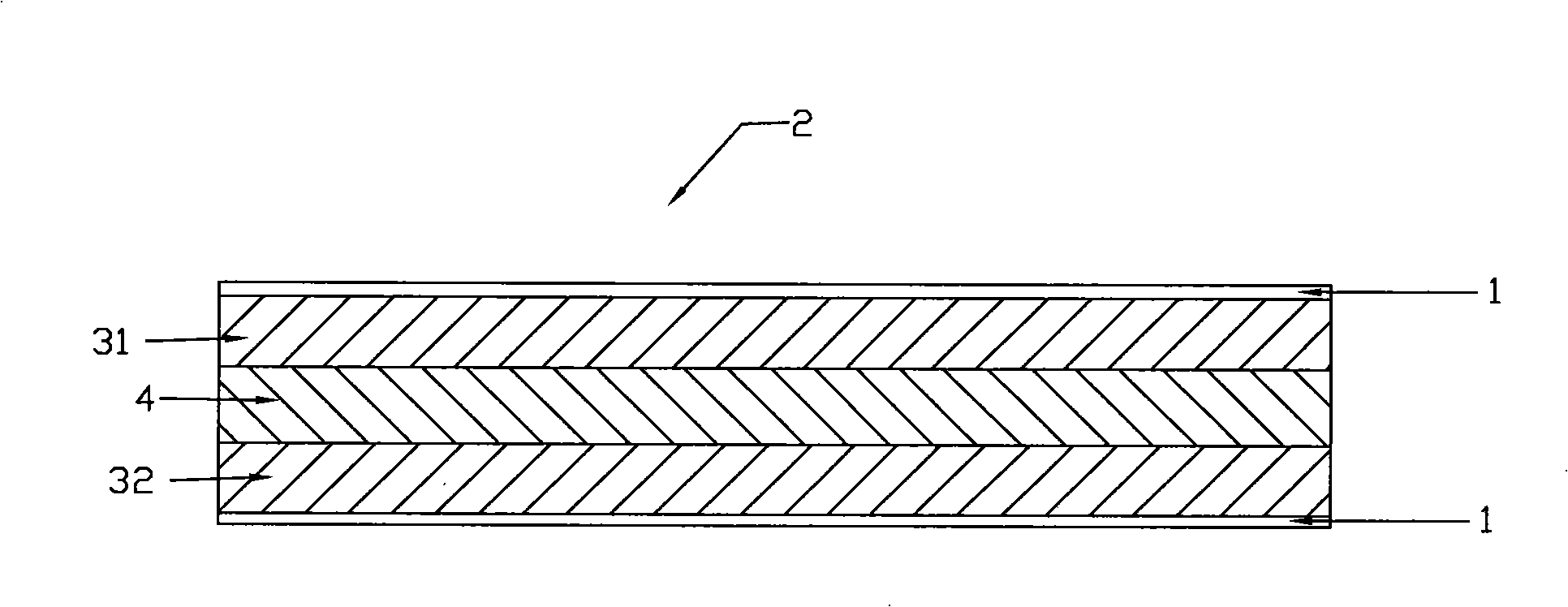

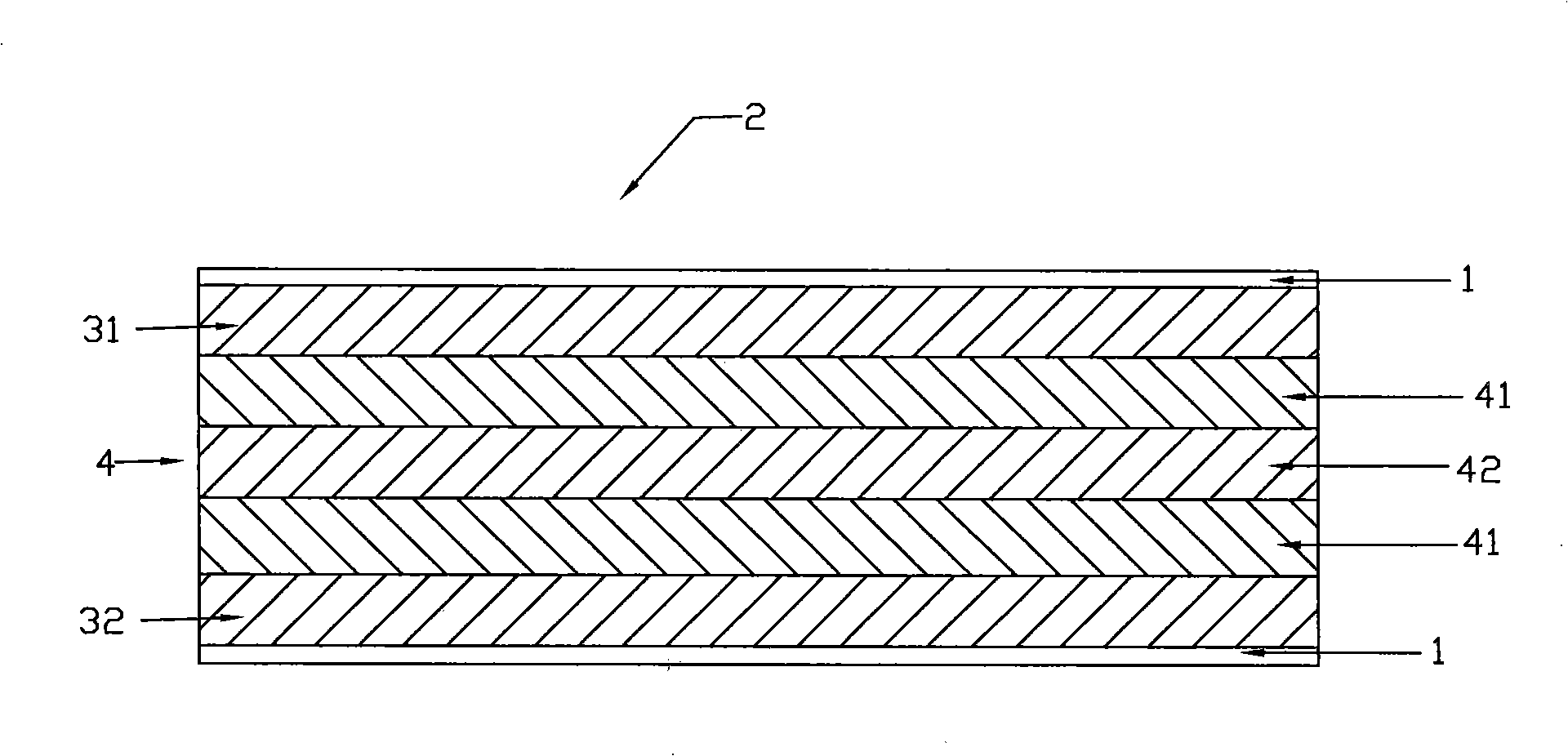

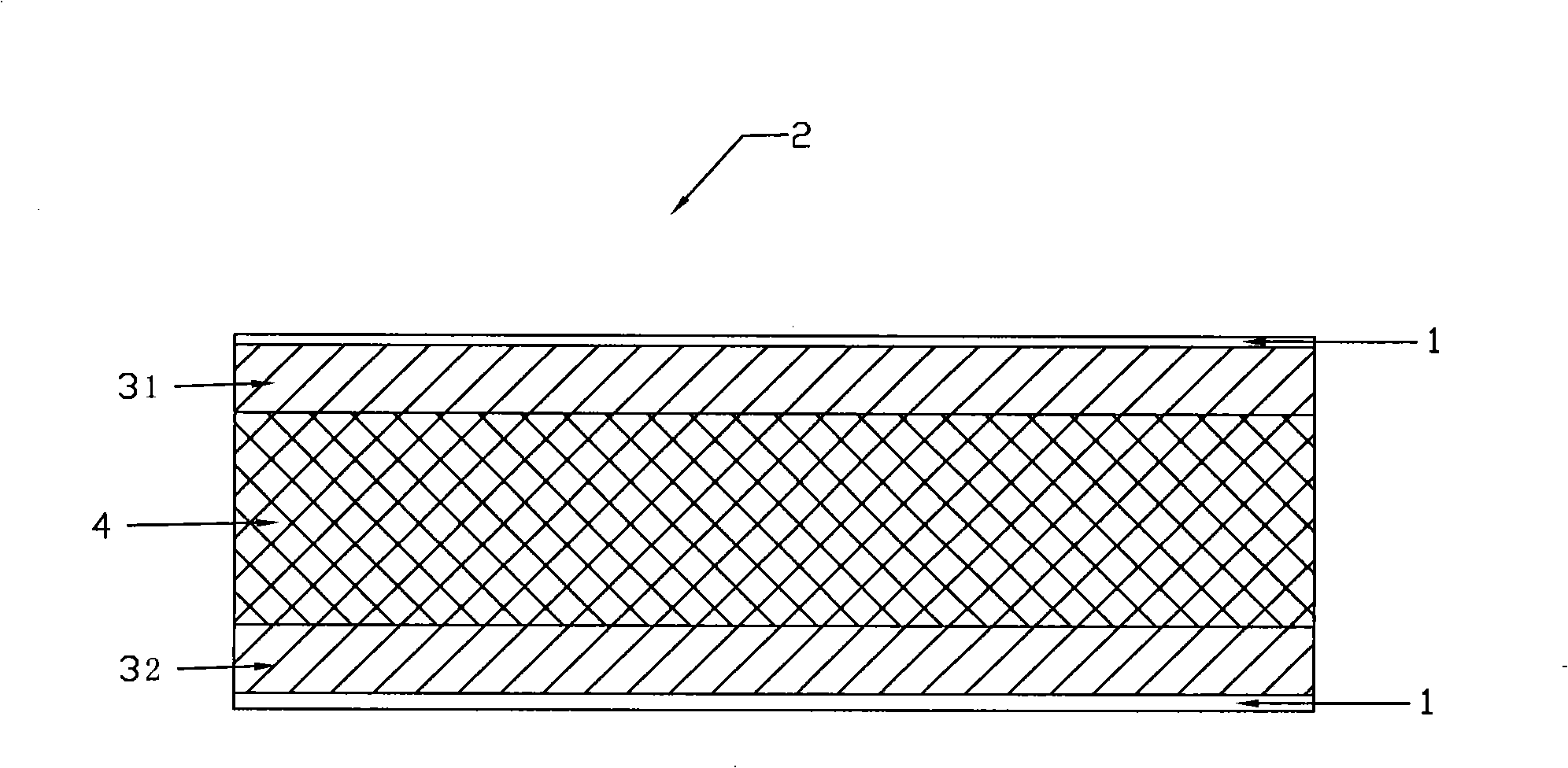

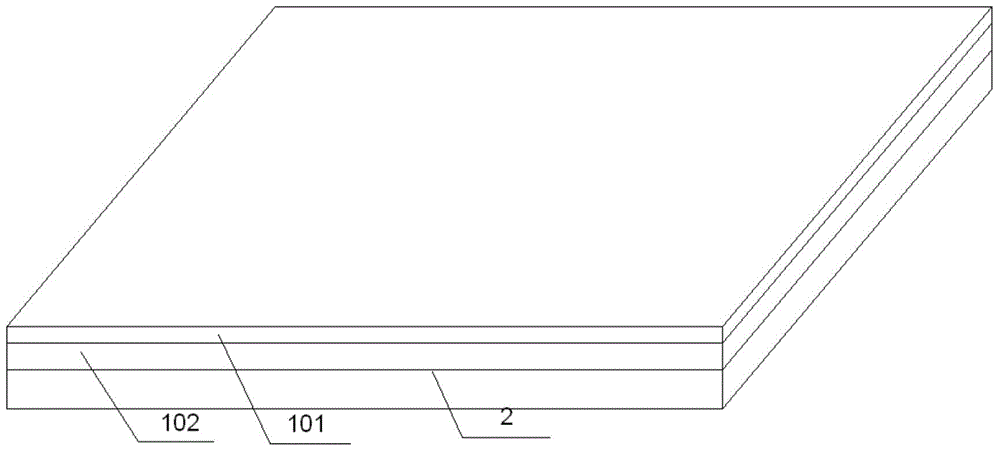

Preparation method for novel insect-resistant fabric

InactiveCN102774059AGood insect repellentImprove breathabilitySynthetic resin layered productsBiotechnologyEngineering

The invention provides a preparation method for a novel insect-resistant fabric. The preparation method includes the following steps: (a) preparation of a surface fabric; (b) preparation of a middle fabric; (c) knitting of an inner fabric; (d) dyeing of the surface fabric; (e) bonding of the layers of the fabric; and (f) aftertreatment of the fabric. The process arrangement of the preparation method for the novel insect-resistant fabric, which is disclosed by the invention, is reasonable, the preparation steps are compact, the cost is moderate, the prepared fabric has excellent insect resistance, and can prevent mosquitoes, mites, fleas and other poisonous insects from harming the human body, moreover, the fabric keeps excellent air permeability and elasticity, the appearance is stylish, and the service performance is excellent.

Owner:KUSN ZHOUSHI HUIHONG GARMENT FACTORY

Sandwich silk filling core material

The invention relates to a sandwich silk filling core material, which is characterized in that the sandwich silk filling core material comprises an upper surface silk layer, a lower surface silk layer and a fibrilia interlayer between the upper surface silk layer and the lower surface silk layer, wherein the weight percentage content of the fibrilia in the sandwich silk filling core material is 35-80 percent. The sandwich silk filling core material of the invention has the advantages of softness and comfort, insect prevention and expelling, antimicrobial effect, effective mildew prevention and low price.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Bamboo insect prevention treatment method

InactiveCN105946080ASoothe body and mindRelax the mindWood treatment detailsReed/straw treatmentHorticultureInsect

The invention discloses a bamboo insect prevention treatment method, and belongs to the technical field of bamboo processing. The method adopts the following raw materials in parts by weight: 6-8 parts of plant insect killing and preventing liquid, 70-80 parts of water, and 10-22 parts of quicklime. The method comprises the following steps: (a) the quicklime is put in a pool; the plant insect killing and preventing liquid and the water are uniformly stirred; and then, a bamboo product is dipped by 68-72 hours; (b) the bamboo product is taken out from the pool, and is put in a shady place for airing by 68-72 hours; and (c) the bamboo product, aired in the step (b), is put in an oven by 20-23 minutes at a temperature of 72-80 DEG C. The method can solve the problem of easiness in insect generation in traditional bamboo products.

Owner:三江县善茶轩工艺品有限公司

Preparation method of medicinal cushion core material

InactiveCN1919718AImprove anti-corrosion performanceImprove moisture resistanceUpholstery fillingArtemisia vulgarisMugwort

The invention discloses a preparing method of drug pad core material, which comprises the following steps: cutting main stem of straw as raw material, adding water to boil 200g Artemisia vulgaris, 100g night-cross, 50g schisandra fruit, 30g lily, 40g albizia bark bough, 50g fried date core, 30g amomum fruit, 30g matrimony vine and 10g safflower into 3000-4000g traditional Chinese medicine, mating raw material and traditional Chinese medicine with weight rate at 10:0.5-2, soaking for 60-80h, adding 0.5-2% benzine as dried soaked weight of main raw material.

Owner:张成春

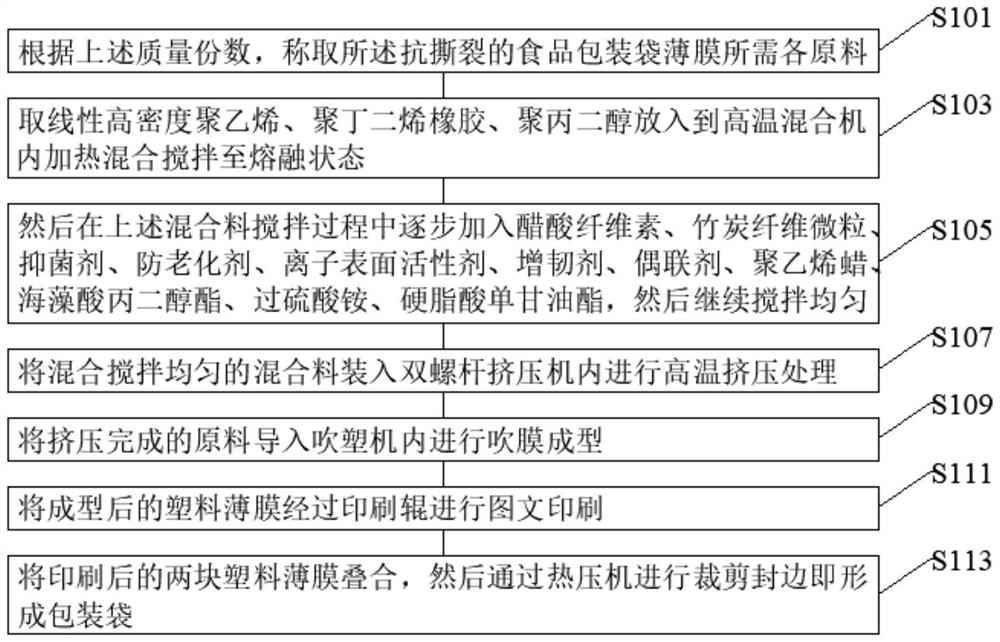

Tear-resistant food packaging bag film and preparation method thereof

The invention discloses a tear-resistant food packaging bag film and a preparation method thereof. The tear-resistant food packaging bag film is prepared from the following raw materials in parts by mass: 45 to 65 parts of linear high density polyethylene; 15 to 25 parts of polybutadiene rubber; 10-15 parts of polypropylene glycol, 7-15 parts of cellulose acetate, 2-3 parts of bamboo charcoal fiber particles, 5-12 parts of a bacteriostatic agent, 2-4 parts of an anti-aging agent, 2-3 parts of an ionic surfactant, 2-3 parts of a toughening agent, 1-2 parts of a coupling agent, 2-3 parts of polyethylene wax, 1-2 parts of propylene glycol alginate, 1-3 parts of ammonium persulfate and 1-2 parts of glyceryl monostearate. The food packaging bag film has the beneficial effects that the food packaging bag film has good tear resistance and also has good antibacterial, mildew-proof, insect-proof and anti-aging properties.

Owner:马鞍山市欧凯包装材料有限公司

Plastic composition, composite floor including plastic composition, and production method of floor

InactiveCN106280060ASimple structureNice appearanceSynthetic resin layered productsLaminationFoaming agentPolyvinyl chloride

The invention discloses a plastic composition, a composite floor including the plastic composition, and a production method of the floor. The plastic composition is produced from, by weight, 30-55 parts of polyvinyl chloride, 35-55 parts of stone flour, 0.5-5 parts of a polyurethane foaming agent and 0.5-5 parts of a stabilizer. The composite floor comprises a decoration layer and a supporting layer, and the supporting layer is made of the plastic composition. The composite floor provided by the invention has the advantages of simple structure, beautiful and great profile, good water, worm and mildew resistance, effective saving of the wood resources, low cost and environmental protection.

Owner:JIANGSU SEMAO BAMBOO & WOOD IND CO LTD

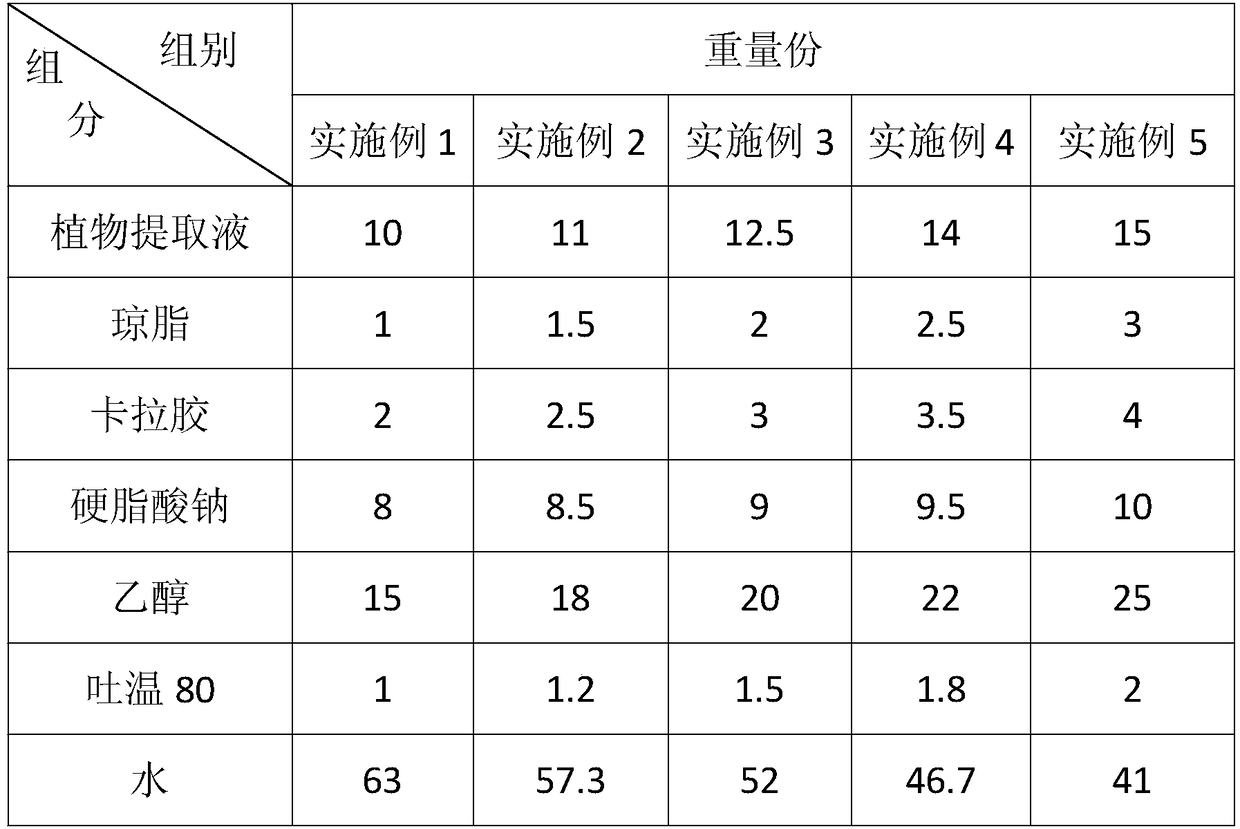

Gel-type air freshener and preparation method thereof

The invention belongs to the technical field of air freshening and particularly relates to a gel-type air freshener and a preparation method thereof. The air freshener contains the following components: 10-15 parts of plant extract, 1-3 parts of agar, 1-2 parts of Tween 80, 2-4 parts of carrageenan, 8-10 parts of sodium stearate, 15-25 parts of ethanol and the balance of distilled water tilling reaching 100 part. The air freshener disclosed by the invention has the advantages that by selecting the plant extracts of clematis, red smartweed, sweet wormwood, stemona and the like as active ingredients, worms and mosquitoes in bathrooms can be effectively expelled and killed; and the air freshener has the effects of restraining and killing various bacteria and can also emit an aromatic smell topurify the bathroom air and make people feel pleasant.

Owner:李远响

Worm-resistant bookmark manufacturing method

InactiveCN107415516AGood insect repellentFunction increaseBiocidePest repellentsCymbopogon distansBletilla striata

The invention discloses a worm-resistant bookmark manufacturing method. The worm-resistant bookmark manufacturing method comprises the following steps: (1) selecting dry lavender flowers, pulverizing the dry lavender flowers, screening the pulverized dry lavender flowers with a 10-mesh filter screen and screening the screened dry lavender flowers with a 50-mesh filter screen to obtain plus-sieve pulverized dry lavender flowers and minus-sieve pulverized dry lavender flowers; and grinding cymbopogon distans, saponin, alum and bletilla striata into powder, adding the minus-sieve pulverized dry lavender flowers, and performing uniform mixing to obtain worm-resistant powder; (2) adding glue into the worm-resistant powder, and performing uniform stirring to obtain worm-resistant powder glue for later use; (3) pasting two pieces of bookmark paper with the worm-resistant powder glue, then pressing into a bookmark and performing airing; and (4) coating the surface of the bookmark with a layer of the plus-sieve pulverized dry lavender flowers, and pressing an air-permeable plastic film on the bookmark by a laminator to obtain the worm-resistant bookmark. The worm-resistant bookmark manufacturing method not only can prevent book worms from destroying books but also carries faint lavender fragrance, and therefore improves the reading experience of people.

Owner:贵州茵莱特教育科技有限责任公司

Wooden product insect repellent agent and preparation method thereof

InactiveCN108081413AGood insect repellentGood antibacterial effectWood treatment detailsCoating impregnationEssence oilBiology

The invention relates to a wooden product insect repellent agent which comprises, by weight, 10-15 parts of Chinese herbal medicines, 1-2 parts of sodium chloride, 22-25 parts of absolute ethyl alcohol, 0.5-0.8 part of potassium sorbate, 2-3 parts of wood vinegar and 3-5 parts of essential oil. The invention further relates to a preparation method of the wooden product insect repellent agent. Thepreparation method includes the steps: cleaning the Chinese herbal medicines, soaking the Chinese herbal medicines for 4-6 hours after drying, heating and decocting the Chinese herbal medicines for 30-40 minutes, filtering the Chinese herbal medicines to obtain liquid medicines and medicine residues; concentrating the liquid medicines to reach 30-40% of original volume; drying and crushing the medicine residues, grinding the medicine residues into powder, sieving the powder by a 300-mesh sieve, adding the absolute ethyl alcohol, soaking the powder for 8-10 hours and centrifugally separating and collecting supernate; mixing the supernate with the concentrated liquid medicines, the sodium chloride, the potassium sorbate, the wood vinegar and the essential oil, and uniformly stirring the components to obtain a finished product. The prepared wooden product insect repellent agent has good insect repelling and preventing, antisepsis and bacteriostasis effects, can prevent wood borers such aspowder-pest beetles, has the advantages of strong efficacy, long residual period and the like, and is applicable to maintenance of wooden products.

Owner:湖州南浔丽学木制品厂

Multi-layer structure composite board manufactured by squeezing glue-free straw boards at high temperature

InactiveCN104989032ASolve the problem of not being suitable for interconnecting socketsSolve technical problemsBuilding componentsJoistEngineering

The invention discloses a multi-layer structure composite board manufactured by squeezing glue-free straw boards at a high temperature. The two large faces of a composite core board are each provided with a layer of composite outer layer wood board in a composite mode. The composite core board comprises a center skeleton board on the center layer. The two large faces of the center skeleton board are each provided with one layer of glue-free straw board in a composite mode. The outer large face of each glue-free straw board is provided with a fireproof board in a composite mode. A five-layer board formed by the glue-free straw boards, the fireproof boards and the center skeleton board has two opposite flush side faces. The two flush side faces are each provided with a layer of peripheral skeleton board in a composite mode. The two opposite side faces of the two composite outer layer wood boards are flush with the outer edges of the side faces of the peripheral skeleton boards on the same sides as the two composite outer layer wood boards. The composite board has the advantages of being free of glue and air pollution, low in density and light, has the enough connecting performance and strength, is good in flexibility and enables a wall to achieve self bearing, no joist is needed, deformation is avoided, the multi-layer structure composite board has the advantages of water resistance, impact resistance, radiation resistance and the like, and the service life of the board is as long as that of a building.

Owner:烟台金田科技有限公司

Cushion core material with health care action

InactiveCN1919107AImprove anti-corrosion performanceImprove moisture resistanceStuffed mattressesSpring mattressesFilling materialsMedicine

The invention discloses a hygienic bedding material, which is characterized by the following: adopting yphaster stem as main material and traditional Chinese medicine as auxiliary material, setting the weight rate of main and auxiliary material at 100: 1-10. The auxiliary material contains amomum fruit, albizia, jujube core, lily, schisandra fruit, apocynum and apocynum, which also consists of Artemisia vulgaris and camphor.

Owner:张成春

Efficient leather cleansing agent

InactiveCN104357259AStay softKeep it brightSurface-active non-soap compounds and soap mixture detergentsLeather surface finishingPolymer scienceActive agent

The invention relates to an efficient leather cleansing agent. The cleansing agent is prepared from the following raw materials in parts by weight: 1-3 parts of hydrochloric acid, 6-10 parts of aluminum trichloride, 3-8 parts of soap powder, 4-9 parts of ethyl alcohol, 10-15 parts of butyl acrylate, 2-8 parts of a stabilizing agent, 5-10 parts of tert-butyl cresol, 8-11 parts of polyurethane resins, 4-7 parts of mineral oil, 1-5 parts of a surfactant, 5-11 parts of wool fat, 3-10 parts of camphor oil, 2-6 parts of ethylparaben, 7-9 parts of lecithin, and 1-5 parts of wax. The efficient leather cleansing agent disclosed by the invention has the benefits that the cleansing agent can quickly clean stain on leather, can keep the leather soft, shining and bright, and has good mildewproof and mothproof functions.

Owner:QINGDAO TOPLINK INFORMATION TECH

Aluminum composite board and manufacturing method thereof

PendingCN112092469AImprove performanceComposite seamlessNon-macromolecular adhesive additivesCovering/liningsAdhesive glueComposite plate

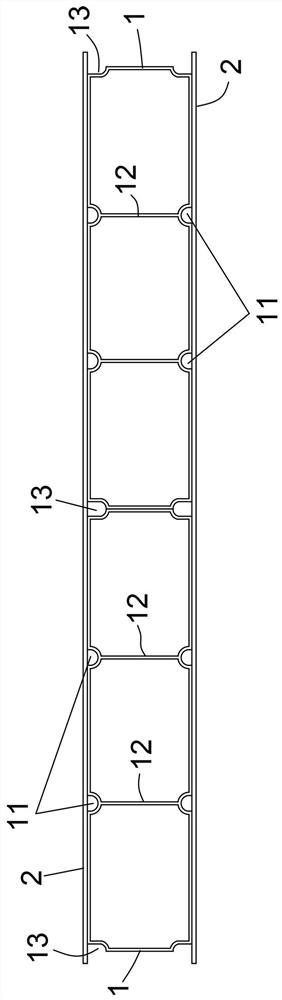

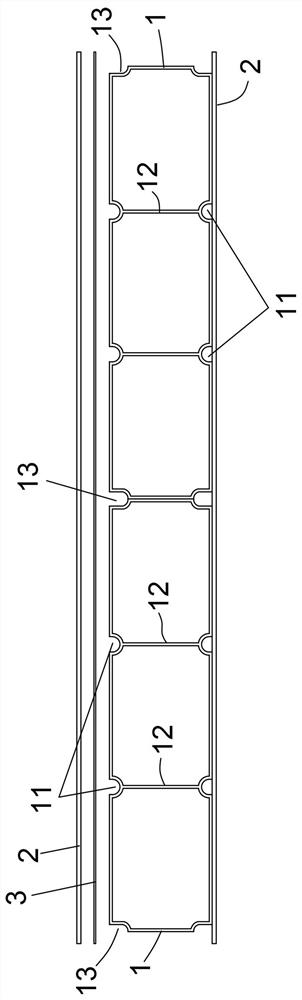

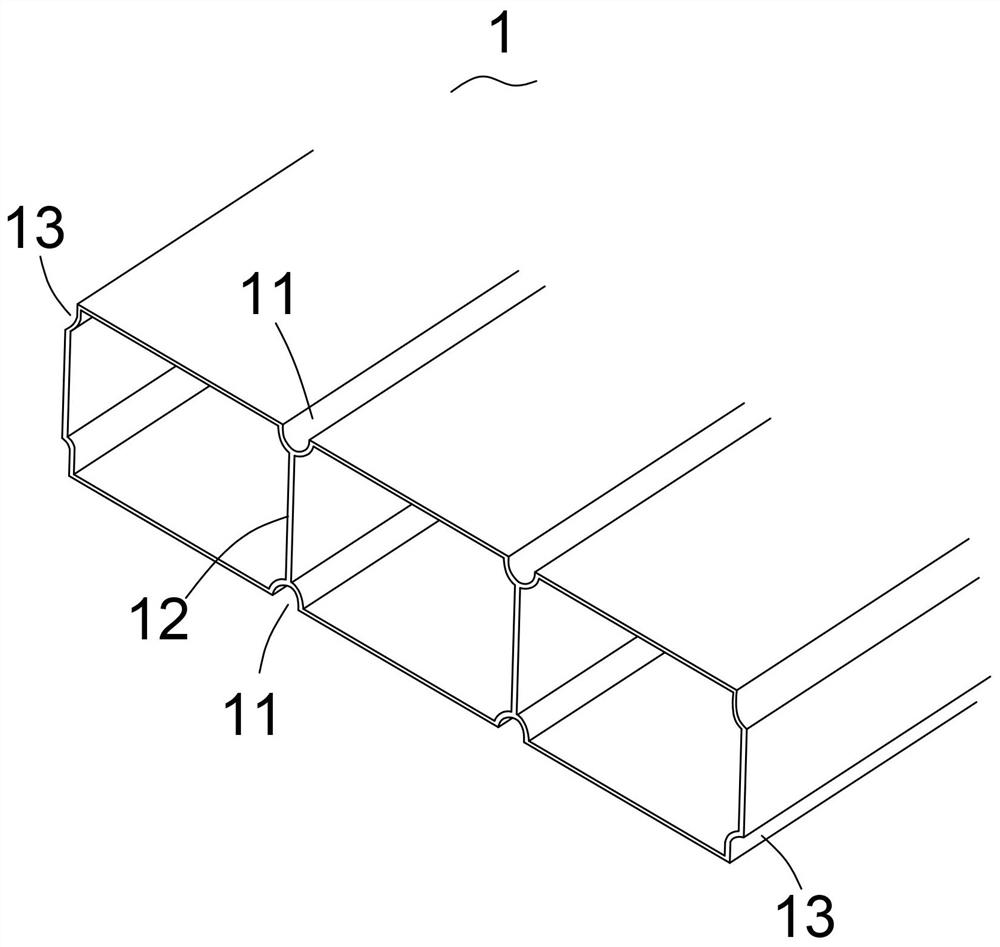

The invention relates to an aluminum composite board and a manufacturing method thereof. The aluminum composite board comprises a base layer formed by sequentially leaning a plurality of aluminum profile square tubes together side by side in the horizontal direction, and aluminum boards covering the upper side face and the lower side face of the base layer respectively. The aluminum boards and thealuminum profile square tubes are bonded together through PUR glue, a ventilation system is constructed between the aluminum boards and the aluminum profile square tubes, external air permeates through the ventilation system, moisture existing in the air reacts with the PUR glue, chain extension is conducted, and a high-molecular polymer with high cohesion is generated. The aluminum board and thealuminum profile square tube are bonded together. The aluminum composite board is composed of the aluminum profile square tubes and the aluminum boards, and the prepared board is stable in performance, seamless in compounding, good in flatness, excellent in hand feeling and sound, low in deformation coefficient and environmentally friendly, has good waterproof, fireproof, insect-proof, anti-corrosion and high-low-temperature-resistant effects and can be used as a wall board or a furniture board. The production process is simple, high in efficiency, high in productivity and low in energy consumption.

Owner:广东德派克家居科技有限公司

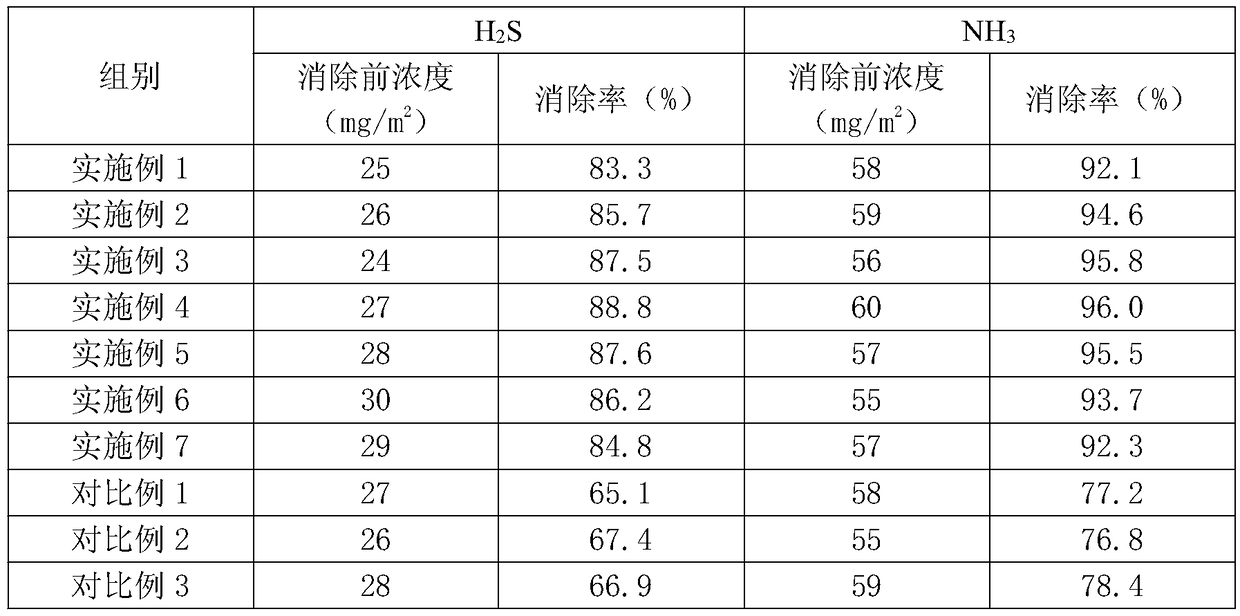

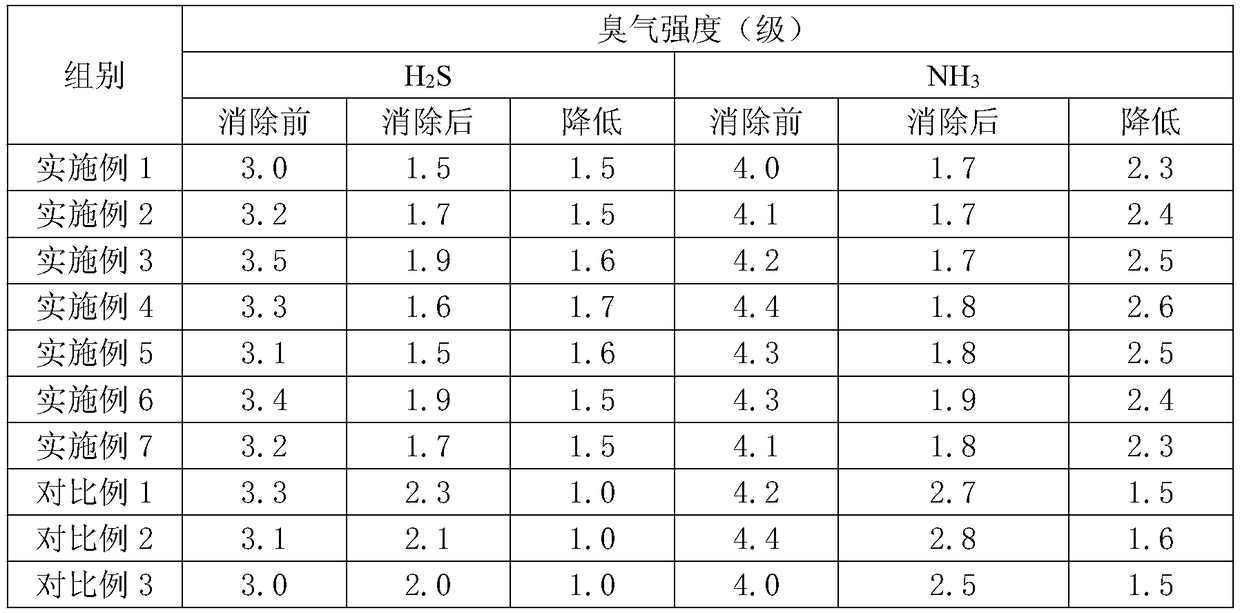

Antibacterial deodorant composition

PendingCN112138198AGood odor eliminationExcellent decontaminationBiocidePest repellentsMedicinal chemistryPharmacology

The invention discloses an antibacterial deodorant composition. The antibacterial deodorant composition comprises carbonate and an active adsorption material; and the carbonate and the active adsorbent material are present in the form of a mixture. According to the antibacterial deodorant composition, the carbonate and the active adsorption material are taken as main components, so that the antibacterial deodorant composition is safe, non-toxic and odorless, and has the beneficial effects of peculiar smell elimination, decontamination, bacteriostasis, insect prevention, moisture prevention, agglomeration and the like.

Owner:白杨

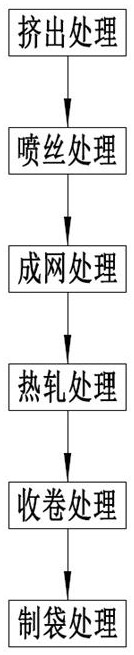

Production method of antibacterial non-woven fabric fruit bag

PendingCN114148035AGood antibacterialExcellent antibacterial propertiesBag making operationsPaper-makingPolypropyleneAnti bacterial

The invention relates to the technical field of non-woven fabric fruit bag production, and discloses a production method of an antibacterial non-woven fabric fruit bag, and the method comprises the following steps: (1) extrusion treatment: polypropylene particles are pumped into an extruder to be heated and molten to prepare a molten raw material A; (2) spinning treatment, wherein the molten raw material A is sprayed out of tows B through a spinneret plate; (3) web forming treatment, wherein the tows are stretched and fall onto a web curtain of a web forming machine through a drafting fan to be laid into a fluffy net-shaped object C; (4) hot rolling treatment: placing the mesh C in a hot rolling mill for hot rolling forming to obtain a non-woven fabric D; (5) winding treatment: winding the non-woven fabric D on a paper tube to obtain a non-woven fabric roll E; and (6) bag making treatment, wherein the non-woven fabric roll E is put into a non-woven fabric bag making machine to be made into a non-woven fabric fruit bag. The non-woven fabric fruit bag is good in light transmission and air permeability, fruits are sweeter and more delicious, the fruits and the bag only need to be picked off together during harvesting, netting is not needed, labor intensity is reduced, and labor is saved.

Owner:莱州锦宏纺织有限公司

Worm expelling wood lacquer for home furnishing

InactiveCN104327603AImprove the finishGood insect repellentAntifouling/underwater paintsPaints with biocidesEpoxyPolymer science

The invention discloses a worm expelling wood lacquer for home furnishing. The wood lacquer is prepared from the following raw materials in parts by weight: 8-15 parts of cellulose acetate, 6-10 parts of N-o-methylphenyl diethanolamine, 3-9 parts of ethylene glycol, 5-9 parts of defoaming agent, 3-8 parts of lavender, 4-8 parts of geranium, 2-6 parts of blumea hongkongensis, 1-5 parts of propylene glycol, 4-9 parts of superfine silicon dioxide, 2-8 parts of epoxy emulsion, 1-5 parts of polyaspartic acid ester, 4-6 parts of amorphous silicic acid, 4-9 parts of propylene glycol methyl ether acetate and 1-5 parts of micronized polyethylene wax. The worm expelling wood lacquer for home furnishing has a good worm and mosquito expelling effect, and can improve the finish of home furnishing and improve the attractiveness at the same time.

Owner:QINGDAO KELIKE INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com