Polymeric titanium sulfate-PDMDAAC (poly dimethyl diallyl ammonium chloride) composite coagulant as well as preparation and application methods thereof

A technology of polydimethyldiallyl ammonium chloride and polysulfuric acid is applied in the direction of flocculation/sedimentation water/sewage treatment to achieve the effects of high molecular weight, good flocculation effect and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

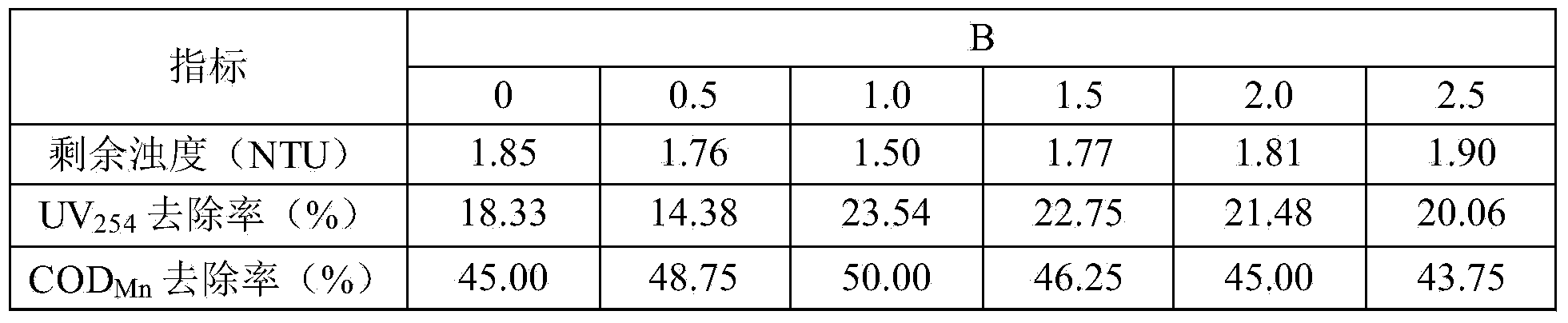

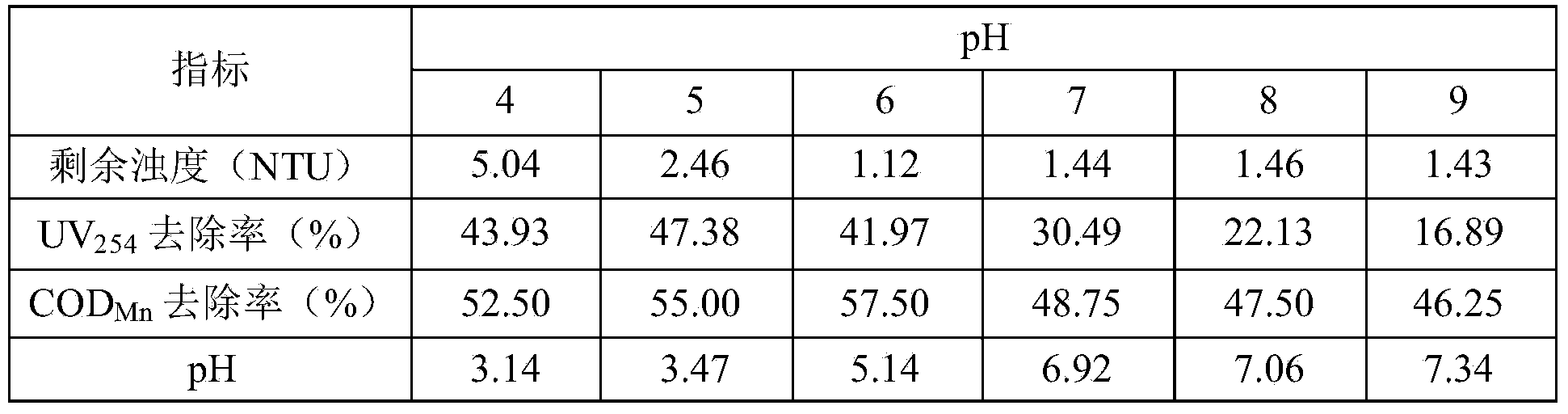

[0026] (1) Weigh 12.5g Ti(SO 4 ) 2 Dissolve in 150mL pure water, add NaOH with a concentration of 240g / L drop by drop under continuous stirring, the dropping volume is 4.34mL, 8.68mL, 13.02mL, 17.36mL, 26.04mL, and the dropping time is controlled at 20-40min , After the dropwise addition was completed, the stirring was continued for 1 h to obtain polymerized titanium sulfate solutions with alkalization degrees (B) of 0.5, 1.0, 1.5, 2.0, and 2.5.

[0027] (2) Divide the polymerized titanium sulfate solutions with different degrees of alkalinity into five parts, add a certain mass of PDMDAAC according to the mass ratio of Ti / PDMDAAC as 10, 8, 6, 4, 0 (for comparison), and continue stirring for 3 hours , filter out the insolubles, and prepare polymeric titanium sulfate-polydimethyldiallylammonium chloride organic polymer composite flocculants with different alkalization degrees and different mass ratios of Ti / PDMDAAC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com