Patents

Literature

62results about How to "Efficient treatment process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

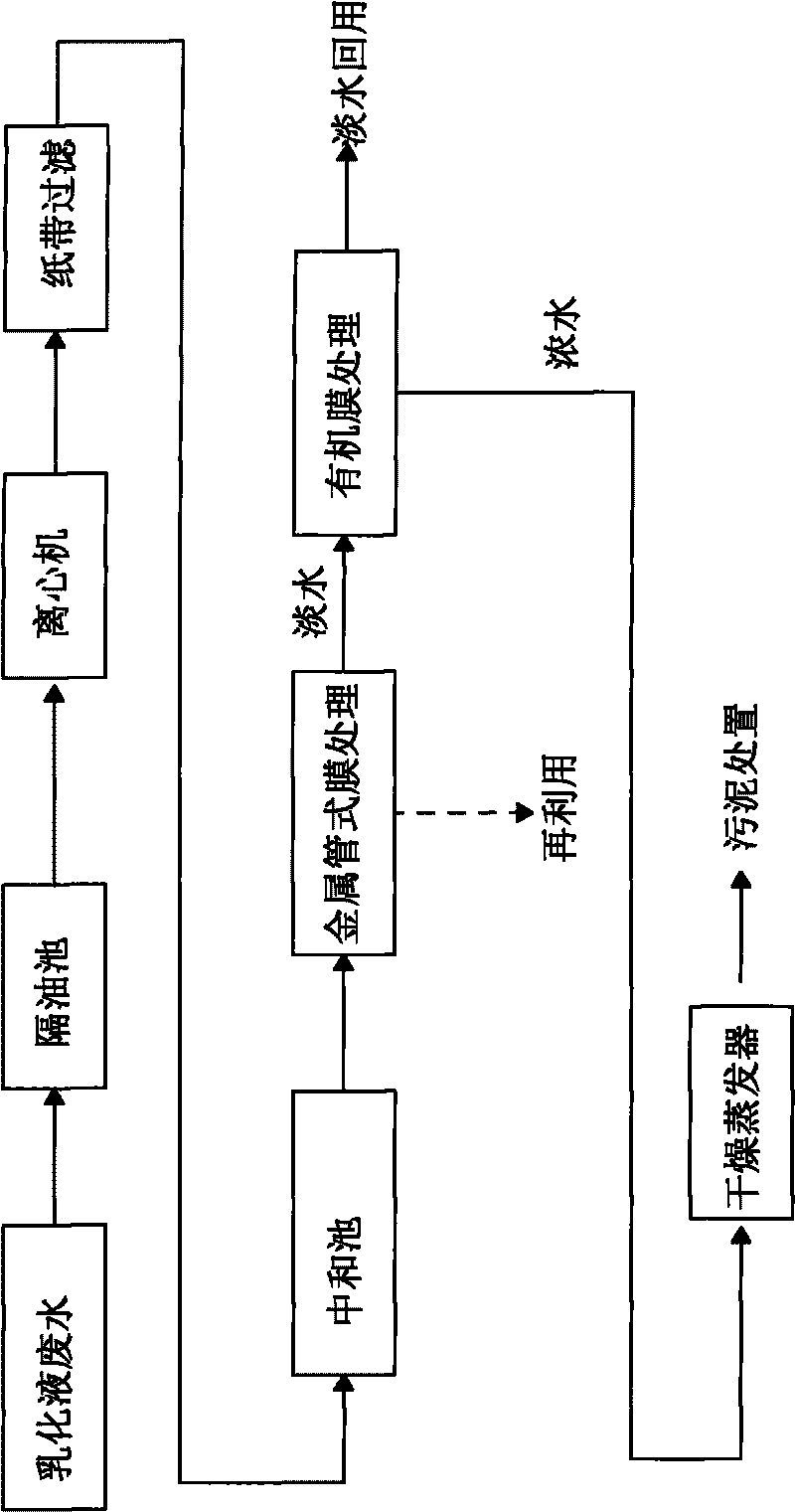

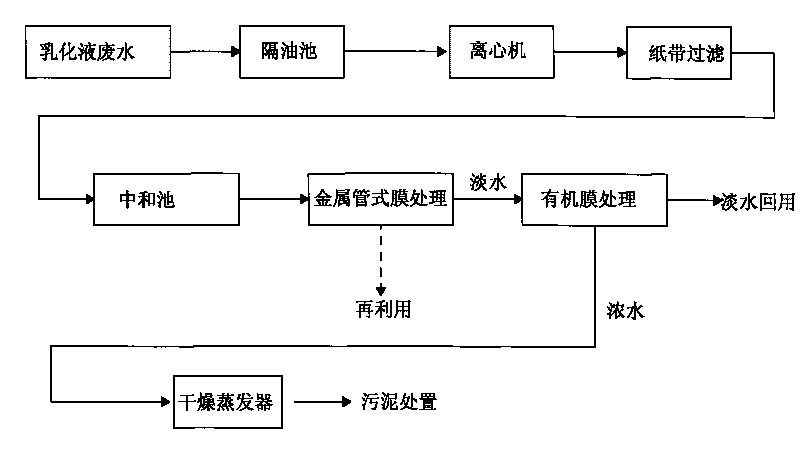

Emulsifying liquid wastewater membrane treatment process

InactiveCN101708912AEfficient treatment processEasy to operateWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesUltrafiltrationChemistry

The invention discloses an emulsifying liquid wastewater membrane treatment process. The process comprises the steps of pretreatment, metal tube type membrane ultrafiltration and organic membrane pretreatment. The process has the advantages that the problem that the current emulsifying liquid wastewater treatment has high cost, complex operation, low treatment efficiency and poor comprehensive recycling effect can be effectively solved so that the oil content of the treated emulsifying liquid wastewater is 10mg / l or less, the suspended substance (SS) content is 30mg / l or less and the chemical oxygen demand (CODcr) is 100mg / l or less, the problem that the emulsifying liquid wastewater is treated and discharged according to the related standard or is reused is fully solved; and the comprehensive utilization of the emulsifying oil is realized, the treatment process is efficiency and energy-saving, is easy to operate and use, the environmental pollution is reduced, the cost is low, and the process has great economic and social benefits.

Owner:苏州凯新分离科技有限公司

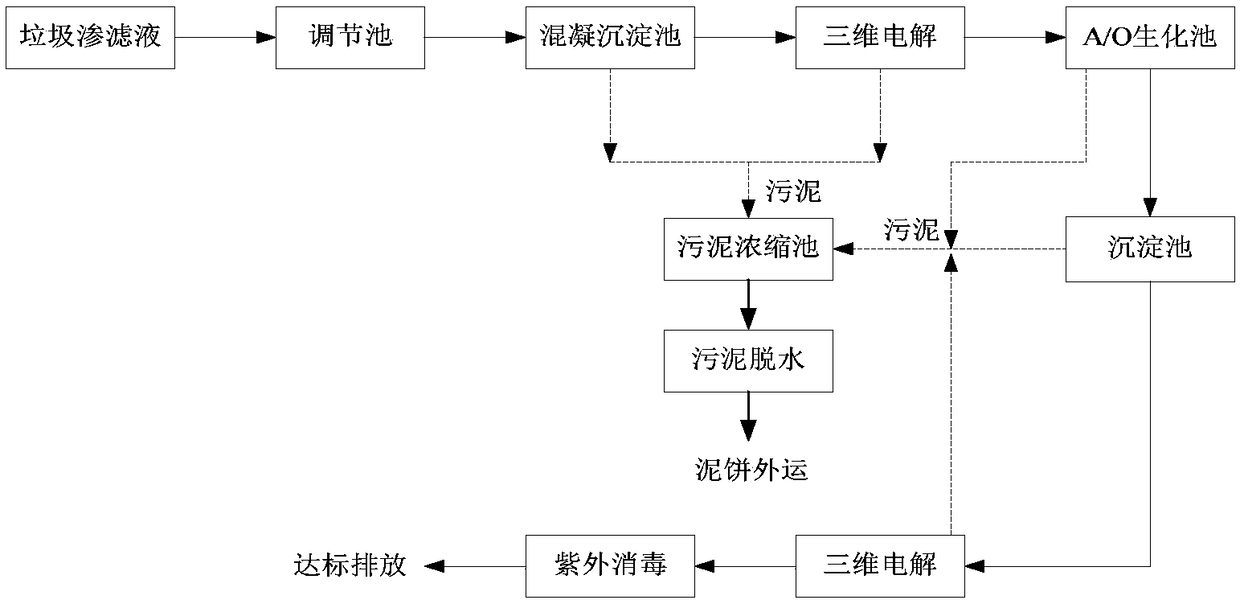

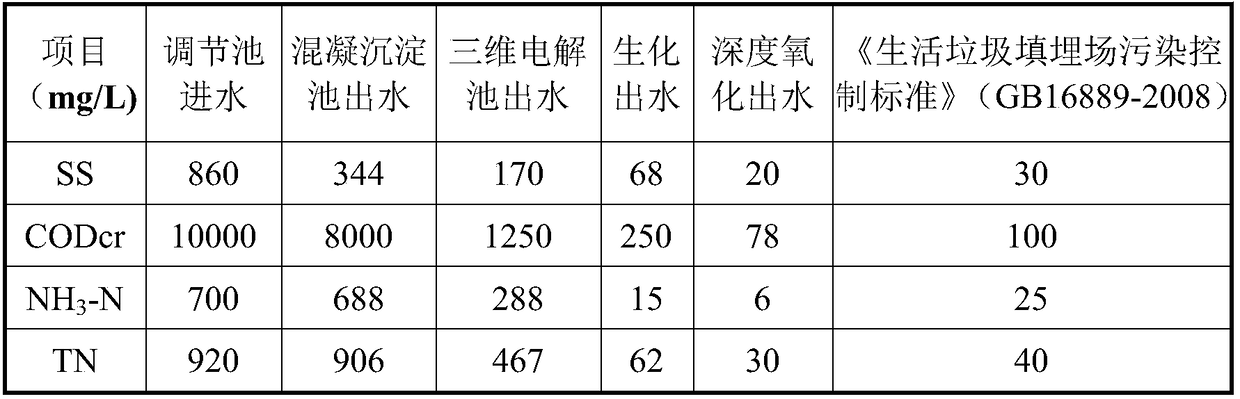

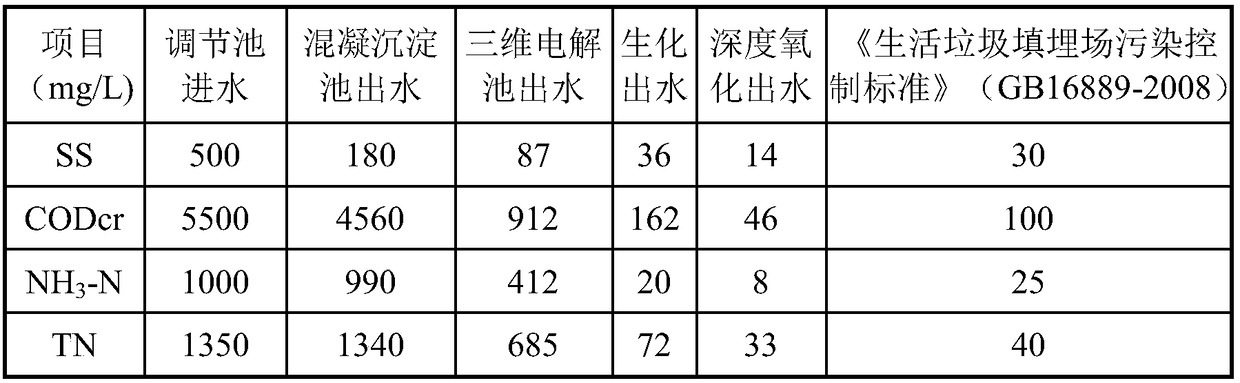

Landfill leachate treatment process system and method

InactiveCN109133522AGood coagulation effectAchieve biodegradabilityWater treatment parameter controlWater/sewage treatment by irradiationElectrolysisHydrogen

The invention discloses a landfill leachate treatment process system and method. The method includes the process steps: (1) enabling landfill leachate to automatically flow into a regulating tank andhomogenizing water in the regulating tank; (2) enabling waste water in the regulating tank to automatically flow into a coagulative precipitation tank; (3) enabling coagulative precipitation effluentto automatically flow into a three-dimensional electrolytic tank and performing oxidizing reaction on organic pollutants in the waste water; (4) adjusting the pH (potential of hydrogen) value of the waste water to be 6.8-7.2, enabling the waste water to be suitable for biochemical treatment, and then enabling the waste water to automatically flow into an A / O biochemical system; (5) setting three-dimensional electrolysis behind a biochemical system to take deep treatment measures. After the effluent is subjected to ultraviolet disinfection, various indexes can reach discharge standards. The system and the method have the advantages of high efficiency, economical efficiency, easiness in operation management and the like.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

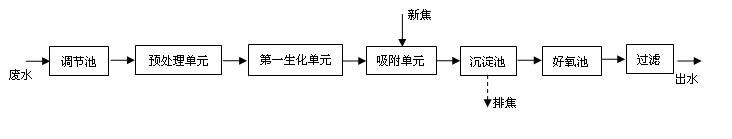

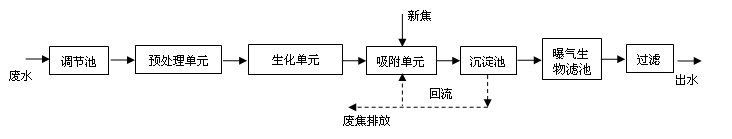

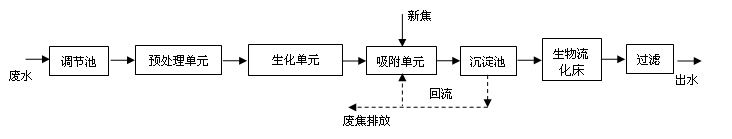

Method for treating coal chemical wastewater

InactiveCN102211839AEfficient treatment processHandling process safetyMultistage water/sewage treatmentWastewaterWater quality

The invention relates to a method for treating coal chemical wastewater, which comprises the following steps in turn: pretreatment, biochemical treatment with a first biochemical unit, adsorption treatment with an adsorption unit, sedimentation treatment with a sedimentation tank, and advanced biochemical treatment. The method solves the technical problems of high ozone electric power consumption, high cost and influence on yielding water quality because ozone is used for performing advanced treatment in the method for treating the coal chemical wastewater in the prior art. In the method for treating the coal chemical wastewater, the ozone is not used, resources are saved, and the yielding water quality can be well guaranteed, so the method is particularly suitable for treating the coal chemical wastewater.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV +1

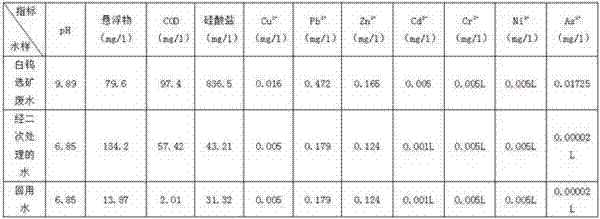

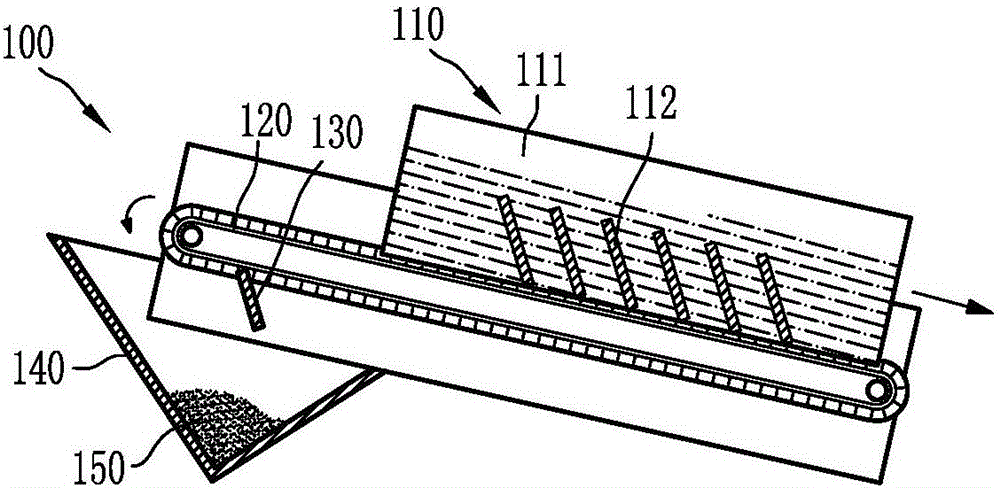

Stone processing sewage treatment system

InactiveCN105169806ASimple structureEasy to install and maintainFiltration circuitsSewageTherapeutic effect

The invention discloses a stone processing sewage treatment system which comprises a sewage sediment treating device and a sewage mud treating device. The sewage sediment treating device comprises a sediment settling pool with the upper end larger than the lower end, a filter funnel is arranged on a water inlet of the sediment settling pool, a spiral conveying device is arranged at the bottom of the sediment settling pool, and a sediment vibration dehydration conveying device is arranged on a sediment conveying outlet of the spiral conveying device. The sewage mud treating device comprises a mud settling pool with the upper end larger than the lower end, the mud settling pool is communicated with the sediment settling pool through a pipeline, and a mud settling dehydration conveying device is arranged at the bottom of the mud settling pool. The stone processing sewage treatment system is reasonable in structural design, equipment investment cost and running cost are low, sewage and sediment are separated fast and thoroughly, and the sewage treatment effect is good.

Owner:丁西军

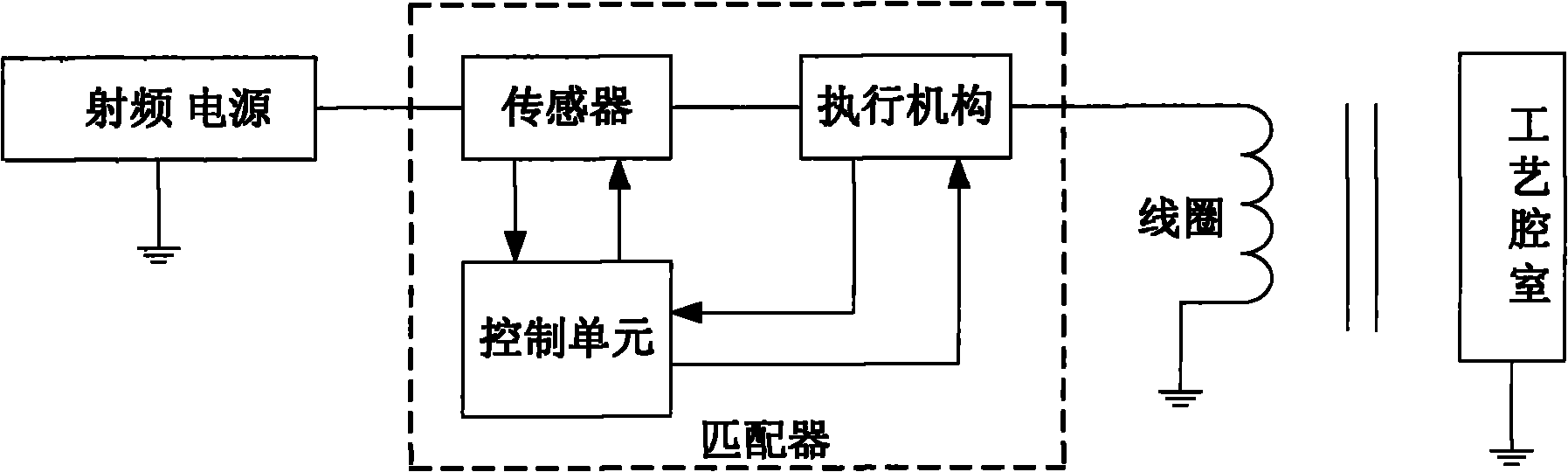

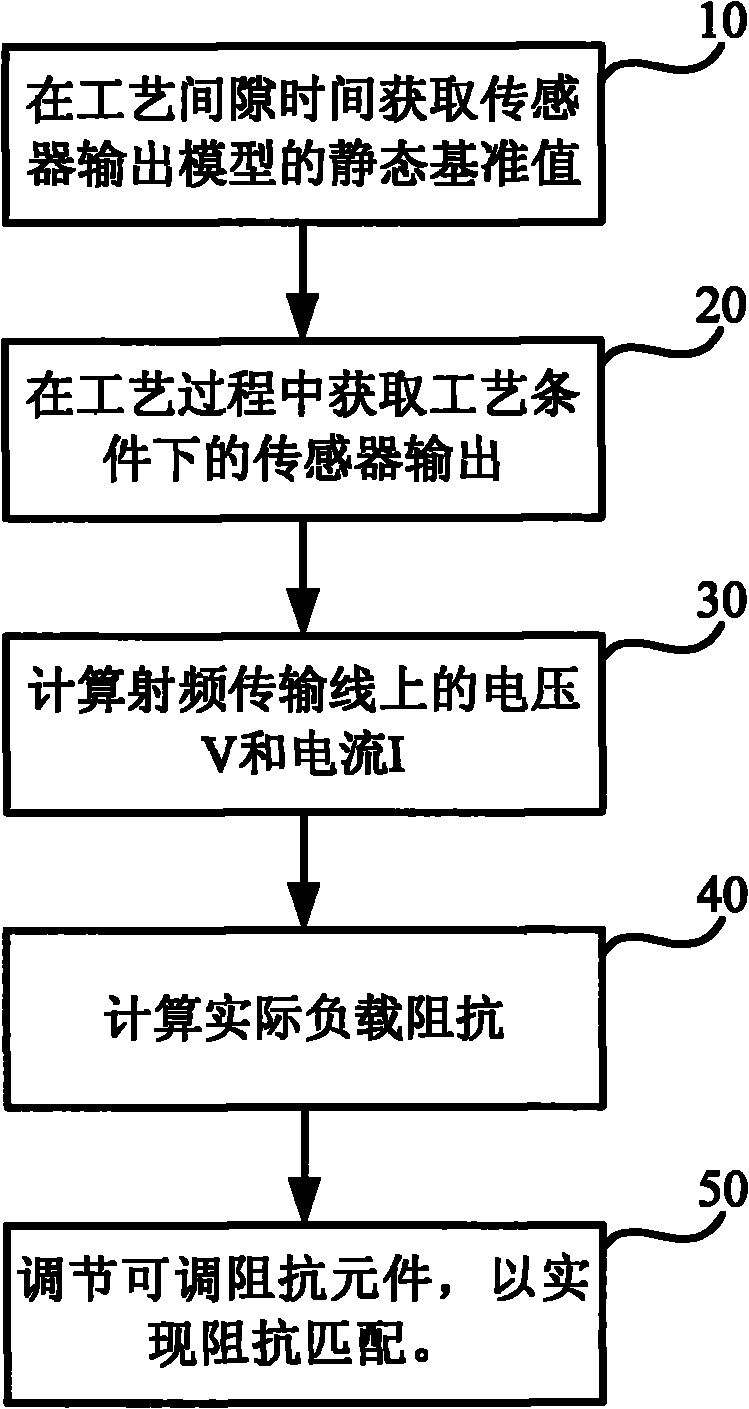

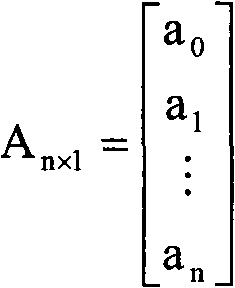

Impedance matching method and plasma processing equipment

ActiveCN101964295AEfficient treatment processFast and efficient glowElectric discharge tubesEngineeringImpedance matching

The invention provides an impedance matching method. The method comprises the following steps of: in a process time slot, reading the output value of a sensor in a state that a radio frequency power source output power is zero, wherein the output value serves as the static reference value of a sensor output model in the subsequent process; in the process, acquiring the practical load impedance according to the sensor output model, the static reference value and the sensor output, and adjusting an adjustable impedance element in a matcher so as to realize the impedance matching in plasma processing equipment; and repeating the steps until the whole process is finished. The invention also provides the plasma processing equipment. The impedance matching method and the plasma processing equipment can stably, effectively and accurately realize the impedance matching in the plasma processing equipment, so that the reflection power on a radio-frequency transmission line is relatively low andthen the radio frequency power source output power is applied to a plasma technical chamber more effectively.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

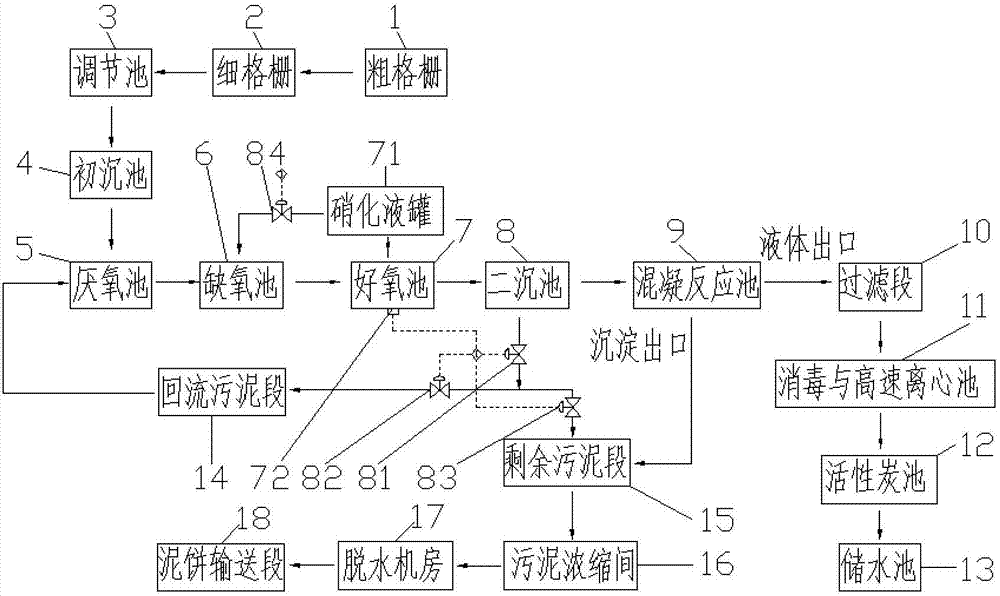

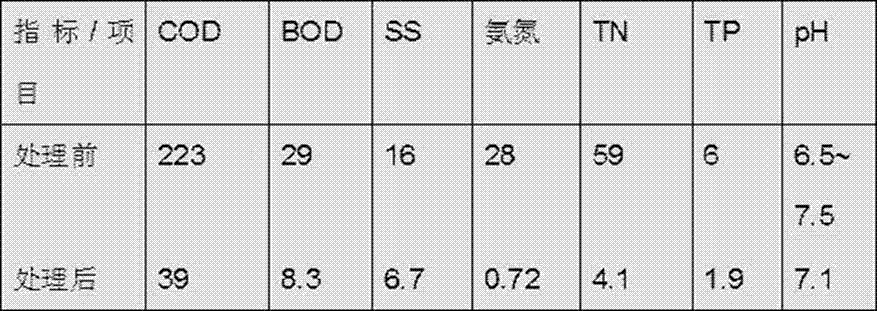

Sewage treatment system and sewage treatment method

InactiveCN107417032ACompact structureGood processing effectWater/sewage treatment by centrifugal separationWater/sewage treatment by irradiationActivated carbonLiquid tank

The invention discloses a sewage treatment system, comprising a coarse grid, a fine grid, an adjustment pond, a primary sedimentation pond, an anaerobic pond, an anoxic pond, an aerobic pond, a secondary sedimentation pond, a coagulation reaction tank, a filtration section, a disinfection and high-speed centrifugal pond, an activated carbon pond and a water storage pond which are sequentially connected by pipes; the secondary sedimentation pond is downwards connected with a first control valve, part of the sludge generated by the secondary sedimentation pond is connected with a second control valve, and returns to the anaerobic pond through a returned sludge section, the other part of the sludge is connected to a third control valve, passes through a surplus sludge section and then is backwards connected with a sludge concentration room, a dehydration room, and a mud cake delivery section; the liquid outlet of the coagulation reaction pond is connected with the disinfection and high-speed centrifugation pond, the sediment outlet is connected with the surplus sludge section, the inlet of the anoxic pond is connected with a nitrification liquid tank, and the aerobic pond is also provided with a detection mechanism. The system and the method of the invention have the advantages of flexible and efficient process and excellent removal effect on various organic pollutants, especially nitrogen, combination of batch processing and continuous processing, and certain-extent automation.

Owner:ANYANG INST OF TECH

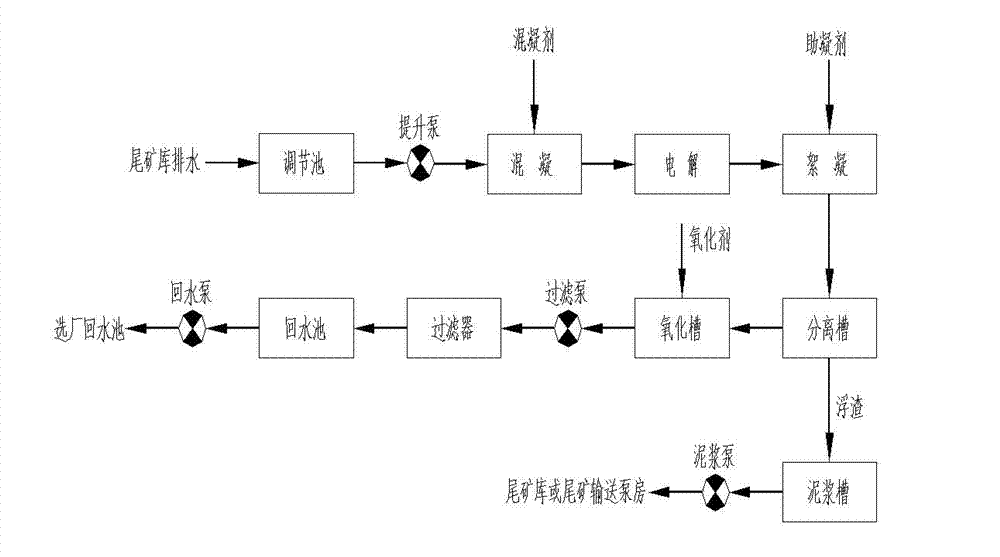

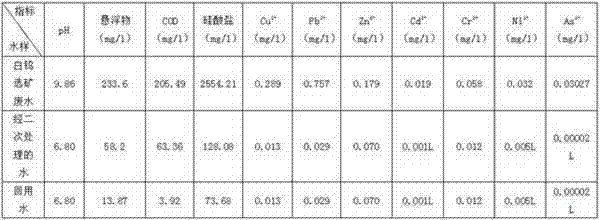

Scheelite beneficiation wastewater treatment technique

InactiveCN102826695AAccelerate the speed of decomposition and sedimentationProcess stabilityWaste water treatment from quariesMultistage water/sewage treatmentEmission standardWater quality

The invention relates to a scheelite beneficiation wastewater treatment technique which comprises the following steps: electrolyzing to remove most water glass and most organic reagents, adding a coagulant aid to precipitate so as to remove the water glass and organic reagents, and finally, adding an oxidizer to remove residual organic reagents in the wastewater. By using the technique provided by the invention, the removal rate of the water glass is higher than 94.5%, and the removal rate of the beneficiation organic reagents is higher than 98%; the quality of the effluent water is stable, and exceeds the requirements of GB8978-1996 'Sewage Comprehensive Discharge Standard' Grade 1; and the treated water can be reclaimed for the beneficiation technique. The technique provided by the invention has the advantages of stable treatment effect, high efficiency, short technical process, small occupied area, low cost, energy saving and environmental protection, and is simple to operate.

Owner:中铝环保节能科技(湖南)有限公司

Nano alumina-containing modified wood production method

InactiveCN104859011AHigh surface hardnessEfficient processingWood treatment detailsPretreatment apparatusPolyethylene glycolNano al2o3

The invention discloses a nano alumina-containing modified wood production method including five steps of wood pretreatment, preparation of a wood modification agent, preparation of a wood modification fluid, dipping treatment and post drying treatment, the wood modification agent comprises nano alumina, polyethylene glycol (peg), aluminum and titanium compound coupling agent OL-AT1618, distilled water, sodium octaborate, diammonium phosphate, boric acid, carbendazim, dodecyl dimethyl benzyl ammonium chloride, sodium dodecyl benzene sulfonate and silicon sol, and the particle size of the nano alumina is in the 1-100 nm range. The beneficial effect is that the nano alumina-containing modified wood has the advantages of simple process, high efficiency, environmental protection, strong permeability, stable performance, even composite and the like, and the surface hardness, smoothness, wear resistance, cold and hot fatigue, fracture toughness, good processing properties, dimension stability, anti-corrosion flame retardant properties and the like of the treated wood are improved obviously.

Owner:王玉燕

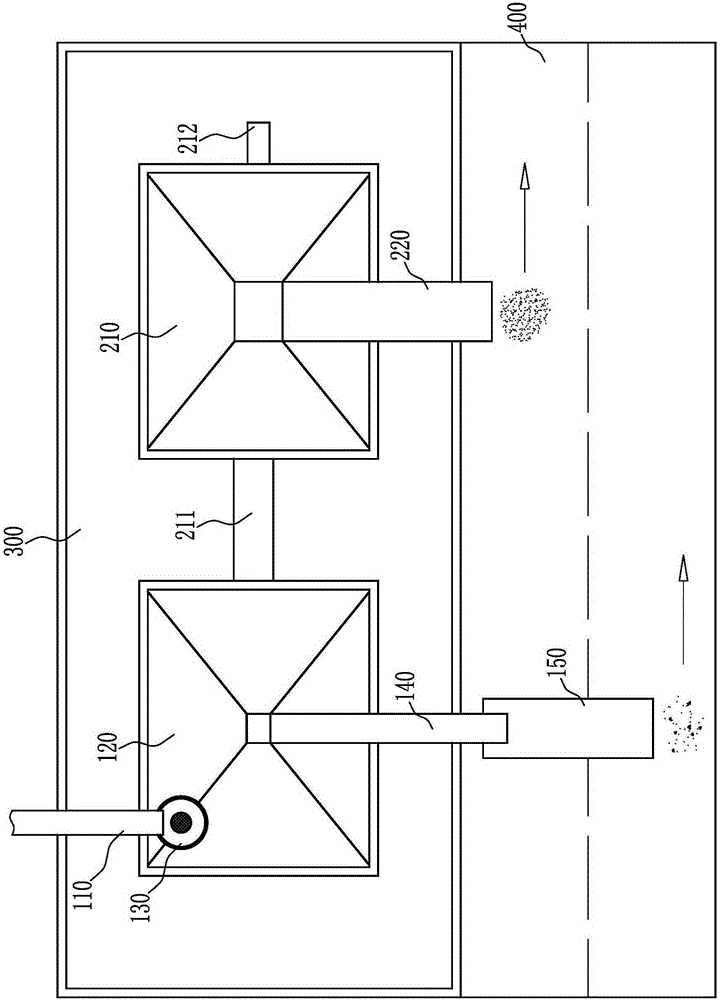

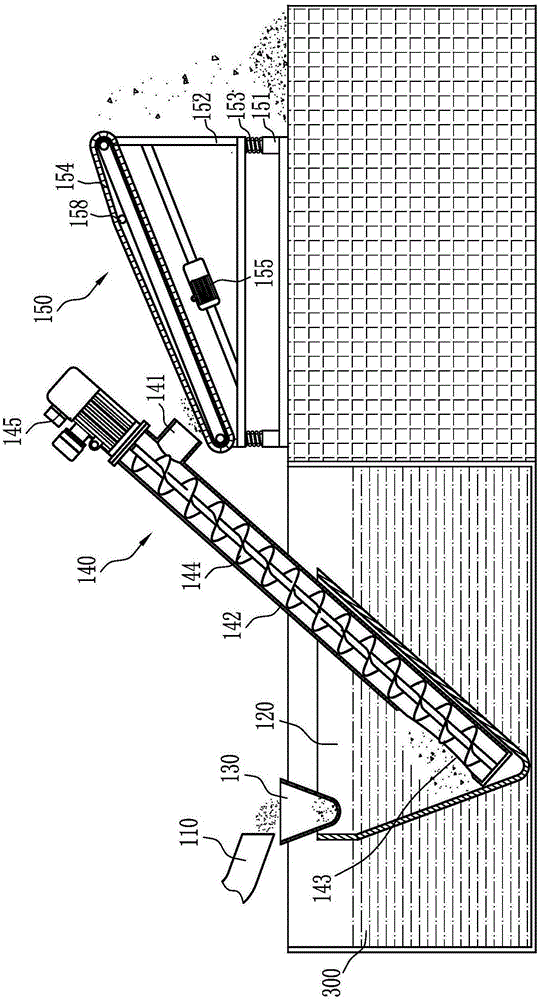

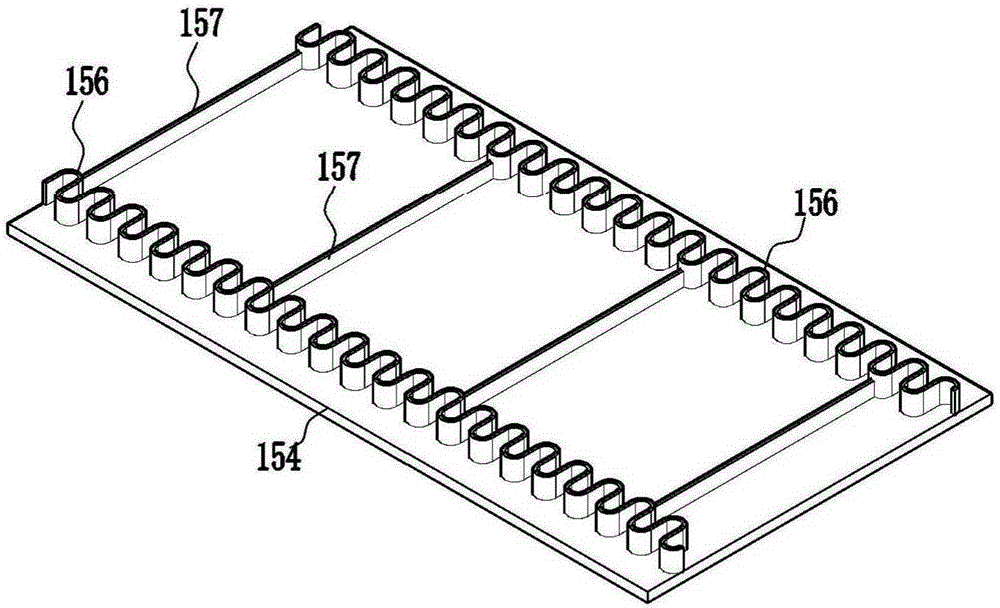

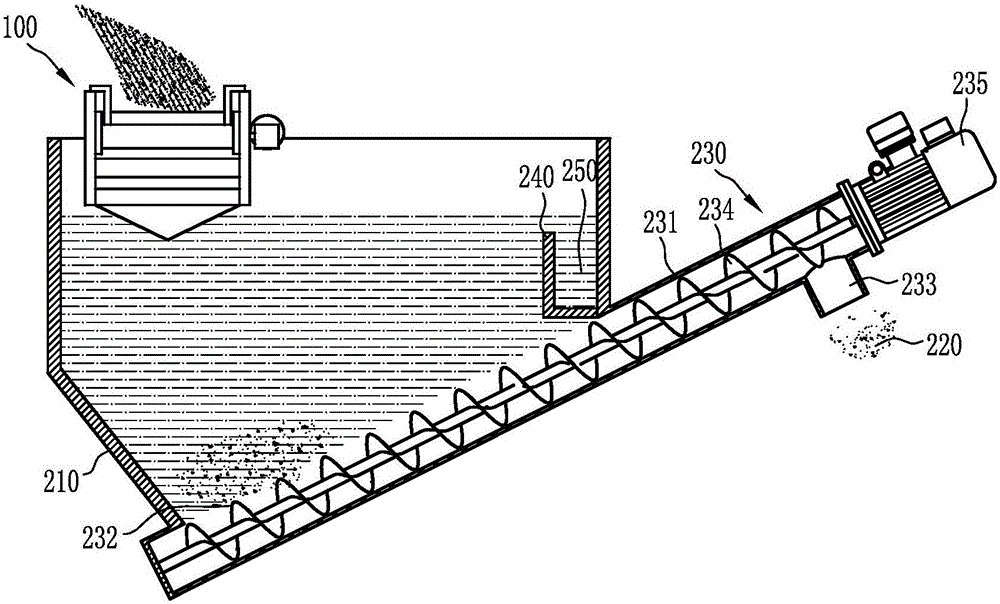

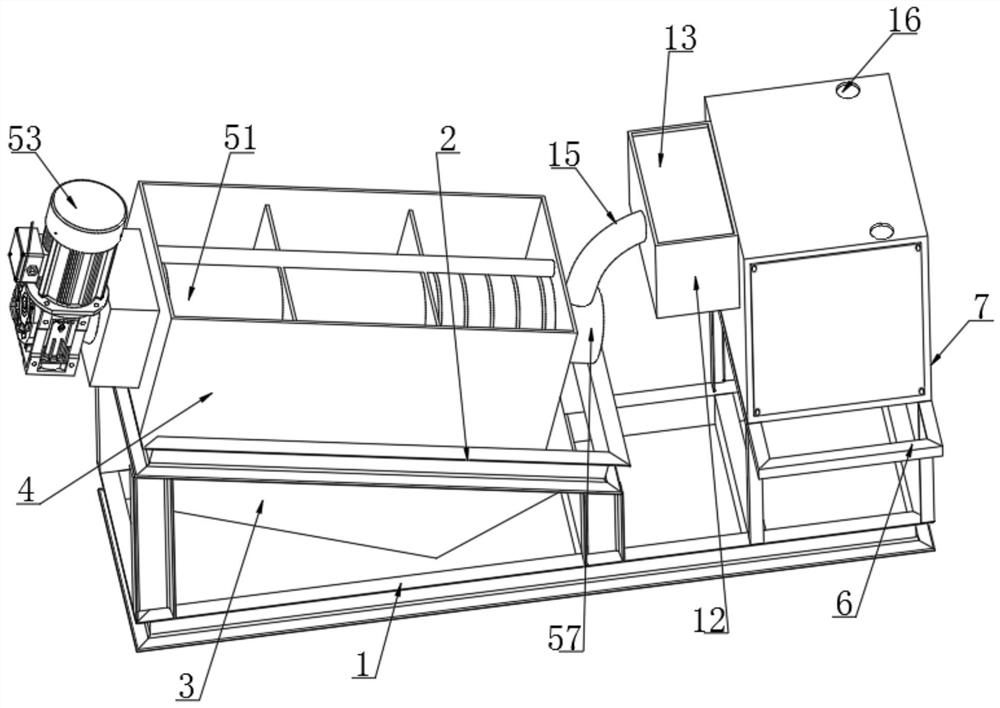

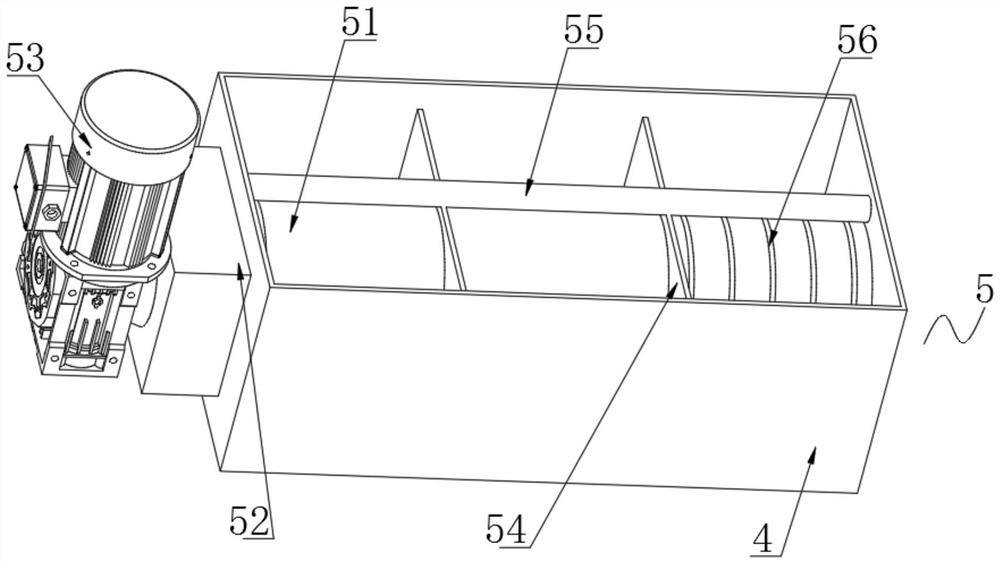

Stone cutting wastewater resourceful treatment system

ActiveCN106512489AAvoid pollutionImprove resource managementSettling tanks feed/dischargeMagnetic separationIron powderWastewater

The invention discloses a stone cutting wastewater resourceful treatment system. The stone cutting wastewater resourceful treatment system comprises a wastewater ore-dressing device, a coarse sand settling and water discharging device and a fine sand settling and sand discharging device. The wastewater ore-dressing device comprises a water-distributing and ore-stopping device, and a magnetic picking belt is rotatably arranged below the water-distributing and ore-stopping device. The coarse sand settling and water discharging device comprises a coarse sand settling tank, and a spiral coarse sand conveying device is arranged at the bottom of the coarse sand settling tank. A sand-stopping baffle plate is arranged in the coarse sand settling tank, and a fine sand wastewater discharging chamber is formed between the sand-stopping baffle plate and the coarse sand settling tank and is provided with a fine sand wastewater delivery device. The fine sand settling and sand discharging device comprises a fine sand settling tank, and a fine sand wastewater distributing device and a fine sand settling baffling device are arranged on the inner upper portion of the fine sand settling tank. The stone cutting wastewater resourceful treatment system is capable of achieving graded recycling of iron powder, coarse sand and fine sand in wastewater and is beneficial to stone cutting wastewater resourceful treatment.

Owner:日照市勇明环保科技有限公司

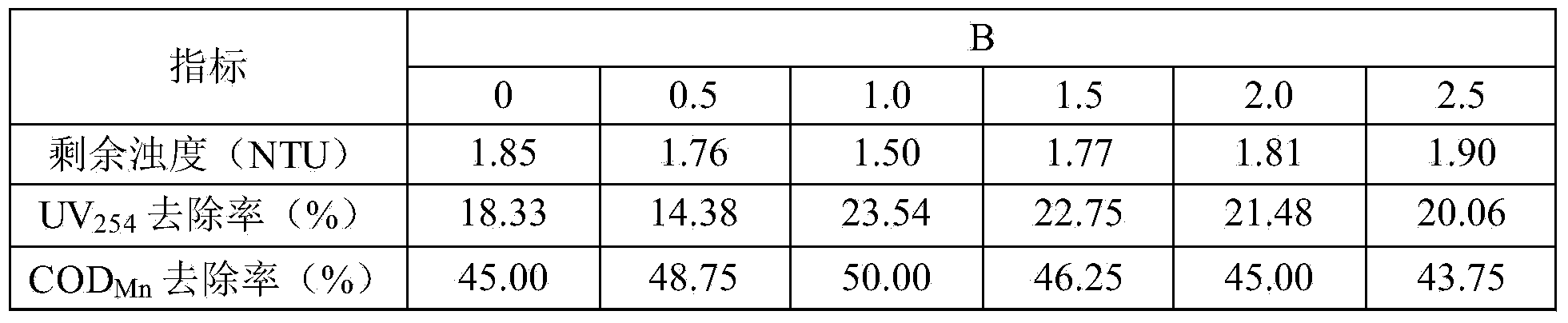

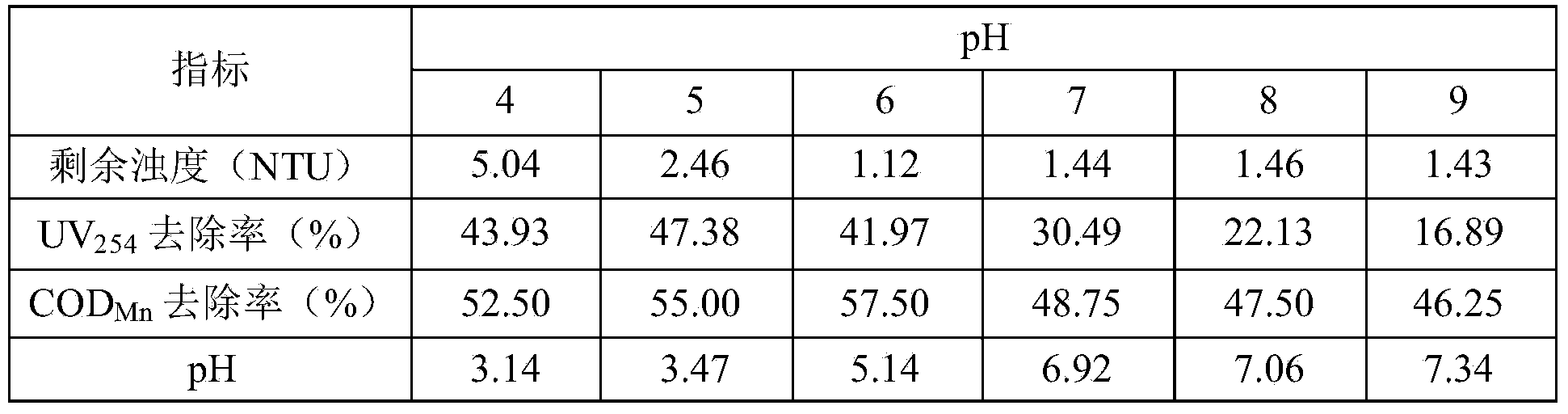

Polymeric titanium sulfate-PDMDAAC (poly dimethyl diallyl ammonium chloride) composite coagulant as well as preparation and application methods thereof

InactiveCN103964554AHigh molecular weightGood flocculation effectWater/sewage treatment by flocculation/precipitationChemical industryWater supply

The invention discloses a polymeric titanium sulfate-PDMDAAC (poly dimethyl diallyl ammonium chloride) composite coagulant as well as preparation and application methods thereof. The preparation method comprises the following steps: 1, preparing a titanium sulfate solution with certain concentration by adding water, placing the titanium sulfate solution in a mixing kettle, dropwise adding a sodium hydroxide solution by controlling certain speed, performing polymerization reaction, stopping adding the materials when the basicity (B) is 0.5-2.5, and continuously stirring for 0.5-1.5h after finishing adding, so as to prepare a colorless and transparent polymeric titanium sulfate solution; 2, placing the prepared polymeric titanium sulfate solution in a mixing reaction kettle, matching according to the fact that the mass ratio of Ti to PDMDAAC is (4-10):1, adding branched-chain PDMDAAC colloid or dry powder under the normal temperature or heating condition; 3, stirring the mixed solution at the normal temperature for 2-4 h, and filtering away insoluble substances, so as to obtain the polymeric titanium sulfate-PDMDAAC inorganic composite coagulant and polymeric titanium sulfate-PDMDAAC organic composite coagulant. The polymeric titanium sulfate-PDMDAAC composite coagulant can be widely applied to fields such as water supply, waste water treatment, papermaking, textile dyeing and printing, and daily-use chemical industry, and has good water treatment effect.

Owner:TONGJI UNIV

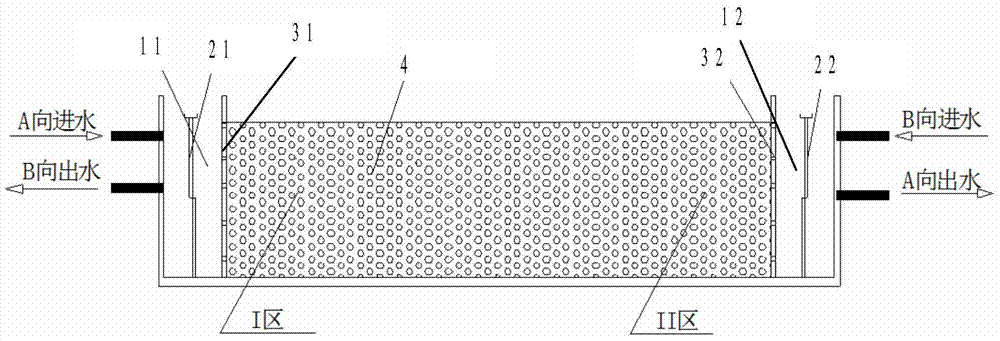

Crossflow type biofilter and filter system for surface water

ActiveCN104743668AEfficient treatment processLow costTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentEngineeringWater treatment

The invention provides a crossflow type biofilter for surface water. A water distribution channel I is formed in one end of the filter, and a water distribution channel II is formed in the other end of the filter, and a packing region is formed between the water distribution channel I and the water distribution channel II; the water distribution channel I and the packing region are separated by a perforated wall I, and the water distribution channel II and the packing region are separated by a perforated wall II; a height-adjusted water inlet and outlet dam I is arranged in the water distribution channel I, and a height-adjusted water inlet and outlet dam II is arranged in the water distribution channel II; when water enters from the water distribution I, the height of the water inlet and outlet dam I heightened, and the height of the water inlet and outlet dam II is lowered, so that bi-directional crossflow water intake can be realized; the aerobic zone and the anaerobic zone of the packing region are switched, the aerobic zone has an effect of nitrifying, and denitrification is carried out by utilizing microorganism endogenesis in the anaerobic zone, so that a good denitrification effect can be achieved. According to the biofilter, the denitrification process can be smoothly performed under a condition of overcoming carbon source deficiency, and high-efficiency low-cost water treatment process can be realized.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Urban sewage treatment agent and sewage treatment technology

PendingCN110143627AWide variety of sourcesImprove processing efficiencyWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionTotal nitrogenIron(III) sulfate

The invention discloses an urban sewage treatment agent and a sewage treatment technology. The urban sewage treatment agent comprises the following raw materials: polyaluminum chloride, polyferric sulfate, sodium silicate, active carbon, zeolite powder, an antifoaming agent, a surfactant and water. The urban sewage treatment agent of the invention has wide sources of the raw materials. Active carbon has a strong adsorption effect and can effectively adsorb inorganic salt in a water body. polyaluminum chloride and polyferric sulfate have a strong flocculation effect, and can significantly reduce suspended solids and small granules in sewage. The preparation technology is simple, and the application method is simple. The urban sewage treatment agent has good adsorption, flocculation and precipitation effects, has high sewage treatment efficiency, and is a comprehensive sewage treatment medicament with very stable performance. The sewage treatment technology is simple and efficient, has an excellent removal effect on total nitrogen, total phosphorus, ammonia nitrogen, COD, BOD and SS in water, and will not cause secondary pollution.

Owner:李洪

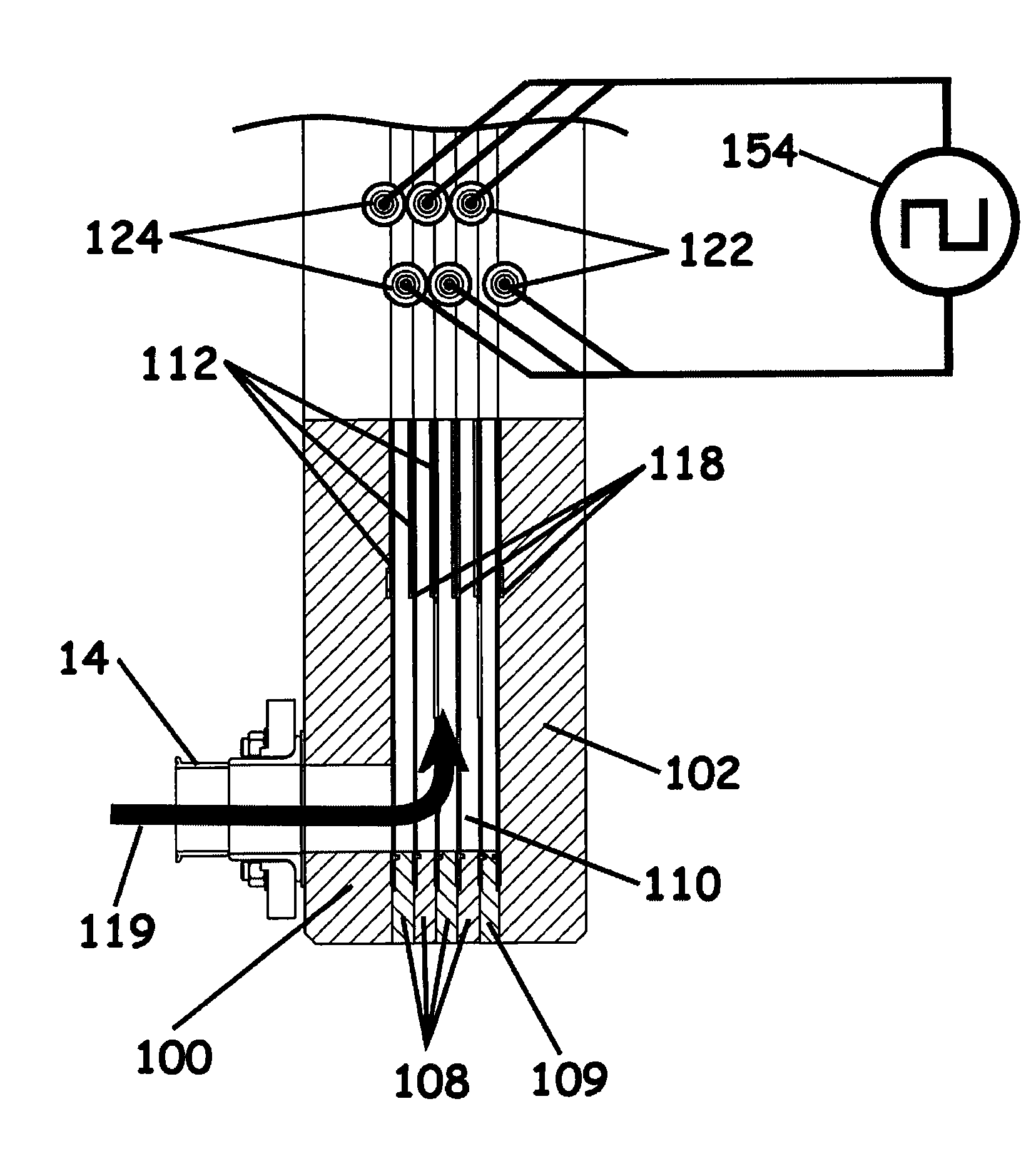

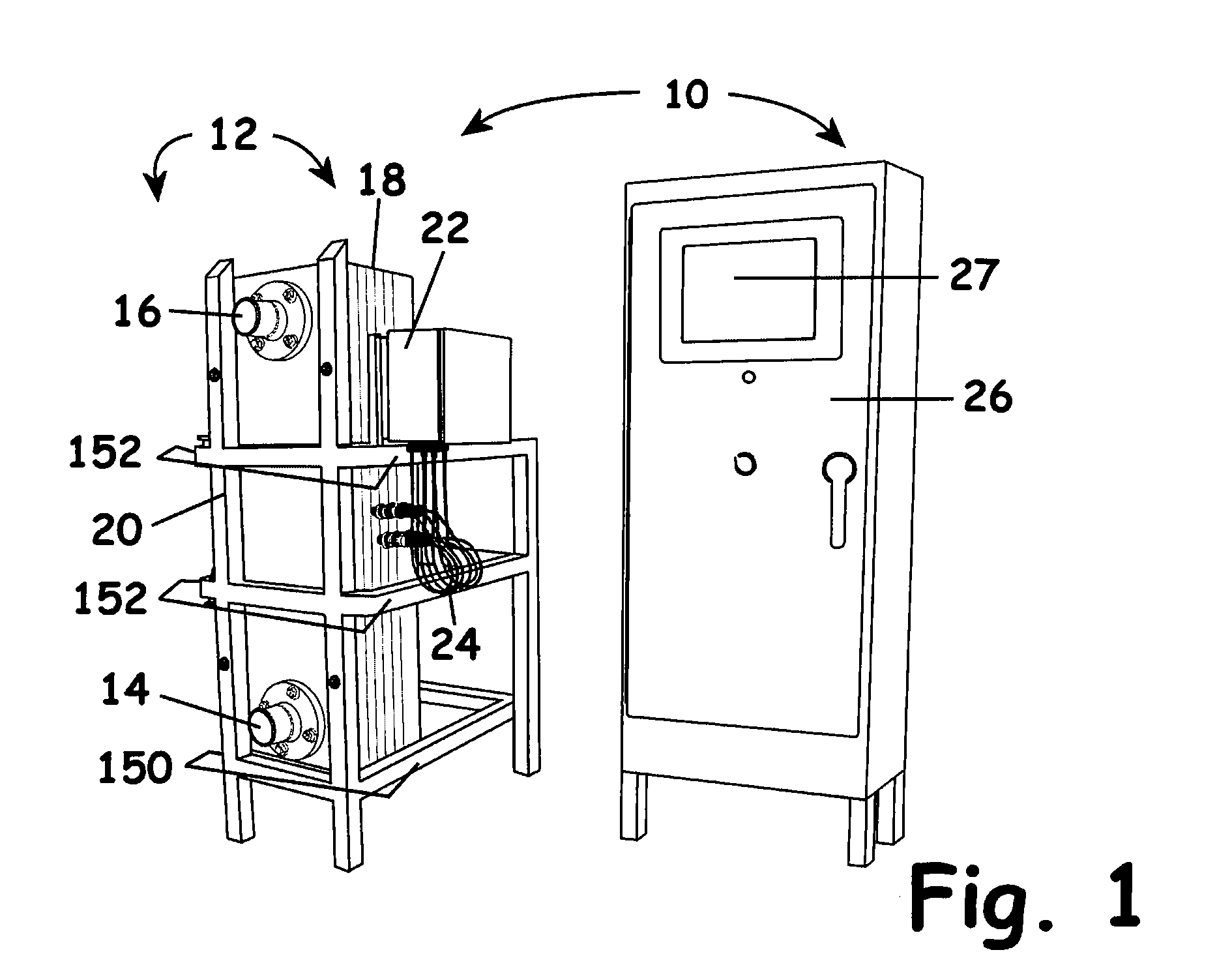

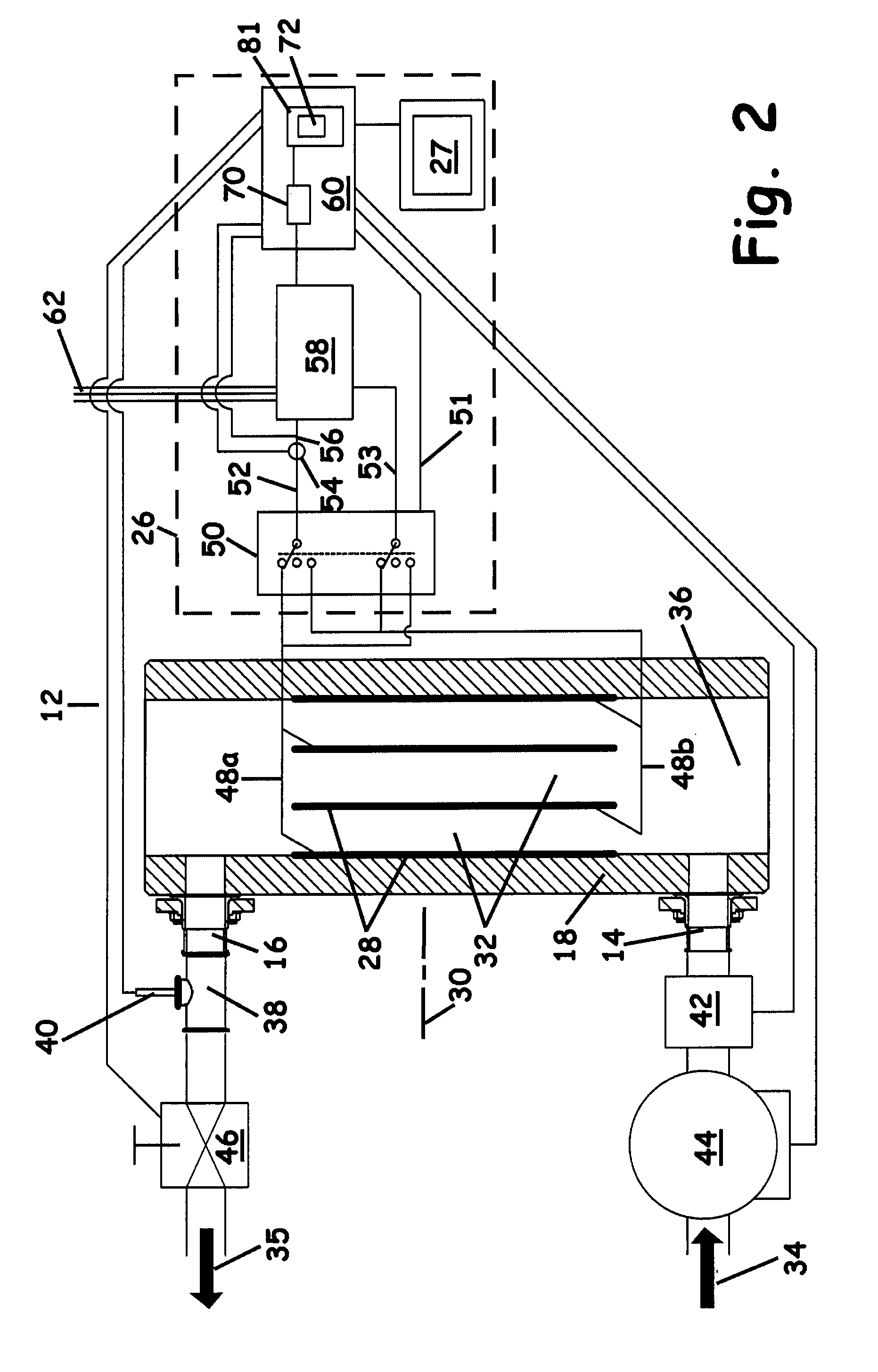

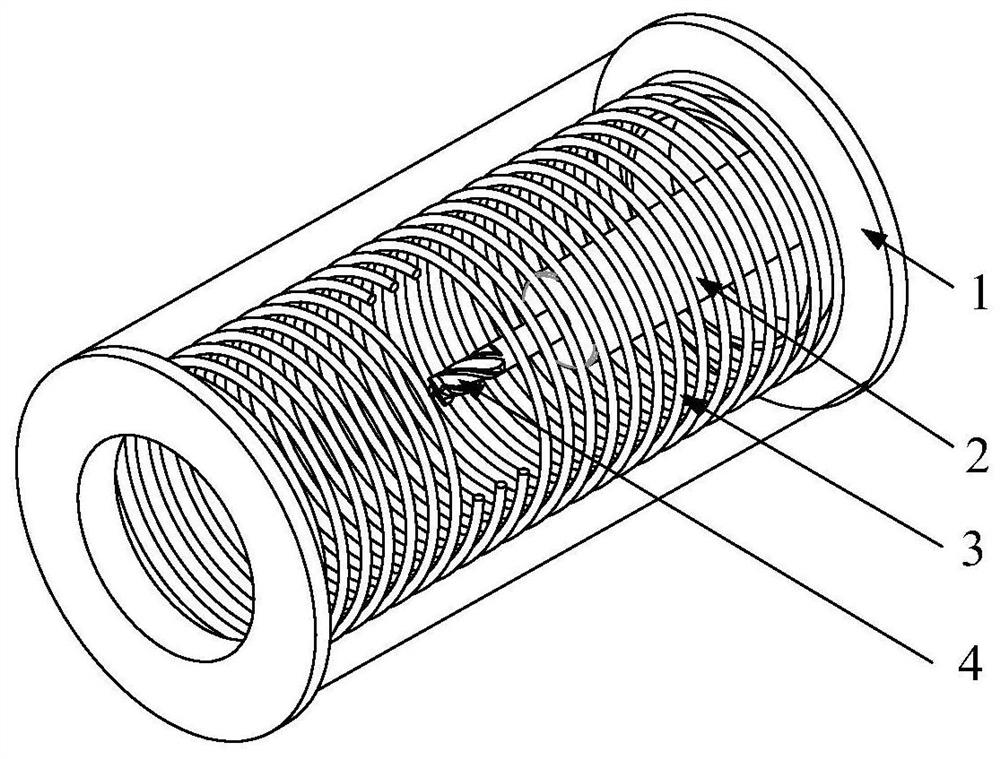

Electrochemical Liquid Treatment Cell with Modular Construction

ActiveUS20110079510A1Efficient treatment processExpand capacityCellsWater treatment parameter controlModular constructionElectrical battery

A cell for direct treatment of liquid using electrolysis uses a modular construction of electrode plates and spacer assemblies positioned between end plates. Changes in the liquid flow capacity of the cell may be made by changing the number of module housing sections and electrode plate assemblies. The design includes electrode plates that lock into a mating module housing section to resist the pressure of the fluid being treated. The design further provides for multiple fluid flow paths and for automatic cleaning of the cell using standard clean-in-place methods.

Owner:BIOIONIX

Method for improving biogas slurry SBR (styrene butadiene rubber) treatment process efficiency by utilizing zeolite synthesized from fly ash

InactiveCN103523917AHigh removal rateOptimal treatment processTreatment with anaerobic digestion processesChemical oxygen demandSlurry

The invention provides a method for improving biogas slurry SBR (styrene butadiene rubber) treatment process efficiency by utilizing zeolite synthesized from fly ash, and belongs to the technical field of water pollution treatment. The method is characterized in that the zeolite synthesized from fly ash by adopting a hydrothermal crystallization method has high alkalinity, so that massive consumed alkalinity in the nitrifying process can be made up after the zeolite synthesized from fly ash is put in an SBR system (the concentration of the zeolite is maintained at 2.5g / L), so that the pH value of the biogas slurry can be stabilized in a range that microorganisms grow and metabolize normally, and a biomembrane is formed on the surface of the zeolite, and the simulataneous nitrification denitrification (SND) effect can be reinforced, so that the biogas slurry NH3-N, TN (total nitrogen), COD (chemical oxygen demand) removal rate and other indexes can be increased. The method, namely zeolite synthesized from fly ash dosed SBR (ZFA-SBR), is simple and easy, and practical and reliable, and is a method with small investment for effectively improving the pollutant removing efficiency in the biogas SBR treatment process.

Owner:SOUTHWEST UNIVERSITY

Anticorrosive wood production method

InactiveCN104858964ASimple processEfficient treatment processBiocideWood treatment detailsBronopolMethyl carbamate

The invention discloses an anticorrosive wood production method including five steps of wood pretreatment, preservative preparation, preservative liquid preparation, dipping treatment and post-drying treatment, a preservative comprises polyethylene glycol (peg), bronopol, 4, 5-dichloro-N-octyl-4-isothiazoline-3-one, imidacloprid, 2-chloro-5-hydroxy meta-xylene, dithiocyano-methane, dodecyl dimethyl benzyl ammonium chloride and N-(2-benzimidazole)-methyl carbamate and fatty alcohol polyvinyl chloride (PVC) ether. The beneficial effects are that the anticorrosive wood production method has the advantages of simple process, high efficiency, and easy operation, and the like, the processed wood maintains the original features, meanwhile has excellent anti-corrosion, mouldproof, insect-resistant, antibacterial and other effects, and is good in environmental protection property, stable in performance, and durable.

Owner:王玉燕

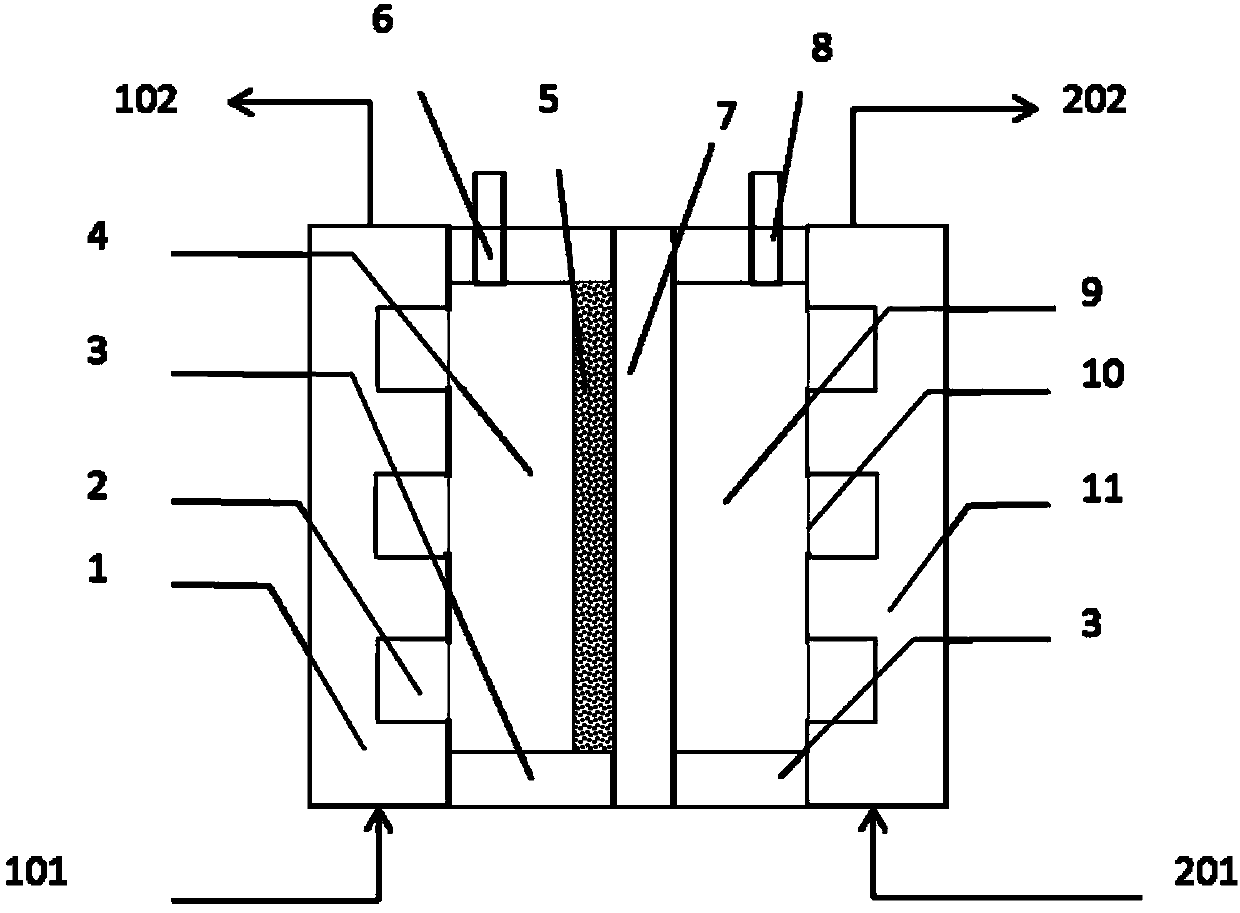

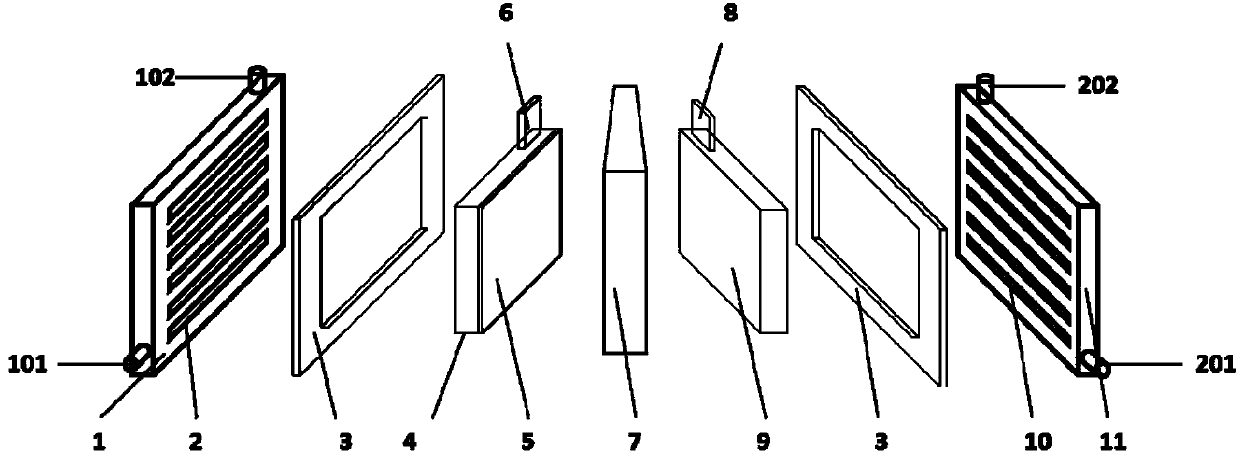

Solid electrolyte electrolytic cell device using anion-exchange membrane

ActiveCN104192957AReduce foulingAvoid cloggingDispersed particle separationPolymer electrolytesIon-exchange membranes

The invention relates to a solid electrolyte electrolytic cell device using an anion exchange membrane. The solid electrolyte electrolytic cell device comprises an ion exchange membrane as well as an anode chamber and a cathode chamber arranged at both sides of the ion exchange membrane, wherein the anode chamber comprises an anode terminal plate, a porous anode support material and an anode catalytic layer; the cathode chamber comprises a cathode terminal plate and a porous cathode catalytic material and the ion exchange membrane material is the anion exchange membrane. By virtue of the solid electrolyte electrolytic cell device disclosed by the invention, the problem of scaling at an interface between the membrane and the electrode is avoided, the phenomenon of scaling of the ion exchange membrane is greatly retarded, the problem of blocking due to the scaling of the SPE (Solid Polymer Electrolyte) electrolytic cell is avoided and the stability and service life of the sewage treatment device are prolonged. The selection of the cathode catalytic material of the SPE electrolytic cell can be also broadened and the cost of the sewage treatment device can be significantly reduced.

Owner:BEIJING JINDAYU ENVIRONMENT TECH CO LTD

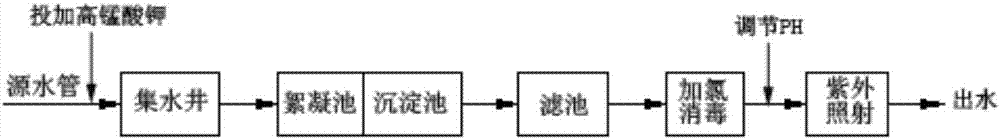

Treatment method for controlling halogenated disinfection byproducts in drinking water

InactiveCN107879522AReduce precursorsGood removal effectWater contaminantsTreatment involving filtrationChloramine BFiltration

The invention discloses a treatment method for controlling halogenated disinfection byproducts in drinking water. The treatment method comprises the following steps: (1) feeding source water into a water collection well through a source water tube, and adding potassium permanganate for preoxidation from the water outlet end of the source water tube, wherein the addition amount of the potassium permanganate is 0.5-2.0mg / L; (2) collecting water from the water collection wheel through a water collection pump room, coagulating with a coagulant, performing precipitation and filtration, and disinfecting the filtered water with chlorine or chloramines; and (3) adjusting the pH value of a disinfected water sample to 7-10, performing radiation treatment with ultraviolet light of which the wavelength is 150-280nm, and implementing light degradation by virtue of absorption properties of disinfection byproducts at the wave band. By adopting the treatment method disclosed by the invention, teratogenesis toxic substances in effluents are effectively reduced.

Owner:TIANJIN UNIV

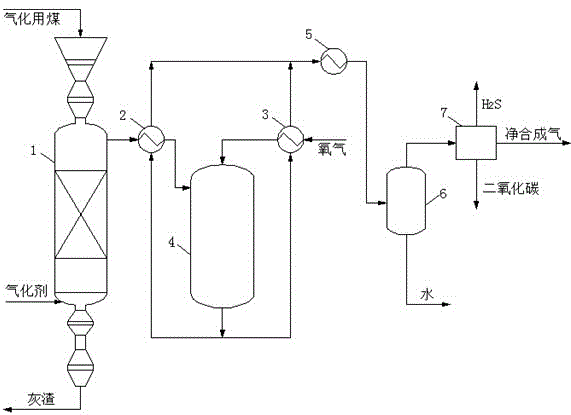

Process for producing clean synthesis gas from crushed coal

ActiveCN104593079AHigh yieldReduce the burden onHydrogenGasification processes detailsChemistryCarbon dioxide

The invention discloses a process for producing clean synthesis gas from crushed coal. The process comprises the steps of producing crude coal gas by virtue of a crushed coal pressurizing gasifying furnace, after carrying out heat exchange, supplying the crude coal gas together with preheated oxygen into a high-temperature pyrolysis reforming reactor to enable original water vapor and carbon dioxide in the added oxygen and crude coal gas to serve as oxygen-containing reaction media to react with organic matters such as various oil, low carbon hydrocarbon and CH4 in the crude coal gas, reforming the mixed gas into CO and H2, and converting most of ammonia gas in the crude coal gas into nitrogen by virtue of a high temperature action, wherein the temperature in the reactor can reach 900-1400 DEG C, and the outlet temperature of crude synthesis gas is 900-1200 DEG C. The crude synthesis gas does not contain tar, low carbon hydrocarbon and phenolic compounds, the content of NH3-N and the CODCr of condensed water are substantially decreased, and the yields of CO and H2 of low-rank coal are substantially increased.

Owner:TAIYUAN UNIV OF TECH

Wood preservation flame retardant reinforcement modification production method

The invention discloses a wood preservation flame retardant reinforcement modification production method, including five steps of wood pretreatment, wood modification agent preparation, wood modification liquid preparation, dipping treatment and post-drying treatment; and a wood modification agent comprises tetraethoxysilane (TEOS), polyethylene glycol (PEG), phosphoric acid, water, sodium octaborate, carbendazim, zinc borate, ammonium molybdate and sodium dodecyl benzene sulfonate. The beneficial effects are that th wood preservation flame retardant reinforcement modification production method has the advantages of simple treatment process, high efficiency, low cost, strong permeability, and the like, the tetraethoxysilane is used as a precursor for formation of titanium dioxide, the titanium dioxide has reinforcement, and toughening, synergistic flame retardant and other effects, and corrosion resistance, flame resistance, surface hardness, wear resistance, bending resistance, bend elastic modulus, processing good properties, dimension stability, and the like of the processed wood are greatly improved.

Owner:王玉燕

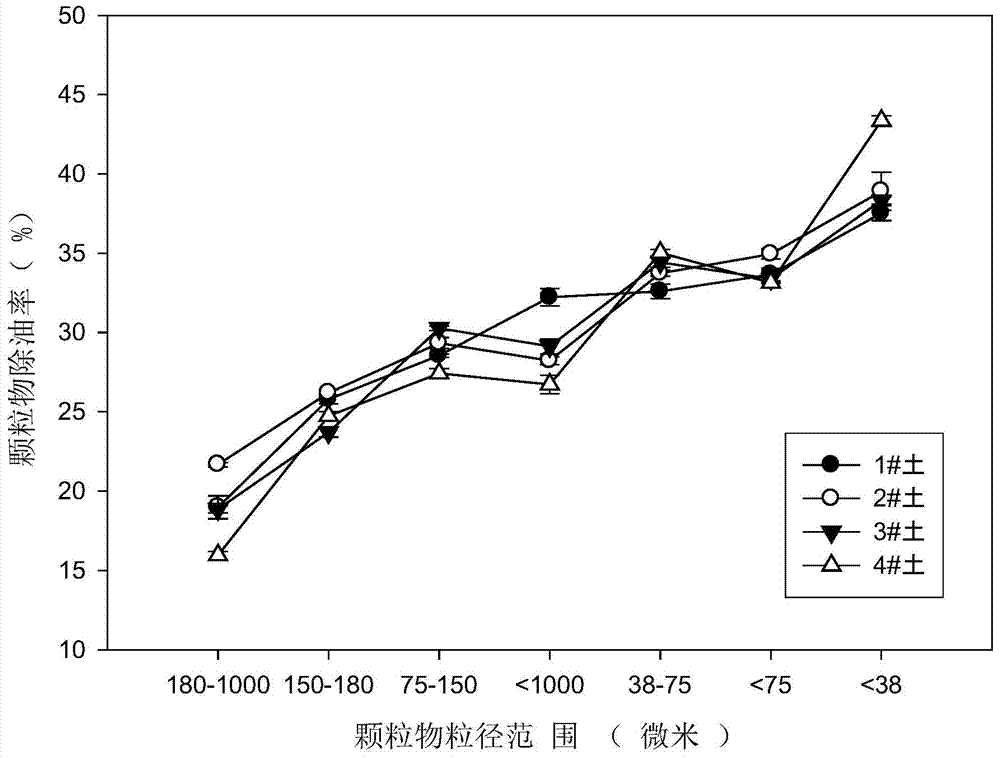

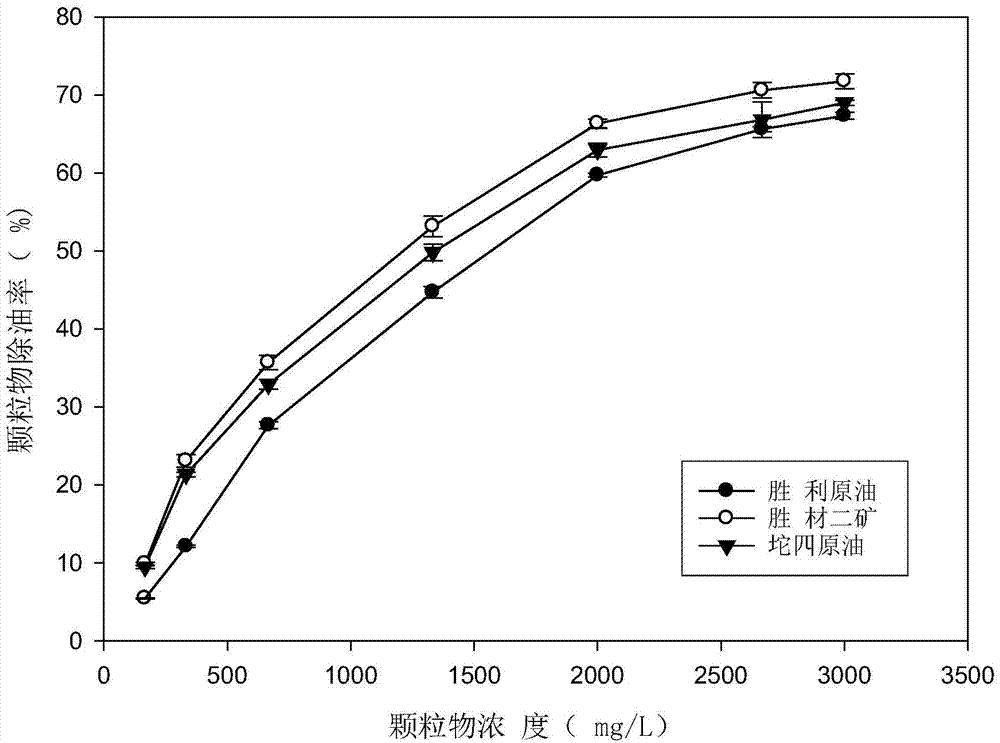

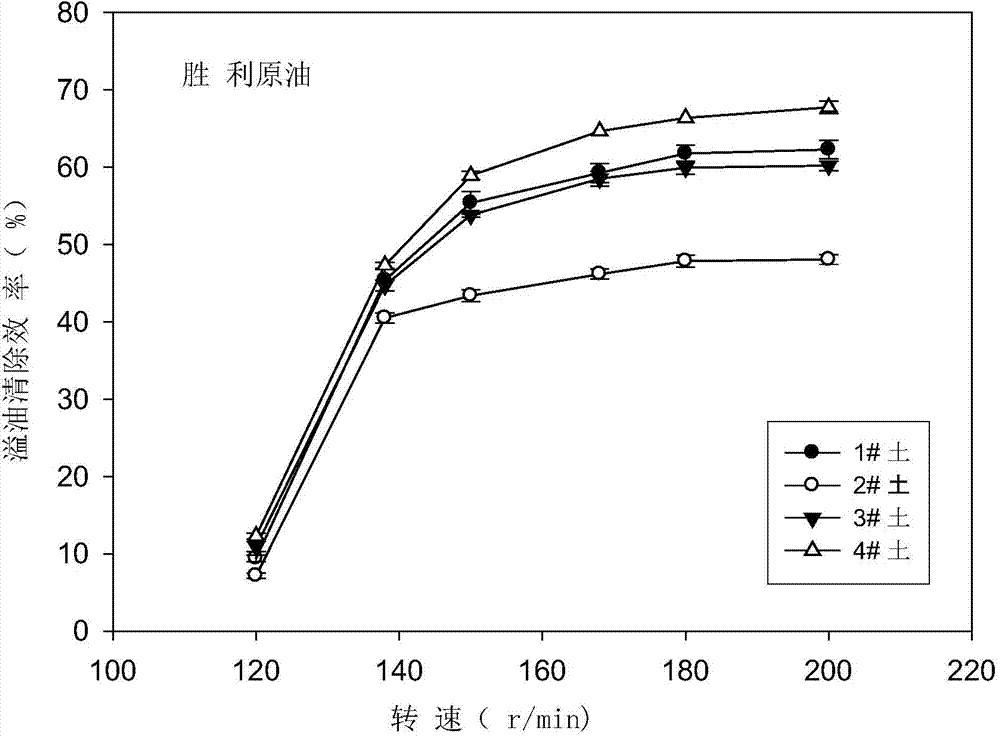

High-efficiency treatment process for removing marine spill oil

ActiveCN104727285AGood dispersionPromote degradationWater cleaningGeneral water supply conservationParticulatesSurface layer

The invention provides a high-efficiency treatment process for removing marine spill oil. The process comprises the steps that 1, sediment taken from a muddy beach at the mouth of the Yellow River is air-dried and screened to obtain particles with the particle sizes not more than 38 microns, and an appropriate number of particles and seawater are mixed to prepare a particle solution of 1.0-3.0 g / L, and the particle solution is canned and stored; 2, a waste cleaning boat is used for spraying oil dispersant and the particle solution with the appropriate concentration to the surface layer of the spill oil, and a stirring device is used for enabling a spill oil region to maintain a turbulent fluctuation state until the spill oil is cleared away; the mass ratio of the particles to the oil dispersant ranges from 7.5:1 to 12.0:1, and the use amount of the oil dispersant accounts for 15-20 percent of the amount of the spill oil. According to the process, the particles and the oil dispersant are combined to remove the marine spill oil, the oil dispersant is used for promoting dispersion of the spill oil, power is supplied through the hydrodynamic condition of the ocean, a propeller of the waste cleaning boat and the shipborne stirring device, particle materials play a role of dispersing agents and oil gelling agents, and the clearance efficiency of the spill oil is greatly improved on the basis of reducing the use amount of the oil dispersant.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Industrial water treatment equipment and process

InactiveCN112408642AEasy to handleReduce turbidityWater treatment parameter controlSpecific water treatment objectivesIndustrial waste waterProcess engineering

The invention discloses an industrial water treatment process, which comprises the following steps: 1) conveying industrial wastewater to industrial water treatment equipment, and retaining and filtering solid impurities in the wastewater; 2) adding a phosphorus removal agent through a dosing pipe; and 3) starting a servo motor for driving the two stirring paddles to rotate by the servo motor so as to stir, mix and remove phosphorus. According to the industrial water treatment process, the treatment process steps are optimized, the industrial water treatment equipment is adopted, a proper amount of specially-made phosphorus removal agent is added, the phosphorus removal rate is high, the turbidity of treated water is low, the treatment effect is good, and the industrial water treatment process is efficient.

Owner:神美科技有限公司

Nano kaolin modified wood production method

InactiveCN104858961AImprove thermal stabilityGood hygroscopicityWood treatment detailsPressure impregnationPhosphateMoisture absorption

The invention discloses a nano kaolin modified wood production method, including five steps of wood pretreatment, preparation of a wood modification agent, preparation of a wood modification fluid, dipping treatment and post drying treatment, the wood modification agent comprises nano kaolin, isopropyl alcohol, titanium aluminum composite coupling agent DL-411, distilled water, trimethyl borate, amidinourea phosphate, ammonium heptamolybdate, N-hydroxyethyl ethyl amine triacetic acid and fatty acid polyoxyethylene ester. The beneficial effect is that the nano kaolin modified wood has the advantages of being simple in treatment process, high in efficiency, environmental-friendly, strong in permeability, stable in performance, even in compounding, and the like, the treated wood has no significant changes in appearance, the thermal stability, moisture absorption and water proofing properties are obviously improved, mechanical properties and dimensional stability, resistance to wear, and the like are greatly improved, the flame retardant and anticorrosion performance is good, and the cost is low.

Owner:王玉燕

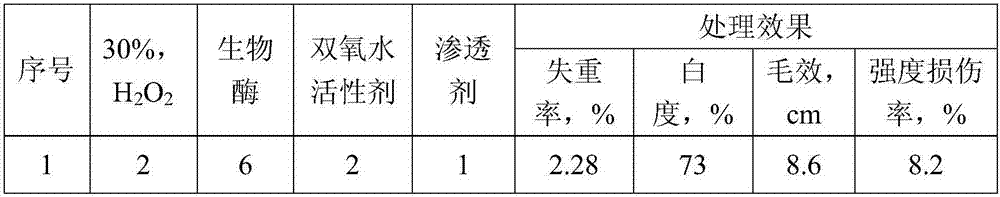

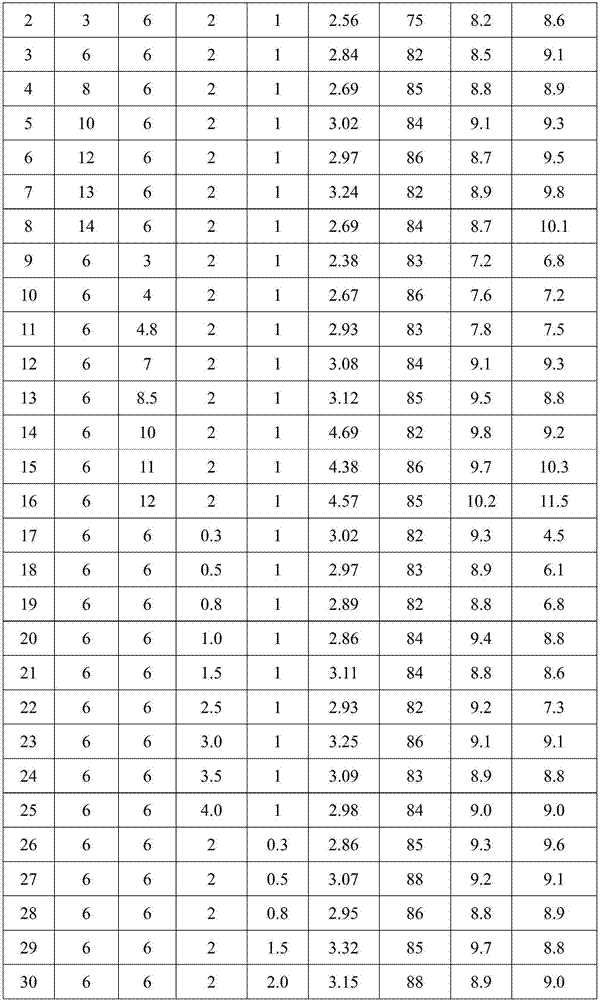

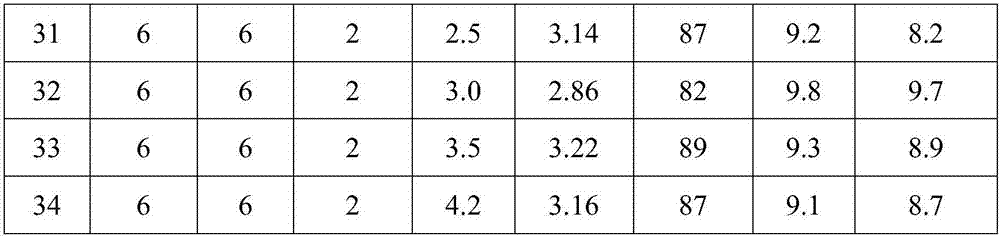

Pretreatment agent and method for using pretreatment agent for dyeing pretreatment of cotton cheese yarns

InactiveCN107142734AImprove bleaching effectGood low temperature bleaching abilityBiochemical fibre treatmentVegetal fibresYarnFiber

The invention relates to a pretreatment agent and a method for using the pretreatment agent for dyeing pretreatment of cotton cheese yarns, and belongs to the technical field of biochemical treatment of fibers, yarns, threads, fabrics or fibrous products made of the raw materials. The method comprises the following steps: using bio-enzyme, hydrogen peroxide, a hydrogen peroxide activator and an additive for dyeing pretreatment, wherein the contents of the added components are as follows: 4-12 g / L of 30% hydrogen peroxide, 5-10 g / L of bio-enzyme, 1-3 g / L of hydrogen peroxide activator and 1-3 g / L of a permeating agent; adjusting a pH value to 7-9 at a bath ratio ranging from (5:1) to (20:1); heating to a treatment temperature at 2 DEG C / min at room temperature, wherein the treatment temperature is 50-65 DEG C, and the treatment time is 40-60 min. The method is applied to the dyeing treatment of cheese yarns, and can not only reduce the treatment temperature and the pH value of hydrogen peroxide and solve energy consumption problem caused by high temperature, pollution of treatment waste liquid to environment caused by strong alkali and other problems, but also shorten process flow, improve production efficiency and achieve a satisfactory treatment effect.

Owner:浙江七色彩虹纺织整理有限公司

Hydrophilic polyethylene microporous membrane and preparation method thereof

ActiveCN112044281ASimple processEfficient treatment processSemi-permeable membranesMembranesPolymer scienceCross linker

The invention relates to a hydrophilic polyethylene microporous membrane and a preparation method thereof. The preparation method comprises the following specific steps: 1, wetting the polyethylene microporous membrane with a wetting agent; 2, uniformly coating the polyethylene microporous membrane wetted in the step 1 with a solution consisting of a hydrophilic substance, a cross-linking agent and a solvent; 3, standing at room temperature, and then heating for heat treatment; 4, taking out the membrane subjected to heat treatment on the first surface, and uniformly coating the other surfaceof the polyethylene microporous membrane with a solution consisting of a hydrophilic substance, a cross-linking agent and a solvent; step 5, standing at room temperature, then carrying out heating heat treatment, putting the polyethylene microporous membrane treated in the step 5 into water, soaking for 6-12 hours, and drying for later use. The hydrophilic polyethylene microporous membrane is obtained. Complete hydrophilic modification of the polyethylene microporous membrane is achieved, and the hydrophilic performance of the polyethylene microporous membrane has the advantage of being permanently effective. Moreover, the method has low requirements on equipment, is simple, feasible, energy-saving and environment-friendly, and is suitable for large-scale production of the hydrophilic polyethylene microporous membrane .

Owner:WUXI ENERGY NEW MATERIALS TECH CO LTD

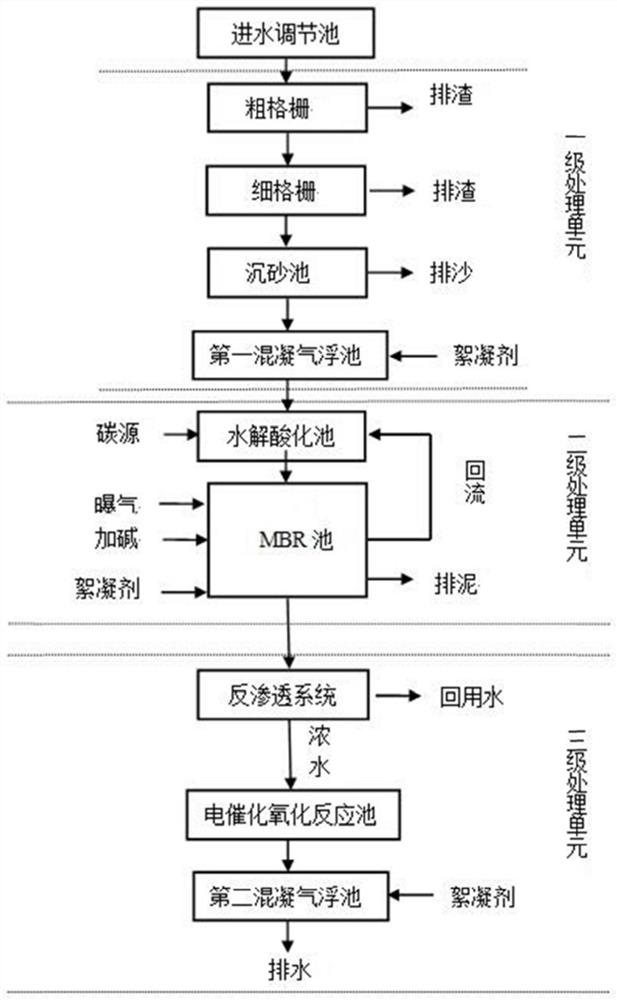

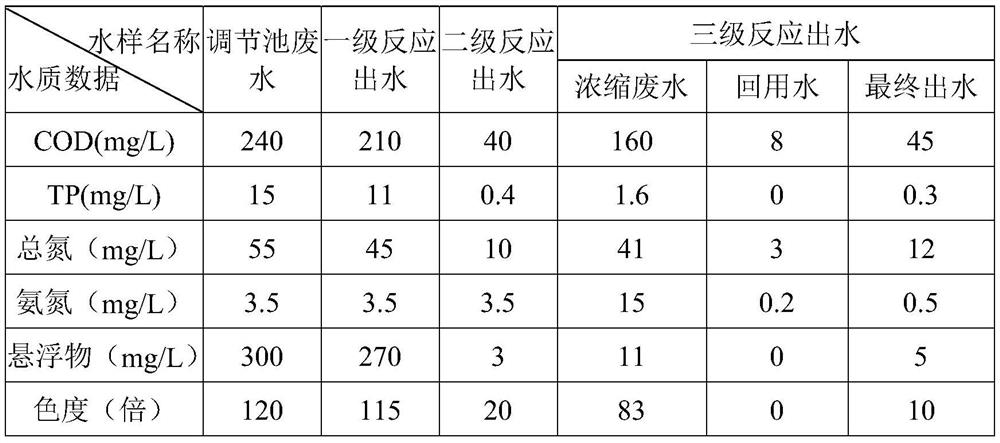

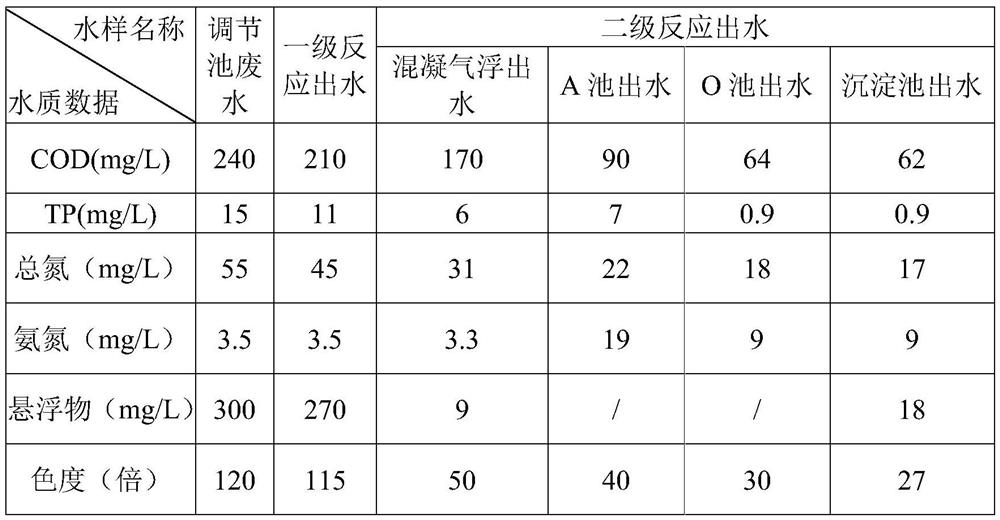

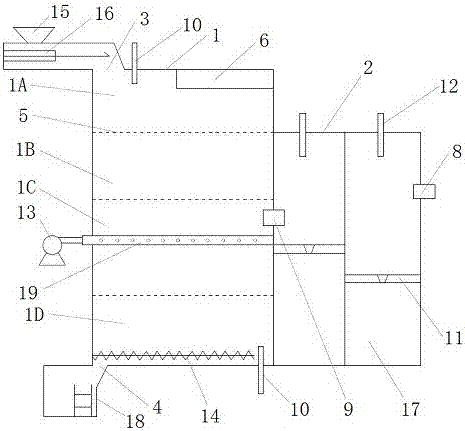

Laver processing wastewater treatment facility and method capable of realizing ultra-clean discharge

PendingCN112723651AShort processCost-effective treatment processWater treatment parameter controlTreatment involving filtrationReverse osmosisCatalytic oxidation

The invention discloses a laver processing wastewater treatment facility and method capable of realizing ultra-clean discharge. The treatment facility comprises a water inlet regulating tank, a primary treatment unit, a secondary treatment unit and a tertiary treatment unit, wherein the primary treatment unit comprises a coarse screen, a fine screen, a grit chamber and a first coagulation air floatation tank which communicate with one another in sequence; the secondary treatment unit comprises a hydrolysis acidification pool and an MBR pool which communicate with each other in sequence; the lower part of the MBR pool is externally connected with a return pipe, and the return pipe is used for returning a mud-water mixed solution in the MBR tank to the hydrolysis acidification tank; the tertiary treatment unit comprises a reverse osmosis system, an electrocatalytic oxidation reaction tank and a second coagulation air floatation tank which communicate with one another in sequence; and a water inlet of the reverse osmosis system communicates with a water outlet of the MBR pool, and a concentrated water outlet communicates with a water inlet of the electrocatalytic oxidation reaction tank. A corresponding treatment process is designed according to the characteristics of pollutants in the laver processing wastewater, and the process has the characteristics of short flow, economical and efficient treatment and safe and stable operation.

Owner:ZHEJIANG HI TECH ENVIRONMENTAL TECH

Microwave-assisted pyrolysis gasifier and waste pyrolysis gasification incineration method

PendingCN107152686ADecompose thoroughlyLess dioxin residueIncinerator apparatusCombined combustion mitigationCombustion chamberThermodynamics

The invention discloses a microwave-assisted pyrolysis gasifier. The microwave-assisted pyrolysis gasifier mainly comprises a first combustion chamber and a second combustion chamber. The first combustion chamber is divided into a drying region, a pyrolysis gasification region, a combustion region and a burnout region. A microwave transmitter is arranged in the drying region, and multiple regional hearths are arranged in the second combustion chamber. Through the unique structure arrangement, the efficient and reasonable drying, pyrolysis gasification and combustion of waste are achieved, the efficient treatment of the waste is achieved, and the generation and discharge of the waste are reduced. The invention further provides a waste pyrolysis gasification incineration method, mutual independence, complement and promotion of waste drying, pyrolysis gasification, combustion, burnout, flue gas combustion and the like are achieved, the efficient operation of the waste pyrolysis gasification incineration is achieved, and the problems of waste gas pollution and the like are solved effectively.

Owner:广西万景星禾科技有限公司

Method for treating combination of ferromagnetic tool and magnetic cutting fluid through pulsed magnetic field

ActiveCN113021071AImprove wear resistanceReduce frictional heatMagnetic bodiesMaintainance and safety accessoriesFerromagnetic particleMagnetic tension force

The invention provides a method for treating a combination of a ferromagnetic tool and a magnetic cutting fluid through a pulsed magnetic field, and relates to the technical field of machining. The method specifically comprises the following steps: a water-based magnetic cutting fluid or an oil-based magnetic cutting fluid containing micro-nano ferromagnetic particles is prepared according to the magnetic strength of a tool material; the tool is magnetized through a pulse magnetizing method, so that the magnetic force of the magnetized tool is not smaller than the maximum centrifugal force borne by micro-nano ferromagnetic particles in the cutting fluid at the same position; the tool is installed on a machine tool spindle, cutting fluid is placed in a machine tool fluid storage tank, at least two cutting fluid nozzles are used for being aligned to the contact face of the tool and a workpiece at intervals, and the inner diameter of the nozzles is not smaller than three quarters of the cutting width of the tool; and the machine tool is started for machining. The problems that in the prior art, a method for strengthening the metal cutting tool is complex in process and not ideal in strengthening performance are solved.

Owner:成都昆吾科技有限公司

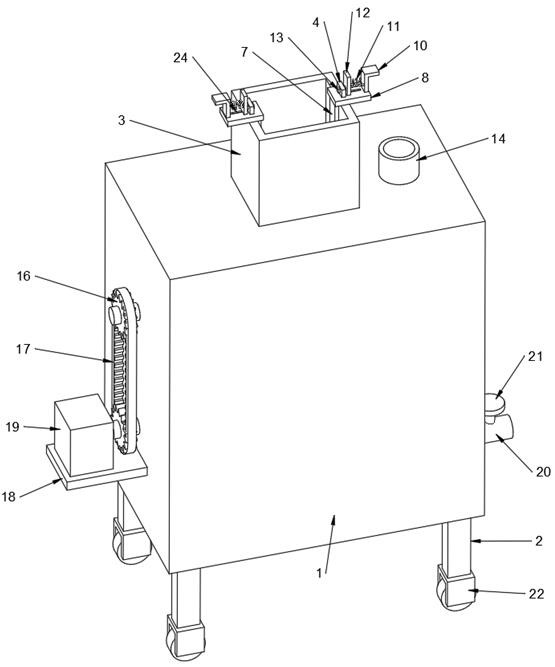

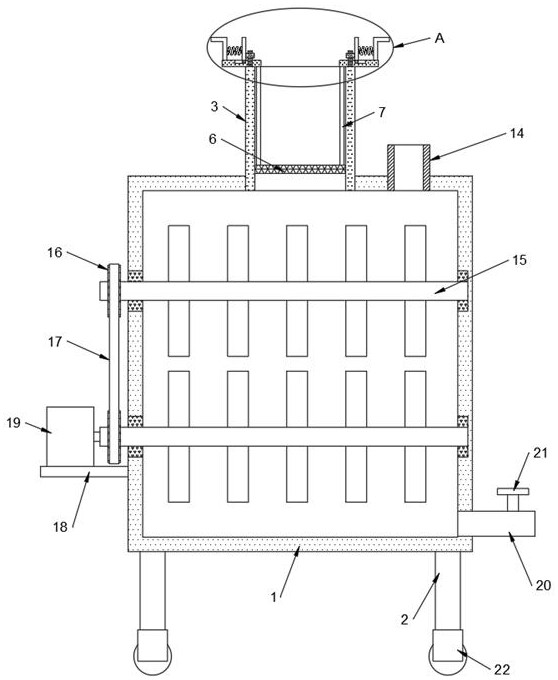

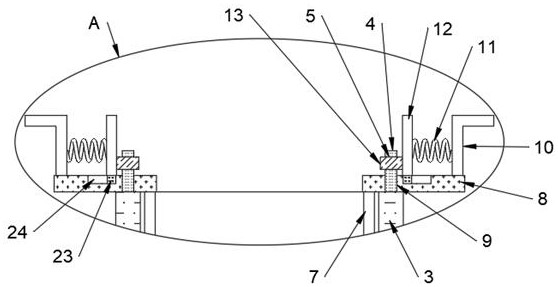

Industrial sewage efficient treatment process

InactiveCN112250216AEfficient treatment processEasy to take outFatty/oily/floating substances removal devicesTreatment involving filtrationElectric machinerySewage

The invention discloses an efficient industrial sewage treatment process, in which sewage purification equipment in the step 4 comprises a base, wherein a high-low frame is fixedly mounted on the leftside of the top of the base, a fixed seat is fixedly mounted at the top of the high-low frame, and a filter tank is fixedly mounted at the top of the fixed seat. According to the efficient industrialsewage treatment process, the filter tank is fixedly mounted at the top of the fixed base, and the filter mechanism is arranged between the interior and the exterior of the filter tank, so that the large solid matters in sewage are filtered through an arranged double-layer filter plate, and a rotary drum is made to rotate through a driving motor and a reduction gearbox; thus, the solid matters can be prevented from adhering to the filter plate through vortex formed by rotation of the rotary drum, blockage of the filter plate is avoided, meanwhile, the net groove and the water pump are communicated, filtered sewage can be taken out conveniently, the service life of the filter plate is not affected, and the blockage preventing effect is good.

Owner:张朝阳

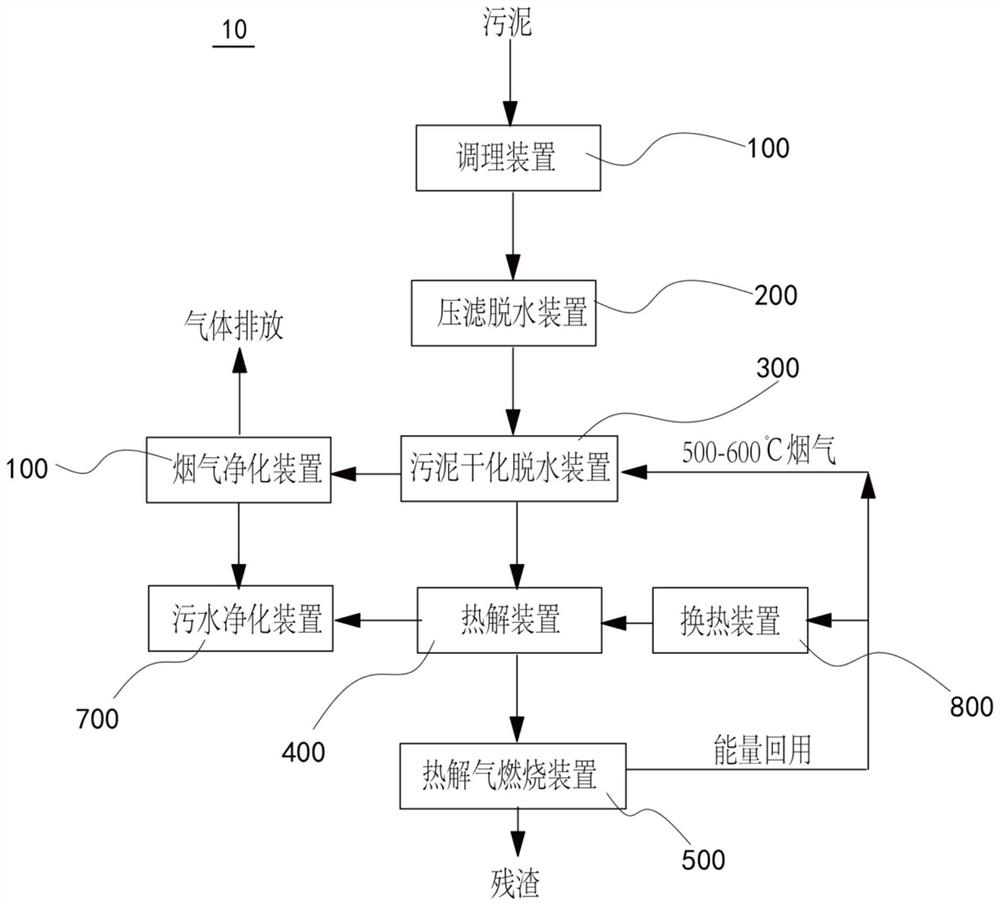

Sludge deep dehydration coupled biomass pyrolysis system and method thereof

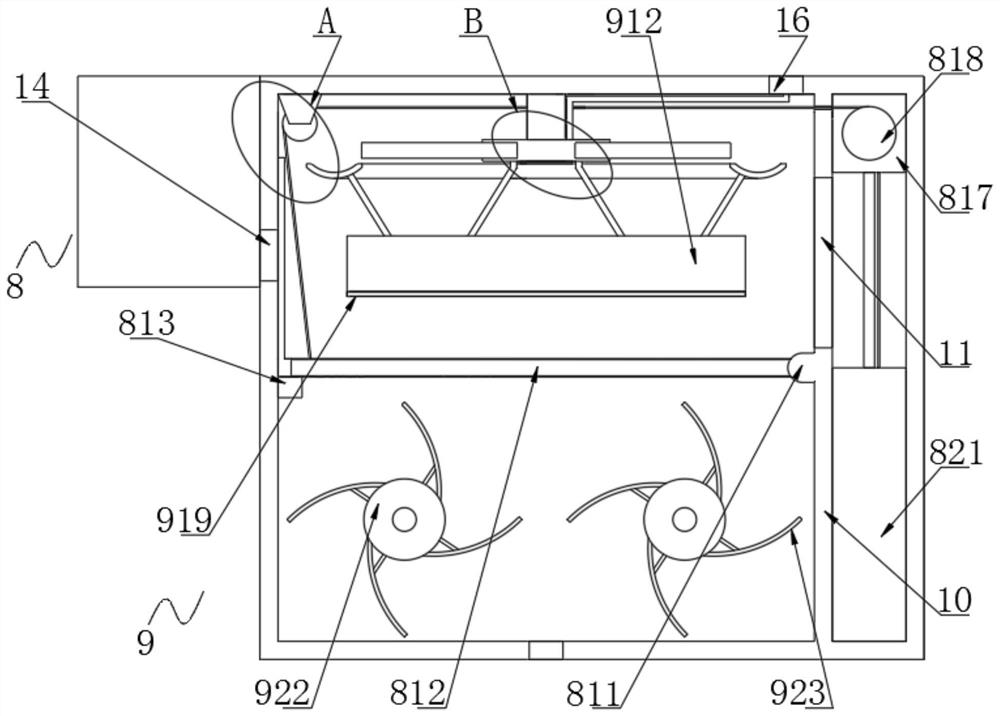

PendingCN111960632AAchieve reductionAchieve stabilizationSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisFlue gasSludge

The invention discloses a sludge deep dehydration coupled biomass pyrolysis system and a method thereof. The sludge deep dehydration coupled biomass pyrolysis system comprises a sludge conditioning device, a filter pressing dehydration device, a sludge drying dehydration device, a pyrolysis device, a pyrolysis gas combustion device and a flue gas purification device, wherein the sludge conditioning device, the filter pressing dehydration device, the sludge drying dehydration device, the pyrolysis device and the pyrolysis gas combustion device are sequentially communicated, and the flue gas purification device is connected with the sludge drying dehydration device. The sludge deep dehydration coupled biomass pyrolysis system has the advantages of sludge dehydration reduction, full utilization of a heat value, few technological processes and low operation cost, can realize recycling of pyrolysis productivity, meets the national requirements of sludge reduction and harmless treatment, andachieves the goal of resource utilization.

Owner:SHENZHEN HONGKONG INSTITUTION OF IND EDUCATION & RES ENVIRONMENTAL ENG TECH CO LTD +1

High-efficiency black and stinky bottom mud degrading agent in water ecological restoration

The invention discloses a high-efficiency black and stinky bottom mud degrading agent in water ecological restoration; the degrading agent includes volcanic rock ceramsite, an EM compound bacterial liquid, reductase, cellulase, lipase, lignase, urease and xylanase. The high-efficiency black and stinky bottom mud degrading agent in water ecological restoration provided by the invention is an improvement of a method for activation of black and stinky river way bottom deposit microorganisms and improvement of black and smelly bottom mud; through activation of native microorganisms in the bottom mud, original microorganisms in the bottom mud are gradually changed from an anoxic state to an anoxic state to an aerobic state through the addition of a biological carrier, and a compound bioenzyme liquid containing reductase, cellulase, lipase, lignase, urease, xylanase and the like is added and is mixed with the biological carrier, and then the mixture is splashed into a river way, the black and stinky bottom mud are improved, and the degrading agent has the effects of simple treatment process, high efficiency and the like.

Owner:SHANGHAI SHANHENG ECOLOGICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com