Pretreatment agent and method for using pretreatment agent for dyeing pretreatment of cotton cheese yarns

A technology of dyeing pretreatment and pretreatment agent, which is applied in fiber treatment, biochemical fiber treatment, textiles and papermaking, etc., can solve the problem of high yarn wool efficiency and whiteness requirements, unable to use cotton cheese yarn, and difficult to obtain treatment effect. and other problems, to achieve the effect of reducing energy consumption, reducing the burden of sewage treatment, and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

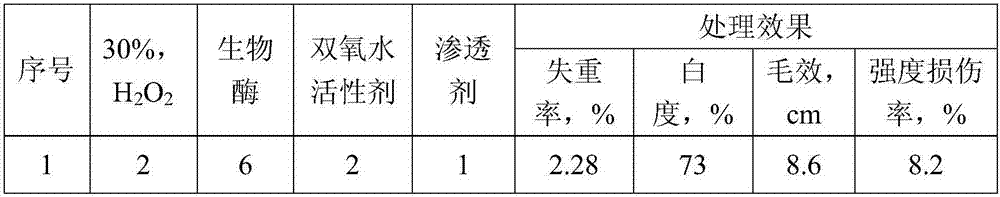

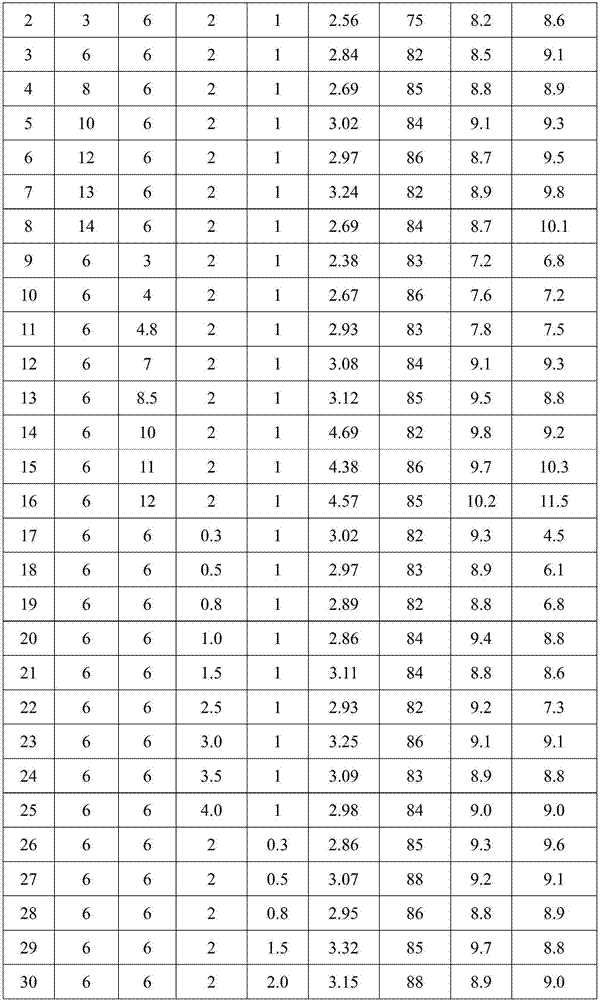

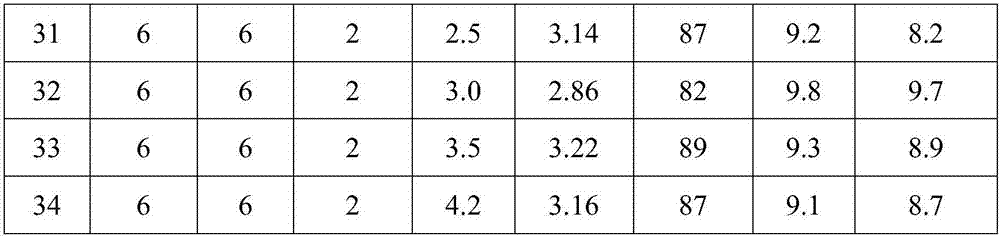

[0026] Embodiment 1: the pretreatment effect of different formulation pretreatment agents

[0027] The pretreatment agent is one of the most basic factors affecting the treatment effect. In this example, under the conditions of pH 8, bath ratio 10:1, heating rate 2°C / min, treatment temperature 55°C, and treatment time 50min, the pretreatment of different formulations The treatment agent was tested, and the formulation of the pretreatment agent and the comparison of treatment effects are shown in Table 1.

[0028] Table 1 The effect comparison table of pretreatment agents (units are g / L) of different formulations

[0029]

[0030]

[0031]

[0032] Hydrogen peroxide and biological enzymes are the main active components of pretreatment. In this embodiment, hydrogen peroxide is mainly used for bleaching. When the content of hydrogen peroxide is low, the treatment effect is not good due to insufficient dosage, which is specifically reflected when the amount of hydrogen pe...

Embodiment 2

[0037] Embodiment 2: the impact of different pretreatment conditions on the treatment effect

[0038] The pre-treatment process is also a key factor affecting the treatment effect. In this embodiment, under the conditions of 30% hydrogen peroxide 4g / L, biological enzyme 6g / L, hydrogen peroxide active agent 3g / L, and penetrant 2g / L, the different treatment conditions The treatment effect was tested, and the pretreatment conditions and treatment effect comparison are shown in Table 2.

[0039] Table 2 Effect comparison table of different pretreatment conditions

[0040]

[0041]

[0042] In the pretreatment process, pH and treatment temperature are the biggest differences between this application and the conventional alkali scouring process, because under the pretreatment agent atmosphere of this application, the optimum pH value of biological enzymes is close to neutral and hydrogen peroxide The effect is more obvious under alkaline conditions, etc. When the pH value is ...

Embodiment 3

[0046] This embodiment is used for the pre-treatment method of cotton cheese dyeing, which is formed by the combination of treatment agent formula, pH value of treatment solution, and treatment process parameters, wherein:

[0047] (1) The pretreatment agent is: 30% hydrogen peroxide 4g / L, biological enzyme 6g / L, hydrogen peroxide active agent 2g / L, osmotic agent 1g / L; the pH value is adjusted to 8, and the bath ratio is 10:1.

[0048] (2) Process parameters: at room temperature, the temperature is raised to the treatment temperature at 2°C / min, the treatment temperature is 50°C, and the treatment time is 60 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com