Method for treating coal chemical wastewater

A technology for coal chemical wastewater and treatment methods, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of large ozone power consumption, affecting water quality and high cost , to achieve the effect of improving treatment efficiency, improving biodegradability, and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

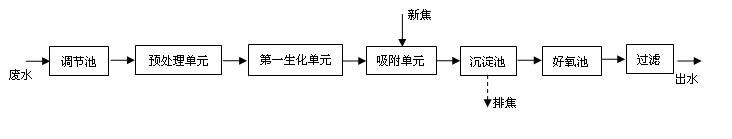

[0032] Such as figure 1 A specific embodiment of the coal chemical industry wastewater treatment method of the present invention is shown, comprising the steps:

[0033] ① Pretreatment: The coal chemical wastewater in the regulating pool is passed into the pretreatment unit for pretreatment. The regulating pond is used to adjust the homogeneity and quantity of the coal chemical wastewater. Precipitation, hydrolysis and acidification to improve the biodegradability of wastewater;

[0034] ② Biochemical treatment of the first biochemical unit: pass the pretreated wastewater into the first biochemical unit for biochemical treatment, and degrade organic matter and ammonia nitrogen in the first biochemical unit to reduce the content of nitrogen elements;

[0035] ③ Adsorption unit adsorption treatment: the above-mentioned biochemically treated wastewater is passed into the adsorption unit for adsorption treatment. The adsorption unit is equipped with an adsorption material to perf...

Embodiment 2

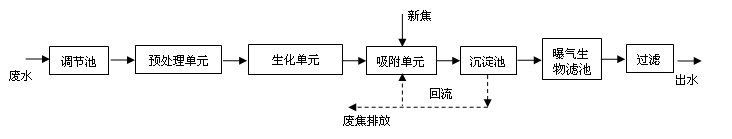

[0039] figure 2 Another embodiment of the coal chemical industry wastewater treatment method described in the present invention is provided, comprising the steps of:

[0040] ① Pretreatment: The coal chemical wastewater in the regulating tank is passed into the pretreatment unit for pretreatment;

[0041] ② Biochemical treatment of the first biochemical unit: pass the pretreated wastewater into the first biochemical unit for biochemical treatment, and degrade organic matter and ammonia nitrogen in the first biochemical unit to reduce the content of nitrogen elements;

[0042] ③ Adsorption unit adsorption treatment: the above-mentioned biochemically treated wastewater is passed into the adsorption unit for adsorption treatment. The adsorption unit is equipped with an adsorption material to perform adsorption treatment on the wastewater. Here, the coke powder of active coke is selected, and the new The coke powder is added into the adsorption unit, and the mass ratio of the wa...

Embodiment 3

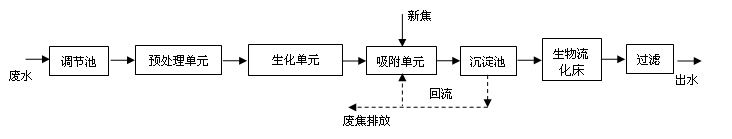

[0046] ① Pretreatment: The coal chemical wastewater in the regulating tank is passed into the pretreatment unit for pretreatment;

[0047] ② Biochemical treatment of the first biochemical unit: pass the pretreated wastewater into the first biochemical unit for biochemical treatment, and degrade organic matter and ammonia nitrogen in the first biochemical unit to reduce the content of nitrogen elements;

[0048] ③ Adsorption unit adsorption treatment: the above-mentioned biochemically treated wastewater is passed into the adsorption unit for adsorption treatment. The adsorption unit is equipped with an adsorption material to perform adsorption treatment on the wastewater. Here, the coke powder of active coke is selected, and the new The coke powder is added into the adsorption unit, and the mass ratio of the waste water in the adsorption unit to the active coke is 1000:1;

[0049] ④ Sedimentation treatment in sedimentation tank: The wastewater after the adsorption treatment is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com