Impedance matching method and plasma processing equipment

A technology for impedance matching and processing equipment, applied in the field of microelectronics, can solve the problems of poor matching path, low matching accuracy, and long matching time of the actuator, and achieve the effect of efficient application, improved calculation accuracy, and impedance matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

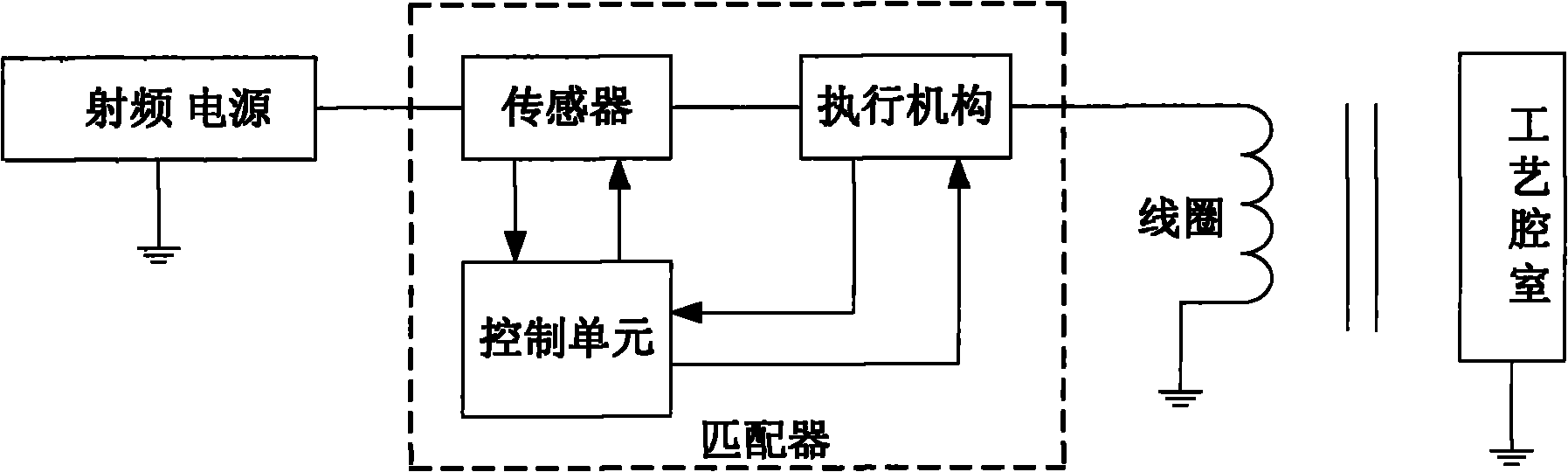

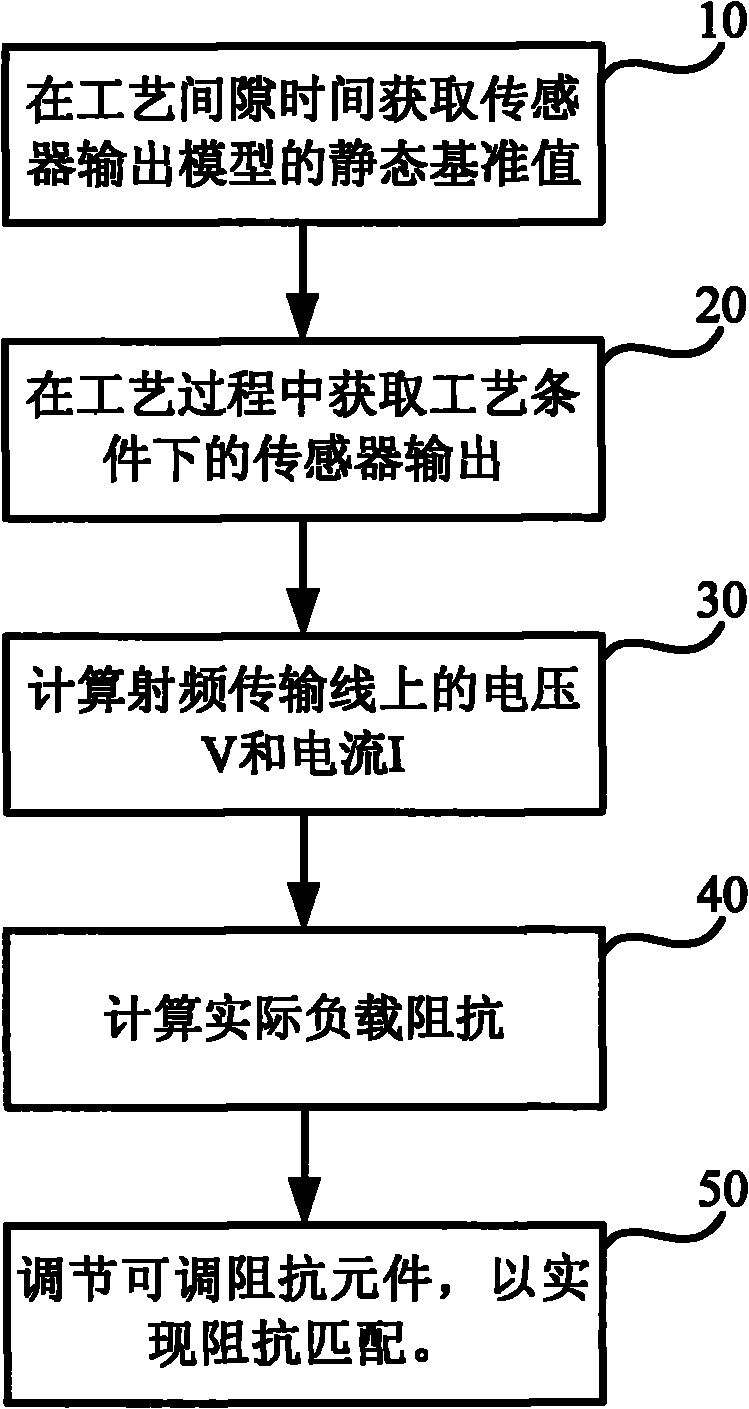

[0040] The technical core of the present invention is: considering the problem that the analog circuit in the sensor will drift over time, the sensor output value is obtained during the process gap time, and it is used as the sensor output in the next process / procedure The static reference value of the model, in order to replace the static reference value of the constant quantity adopted in the background technology with the static reference value that changes with time, thus can obtain the voltage V and the current I on the radio frequency transmission line more accurately, and then more Accurately obtain the load impedance value, and accordingly realize the impedance matching between the internal impedance of the RF power supply and the load impedance.

[0041] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the impedance matching method and plasma processing equipment provided by the present invention will be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com