Sewage treatment system and sewage treatment method

A sewage treatment system and sewage technology, applied in water/sewage treatment, light water/sewage treatment, neutralized water/sewage treatment, etc. Affect production efficiency and other problems, and achieve the effect of excellent treatment effect, high work efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

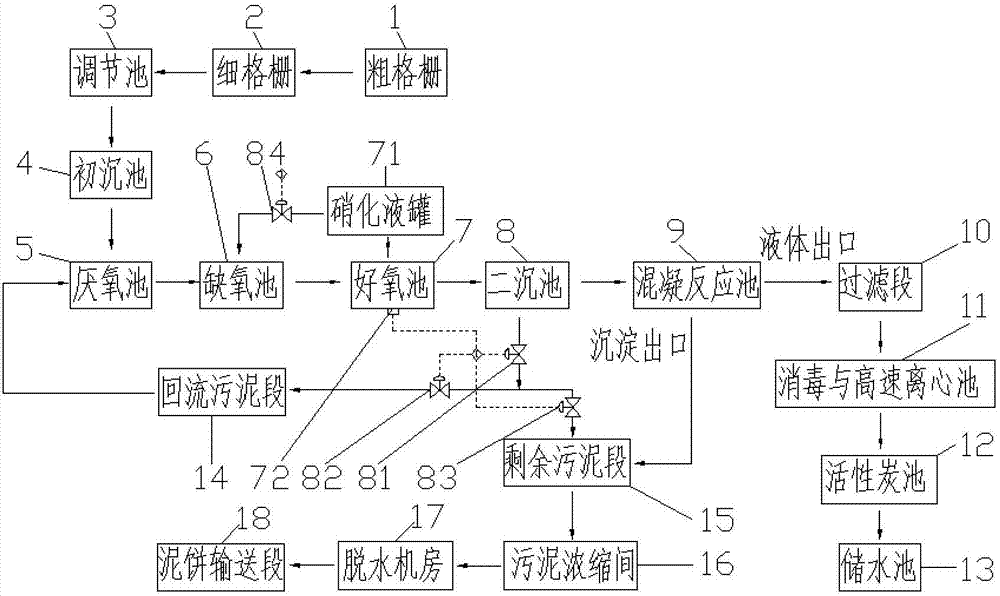

[0033] Such as figure 1 , a sewage treatment system, including a coarse grid 1, a fine grid 2, a regulating tank 3, a primary sedimentation tank 4, an anaerobic tank 5, an anoxic tank 6, an aerobic tank 7, and a secondary sedimentation tank connected by pipelines in sequence pool 8, coagulation reaction pool 9, filter section 10, disinfection and high-speed centrifugal pool 11, activated carbon pool 12, water storage pool 13;

[0034] The coarse grid 1 is divided into a first coarse grid and a second coarse grid, the first coarse grid has a grid pitch of 30-50mm, and the second coarse grid has a grid pitch of 12- 20mm, the pitch of the fine grid 2 is 4-8mm;

[0035]The secondary settling tank 8 is connected downward to the first control valve 81, and a part of the sludge produced by the secondary settling tank 8 is connected to the second control valve 82, and flows back to the anaerobic tank 5 through the return sludge section 14. The other part of the sludge is connected t...

Embodiment 2

[0053] Such as figure 1 , a sewage treatment system, including a coarse grid 1, a fine grid 2, a regulating tank 3, a primary sedimentation tank 4, an anaerobic tank 5, an anoxic tank 6, an aerobic tank 7, and a secondary sedimentation tank connected by pipelines in sequence pool 8, coagulation reaction pool 9, filter section 10, disinfection and high-speed centrifugal pool 11, activated carbon pool 12, water storage pool 13;

[0054] The coarse grid 1 is divided into a first coarse grid and a second coarse grid, the first coarse grid has a grid pitch of 30-50mm, and the second coarse grid has a grid pitch of 12- 20mm, the pitch of the fine grid 2 is 4-8mm;

[0055] The secondary settling tank 8 is connected downward to the first control valve 81, and a part of the sludge produced by the secondary settling tank 8 is connected to the second control valve 82, and flows back to the anaerobic tank 5 through the return sludge section 14. The other part of the sludge is connected ...

Embodiment 3

[0062] Such as figure 1 , a sewage treatment system, including a coarse grid 1, a fine grid 2, a regulating tank 3, a primary sedimentation tank 4, an anaerobic tank 5, an anoxic tank 6, an aerobic tank 7, and a secondary sedimentation tank connected by pipelines in sequence pool 8, coagulation reaction pool 9, filter section 10, disinfection and high-speed centrifugal pool 11, activated carbon pool 12, water storage pool 13;

[0063] The coarse grid 1 is divided into a first coarse grid and a second coarse grid, the first coarse grid has a grid pitch of 30-50mm, and the second coarse grid has a grid pitch of 12- 20mm, the pitch of the fine grid 2 is 4-8mm;

[0064] The secondary settling tank 8 is connected downward to the first control valve 81, and a part of the sludge produced by the secondary settling tank 8 is connected to the second control valve 82, and flows back to the anaerobic tank 5 through the return sludge section 14. The other part of the sludge is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com